Escolar Documentos

Profissional Documentos

Cultura Documentos

Re Crystallization Formal Report

Enviado por

Jo_Rocel_Lacso_8119Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Re Crystallization Formal Report

Enviado por

Jo_Rocel_Lacso_8119Direitos autorais:

Formatos disponíveis

University of Santo Tomas Faculty of Pharmacy Organic Chemistry Laboratory

Recrystallization of Acetanilide with Water Herrera, D.A.; Idanan, M.J.; Izon, N.A.; *Lacson, J.R.; Maglente, K. Abstract

Recrystallization is a common method of purifying organic compounds through their differences in solubility at different temperature. In this experiment, acetylation of aniline with acetic anhydride was used to synthesize crude acetanilide. The crude acetanilide was purified by dissolving them in a hot water and then the solution was cooled slowly by placing in an ice bath. The yielded crystals are pure acetanilide since molecules of other compounds present in the crude acetanilide are excluded from growing crystal lattice. Lattice is a fixed and rigid arrangement of atoms, molecules or ions.

Introduction Natural organic compounds, whether solid or liquid, contain impurities, thus requiring different and various methods of purification. Purification methods to be applied are determined by the specific chemical and physical characteristics of certain compounds. For liquids, distillation is most commonly used and practiced on the basis of the boiling points of the compounds involved. If the product is a solid, it can be purified by either the process of sublimation or crystallization. Organic compounds that undergo sublimation pass directly into the vapour phase without passing through the liquid phase. Organic compounds which lack this property and are solid at room temperature are purified by recrystallization which is the simplest and most widely used purification method. Recrystallization is a method in which two crystallization processes were performed, thus such term was derived. It involves dissolving a solid that, in most cases, had originally crystallized from a reaction of mixture or another solution, and then causing it again to crystallize from solution. The main factor that affects crystallization is solubility which is the degree of solute to be dissolved in the solvent. Identification of a recrystallizing solvent is

significant. The substance to be crystallized should show the ideal solubility behaviour in solvent. The desired substance will crystallize upon cooling but the impurities will not. Methodology A corn-grain sized amount of pure acetanilide was deposited into three (3) different test tubes. Distilled water was then added to one test tube, hexane to another, and methanol to the last. The test tubes were shaken and placed in a water bath for 1-5 minutes. After heating, the test tubes were placed immediately to an ice bath. The solubility of the pure acetanilide in the different solvents at varying temperature was noted. This process will determine the appropriate and the best solvent that will yield pure Acetanilide through the acetylation of Aniline and Acetic Anhydride. In an Erlenmeyer flask, 2 ml of Aniline was added with 20ml of distilled water then slowly added with 3 mL of acetic anhydride. The flask was put in an ice bath to hasten the crystallization of the solution. When the crystals were fully formed, the solution was filtered to obtain the formed crystals, which will be the crude Acetanilide. After filtering, the crystals were dried by pressing with filter paper that will

sip the remaining liquid. This process is the first crystallization on the experiment. When the crude Acetanilide was completely dry, 20ml of water was added which is the chosen recrystallizing solvent. The solution was subjected in a water bath until all the solid dissolves. Since the solution became colored, activated charcoal was used to remove the colored impurities and was heated again. After heating, the solution was filtered immediately while it is hot and the filtrate was placed on an ice bath to hasten the crystallization of the solution. When the solution is done crystallizing, the solution was filtered and the crystals were collected. The crystals were dried by pressing in-between filter papers. The yielded pure acetanilide was weighed. Results and Discussion Recrystallization starts with finding the right crystallizing solvent which is a solvent that shows the desired solubility behavior for the substance to be crystallized. Identifying the ideal recrystallizing solvent of a compound is necessary to purify the organic compound. In choosing the recrystallizing solvent, the compound being purified must be insoluble in solvent at room temperature and must be soluble in boiling solvent. The solvents boiling point must be lower than the melting point of the compound. The unwanted impurities should be soluble at room temperature or insoluble during heating. The solubility of Acetanilide was tested for the three (3) given solvents, Water, Hexane, and Methanol respectively. A compound usually exhibits one of the three general solubility behaviors: (1), the compound has a high solubility in both hot and cold solvent, (2), the compound has a low solubility in both hot and cold solvent, and (3), the compound has a high solubility in hot solvent and low solubility in cold solvent. A solvent showing the 3rd characteristic or behavior is the one suitable as a Recrystallizing Solvent.

Solvents

At Room During During temperature heating cooling Water Insoluble Soluble Insoluble Methanol Soluble soluble Soluble Hexane Insoluble insoluble Insoluble Table 1. Solubility of Pure Acetanilide in Different Solvents at Different temperature. Table 1 shows the solubility of pure acetanilide in water, methanol and hexane at different temperature. Methanol and hexane are not suitable solvent because the acetanilide will not undergo recrystallization since the solvents are soluble and insoluble, respectively in all the system. In addition, safety measures must be practiced because methanol and hexane are flammable and highly volatile. Water exhibits the desired solubility behavior of an ideal recrystallizing solvent for acetanilide. At room temperature, it was insoluble; during heating it was soluble; and when placed upon cooling it was insoluble. In acetylation of aniline with acetic anhydride, yielding acetanilide exhibits an exothermic reaction. Exothermic reaction is the release of heat from the system. In case of cooling, the heat has to be removed from the system, the temperature is lowered. Thus, crystals form. Hastening crystallization is done through ice bath. This method decreases the solubility of acetanilide. The weight of the crude acetanilide is 2.70 g. The crude acetanilide was then subjected to the addition of the recrystallizing solvent which is water and placed in a hot plate. During the process of heating in a water bath, impurities may make the solution appeared colored. Decolorization can be applied to remove the colored impurities by using activated charcoal. Small amount of colored impurities will remain in solution during crystallization, making decolorizing step unnecessary. Activated charcoal adsorbs the

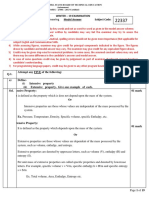

impurities because it has a large surface area and it can remove impurities more effectively. Only small amount of activated charcoal should be added. Too much activated charcoal used will not only adsorb the impurities but also the desired product. When adding activated charcoal, be cautious so that the solution will not erupt. Using activated charcoal in a minimum amount may reduce the risk of lung irritation. When the acetanilide was dissolved, the solution should be immediately filtered while hot using a fluted filter paper. The filtrate was subjected to ice bath to speed up the cooling process. The crystals collected were dried by pressing in-between filter papers. To calculate the percentage yield of the recrystallized acetanilide, the limiting reagent which is the reactant that is used up first in a reaction must be determined first. It also limits the amount of product to be formed. Calculation for the determination of the limiting reagent:

Figure 1. Calculation for the determination of the limiting reagent. The limiting reagent is aniline because it needed 2.96 g to react with 3 ml of acetic anhydride but only 2.0434 g is available to be used. Theoretical yield, the maximum yield of pure crystals that could be obtained by cooling or evaporating a given solution, will be the mass of the limiting reagent. This refers to the quantity of pure crystals deposited from the solution.

2 ml aniline = 2.0434 g aniline

The calculated percentage yield was 90.9 %. Percentage recovery is the percent of the pure form of a compound formed during the reaction. This refers to the percent of pure acetanilide formed after recrystallization.

3 ml acetic anhydride = 3.246 g acetic anhydride

x 100

The calculated values are the amounts of the two reactants in terms of mass. These are used to determine if the amount of each reactant is enough or more than what is needed for the chemical reaction.

The yielded acetanilide was 24% the weight of the crude acetanilide. This is the pure

acetanilide synthesized from the acetylation of aniline with acetic anhydride.

References: http://www.cerlabs.com/experiments/1087540 703X.pdf http://answers.yahoo.com/question/index?qid =20080728154024AAPVB6B http://www.sciencedirect.com/science/article/ pii/S0006291X88810337 http://forums.about.com/n/pfx/forum.aspx?na v=messages&webtag=abchemistry&tid=10262 http://answers.yahoo.com/question/index?qid =20091001034357AArsoVg

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Chemistry - Ionic Equilibrium DPPDocumento6 páginasChemistry - Ionic Equilibrium DPPmy missionAinda não há avaliações

- Bull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault SynthesisDocumento3 páginasBull Soc Chim Belg 1992 - A Convenient Preparation of Pivalaldehyde-Some Remarks On The Bouveault Synthesisjanina_nazarskaAinda não há avaliações

- PLTL Ch. 16 AssignmentDocumento6 páginasPLTL Ch. 16 AssignmentJules BrunoAinda não há avaliações

- Module 1.2: Parameters of ComfortDocumento2 páginasModule 1.2: Parameters of ComfortkaushikaAinda não há avaliações

- GC2 3 ThermochemistryDocumento34 páginasGC2 3 ThermochemistryBea MoradaAinda não há avaliações

- 6 EqDocumento4 páginas6 Eqchihingho19930903130Ainda não há avaliações

- Physical Chemistry 3th CastellanDocumento1.038 páginasPhysical Chemistry 3th CastellanPablo Gallardo94% (18)

- Examples in ThermodynamicsDocumento60 páginasExamples in ThermodynamicsCHAITANYAAinda não há avaliações

- Arrhenius Theory of IonizationDocumento10 páginasArrhenius Theory of IonizationALaa Yahia100% (1)

- Ms 4 Ss A Introduction To PolymersDocumento132 páginasMs 4 Ss A Introduction To Polymersbianca reyesAinda não há avaliações

- Actual 2006 STPM ChemistryDocumento20 páginasActual 2006 STPM ChemistryShin Yi100% (1)

- Table of SpecificationsDocumento1 páginaTable of SpecificationsCesar MagaroAinda não há avaliações

- CFD Analysis of Shell and Coil Heat Exchanger by Using Different Mass Flow Rate For Hot and Cold FluidDocumento19 páginasCFD Analysis of Shell and Coil Heat Exchanger by Using Different Mass Flow Rate For Hot and Cold FluidIJRASETPublicationsAinda não há avaliações

- Model Answer Winter 2019Documento19 páginasModel Answer Winter 2019Mohit D MoreAinda não há avaliações

- HK I TermodinamikaDocumento21 páginasHK I TermodinamikaPutri Desty AmeliaAinda não há avaliações

- 1 Introduction Lecture 2022Documento45 páginas1 Introduction Lecture 2022Ikushou SoAinda não há avaliações

- AM Week 2 ECM NOTESDocumento19 páginasAM Week 2 ECM NOTESa38659158Ainda não há avaliações

- Turowicz 6Documento27 páginasTurowicz 6ahmoxxxAinda não há avaliações

- Photoelectric Effect & Atomic Spectra 2 QPDocumento13 páginasPhotoelectric Effect & Atomic Spectra 2 QPMuhammad El-ElemyAinda não há avaliações

- Chemistry IA FinalDocumento10 páginasChemistry IA FinalDhiman RoyAinda não há avaliações

- Scanning Electron Microscope (SEM)Documento51 páginasScanning Electron Microscope (SEM)Maaz ZafarAinda não há avaliações

- Jjmie: Modeling and Verification of Double Slope Single Basin Solar Still Using Laboratory and Actual Solar ConditionsDocumento8 páginasJjmie: Modeling and Verification of Double Slope Single Basin Solar Still Using Laboratory and Actual Solar ConditionsSindhuvkreddyAinda não há avaliações

- Tobbala2020 PDFDocumento16 páginasTobbala2020 PDFSaber AlsidAinda não há avaliações

- WT ch1Documento20 páginasWT ch1አድሜ ልስልሱAinda não há avaliações

- Analyze Hydrate LabDocumento2 páginasAnalyze Hydrate LabJohnAinda não há avaliações

- Basic of Hvac: Prepared By: Engr. Mark Ivan C. EspinosaDocumento26 páginasBasic of Hvac: Prepared By: Engr. Mark Ivan C. EspinosaMark Ivan EspinosaAinda não há avaliações

- 11.3 Relative Stability of Element Group 14Documento13 páginas11.3 Relative Stability of Element Group 14吴绍轩Ainda não há avaliações

- CHEM225 Organic Chemistry 1 Module Week 1-4Documento17 páginasCHEM225 Organic Chemistry 1 Module Week 1-4Kezia CaratorAinda não há avaliações

- Aging of PETNDocumento44 páginasAging of PETNCarolina CasallasAinda não há avaliações

- PETSOC-95-09 Towards Optimizing Gas Condensate ReservoirsDocumento18 páginasPETSOC-95-09 Towards Optimizing Gas Condensate ReservoirsMiguel Angel GonzalesAinda não há avaliações