Escolar Documentos

Profissional Documentos

Cultura Documentos

Industeel Tableau Nuances Special Carbon and Low Alloy

Enviado por

Pravin VisputeDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Industeel Tableau Nuances Special Carbon and Low Alloy

Enviado por

Pravin VisputeDireitos autorais:

Formatos disponíveis

For more information and contact :

www.industeel.info INDUSTEEL LOIRE

BP 368 Chteauneuf - 42803 RIVE-DE-GIER Cedex - FRANCE Phone : + 33 4 77 75 21 41 - Fax : + 33 4 77 75 20 01

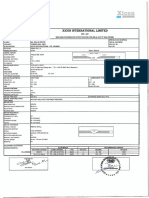

SPECIAL CARBON AND LOW ALLOY STEEL SOLUTIONS FOR PRESSURE EQUIPMENT AND STORAGE TANKS

STEEL TYPE INDUSTEEL TRADEMARKS

(DATASHEETS AVAILABLE ON REQUEST)

INDUSTEEL BELGIUM

266, rue de Chtelet - 6030 CHARLEROI - BELGIUM Phone : + 32 71 44 16 99 - Fax : + 32 71 44 19 56

MECHANICAL PROPERTIES AS DEFINED BY CODES AND NATIONAL STANDARDS USA EUROPE JAPAN ASME (or ASTM) EN 10028 Series JIS

SA 516 gr 60 P275NH-NL1-NL2 SA 516 gr 65 G3115 SPV 235/SPV 315 G3118 SGV 410/SGV 450 G3103 SB 410/SB 450 G3126 SLA 235/SLA325 G3115 SPV G3118 SGV G3103 SB G3126 SLA 235/SPV 355 410/SGV 480 410/SB 480 235/SLA 325

ADDITIONAL TRADEMARK FEATURES

CHEMICAL ANALYSIS SPECIAL PROPERTIES

TYPICAL APPLICATIONS

CARELSO 60 CARELSO 65 CARELSO 70

S 0.004%, P 0.01% and extra low carbon equivalent (Ceq.) for excellent weldability S 0.004%, P 0.01% and extra low carbon equivalent (Ceq.) for improved weldability

Hardness 22HRC reduction of area in Z 35%

Clean steels for mild service applications according to NACE MR 0175/ ISO 15156, including improved behaviour in the Heat Affected Zone (HAZ) of welds (refining, oil and gas production)

SA 516 gr 70 SA 537 cl1

P355N-NH-NL1-NL2

Hardness 22HRC reduction of area in Z 35%

Clean steels for mild service applications according to NACE MR 0175/ ISO 15156, including improved behaviour in the Heat Affected Zone (HAZ) of welds after Post Weld Heat Treatment (PWHT) (refining, oil and gas production)

SPECIAL CARBON MANGANESE STEELS

CARELSO 60 HIC CARELSO 65 HIC CARELSO 70 HIC CARELSO 70 SOHIC

SA 516 gr 60 P275NH-NL1-NL2 SA 516 gr 65 SA 516 gr 70 SA 537 cl1 SA 516 gr 70 SA 737 B SA 533 C cl2 modified SA 533 C cl2 modified A 517 Q modified SA 387 gr 11 SA 387 gr 12 SA 387 gr 22 SA 542 D SA 387 gr 5 SA 387 gr 9 SA 387 gr 91 Seamless SA213 T92 & SA335 P92 + ASME code case 2179-4 X10CrMoVNb9-1 P355N-NH-NL1-NL2 idem CarElso 70 P355Q-QH-QL1-QL2 idem CarElso 60/65

idem CarElso 60/65 + S 0.002%, P 0.008, O2 20ppm idem CarElso 70 + S 0.002%, P 0.008, O2 20ppm idem CarElso 70 HIC + microstructural control + improved HAZ behaviour low C, MnNiMo microalloyed steel

as above + HIC resistance (guarantee for CLR, CTR, CSR)

Mill-certified HIC resistant steels for sour service applications (refining and gas treatment)

as above + SOHIC resistance YS = 72 ksi (500 MPa) UTS = 90 ksi (620 MPa) Hardness max 22HRC + HIC resistance High strength steel with improved low temperature impact properties enhanced creep cracking ductility enhanced creep cracking ductility excellent low temperature impact properties V addition for enhanced resistance to creep and hydrogen damage excellent hydrogen attack resistance excellent creep and hydrogen attack resistance excellent creep and hydrogen attack resistance excellent creep and hydrogen attack resistance CharpyV 27J at - 60C CharpyV 27J at - 80C, low NDTT CharpyV 27J at - 101C CharpyV 50J at - 101C low NDTT CharpyV 27J at -120C CharpyV 27J at - 196C CharpyV 100J at - 196C very low thermal expansion in the cryogenic range

SOHIC resistant steel for severe sour service applications (refining and gas treatment) Special high yield strength pressure vessel steel for wall thickness reduction in oil and gas production Can be supplied either in solid or clad plates Special high yield stress pressure vessel steel for sour service applications in oil and gas production (subsea separator). Can be supplied either in solid or clad plates Racks for jack-up offshore platforms Industeel can supply welded racks, ready for use Special steel for Hydrodesulfuration (HDS) and Hydrotreatment (HDT) units in refining and power plant Special steel for Hydrodesulfuration (HDS) and Hydrotreatment (HDT) units in refining and power plant Special steel for HDS, HDT and Hydrocracking (HDC) units with very low sensivity to temper embrittlement and disbonding Special high strength steel for HDC units under high temperature/ high pressure service with low sensivity to temper embrittlement and disbonding Sulfur resistant steel for refinery applications Sulfur resistant steel for refinery applications Creep-resistant steel for high service temperature welded-pipe applications (power plant) and pressure vessels Creep-resistant steel for high service temperature welded-pipe applications (power plant) and pressure vessels Creep-resistant steel for ultra high service temperature welded-pipe applications (power plant) and pressure vessels Gas storage and transportation Gas storage plants and nuclear waste containers Gas storage plants and pressure vessels for low temperatures Gas storage plants, nuclear waste containers and pressure vessels for low temperatures Gas storage and transportation at very low temperatures Cryogenic storage at -163C (small LNG tanks) Cryogenic storage at -163C (LNG terminals) pressure vessels, compressors and cryogenic piping for LNG transportation

- May 2008

SUPERELSO 500

P500Q-QH-QL1 G3120 SQV 3B modified P500 QL2 EN 10025-6 : S690 QL2 13 CrMoSi5-5 13 CrMo4-5 10 CrMo9-10 13 CrMoV9-10 X12CrMo5 G 4109 SCM V6 G 4109 SC MV3 G 4109 SCM V2 G 4109 SCM V4

WELDABLE HIGH STRENGTH STEELS

SUPERELSO 500 HIC

extra low C, MnNiMo steel with PCM 0.28% low C, MnNiCrMo steel P 0.007% J factor 150 P 0.007% C 0.15%, P+Sn 0.012%, J factor 100 C 0.15%, P+Sn 0.012%, 0.25% V, J factor 80 low C, 5 Cr 0.5Mo steel 0.1%C, P 0.020%, 0.25%V 0.1%C, P 0.020%, 0.25%V, 0.05%N 0.1%C, P 0.020%, 0.20%V, 1.8%W low P 0.010 % low P 0.010 %

SUPERELSO 690 CR CROMELSO 11 CROMELSO 12 CROMELSO 22

CHROMIUM MOLYBDENUM STEELS FOR HIGH TEMPERATURE HYDROGEN SERVICE

CROMELSO 22V CROMELSO 5 CROMELSO 9 CROMELSO 91 CROMELSO 92 CRYELSO 0.5 CRYELSO 1.5 CRYELSO 2.25

Type 9Cr 0.4Mo 1.8W 0.2V 13 Mn Ni 6-3 15 NiMn 6

SA 203 gr A & B SA 203 gr D, E & F (SA 645) SA 353 SA 553 Type 1 UNS K93601 12 Ni 14 X 12 Ni 5 X 8 Ni 9 NT 640 X 7 Ni 9 X 8 Ni 9 QT 680 WN 1.3912

G3127 SL2N 255 G3127 SL3N 255/ SL3N 275/SLN 440 G3127 SL5N 590 G3127 SL9N 520 G3127 SL9N 590

low P 0.010 % low P 0.010 % C 0.10% max, low P 0.010 % C 0.08% max, Cr 0.25%, Mo 0.08% C 0.08% max, Cr 0.25%, Mo 0.08% 36% Ni, extra low impurities P, S

HIGH TOUGHNESS NICKEL STEELS FOR CRYOGENIC APPLICATIONS

CRYELSO 3.5 CRYELSO 5 CRYELSO 9N CRYELSO 9Q CRYELSO N36

Cryogenic piping for LNG transportation

DIMENSIONAL PROGRAM

Quarto plates Preforged & rolled Discs Formed pieces (heads, half shells)

Thickness (mm)

4-600 (0,16-23,6) 200-900 (7,9-35,4) up to 700 (up to 27,6) 50-450 (2-17,7)

Max. Width Max.Weight (mm) (t)

4350 (171) 4350 (171) 4500 (177) 5-100 t 5-100 t 5-60 t up to 80 t

Heat treatment

N; N+T; Q+T N; N+T; Q+T N; N+T; Q+T N; N+T; Q+T

Steel grades

all grades all grades all grades all grades

As well as the above trademarks, Industeel supplies all steel grades for pressure equipment according to national standards

all steel grades : C, C Mn, Mo, MnMo, MnMoNi, Cr, CrMo, CrMoV, NiCrMo, Ni ... * Former European standards NF / BS / TUV / DIN / UNI ... * ASTM/ASME standards A / SA 299/302/387/514/515/516/517/533/537/542/543 ... * Other standards such as GOST / ... Industeel complies with and is certified according to all major quality assurance systems : ASME, ISO 9001, VDTUV, DNV, ABS, RAQ 1/2 ...

Registered trademarks of Industeel Products in accordance with National Standards, with additional guarantees adapted to the final use. Any different properties can be studied by the mill on request. Industeel reserves the right to modify above data.

I M P R I M E R I E

Le Creusot/Chalon - 03 85 77 47 00

All steels are produced by a special steelmaking process including selected scrap melting in electric arc furnace, with heated ladle refining and stringent vacuum degassing (VOD, VAD) to produce extra-clean, homogeneous, reproducible, compact steels with extra-low gas levels.

Você também pode gostar

- Carbon Steel and Alloy Steel FastenersDocumento2 páginasCarbon Steel and Alloy Steel FastenersagnisivadasanAinda não há avaliações

- Cahpter 5 Special SteelDocumento50 páginasCahpter 5 Special SteelhealgoseAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento7 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento8 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Structural SpecsDocumento42 páginasStructural SpecsJosh Jaymes MasseAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento5 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento6 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento6 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- T500 VeeyesDocumento5 páginasT500 VeeyesTimothy TaylorAinda não há avaliações

- Steel PropertiesDocumento22 páginasSteel PropertiesMOHD SALMANAinda não há avaliações

- Deu PointDocumento2 páginasDeu PointP.S.J.SarmaAinda não há avaliações

- M M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / HDocumento1 páginaM M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / Hahm3d16nAinda não há avaliações

- Specific Heat Chart of WaterDocumento2 páginasSpecific Heat Chart of WaterDaud IfadahAinda não há avaliações

- 5729 - 5729 - Bitzer 4T-12.2Documento2 páginas5729 - 5729 - Bitzer 4T-12.2Jose CordovaAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento6 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento7 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento7 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Material PropertiesDocumento2 páginasMaterial PropertiesCelineKevinAinda não há avaliações

- Chemical TitrationDocumento5 páginasChemical TitrationVikasAinda não há avaliações

- AntoineDocumento64 páginasAntoinealexis19714aAinda não há avaliações

- Vapor Pressure CalculatorDocumento120 páginasVapor Pressure Calculatorhilman_hilmawanAinda não há avaliações

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento23 páginasChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallselisenAinda não há avaliações

- Deu PointDocumento4 páginasDeu PointDurjoy ChakrabortyAinda não há avaliações

- Countercurrent Flow: T1 (F) T2 (F) T3 (F) T4 (F)Documento32 páginasCountercurrent Flow: T1 (F) T2 (F) T3 (F) T4 (F)Partho GiriAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento6 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- Global Marketing For Tube & PipeDocumento4 páginasGlobal Marketing For Tube & PipedsyashankaAinda não há avaliações

- Boundary Layer CalculatorDocumento10 páginasBoundary Layer CalculatorTint TigerAinda não há avaliações

- Subject: Positive Temperature DifferenceDocumento6 páginasSubject: Positive Temperature Differenceanuj3936Ainda não há avaliações

- Chemical Properties Joback MethodDocumento10 páginasChemical Properties Joback MethodSatria 'igin' Girindra NugrahaAinda não há avaliações

- Blank Calc Template - Steel Tools1Documento656 páginasBlank Calc Template - Steel Tools1magdy.kamel6528Ainda não há avaliações

- Glass Lined BrochureDocumento8 páginasGlass Lined BrochureKarna2504Ainda não há avaliações

- Chemical Composition of Carbon Steel, Carbon Steel Pipe, Carbon Steel Tubes, Alloy Steel Pipe, Alloy Steel Tubes, Mumbai, IndiaDocumento2 páginasChemical Composition of Carbon Steel, Carbon Steel Pipe, Carbon Steel Tubes, Alloy Steel Pipe, Alloy Steel Tubes, Mumbai, IndiaVamsikrishna LakamsaniAinda não há avaliações

- Liquid Orals QuestionnaireDocumento6 páginasLiquid Orals Questionnairedhanu_lagwankarAinda não há avaliações

- Stress Analysis ReportDocumento123 páginasStress Analysis ReportNOXOLO PETUNIA SAMBOAinda não há avaliações

- PDS-Sparkler FilterDocumento5 páginasPDS-Sparkler FilterDHAVALESH AMAinda não há avaliações

- Oilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ADocumento3 páginasOilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ATifano KhristiyantoAinda não há avaliações

- Polycab Armoured Cables Price List Wef 14-11-2016 CustomerDocumento1 páginaPolycab Armoured Cables Price List Wef 14-11-2016 CustomernavneetAinda não há avaliações

- Pipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2Documento51 páginasPipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2JMVAinda não há avaliações

- Yanbu: Export Refinery ProjectDocumento7 páginasYanbu: Export Refinery ProjectJanakiraman MalligaAinda não há avaliações

- WPS PQR For S 1 S Piping 02Documento5 páginasWPS PQR For S 1 S Piping 02ravi00098Ainda não há avaliações

- Jyoti Engineering Works: Chemical AnalysisDocumento8 páginasJyoti Engineering Works: Chemical AnalysisKristin CrawfordAinda não há avaliações

- 0497 4 Flow Straightener Catalog Sheet 05 14Documento2 páginas0497 4 Flow Straightener Catalog Sheet 05 14mkfe2006Ainda não há avaliações

- Gawish SPE Paper PDFDocumento11 páginasGawish SPE Paper PDFEdsonAinda não há avaliações

- MATERIALESDocumento1 páginaMATERIALESRa ClAinda não há avaliações

- PREOSDocumento16 páginasPREOSMary KeoghAinda não há avaliações

- Composition and Characteristics of Crude PetroleumDocumento57 páginasComposition and Characteristics of Crude PetroleumPrateek Chandra100% (1)

- KFHC TPB Reguler ZfactorDocumento9 páginasKFHC TPB Reguler ZfactorIlhamRifaldiAinda não há avaliações

- Bk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Documento34 páginasBk91 1310 CPF 114 Mef Das 0003 - C - Data Sheet For Stabilizer (CPF 114 C 03cpf 214 C 03)Anonymous bHh1L1Ainda não há avaliações

- Materials Properties DatabaseDocumento40 páginasMaterials Properties DatabaseJuan Pablo ApazaAinda não há avaliações

- SwageloK MS 02 468Documento20 páginasSwageloK MS 02 468meseicarmeAinda não há avaliações

- Mass Balance 3Documento22 páginasMass Balance 3barbadosiyAinda não há avaliações

- 300 NB HE SpectrumDocumento8 páginas300 NB HE SpectrumShailesh DeshmukhAinda não há avaliações

- Calibration Curve: Tartaric Acid: Peak AreaDocumento10 páginasCalibration Curve: Tartaric Acid: Peak Areajanesalazar3369Ainda não há avaliações

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Documento3 páginasSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesAinda não há avaliações

- URB25Documento4 páginasURB25malika_00Ainda não há avaliações

- API6A Trim Material RatingsDocumento5 páginasAPI6A Trim Material RatingsAneez MhdAinda não há avaliações

- Ga 250Documento16 páginasGa 250g9g9Ainda não há avaliações

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocumento6 páginasARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UAinda não há avaliações

- Tubular Products From Special MetalsDocumento26 páginasTubular Products From Special Metalskaveh-bahiraeeAinda não há avaliações

- Product CatalogueDocumento2 páginasProduct CatalogueHibozoAinda não há avaliações

- Heat Treatment Training ManualDocumento118 páginasHeat Treatment Training ManualPravin VisputeAinda não há avaliações

- WeldingDocumento43 páginasWeldingPravin VisputeAinda não há avaliações

- ASME B31.3 - Practice QuestionDocumento18 páginasASME B31.3 - Practice QuestionPravin Vispute100% (1)

- Metal Fabricator WelderDocumento2 páginasMetal Fabricator WelderPravin VisputeAinda não há avaliações

- Welding Code of EthicsDocumento2 páginasWelding Code of EthicsPravin VisputeAinda não há avaliações

- Welding Code of EthicsDocumento2 páginasWelding Code of EthicsPravin VisputeAinda não há avaliações

- b205g - MS Plus - 201601Documento32 páginasb205g - MS Plus - 201601Alexandre SouzaAinda não há avaliações

- Filler Metal Selection Guide: Cronacast-211 Ni-Rod-55Documento9 páginasFiller Metal Selection Guide: Cronacast-211 Ni-Rod-55Vijaya BaraniAinda não há avaliações

- ISO 17025 Credentials - SGS UKDocumento8 páginasISO 17025 Credentials - SGS UKkarthicbc2020Ainda não há avaliações

- Metalography and Microstructures of Stainless Steels and Maraging SteelsDocumento32 páginasMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraAinda não há avaliações

- MS35758DDocumento5 páginasMS35758DchemtausifAinda não há avaliações

- Class Viii Week 6 Lesson 3Documento12 páginasClass Viii Week 6 Lesson 3Mahrukh JawedAinda não há avaliações

- Material Groups and StandardsDocumento1 páginaMaterial Groups and StandardsJohn Rymar LameraAinda não há avaliações

- Most Common Qualities and Their Equivalents: Carbon SteelsDocumento6 páginasMost Common Qualities and Their Equivalents: Carbon SteelsretrogradesAinda não há avaliações

- D1.6-2017 (First Proof) (Received 03-15-2017) 242Documento1 páginaD1.6-2017 (First Proof) (Received 03-15-2017) 242mrAinda não há avaliações

- Macho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1Documento2 páginasMacho Laminador: M DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 MF DIN 13. ISO 724/965.1 Unc Asme B1.1emerson.mineiro100% (1)

- Tabelle Gewicht RundstahlDocumento1 páginaTabelle Gewicht RundstahlAzur OmranAinda não há avaliações

- SUDocumento1 páginaSURajkumar AAinda não há avaliações

- ELECTROWINNING TEMBAGA CuDocumento12 páginasELECTROWINNING TEMBAGA Cuadetha regicaAinda não há avaliações

- en 15608 Euro Matls GroupingDocumento12 páginasen 15608 Euro Matls GroupingCarlos Nombela Palacios100% (2)

- Classification of Steels: M S A EDocumento27 páginasClassification of Steels: M S A Emuhammad irfanAinda não há avaliações

- 25 Q Uiii AwtDocumento5 páginas25 Q Uiii Awtsachin rajputAinda não há avaliações

- Stoic H Practice KeyDocumento2 páginasStoic H Practice KeyHarisAwanAinda não há avaliações

- Fasteners Exporter Manufacturer-Repute Steel INDIA BOLTSDocumento4 páginasFasteners Exporter Manufacturer-Repute Steel INDIA BOLTSPRAVINAinda não há avaliações

- Spare Parts ListDocumento4 páginasSpare Parts ListFuqingliAinda não há avaliações

- Materials Science and Engineering-Chapter 11Documento3 páginasMaterials Science and Engineering-Chapter 11JurgenAinda não há avaliações

- Steel Making: Basic Oxygen ProcessDocumento1 páginaSteel Making: Basic Oxygen ProcessPablo GomesAinda não há avaliações

- Tool Steel SelectionDocumento4 páginasTool Steel SelectionX800XLAinda não há avaliações

- 304HCu 310NDocumento40 páginas304HCu 310NmalsttarAinda não há avaliações

- Unit Iii: V 6Cwodc-3VrkDocumento237 páginasUnit Iii: V 6Cwodc-3VrkDinesh KumarAinda não há avaliações

- Dental Casting AlloysDocumento57 páginasDental Casting Alloysbaltayar51Ainda não há avaliações

- 'Dokumen - Tips - Table of Friction Coefficient PDFDocumento2 páginas'Dokumen - Tips - Table of Friction Coefficient PDFtoligado27Ainda não há avaliações

- MS-1000-Material Specifications For SteelDocumento44 páginasMS-1000-Material Specifications For SteelALEX MURPHYAinda não há avaliações

- Extractive Metallurgy PDFDocumento3 páginasExtractive Metallurgy PDFRajat AgarwalAinda não há avaliações

- New A5Documento7 páginasNew A5Yas kiAinda não há avaliações

- BC METAL - Historical Metal Production in B.C. 1888-1988: Sort by Mine NameDocumento26 páginasBC METAL - Historical Metal Production in B.C. 1888-1988: Sort by Mine NamejanoyAinda não há avaliações