Escolar Documentos

Profissional Documentos

Cultura Documentos

Blain EV 0-1-10-100 Adj-proc-EV

Enviado por

Sylvester SullivanDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Blain EV 0-1-10-100 Adj-proc-EV

Enviado por

Sylvester SullivanDireitos autorais:

Formatos disponíveis

Warning: Only qualified personell should adjust or service valves.

Unauthorised manipulation may result in injury, loss of life or damage to equipment. Prior to servicing internal parts, ensure that the electrical power is switched off and residual pressure in the valve is reduced to zero.

Adjustments UP

Valves are already adjusted and tested. Check electrical operation before changing valve settings. Test that the correct solenoid is energised, by removing nut and raising solenoid slighty to feel pull. Nominal Settings: Adjustments 1 & 4 approx. level with flange faces. Up to two turns in either direction may then be necessary. Adjustments 2, 3 & 5 all the way 'in' (clockwise) then 2 & 5 two turns 'out' (c-clockwise), 3 three turns out. A small final adjustment may be necessary.

EV 0

1. By Pass: When the pump is started, the unloaded car should remain stationary at the floor for a period of 1 to 2 seconds before starting upwards. The length of this delay is determined by the setting of adjustment 1. 'In' (clockwise) shortens the delay, 'out' (c-clockwise) lengthens the delay. 2. Up Acceleration: With the pump running, the car will accelerate according to the setting of adjustment 2. 'In' (clockwise) provides a softer acceleration, 'out' (c-clockwise) a quicker acceleration. Up Stop: The pump-motor is de-energised. There is no adjustment. Alternative Up Stop with Over-travel: The motor is de-energised at floor level. Through the flywheelaction of the pumpmotor drive the car will travel to just above floor level. In overtravelling the floor, down levelling solenoid D is energised, lowering the car smoothly back down to floor level where D is de-energised. S Relief Valve: 'In' (clockwise) produces a higher, 'out' (c-clockwise) a lower maximum pressure setting. After turning 'out', open manual lowering H for an instant. Important: When testing relief valve, do not close ball valve sharply.

EV 1

1. By Pass: When the pump is started and solenoid A energised, the unloaded car should remain stationary at the floor for a period of 1 to 2 seconds before starting upwards. The length of this delay is determined by the setting of adjustment 1. 'In' (clockwise) shortens the delay, 'out' (c-clockwise) lengthens the delay. 2. Up Acceleration: With the pump running and solenoid A energised as in 1, the car will accelerate according to the setting of adjustment 2. 'In' (clockwise) provides a softer acceleration, 'out' (c-clockwise) a quicker acceleration. 5. Up Stop: At floor level, solenoid A is de-energised. Through a time relay the pump should run approx. second longer to allow the car to stop smoothly by valve operation according to the setting of adjustment 5. 'In' (clockwise) provides a softer stop, 'out' (c-clockwise) a quicker stop. Alternative Up Stop: At relatively higher speeds, the car will travel to just above floor level. In overtravelling the floor, down levelling solenoid D is energised, lowering the car smoothly back down to floor level where D is de-energised. S Relief Valve: 'In' (clockwise) produces a higher, 'out' (c-clockwise) a lower maximum pressure setting. After turning 'out', open manual lowering H for an instant. Important: When testing relief valve, do not close ball valve sharply.

EV 10

1. By Pass: When the pump is started and solenoid B energised, the unloaded car should remain stationary at the floor for a period of 1 to 2 seconds before starting upwards. The length of this delay is determined by the setting of adjustment 1. 'In' (clockwise) shortens the delay, 'out' (c-clockwise) lengthens the delay. 2. Up Acceleration: With the pump running and solenoid B energised as in 1, the car will accelerate according to the setting of adjustment 2. 'In' (clockwise) provides a softer acceleration, 'out' (c-clockwise) a quicker acceleration. 3. Up Deceleration: When solenoid B is de-energised, the car will decelerate according to the setting of adjustment 3. 'In' (clockwise) provides a softer deceleration, 'out' (c-clockwise) a quicker deceleration. 4. Up Levelling: With solenoid B de-energised as in 3, the car will proceed at its levelling speed according to the setting of adjustment 4. 'In' (clockwise) provides a slower, 'out' (c-clockwise) a faster up levelling. Up stop: The pump-motor is de-energised. There is no adjustment. S Relief Valve: 'In' (clockwise) produces a higher, 'out' (c-clockwise) a lower maximum pressure setting. After turning 'out', open manual lowering H for an instant. Important: When testing relief valve, do not close ball valve sharply.

EV 100

1. By Pass: When the pump is started, and solenoids A and B energised, the unloaded car should remain stationary at the floor for a period of 1 to 2 seconds before starting upwards. The length of this delay is determined by the setting of adjustment 1. 'In' (clockwise) shortens the delay, 'out' (c-clockwise) lengthens the delay. 2. Up Acceleration: With the pump running and solenoids A and B energised as in 1, the car will accelerate according to the setting of adjustment 2. 'In' (clockwise) provides a softer acceleration, 'out' (c-clockwise) a quicker acceleration. 3. Up Deceleration: When solenoid B is de-energised, whilst solenoid A remains energised, the car will decelerate according to the setting of adjustment 3. 'In' (clockwise) provides a softer deceleration, 'out' (c-clockwise) a quicker deceleration. 4. Up Levelling: With solenoid A energised and solenoid B de-energised as in 3., the car will proceed at its levelling speed according to the setting of adjustment 4. 'In' (clockwise) provides a slower, 'out' (c-clockwise) a faster up levelling. 5. Up Stop: At floor level, solenoid A is de-energised with solenoid B remaining de-energised. Through a time relay the pump should run approx. second longer to allow the car to stop smoothly by valve operation according to the setting of adjustment 5. 'In' (clockwise) provides a softer stop, 'out' (c-clockwise) a quicker stop. S Relief Valve: 'In' (clockwise) produces a higher, 'out' (c-clockwise) a lower maximum pressure setting. After turning 'out', open manual lowering H for an instant. Important: When testing relief valve, do not close ball valve sharply.

Pfaffenstrasse 1 Boellinger Hoefe 74078 Heilbronn Germany

Tel. 07131 2821-0 Fax 07131 485216 http://www.blain.de e-mail:info@blain.de

GmbH

Manufacturer of the Highest Quality: Control Valves for Elevators Tank Heaters - Hand Pumps Pipe Rupture Valves - Ball Valves

Warning: Only qualified personell should adjust or service valves. Unauthorised manipulation may result in injury, loss of life or damage to equipment. Prior to servicing internal parts, ensure that the electrical power is switched off and residual pressure in the valve is reduced to zero.

Adjustments DOWN

Valves are already adjusted and tested. Check electrical operation before changing valve settings. Test that the correct solenoid is energised, by removing nut and raising solenoid slighty to feel pull. Nominal Settings: Adjustments 7 & 9 approx. level with flange face. Two turns in either direction may then be necessary. Adjustments 6 & 8 turn all the way 'in' (clockwise), then three turns 'out' (c-clockwise). One final turn in either direction may be necessary. 6. Down Acceleration: When solenoids C and D are energised, the car will accelerate downwards according to the setting of adjustment 6. 'In' (clockwise) provides a softer down acceleration, 'out' (c-clockwise) a quicker acceleration. 7. Down Speed: With solenoids C and D energised as in 6 above, the full down speed of the car is according to the setting of adjustment 7. 'In' (clockwise) provides a slower down speed, 'out' (c-clockwise) a faster down speed. 8. Down Deceleration: When solenoid C is de-energised whilst solenoid D remains energised, the car will decelerate according to the setting of adjustment 8. 'In' (clockwise) provides a softer deceleration, 'out' (c-clockwise) a quicker deceleration. Attention: Do not close all the way! 9. Down Levelling: With solenoid C de-energised and solenoid D energised as in 8 above, the car will proceed at its down levelling speed according to the setting of adjustment 9. 'In' (clockwise) provides a slower, 'out' (c-clockwise) a faster down levelling speed. Down Stop: When solenoid D is de-energised with solenoid C remaining de-energised, the car will stop according to the setting of adjustment 8 and no further adjustment will be required. KS Slack Rope Valve: Solenoids C and D must be de-energised! The KS is adjusted with a 3 mm Allan Key by turning the screw K 'in' for higher pressure and 'out' for lower pressure. With K turned all the way 'in', then half a turn back out, the unloaded car should descend when Manual Lowering H is opened. Should the car not descend, K must be backed off until the car just begins to descend, then backed off a further half turn to ensure that with cold oil, the car can be lowered as required.

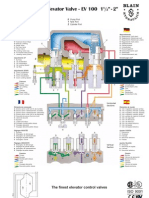

Positions of Adjustments

V

Z1

EV 100 1", 2", 2"

U

Z1

Z Y W

Z1

Horizontal Sections

Adjustments UP 1 By Pass 2 Up Acceleration 3 Up Deceleration 4 Up Levelling Speed 5 Up Stop Adjustments DOWN 6 Down Acceleration 7 Down Full Speed 8 Down Deceleration 9 Down Levelling Speed Valve Types EV 0 EV 1 EV 10 EV 100

KS Option Control Elements A Solenoid (Up Stop) B Solenoid (Up Deceleration) C Solenoid (Down Deceleration) D Solenoid (Down Stop) H Manual Lowering S Relief Valve U By Pass Valve V Check Valve W Levelling Valve (Up) X Full Speed Valve (Down) Y Levelling Valve (Down)

6 H

3 S

Vertical Section

D C B A

Elements Omitted A, B, W, 3, 4 & 5 B, W, 3 & 4 A&5 as shown

Jun 00

BLAIN HYDRAULICS

Você também pode gostar

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Ev Adjust gb-1Documento2 páginasEv Adjust gb-1mahfoud ascenseursAinda não há avaliações

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAinda não há avaliações

- Adj Proc KVDocumento2 páginasAdj Proc KVSylvester SullivanAinda não há avaliações

- Blain KV-GBDocumento6 páginasBlain KV-GBSylvester SullivanAinda não há avaliações

- Blain EV100Documento6 páginasBlain EV100Sylvester SullivanAinda não há avaliações

- Blain Ev100 - GBDocumento6 páginasBlain Ev100 - GBSylvester SullivanAinda não há avaliações

- Full KV Valves InfoDocumento6 páginasFull KV Valves InfoSylvester Sullivan100% (1)

- Hydratec BlainDocumento6 páginasHydratec Blaincoco MPAinda não há avaliações

- Blain EV 100 Ev - Quick-GbDocumento2 páginasBlain EV 100 Ev - Quick-GbSylvester SullivanAinda não há avaliações

- Maintenance and Service Manual For Elevator Control Valve EV 100 BlainDocumento13 páginasMaintenance and Service Manual For Elevator Control Valve EV 100 BlainCristian Liviu CiovicaAinda não há avaliações

- Ev Quick-GbDocumento2 páginasEv Quick-GbJean Luis SaviñónAinda não há avaliações

- Ev Quick-GbDocumento2 páginasEv Quick-GbGul Nawab KhanAinda não há avaliações

- Ev100manual en PDFDocumento13 páginasEv100manual en PDFdragishabl100% (1)

- Maintenance and Service Manual For Elevator Control Valve: EV 100 BlainDocumento13 páginasMaintenance and Service Manual For Elevator Control Valve: EV 100 Blainsuk2010Ainda não há avaliações

- Blain Service Manual LowDocumento15 páginasBlain Service Manual LowSylvester SullivanAinda não há avaliações

- Toyota Corolla 1997 Ignition Switch Transmission and Parking BrakeDocumento12 páginasToyota Corolla 1997 Ignition Switch Transmission and Parking Brakeairtarlac100% (1)

- Ronco 14 Harger 12 Harger 10 Automa Tic'S: Owners ManualDocumento8 páginasRonco 14 Harger 12 Harger 10 Automa Tic'S: Owners Manualhildy6Ainda não há avaliações

- Belarus MTZ 50 52 Operations MaintenancesDocumento23 páginasBelarus MTZ 50 52 Operations Maintenanceslulu323283% (6)

- Uc4 4mapDocumento2 páginasUc4 4mapUryAinda não há avaliações

- Blain EV Troubleshooting Ev - Trouble-GbDocumento2 páginasBlain EV Troubleshooting Ev - Trouble-GbSylvester SullivanAinda não há avaliações

- Operating Manual For Rear Tipping Bodies S1 Abridged Instruction For DriverDocumento15 páginasOperating Manual For Rear Tipping Bodies S1 Abridged Instruction For DriverAhmad Khaerul AnamAinda não há avaliações

- Tekonsha Envoy ManualDocumento6 páginasTekonsha Envoy Manualdoodahday69Ainda não há avaliações

- Ajuste de La Velocidad de Movimientos Del Brazo TD40150Documento6 páginasAjuste de La Velocidad de Movimientos Del Brazo TD40150RodrigoAinda não há avaliações

- Belarus MTZ 50 52 Operations MaintenancesDocumento36 páginasBelarus MTZ 50 52 Operations Maintenanceshotmail100% (1)

- Section : Operation of Instruments and ControlsDocumento18 páginasSection : Operation of Instruments and ControlsFlorian_AngererAinda não há avaliações

- Steering System PDFDocumento49 páginasSteering System PDFErkki IsokangasAinda não há avaliações

- Uc1 Uc2 Adjustment ProcedureDocumento2 páginasUc1 Uc2 Adjustment Proceduresaid luyAinda não há avaliações

- Pneum Act AdjDocumento12 páginasPneum Act AdjFENGAinda não há avaliações

- B1 - Main Engine & ShaftingDocumento29 páginasB1 - Main Engine & Shaftingefendi kaptanAinda não há avaliações

- WheelHorse TR 1977 B-C-Series Om 810001r1Documento24 páginasWheelHorse TR 1977 B-C-Series Om 810001r1Andras Tuba100% (1)

- Manual 3 PDFDocumento66 páginasManual 3 PDFciobiiuliAinda não há avaliações

- Pneumatics ProblemsDocumento22 páginasPneumatics ProblemsMatthew Laureano ResurreccionAinda não há avaliações

- Controles Et Reglages D8RDocumento18 páginasControles Et Reglages D8REZIUZEAinda não há avaliações

- McCulloch ProMac 46 II Mac 545EDocumento4 páginasMcCulloch ProMac 46 II Mac 545Eadyhansolo2Ainda não há avaliações

- McCulloch ProMac 46 II Mac 545EDocumento4 páginasMcCulloch ProMac 46 II Mac 545Eadyhansolo2Ainda não há avaliações

- 123manual TUNEPLUSDocumento16 páginas123manual TUNEPLUSrazvan33Ainda não há avaliações

- C4203 (New Syllabus) : General InfoDocumento6 páginasC4203 (New Syllabus) : General InfoMatt ConlonAinda não há avaliações

- Volvo Ew160b Wheeled ExcavatorDocumento23 páginasVolvo Ew160b Wheeled ExcavatorМирбек Майрыков100% (2)

- 1528224612cooper SP-550 Rig601 2Documento352 páginas1528224612cooper SP-550 Rig601 2Schneider GaviriaAinda não há avaliações

- Manual Toyota CorollaDocumento18 páginasManual Toyota CorollaWilliamStolovnovAinda não há avaliações

- 2.steering GearDocumento15 páginas2.steering GearMehedy Masud100% (1)

- Manual de Operacion Wj-1 (d914l04)Documento63 páginasManual de Operacion Wj-1 (d914l04)Jhonatan rincon martinezAinda não há avaliações

- 737NG QuestionDocumento18 páginas737NG QuestionPedro Casas Espinosa89% (9)

- Diesel Locomotive EngineDocumento21 páginasDiesel Locomotive Enginesinghnisha006482100% (1)

- Snowblower Manual0001Documento27 páginasSnowblower Manual0001WA9GXR100% (1)

- CPP PDFDocumento69 páginasCPP PDFiqha iqhoAinda não há avaliações

- Manual SG2100 New1Documento10 páginasManual SG2100 New1miki1zgAinda não há avaliações

- BMW Cruise Control E23 E28Documento14 páginasBMW Cruise Control E23 E28onukvedat72190% (1)

- TY S2009-004 Phazer BeltDocumento4 páginasTY S2009-004 Phazer BeltVlad TatymovAinda não há avaliações

- 102 112 Disc Brake Adjustments - OBS 102 075 Monitor E 128Documento11 páginas102 112 Disc Brake Adjustments - OBS 102 075 Monitor E 128Tomas Enrique Ramirez GomezAinda não há avaliações

- Mep Oral AnswersDocumento28 páginasMep Oral AnswersAshjo Gamer100% (1)

- Uv-5Atc: (Constant Down Speed Valve) Adjustment ProcedureDocumento2 páginasUv-5Atc: (Constant Down Speed Valve) Adjustment Procedurewayne mcmurrayAinda não há avaliações

- Blain KV Trouble-GbDocumento2 páginasBlain KV Trouble-GbSylvester Sullivan100% (1)

- Pianodisc 23510800Documento29 páginasPianodisc 23510800BEALE PLAYER PIANOAinda não há avaliações

- General: Extension and RetractionDocumento3 páginasGeneral: Extension and RetractionMohammed MilatAinda não há avaliações

- Landing GearDocumento21 páginasLanding GearMr.Me Almulla100% (1)

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsDocumento44 páginasOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1Ainda não há avaliações

- Excavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Documento17 páginasExcavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Maquinaria Pesada ServisAinda não há avaliações

- Industrial Hydraulic Circuits Slide ShareDocumento35 páginasIndustrial Hydraulic Circuits Slide ShareUMIPL HydAinda não há avaliações

- Blain Spare Parts EV KVDocumento2 páginasBlain Spare Parts EV KVSylvester SullivanAinda não há avaliações

- Troubleshooting GuideDocumento8 páginasTroubleshooting GuideSylvester SullivanAinda não há avaliações

- Blain Sys Leak KVDocumento1 páginaBlain Sys Leak KVSylvester SullivanAinda não há avaliações

- Trouble Ev eDocumento2 páginasTrouble Ev eSylvester SullivanAinda não há avaliações

- Sys Leak EVDocumento1 páginaSys Leak EVSylvester SullivanAinda não há avaliações

- Trouble KV eDocumento2 páginasTrouble KV eSylvester SullivanAinda não há avaliações

- Full KV Valves InfoDocumento6 páginasFull KV Valves InfoSylvester Sullivan100% (1)

- MD eDocumento4 páginasMD eSylvester SullivanAinda não há avaliações

- RL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocDocumento5 páginasRL RL RL RL RL: R R R R R Amloc Amloc Amloc Amloc AmlocSylvester SullivanAinda não há avaliações

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Documento1 páginaSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanAinda não há avaliações

- Slack Rope Valve KS For BLAIN EV, KV Down Valve and L10Documento1 páginaSlack Rope Valve KS For BLAIN EV, KV Down Valve and L10Sylvester SullivanAinda não há avaliações

- Blain RL-EDocumento4 páginasBlain RL-ESylvester SullivanAinda não há avaliações

- Quick Adj Ev eDocumento2 páginasQuick Adj Ev eSylvester SullivanAinda não há avaliações

- HPDocumento2 páginasHPSylvester SullivanAinda não há avaliações

- Blain CX-EDocumento1 páginaBlain CX-ESylvester SullivanAinda não há avaliações

- Blain Sys Leak EVDocumento1 páginaBlain Sys Leak EVSylvester SullivanAinda não há avaliações

- Flow - Pressure Chart (US and Metric)Documento4 páginasFlow - Pressure Chart (US and Metric)Sylvester SullivanAinda não há avaliações

- EV Poster34Documento1 páginaEV Poster34Sylvester SullivanAinda não há avaliações

- Ev eDocumento6 páginasEv eSylvester SullivanAinda não há avaliações

- EV Spare Parts List: Down Leak Solenoid Valves AdjustmentsDocumento1 páginaEV Spare Parts List: Down Leak Solenoid Valves AdjustmentsSylvester SullivanAinda não há avaliações

- Blain BVDocumento2 páginasBlain BVSylvester SullivanAinda não há avaliações

- Blain Sys Leak KVDocumento1 páginaBlain Sys Leak KVSylvester SullivanAinda não há avaliações

- Blain Spare Parts EV KVDocumento2 páginasBlain Spare Parts EV KVSylvester SullivanAinda não há avaliações

- Blain Service Manual LowDocumento15 páginasBlain Service Manual LowSylvester SullivanAinda não há avaliações

- EV Poster1-12Documento1 páginaEV Poster1-12Sylvester SullivanAinda não há avaliações

- Blain MD - GBDocumento4 páginasBlain MD - GBSylvester SullivanAinda não há avaliações

- Blain Price List 300 Euro 2008Documento1 páginaBlain Price List 300 Euro 2008Sylvester SullivanAinda não há avaliações

- Blain HP - 4spDocumento2 páginasBlain HP - 4spSylvester SullivanAinda não há avaliações

- Blain KV Trouble-GbDocumento2 páginasBlain KV Trouble-GbSylvester Sullivan100% (1)

- Fall 20122Documento98 páginasFall 20122DobarCovek67% (3)

- Cyrille MATH INVESTIGATION Part2Documento18 páginasCyrille MATH INVESTIGATION Part2Jessie jorgeAinda não há avaliações

- CH 4 Naac PPT 07-12Documento13 páginasCH 4 Naac PPT 07-12Arshad MohammedAinda não há avaliações

- CE Laws L8 L15Documento470 páginasCE Laws L8 L15Edwin BernatAinda não há avaliações

- 7273X 47 ITOW Mozart PDFDocumento3 páginas7273X 47 ITOW Mozart PDFAdrian KranjcevicAinda não há avaliações

- Preliminary Voters ListDocumento86 páginasPreliminary Voters Listمحمد منيب عبادAinda não há avaliações

- Auburn Bsci ThesisDocumento5 páginasAuburn Bsci Thesisafksaplhfowdff100% (1)

- WHITE TOWN GROUP-4 FinalDocumento112 páginasWHITE TOWN GROUP-4 Finalaswath manojAinda não há avaliações

- A Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofDocumento65 páginasA Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofMadhavpokale100% (1)

- Automatic Coconut Dehusking MachineDocumento12 páginasAutomatic Coconut Dehusking MachineKumaresh Salem0% (1)

- CfoDocumento13 páginasCfocarmen pirvanAinda não há avaliações

- 10 Problem For The Topic 9 & 10 Hicao GroupDocumento4 páginas10 Problem For The Topic 9 & 10 Hicao GroupArvin ArmojallasAinda não há avaliações

- Trend in Agricultural ProductivityDocumento1 páginaTrend in Agricultural ProductivityGiaAinda não há avaliações

- Advanced Packaging Polymers: Product Selection GuideDocumento12 páginasAdvanced Packaging Polymers: Product Selection GuideDKAinda não há avaliações

- Crusher 4Documento39 páginasCrusher 4kediliterapiAinda não há avaliações

- Q1. What Is JDBC? Explain Different Types JDBC Drivers With Suitable DiagramDocumento64 páginasQ1. What Is JDBC? Explain Different Types JDBC Drivers With Suitable DiagramjyebbwycqmfkuxAinda não há avaliações

- UntitledDocumento17 páginasUntitledSedat100% (1)

- ATA212001Documento3 páginasATA212001Tarek DeghedyAinda não há avaliações

- 28 ESL Discussion Topics Adult StudentsDocumento14 páginas28 ESL Discussion Topics Adult StudentsniallAinda não há avaliações

- Claudio MonteverdiDocumento2 páginasClaudio MonteverdiBrendan LynchAinda não há avaliações

- Syllabus - Building Rehabilitation Anfd Forensic en - 220825 - 181244Documento3 páginasSyllabus - Building Rehabilitation Anfd Forensic en - 220825 - 181244M O H A N A V E LAinda não há avaliações

- Engineering Mathematics Questions and AnswersDocumento9 páginasEngineering Mathematics Questions and AnswersZaky Muzaffar100% (1)

- JHS Integrated Science Preamble, Jan 2012 - FinalDocumento15 páginasJHS Integrated Science Preamble, Jan 2012 - Finalfrank adamsAinda não há avaliações

- Simple Love Spells That WorkDocumento14 páginasSimple Love Spells That Workagg24ankitAinda não há avaliações

- Certain Application of Photovo PDFDocumento235 páginasCertain Application of Photovo PDFaun_nustAinda não há avaliações

- Movie Review of THORDocumento8 páginasMovie Review of THORSiva LetchumiAinda não há avaliações

- Summary of The Pilot ProjectDocumento46 páginasSummary of The Pilot ProjectSrinivasan JeganAinda não há avaliações

- Delegate List - 10th IMRC With Contact Details - Removed (1) - Removed (1) - Removed (1) - RemovedDocumento100 páginasDelegate List - 10th IMRC With Contact Details - Removed (1) - Removed (1) - Removed (1) - RemovedSharon SusmithaAinda não há avaliações

- Job Sheet 1Documento5 páginasJob Sheet 1Sue AzizAinda não há avaliações

- Buy Wholesale China Popular Outdoor Football Boot For Teenagers Casual High Quality Soccer Shoes FG Ag Graffiti Style & FootballDocumento1 páginaBuy Wholesale China Popular Outdoor Football Boot For Teenagers Casual High Quality Soccer Shoes FG Ag Graffiti Style & Footballjcdc9chh8dAinda não há avaliações

- Rules of Thumb for Maintenance and Reliability EngineersNo EverandRules of Thumb for Maintenance and Reliability EngineersNota: 4.5 de 5 estrelas4.5/5 (12)

- Workbook to Accompany Maintenance & Reliability Best PracticesNo EverandWorkbook to Accompany Maintenance & Reliability Best PracticesNota: 3.5 de 5 estrelas3.5/5 (3)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemAinda não há avaliações

- A Complete Guide to Safety Officer Interview Questions and AnswersNo EverandA Complete Guide to Safety Officer Interview Questions and AnswersNota: 4 de 5 estrelas4/5 (1)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesNo EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesNota: 4.5 de 5 estrelas4.5/5 (2)

- Chemical Process Safety: Learning from Case HistoriesNo EverandChemical Process Safety: Learning from Case HistoriesNota: 4 de 5 estrelas4/5 (14)

- Guidelines for Auditing Process Safety Management SystemsNo EverandGuidelines for Auditing Process Safety Management SystemsAinda não há avaliações

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNo EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisNota: 5 de 5 estrelas5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsNo EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsNota: 4 de 5 estrelas4/5 (11)

- General Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismNo EverandGeneral Orders for Security Personnel: A Guide to Maintaining Discipline and ProfessionalismAinda não há avaliações

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações

- The Invisible Rainbow: A History of Electricity and LifeNo EverandThe Invisible Rainbow: A History of Electricity and LifeNota: 4.5 de 5 estrelas4.5/5 (21)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesAinda não há avaliações

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesNo EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesNota: 5 de 5 estrelas5/5 (1)

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersNo EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersNota: 4 de 5 estrelas4/5 (32)

- Tensor Technology Guide: Tensor Ring Benefits and UsesNo EverandTensor Technology Guide: Tensor Ring Benefits and UsesNota: 5 de 5 estrelas5/5 (2)

- Environmental and Health and Safety Management: A Guide to ComplianceNo EverandEnvironmental and Health and Safety Management: A Guide to ComplianceNota: 4 de 5 estrelas4/5 (2)

- Handbook of Hazardous Chemical PropertiesNo EverandHandbook of Hazardous Chemical PropertiesNota: 5 de 5 estrelas5/5 (1)

- Guidelines for Implementing Process Safety ManagementNo EverandGuidelines for Implementing Process Safety ManagementAinda não há avaliações