Escolar Documentos

Profissional Documentos

Cultura Documentos

Quick Exh Valves 13QS1 Rev 0110

Enviado por

136339Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Quick Exh Valves 13QS1 Rev 0110

Enviado por

136339Direitos autorais:

Formatos disponíveis

Quick Exhaust Valve

Pneumatic

1/4" FEMALE NPT, 150 PSI Model 13QS1, Standard Service, 13QS10 H2S SERVICE

Conforms to the SEP category of the European Pressure Equipment Directive Issue No. 97/23/EC

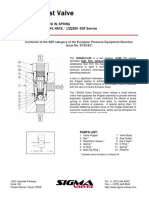

The 13QS1 is a two position, Flapper Seal operated, high flow exhaust control valve assembly. It establishes flow (from the inlet to outlet or Supply-to-Valve connections) to open a Surface Safety Valve (SSV or pneumatic Actuator), automatically with each application of operating pressure. A loss or significant decrease of operating pressure will unseat the Flapper Seal quickly to establish high volume, reverse or Exhaust flow. Rapid closure of an Actuator valve is assured with the use of a Quick Exhaust Valve. The Flapper Seal is manufactured from injection molded Viton material for long product life and reliability.

PARTS LIST:

1. 2. 3. 4. 5. 6. 7. Hex Bolt * Upper Body O Ring * Viton Flapper Seal * Lower Body Hex Nut * Flapper Seal Insert *

* Indicates parts included in a Repair Kit

1420 Lakeside Parkway Suite 109 Flower Mound, Texas 75028

Tel: +1 (972) 446 8250 Fax: +1 (972) 446 8642 http://www.sigma-valves.com

Sigma Model Number 13QS1

1/4" FEMALE NPT, 150 PSI Product Specifications

Flow Control Application: Normally Open Control Function: Three-Way - Flapper Seal Operated Flow Capacity: High Flow Service Pressure Rating Body (Control Ports): 150 PSI maximum (10.34 bar) Seal Material: Viton Connection Size (Body): 1/4-18 Female N.P.T. (Supply, Valve, Exhaust) Component Material (Metal): 316 Stainless Steel Mounting: Field Mount Orifice: 3/8 Diameter Weight: 1.9 Lbs. Operating Temperature: -20 F to +250 F (-29 C to +121 C) Overall Dimensions: 1-3/4 Height x 2-3/8 Diameter (4.45 cm Height x 6.03 cm Diameter) Pressure Equipment Directive (PED): This product conforms to the SEP Category of the European P.E.D. Installation and Maintenance Instructions: Install between the interface valve and the actuator. This is done by threading the pipe or fitting from the control system into the port labeled Supply. The piping from the actuator is threaded into the port labeled Valve. A significant loss in pressure within the control system will trigger an exhaust of the actuator through the valve port and out the exhaust port. Sigma recommends the use of appropriate thread sealant for each port connection. Shelf Position Port Status Supply Inlet Instrument supply pressure open to cylinder (SSV Actuator) Valve Outlet Pressure to cylinder (Closed to Exhaust Port) Exhaust Depressurizes cylinder upon loss of Supply Inlet Repair Kit Information Repair Kits contain all of the Seals and other components typically replaced when repairing the assembly. In order to maintain optimum operating control function. Cv Factor: .82

While this information is presented in good faith and believed to be accurate, Sigma Valves does not guarantee satisfactory results from reliance upon such information. Nothing contained herein is to be constructed as a warranty or guarantee, expressed or implied, regarding the performance, merchantability, and fitness with respect to the products. Sigma Valves reserves the right, without notice, to alter or improve the designs or specifications of the products described herein.

Você também pode gostar

- Quick Exhaust Valve 13QS38 - 39Documento2 páginasQuick Exhaust Valve 13QS38 - 39simplementemoiAinda não há avaliações

- Test Stand Technical ManualDocumento51 páginasTest Stand Technical Manualewhf weGJO100% (1)

- Actuated Valve: Air Distribution Manifold (Instrument Air)Documento45 páginasActuated Valve: Air Distribution Manifold (Instrument Air)Suguna moorthyAinda não há avaliações

- FM-200 Alpha Series SystemsDocumento6 páginasFM-200 Alpha Series SystemsGurusumiAinda não há avaliações

- Section 30 - Relief ValvesDocumento17 páginasSection 30 - Relief ValveshammamiAinda não há avaliações

- FMCTI EPRV BrochureDocumento2 páginasFMCTI EPRV BrochureKaren AndradeAinda não há avaliações

- PVR-108-2 Fueling Model SheetDocumento2 páginasPVR-108-2 Fueling Model SheetLetycia RosalesAinda não há avaliações

- Deluge Valve Wet Pilot Line Single Interlock Preaction SysDocumento16 páginasDeluge Valve Wet Pilot Line Single Interlock Preaction SysDana Guerrero100% (1)

- Fusible Dev 15RS128 Rev 0110Documento2 páginasFusible Dev 15RS128 Rev 0110Ali YusufAinda não há avaliações

- Chemetron Novec Gamma Specs PDFDocumento6 páginasChemetron Novec Gamma Specs PDFambition1340cnAinda não há avaliações

- Manual Comando Control Air Hd2Documento12 páginasManual Comando Control Air Hd2Brian Schmidt100% (2)

- Quick Exh Valves 13QS40 - 41 - 80 Rev 0110Documento2 páginasQuick Exh Valves 13QS40 - 41 - 80 Rev 0110khaldoun samiAinda não há avaliações

- Inspection & Testing of Pressure Vessels and Pressure Relieving Devices - 4Documento7 páginasInspection & Testing of Pressure Vessels and Pressure Relieving Devices - 4DeepakAinda não há avaliações

- FlowCon EVC Instruction 05.2010Documento4 páginasFlowCon EVC Instruction 05.2010Jeff Anderson CollinsAinda não há avaliações

- Anderson Greenwood - Pentair Series 400 Modulating Datasheet PDFDocumento4 páginasAnderson Greenwood - Pentair Series 400 Modulating Datasheet PDFSARATH KRISHNAKUMARAinda não há avaliações

- PRV Oil Safety Valve Henry 5600Documento3 páginasPRV Oil Safety Valve Henry 5600pm2013Ainda não há avaliações

- FunctionalSafety V7666Documento12 páginasFunctionalSafety V7666rufino.perea.2Ainda não há avaliações

- 502 Model A Deluge ValveDocumento4 páginas502 Model A Deluge ValvemanbkkAinda não há avaliações

- Catalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgDocumento20 páginasCatalogo Regulador Mooney Product00288 Manual Slam Shut 2 PLG y 4plgluis_d_mAinda não há avaliações

- Spring Loaded ValvesDocumento10 páginasSpring Loaded ValvesKarl NakouziAinda não há avaliações

- Fluids Entry HBV Cetop 7 & 8 Series 101109Documento12 páginasFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiAinda não há avaliações

- Becker EmergShtdwnValve BrochureDocumento8 páginasBecker EmergShtdwnValve BrochureAnonymous b9ylgFXAinda não há avaliações

- RWF40 Modulating Feedwater Control Valve Application Guide: RWF40 Compact Universal ControllerDocumento24 páginasRWF40 Modulating Feedwater Control Valve Application Guide: RWF40 Compact Universal ControllersakarisoAinda não há avaliações

- ManualsDocumento34 páginasManualsTreeAinda não há avaliações

- Relief Valves: Gases and Gas EquipmentDocumento22 páginasRelief Valves: Gases and Gas EquipmentInspection EngineerAinda não há avaliações

- Model PRS09i-P: In-Line Plastic Pressure Regulator (Reducing Valve)Documento5 páginasModel PRS09i-P: In-Line Plastic Pressure Regulator (Reducing Valve)engp3077Ainda não há avaliações

- FlowCon EVC Instr USDocumento4 páginasFlowCon EVC Instr USb82monicaAinda não há avaliações

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocumento7 páginas52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeAinda não há avaliações

- Operating & Service Manual AZ-1-107-NL SERIES PumpDocumento16 páginasOperating & Service Manual AZ-1-107-NL SERIES PumpREZA ASGARIAinda não há avaliações

- Safety ValvesDocumento66 páginasSafety ValvesMuhammad Afiq Mohd ZaidAinda não há avaliações

- FM 200 Sigma Spec SheetDocumento6 páginasFM 200 Sigma Spec SheetPepe ViteriAinda não há avaliações

- 고려특수금속 (PSV-FLANGED TYPE) PDFDocumento56 páginas고려특수금속 (PSV-FLANGED TYPE) PDFStanley PeterAinda não há avaliações

- TetraSentry Brochure v1.1Documento6 páginasTetraSentry Brochure v1.1Walid FattahAinda não há avaliações

- p100 - 13 Could BeDocumento4 páginasp100 - 13 Could BeEudaldo SaltosAinda não há avaliações

- Models A & B Automatic Pressure Maintenance DevicesDocumento4 páginasModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASAinda não há avaliações

- CO2 AnsulDocumento17 páginasCO2 AnsulJorge RVAinda não há avaliações

- Katalog p310 - 07Documento7 páginasKatalog p310 - 07agustinusidAinda não há avaliações

- Es Acv M115F M1115FDocumento4 páginasEs Acv M115F M1115FWattsAinda não há avaliações

- Sigma Valve 3 WayDocumento2 páginasSigma Valve 3 WayRahimAinda não há avaliações

- 1-1-6 en Frese Optima Aug 10Documento12 páginas1-1-6 en Frese Optima Aug 10mymikeymikesAinda não há avaliações

- 744 Double Interlock Preaction System Type D 8Documento20 páginas744 Double Interlock Preaction System Type D 8Nirmal KvAinda não há avaliações

- DAN-EX Brochure WebDocumento12 páginasDAN-EX Brochure Webzakkyf6455Ainda não há avaliações

- Novec 1230 Extinguishing Agent DescriptionDocumento12 páginasNovec 1230 Extinguishing Agent Descriptionmoh_essamoAinda não há avaliações

- PRX SeriesDocumento12 páginasPRX SeriesIngeniero Junior100% (1)

- Multimatic Deluge Valve A4Documento6 páginasMultimatic Deluge Valve A4Lenin Rajaah AlaganAinda não há avaliações

- In-Line Hydraulic TesterDocumento5 páginasIn-Line Hydraulic TesterMasterrAinda não há avaliações

- 727 PosrvDocumento7 páginas727 Posrvtxlucky80Ainda não há avaliações

- Es Acv 263SSDocumento2 páginasEs Acv 263SSWattsAinda não há avaliações

- Series 825Y Specification SheetDocumento2 páginasSeries 825Y Specification SheetFEBCOAinda não há avaliações

- RTHC Svn02c enDocumento16 páginasRTHC Svn02c enRicardo100% (1)

- Catálogo Anderson Greenwood 400sDocumento32 páginasCatálogo Anderson Greenwood 400sDaniela BeltranAinda não há avaliações

- Pneumatic Control ValvesDocumento59 páginasPneumatic Control Valvespatil_raaj7234Ainda não há avaliações

- 3 WayDocumento18 páginas3 WayLeonardAinda não há avaliações

- Eaton-Airflex Quick Release Valve IOMDocumento8 páginasEaton-Airflex Quick Release Valve IOMIvan AcostaAinda não há avaliações

- An 01 013 Ctrls & Process ValvingDocumento2 páginasAn 01 013 Ctrls & Process ValvingAKSHEYMEHTAAinda não há avaliações

- Bleed Off Valve: Safe and Controlled Bleed Off of The Annulus PressureDocumento2 páginasBleed Off Valve: Safe and Controlled Bleed Off of The Annulus PressurekNdashAinda não há avaliações

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAinda não há avaliações

- Prevention of Actuator Emissions in the Oil and Gas IndustryNo EverandPrevention of Actuator Emissions in the Oil and Gas IndustryAinda não há avaliações

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- Autoclave Technical InfoDocumento16 páginasAutoclave Technical Info136339Ainda não há avaliações

- Newton RaphsonDocumento3 páginasNewton Raphsonnellai kumarAinda não há avaliações

- 485 - Flowcalc ANNUBARDocumento24 páginas485 - Flowcalc ANNUBARMuneéb IrfanAinda não há avaliações

- V ConeDocumento29 páginasV Cone136339Ainda não há avaliações

- Vol 43 - 3 0004Documento112 páginasVol 43 - 3 0004karamniaAinda não há avaliações

- Fired Heaters - IntroductionDocumento108 páginasFired Heaters - Introductions_m_kumar100% (4)

- Methanol PresentationDocumento29 páginasMethanol PresentationCristina OzarciucAinda não há avaliações

- 1.1.4 NGL Fractionation Train - 3Documento20 páginas1.1.4 NGL Fractionation Train - 3Julio Adolfo López PortocarreroAinda não há avaliações

- Cargo Handling EquipmentDocumento5 páginasCargo Handling EquipmentAnonymous UCveMQAinda não há avaliações

- Esp Minas Indonesia Sumatra SLBDocumento10 páginasEsp Minas Indonesia Sumatra SLBGuillermo Ramirez AvilaAinda não há avaliações

- EKM Dec 2016Documento2 páginasEKM Dec 2016Arun SAinda não há avaliações

- BFG Safety How To PreventDocumento25 páginasBFG Safety How To PreventPower PowerAinda não há avaliações

- Manual de Motor Mack Mp8Documento20 páginasManual de Motor Mack Mp8Alex ChampiAinda não há avaliações

- Microtechnique: Dr. Esam Qnais Hashemite UniversityDocumento13 páginasMicrotechnique: Dr. Esam Qnais Hashemite UniversityEnas AhmadAinda não há avaliações

- Megafire ManualDocumento16 páginasMegafire ManualBehnam NoorizadehAinda não há avaliações

- Auxiliary Steam SystemDocumento15 páginasAuxiliary Steam SystemSwaroop KumarAinda não há avaliações

- New Generation and Hybrid VehiclesDocumento35 páginasNew Generation and Hybrid VehiclesAbhi UnnikrishnanAinda não há avaliações

- DINCMRPDocumento7 páginasDINCMRPeduinAinda não há avaliações

- Damen Double Hull Oil Tanker 8000 9393 King-FisherDocumento2 páginasDamen Double Hull Oil Tanker 8000 9393 King-FisherAlina NastasaAinda não há avaliações

- DBKL Carbon Management Plan 2017 2022Documento40 páginasDBKL Carbon Management Plan 2017 2022AlexAinda não há avaliações

- 1 Mounting Engine On Engine StandDocumento12 páginas1 Mounting Engine On Engine StandLyleThereseAinda não há avaliações

- 1.HM Lambda Engine CompletedDocumento10 páginas1.HM Lambda Engine CompletedAlex GarciaAinda não há avaliações

- Everlube 620 CTDSDocumento2 páginasEverlube 620 CTDSchristianAinda não há avaliações

- 12E Spare PartsDocumento66 páginas12E Spare PartsСергей КонкинAinda não há avaliações

- Top Blowing Rotatory ConvertorDocumento4 páginasTop Blowing Rotatory ConvertorVanesa Ramirez CatalanAinda não há avaliações

- 4 MW Biomass Project ReportDocumento56 páginas4 MW Biomass Project ReportsishasailuAinda não há avaliações

- Diesel Generator - Wikipedia, The Free EncyclopediaDocumento4 páginasDiesel Generator - Wikipedia, The Free EncyclopediaErlangga SatyawanAinda não há avaliações

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Documento40 páginasGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610sebasAinda não há avaliações

- Powerplant Text 7-12Documento148 páginasPowerplant Text 7-12francis verzosaAinda não há avaliações

- Copeland Refrigeration Manual - Part 2 - Refrigeration System ComponentsDocumento64 páginasCopeland Refrigeration Manual - Part 2 - Refrigeration System ComponentsMohammad Amer100% (1)

- Fuel Oil Temperature Control System in Marine BoilerDocumento10 páginasFuel Oil Temperature Control System in Marine BoilerArun K DasAinda não há avaliações

- Lecture Notes: Aerospace Propulsion IDocumento65 páginasLecture Notes: Aerospace Propulsion IalokAinda não há avaliações

- Factory Timing Marks PDFDocumento6 páginasFactory Timing Marks PDFvadiAinda não há avaliações

- Mazda BT-50: Training ManualDocumento146 páginasMazda BT-50: Training ManualAndore Bc100% (1)