Escolar Documentos

Profissional Documentos

Cultura Documentos

Piping Flexiblility Calculation

Enviado por

AntoshalDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Piping Flexiblility Calculation

Enviado por

AntoshalDireitos autorais:

Formatos disponíveis

Quick Check on Piping Flexibility

L. C. Peng, PE

Peng Engineering, Houston, Texas

ABSTRACT

One major requirement in piping design is to provide adequate flex-

ibility for absorbing the thermal expansion of the pipe. However,

due to lack of quick method of checking, pipings are often laid-out

to be either too stiff or too flexible. In either case, valuable

time and material are wasted. This paper presents some of the quick

methods for checking piping flexibility. These methods include

visual, hand calculation, and micro computer approaches. They are

all quick and easy for designers to use in planning their layouts.

Once the designers have taken care of the flexibility problem, the

iterative procedure between the stress engineers and the designers

become simpler. The project schedule can also be improved.

PIPING FLEXIBILITY'

As the pipe temperature changes from the installation condition to

the operating condition, it expands or contracts. In the general

term, both expansion and contraction are called thermal expansion.

When a pipe expands it has the potential of generating enormous

force and stress in the system. However, if the piping is flexible

enough, the expansion can be absorbed without creating undue force

or stress. Providing the proper flexibility is one of the major

tasks in the design of piping system.

Piping is used to convey a certain amonut of fluid from one

point to another. It is obvious that the shorter the pipe is used

the lesser the capital expenditure is required. The long pipe may

also generate excessive pressure drop making it unsuitable for the

proper operation. However, the direct shortest layovt generally is

not acceptable for absorbing the thermal expansion.

Figure 1 shows what will happen when a straight pipe is directly

connected from one point to another. First, consider that only one

end is connected and the other end is loose. The loose end will

expands an amount equal to

However, since the other end is not loose, this expansion is to be

absorbed by the piping. This is equivalent to squeezing the pipe

to move the end back an ~ distance. This amount of squczzing

creates a stress of the magnitude

S=Ei.C.jLI=Ee

1

Where,

A

=

thermal expansion, in

L

e

=

expansion rate, in/in

L

=

pipe length, in

s

=

axial stress, psi

F E

=

modulus of

elasticity, psi

A

=

pipe cross section area, inZ

F

=

axial force, lbs

Figure 1

The force required to squeeze this amount is

F = A S = A E e

Take a 6-inch standard wall carbon steel pipe for instance, an

increase of temperature from 70F ambient to 300F operating creates

an axial stress of 42300 psi and an axial force of 236000 lbs in

the pipe. These are excessive even though the temperature is only

300F. It is clear that the straight line direct layout is not

acceptable to most of the piping, Flexibility has to be provided.

EXPANSION LOOP

Piping flexibility are provided in many different ways. The turns

and offsets needed for running the pipe from one point to another

provides some flexibility by themself. This inherent flexibility

may or may not be sufficient depending on the individual cases.

Additional flexibility can be provided by adding expansion loops

or expansion joints. In the straight line example discussed above,

the stress can be reduced by a loop installed as shown in Figure 2

or by an expansion joint as shown in Figure 3.

The idea in Figure 2 is to provide

some pipe perpendicular to the

direction of expansion. In this

way when the pipe expands it bends

the loop leg first before transmi-

tting any load to the anchor. The

longer the loop leg the lesser the

force will be created. The force

created is inversely proportional

to the cube of the loop length and

the stress generated is roughly

Figure 2

inversely proportional to the square of the loop length, The loop

sometimes can take considerably more space and piping than what is

available, or economically justifiable. This is especially true

for large high temperature low

pressure pipings. In this case the : :

better method is to use expansion ~ 11J111

joint. Expansion joints are more g

sophisticated than the pipe loops ::f------.----' J.-r------l

~ h i c h are just extra lengths of

the same piping. For this and Figure 3

2

other reasons, engineers tend to favor piping loops over expansion

joints. However, expansion joints can be used effectively in many

applications when they are properly designed. One of the major

requirements in the design of expansion joint system is to install

sufficient restraints for maintaining the stability. This article

deals mainly the loop approach.

THE CRITICAL PATH

In designing a plant, the piping is generally routed or laid-out

by the piping designers then checked by the stress engineers as

shown in figure 4.

Piping Designer

lfnexperienced)

Layout

Piping-1

Not

Flexible

Layout

Piping-2

Feel

Bad

No

Space

---

Revise Both

Pipings

Slow, Long

Schedule

Stress Engineer Piping Designer

(Experienced)

Check

Stress

OVER PRICED

PROJECT

Figure 4

3

Too

Flexible

No Revision

If Works

Layout

Piping-1

Layout

Piping-2

Feel

Good

Waste

Space

Waste

MS:terial

Excessive

Material

There is a marked difference in the layout done by the experienced

and the inexperienced designers. The experienced designers know

the importance of the flexibility. However, they tend to provide

too much flexibility in contrast to the inexperienced ones who

tend to provide little flexibility. In either case, the resulL is

an over priced project.

The layout done by an inexperienced designer is normally too stiff

because the designer does not know how or too timid to add loops

or offsets. If a piping system is too stiff, the stress engineer

will almost certain to find it out. The stress engineer will send

the design, with recommended loops, back to the designer for

revision. At this time, the designer have made some more layouts

in the same area making the revision very difficulty. On the other

hand, a layout done by an experienced designer often contains

the loops which are excessive or not needed. The excessive loops

are normally maintained without revision, becuase it is a common

prctice not to change something which works. The experienced one

might have saved the manhour needed for the revision. The cost of

the excessive loops can be prohibitive.

The cost of the project can be reduced substantially if ~ h e right

amount of flexibility is built in the piping at the initial layout

stage. This requires some quick methods which can be used br the

designers to check the piping flexibility.

VISUAL CHECK

The visual check is the first important examination on anything we

do. If the design looks strange, then most likely something is

wrong with it. By now we at least know that we can not run a

piping straight from one point to another. This also applies to

the situation when there are two or more line stops installed at a

straight header as shown in Figure 5. The line stop or axial stop

acts directly against the expansion of the pipe. When two axial

stops installed on the same straight leg, the thermal expansion of

the pipe located between the stops has no place to relieve.

Figure 5

The visual check of the piping flexibility is to look for the pipe

legs located in the direction perpendicular to the line connecting

the two anchor or other restraint points. The length of the leg 1s

4

the direct measure of the flexibility, Therefore, the key is to

locate the availability of the perpendicular leg and to determine

if the length of the leg is sufficient. The required leg length

can be estimated by the rule of thumb equation (1) derived by the

guided cantilever approach, for steel pipes.

1 = 5.5 F Ill where,

l = leg length required, ft

D = pipe outside diameter, in

b = expansion to be absorbed, in

To usc Equation (1) efficiently the expansion rate of the pipe has

to be remembered. Table 1 shows the expansion rates of carbon and

stainless steel pipes at several operating temperatures. The rate

at other temperature can be e8timated by proportion. By combining

Equation 1 and Table 1, the designer can estimate the leg length

required without needing a pencil. For instance, an 80 feet long

6-inch carbon steel pipe operating at 600F expands about 4 inches

which requires a 30 feet leg to absorb it. It should be noted that

an expansion loop is considered as two legs with each leg absorbs

one half of the total expansion.

Table 1

Expansion Rate, in/100 ft pipe

Temp,F 70 300 500 800 1000

Carbon Steel

0 1. 82

!

3.62 6.7 8.9

Stainless Steel 0 2. 61 5.01 8.8 11.5

HAND CALCULATION

There are several simplified calculations can be performed quickly

with hand. The most popular one is the so called guided cantilever

approach. The method can be explained using the L-bend given in

Figure 6 as an example. When the system is not constrained the

A 8 8'

}------'1-]

I

I

I

c I

ay:y__j c'

)1x.j

---41dy

"' B I

r-----"fi} c ! ~ j

A

(a) Free Expansion (b) Constrained Expansion

Figure 6

5

points B and C will move to B' and C' respectively due to thermal

expansion. The end point C moves dx and dy respectively in X- and

Y- directions, but no internal force or stress will be generated.

However

1

in the actual case the ends of the piping are alwa.,vs

constrained as shown in Figure 6(b). This is equivalent in moving

the free expanded end C' back to the original point C forcing the

point B to move to B". The dx is the expansion from leg AB, and

dy from leg CB. The deformation of each leg can be assumed to

follow the guided cantilever shape. This is conservative because

the end rotation is ignored. The force and stress of each leg can

now be estimated by the guided cantilever formula. The leg AB is

a guided cantilever subject to dy displacement and leg CB a guided

cantilever subject to dx displacement respectively.

From the basic beam theory, the moment and displacement relation

of a guided cantilever is

!'1 ::

For thin

I:::)tr3 t

s =

where,

6 E I

LZ

6 '

F =

2 M

121

L

wall pipes, Equation

and S:::M/(ltri! t),

(2) can be further reduced. By

the above equation becomes

s

=

E

=

r

=

"'

=

L

=

.l

=

D

=

thermal

modulus

E D L:.

48 .t'

expansion stress,

of elasticity, psi

psi

mean radius of the pipe, in

total expansion to be absorbed,

length

of the leg perpendicular

length in feet unit, ft

outside diameter of the pipe, in

13)

in

to in

using

Equation (3) is a convenient formula for the quick estimation of

the expansion stress. By pre-setting E=29.0x10 psi and 8::20000

psi, Equation (3) becomes Equation (1) used in finding the leg

length required for steel pipes.

The other formula can be used for the quick check is the one given

in AKSI B31 Piping Codes. The Code uses Equation (4l as a measure

of adequate flexibility, subjects to other requirements of the

Code.

D y

< 0.03

where, D

=

outside diameter of the pipe, in

y

=

resultant of total displacement to be absorbed, in

L

=

developed length of piping bet'h'een anchors,

u

=

straight line distance between anchors, ft

Equation {4) is actually equivalent to Equation {1), if

considered as the perpendicular leg length.

6

ft

IL-UJ is

Equation (4) has to be used with great care, because the same extra

length of pipe can have very diferent effects depending on the ways

the pipe is laid-out. more flexibility will be achieved if

the pipe is placed farther away from the elastica! or geometrical

center. For instance with the same extra length of piping, when it

is laid-out as shown in Figure 7 (a) it has much higher flexibility

than when it is laid-out as in Figure 7 (b). Designers often have

the misconception about the amount of flexibility can be provided

by the zig-zag arrangement. Due to the extra elbows placed in the

layout, one tends to think that additional flexibility should have

been created. Unfortunately, the additional flexibility from the

elbows is not enough to compensate the loss of flexibility due to

the placement of pipe toward the geometrical center.

4'

G<"!ometrical

Genter

C'd'

. /

Center

6'' 5TJ, CS @ 5oo"P

'

(a) Stress = 13764 psi (b) Stress = 8226 psi

Figure 7

MICRO COMPUTER APPROACH

i'4'

Currentl7 most large engineering companies use CAD system to do the

piping design. It is possible that one day the system will be able

to tell you if you need an7 extra flexibility, as soon as you place

the line on the screen. However, before that time comes, we still

have to survive the current situation to be able to see the good

thing coming. Nevertheless, the technology of the micro computer

has advanced enough for us to perform accurate flexibility analyses

right beside the drafting board.

The micro computer programs are normally so user friendly that it

takes only a couple of hours to master their usage. With respect

to the flexibility check, a piping designer can do almost as good

a job as a stress engineer can. What it is needed is to enter the

pipe and geometrical information to the program which will almost

instantly give you the forces and stresses expected in the system.

From that information, the designer can then decide if additional

loops or offsets are required.

The use of the micro computer differs substantially depending on

the individual program setup. Each program has its preferred

method of entering the data and generating the output. Appendix A

shows the sample operating procedure using PENG.QFLEX program to

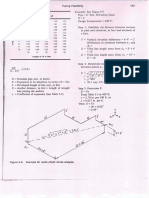

analyze the simple system given in Figure 8.

7

TEA51/3LGioOP

LOCATIONS

Figure 8

Once it is determined that an expansion loop is required, the loop

can be placed at one of the feasible locations before the area is

congested by other layouts. This also saves the iterative process

between the piping designers and the stress engineers.

CONCLUSION

The traditional piping design procedure depends heavily on the

stress engineer to check piping flexibility. With the availability

of quick methods in checking the flexibility, the designer can now

layout the pipe to provide the proper flexibility at the very

beginning. This substantially reduces the number of iterations

required between the piping designer and the stress engineer. The

cost of the plant can be reduced by the shorter schedule and less

manpower required.

Você também pode gostar

- Modeling Procedure of Rigid Strut in Caesar IIDocumento5 páginasModeling Procedure of Rigid Strut in Caesar IIHmd MokhtariAinda não há avaliações

- Piping Flexibility - A Detailed ApproachDocumento5 páginasPiping Flexibility - A Detailed ApproachRUDHRA DHANASEKARAinda não há avaliações

- Pipe Expansion and Support - DeterminationDocumento23 páginasPipe Expansion and Support - DeterminationGodwinAinda não há avaliações

- Pipe Stress Training Course - SSUTADocumento10 páginasPipe Stress Training Course - SSUTAalizadeh2222Ainda não há avaliações

- Expansion & Piping FlexibilityDocumento24 páginasExpansion & Piping FlexibilityChris De100% (1)

- Quick Check On Piping FlexibilityDocumento8 páginasQuick Check On Piping Flexibilitysateesh chandAinda não há avaliações

- 5.00 A Conundrum The Difficulties of Pipe Stress Analysis For Cold PipesDocumento17 páginas5.00 A Conundrum The Difficulties of Pipe Stress Analysis For Cold Pipesprabu2001Ainda não há avaliações

- C2 CAU Express B31.3Documento57 páginasC2 CAU Express B31.3Bhoopendra Singh100% (1)

- Procedure For Pump Line Stress AnalysisDocumento9 páginasProcedure For Pump Line Stress AnalysisNilesh Gohel100% (1)

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodDocumento6 páginasFlange Leakage Checking in Caesar II Using ASME Section VIII Methodwisesa100% (1)

- Piping Stress Analysis Is The Most Important Activity in Piping DesignDocumento10 páginasPiping Stress Analysis Is The Most Important Activity in Piping DesignShreesanth SreenivasanAinda não há avaliações

- FE Pipe DocumentacionDocumento160 páginasFE Pipe Documentacionricardobarort100% (2)

- Thermal Design Considerations For Centrifugal Compressor Piping SystemsDocumento5 páginasThermal Design Considerations For Centrifugal Compressor Piping SystemsSerge Rinaudo100% (1)

- 2905 - Edgar EXPANSION JOINTS WITH CAESAR IIDocumento45 páginas2905 - Edgar EXPANSION JOINTS WITH CAESAR IIDivyesh Patel100% (1)

- Pipe FlangesDocumento7 páginasPipe FlangesAli SafdarAinda não há avaliações

- Trunnion Checking or Dummy Checking During Stress Analysis of A Piping SystemDocumento2 páginasTrunnion Checking or Dummy Checking During Stress Analysis of A Piping SystemAmit SharmaAinda não há avaliações

- Pipe Line Flexibility Manual CalculationDocumento20 páginasPipe Line Flexibility Manual CalculationKagira Drawing Soltuion100% (3)

- Load Cases in Caesar IIDocumento4 páginasLoad Cases in Caesar IIsj22Ainda não há avaliações

- Example From Theory To Caesar IIDocumento12 páginasExample From Theory To Caesar IITon Phichit100% (7)

- Hot Sustained Load Case CaesarIIDocumento6 páginasHot Sustained Load Case CaesarIIshaffetiAinda não há avaliações

- Large Bore DetailsDocumento85 páginasLarge Bore DetailsAmreusit SaschimbnumeleAinda não há avaliações

- Stress Analysis of Column Piping System Using Caesar IIDocumento7 páginasStress Analysis of Column Piping System Using Caesar IIHmd Mokhtari100% (1)

- Sample Calculation ReportDocumento9 páginasSample Calculation ReportmikimecAinda não há avaliações

- 04 - Branch ConnectionsDocumento24 páginas04 - Branch Connectionsdario84100% (1)

- ShoeDocumento1 páginaShoePhornlert Wana100% (1)

- Pipeline Stress Analysis With Caesar IIDocumento16 páginasPipeline Stress Analysis With Caesar IIPugel YeremiasAinda não há avaliações

- Sustained Stress Indices (SSI) in The B31.3 2010 EditionDocumento9 páginasSustained Stress Indices (SSI) in The B31.3 2010 Editiont_rajith1179100% (2)

- Advance Pipe Stress AnalysisDocumento7 páginasAdvance Pipe Stress AnalysisBinodh Daniel0% (1)

- Piping Stress Handbook - by Victor Helguero - Part 2 PDFDocumento121 páginasPiping Stress Handbook - by Victor Helguero - Part 2 PDFCESAR100% (2)

- Nozzle Movement CalculationDocumento23 páginasNozzle Movement CalculationPriyanathan Thayalan100% (4)

- Air Cooler-Modeling and AnalysisDocumento25 páginasAir Cooler-Modeling and Analysisvivek100% (1)

- Selection and Application of FlangesDocumento11 páginasSelection and Application of FlangesbandithaguruAinda não há avaliações

- Anchor SupportsDocumento7 páginasAnchor Supportstejasp8388Ainda não há avaliações

- Cryogenic Piping Stress AnalysisDocumento6 páginasCryogenic Piping Stress AnalysismasilamaniAinda não há avaliações

- How To Create Pipe ClassDocumento6 páginasHow To Create Pipe ClassShyam Prasad K SAinda não há avaliações

- Hexagon PPM Caesar II Dynamics One Lesson Guide Toc2Documento8 páginasHexagon PPM Caesar II Dynamics One Lesson Guide Toc2Valesh Monis100% (1)

- PSV Reaction Forces and DirectionDocumento29 páginasPSV Reaction Forces and Directionpvmsson100% (1)

- Slug Flow Analysis Using Dynamic Spectrum Method in Caesar IIDocumento7 páginasSlug Flow Analysis Using Dynamic Spectrum Method in Caesar IIJ A S JASAinda não há avaliações

- Nozzle Movement CalculationDocumento23 páginasNozzle Movement Calculationdjole112Ainda não há avaliações

- 14.experimental and Stress Analysis of Pipe Routing at Various Temperature and Pressure by Changing The Various Material and SupportDocumento54 páginas14.experimental and Stress Analysis of Pipe Routing at Various Temperature and Pressure by Changing The Various Material and Supporteshu100% (2)

- Supporting of Piping SystemsDocumento3 páginasSupporting of Piping Systemsaap150% (2)

- Nozzle CheckDocumento11 páginasNozzle CheckincaurcoAinda não há avaliações

- KVERNAR - Stress NotesDocumento54 páginasKVERNAR - Stress NoteszahoorAinda não há avaliações

- Anchor Support - Thermal ExpansionDocumento99 páginasAnchor Support - Thermal ExpansionKCFUNG100% (1)

- Stress Critical Line ListDocumento1 páginaStress Critical Line ListJitendraSurveAinda não há avaliações

- Piping Stress - Ysis-EnDocumento98 páginasPiping Stress - Ysis-EnArash Aghagol100% (1)

- Piping IsometricDocumento19 páginasPiping IsometricdeepakAinda não há avaliações

- Piping Flexibility - Thermal Expansion in PipingDocumento6 páginasPiping Flexibility - Thermal Expansion in PipingMohamed Al-OdatAinda não há avaliações

- Piping Flexibility CheckingDocumento5 páginasPiping Flexibility Checkingeko123Ainda não há avaliações

- Expansion Loop DesignDocumento61 páginasExpansion Loop DesignTauqueerAhmadAinda não há avaliações

- WWW Spiraxsarco Com Resources Steam Engineering Tutorials ST 3Documento12 páginasWWW Spiraxsarco Com Resources Steam Engineering Tutorials ST 3Mashudi FikriAinda não há avaliações

- Parte 3.-Piping Design Carrier HandBookDocumento122 páginasParte 3.-Piping Design Carrier HandBookNestor Sanchez Villasmil100% (8)

- Piping DesignDocumento122 páginasPiping Designfacebookshop100% (9)

- Pipe Expansion and SupportDocumento11 páginasPipe Expansion and SupportLorenzoAinda não há avaliações

- Basics of Piping System Thermal Expansion For Process EngineersDocumento14 páginasBasics of Piping System Thermal Expansion For Process EngineersGoce VasilevskiAinda não há avaliações

- Basics of Piping System Thermal Expansion For Process EngDocumento12 páginasBasics of Piping System Thermal Expansion For Process EngAttalh Djaafar AttalhAinda não há avaliações

- TH10 - Pipe Loop or Expansion JointsDocumento3 páginasTH10 - Pipe Loop or Expansion JointsloukatsAinda não há avaliações

- Support LocationsDocumento12 páginasSupport LocationsdasubhaiAinda não há avaliações

- Screenshots of Pipe Stress Analysis in ActionDocumento17 páginasScreenshots of Pipe Stress Analysis in ActionCepi Sindang Kamulan100% (2)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversNo EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversNota: 5 de 5 estrelas5/5 (2)

- Maths Worksheet GameDocumento9 páginasMaths Worksheet GameSham FizAinda não há avaliações

- Maths Worksheet GameDocumento9 páginasMaths Worksheet GameSham FizAinda não há avaliações

- Pipe Support StandardDocumento319 páginasPipe Support StandardAntoshal92% (75)

- Column Piping Nozzle Orientation & Platforms RequirementsDocumento23 páginasColumn Piping Nozzle Orientation & Platforms RequirementsAntoshalAinda não há avaliações

- Maths Worksheet GameDocumento9 páginasMaths Worksheet GameSham FizAinda não há avaliações

- Pipe Fitters ManualDocumento39 páginasPipe Fitters ManualAntoshal100% (11)

- A - Piping Joint HandbookDocumento161 páginasA - Piping Joint HandbookCharles Tauk100% (30)

- Branch Reinforcement Pad Requirement CalculationDocumento2 páginasBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Pig TrapsDocumento16 páginasPig TrapsAntoshal100% (14)

- Pipeline Pigging (Visit http://Piping-Info - Blogspot.com)Documento33 páginasPipeline Pigging (Visit http://Piping-Info - Blogspot.com)Antoshal100% (7)

- Process Piping Design Vol. 2, Rip WeaverDocumento175 páginasProcess Piping Design Vol. 2, Rip WeaverAntoshal100% (24)

- Basics of PipingDocumento29 páginasBasics of PipingAntoshal100% (1)

- Pdms Tips and TricksDocumento1 páginaPdms Tips and TricksAntoshalAinda não há avaliações

- Positioning Radial NozzlesDocumento1 páginaPositioning Radial NozzlesAntoshalAinda não há avaliações

- Piping GA SymbolsDocumento5 páginasPiping GA SymbolsAntoshal50% (2)

- Checking Piping Drawings ProcedureDocumento9 páginasChecking Piping Drawings ProcedureAntoshal83% (6)

- GPD Paper Comparative Study of Laminated Glass Fins - Stutzki Engineering KurarayDocumento6 páginasGPD Paper Comparative Study of Laminated Glass Fins - Stutzki Engineering KurarayGiri DharanAinda não há avaliações

- GAS GAS Vib Rep PDFDocumento15 páginasGAS GAS Vib Rep PDFljv004Ainda não há avaliações

- 30HX 14PDDocumento56 páginas30HX 14PDDaniel TaveiraAinda não há avaliações

- Reservoir Characteristics: The Primary Reservoir Characteristics That Must Be Considered IncludeDocumento52 páginasReservoir Characteristics: The Primary Reservoir Characteristics That Must Be Considered Includehussein alsaedeAinda não há avaliações

- A Case Study On The Application of Passive Control and Seismic Isolation Techniques To Cable-Stayed Bridges - A Comparative Investigation Through Non-Linear Dynamic AnalysesDocumento21 páginasA Case Study On The Application of Passive Control and Seismic Isolation Techniques To Cable-Stayed Bridges - A Comparative Investigation Through Non-Linear Dynamic AnalysesJuan Patricio ReyesAinda não há avaliações

- Essay 2 RRCDocumento31 páginasEssay 2 RRCHamez HabibiAinda não há avaliações

- Organic Rankine Cycle (ORC)Documento4 páginasOrganic Rankine Cycle (ORC)Aalbert MozoAinda não há avaliações

- AMR000155Documento45 páginasAMR000155denzelxiaoAinda não há avaliações

- DUPLEX 1400 - 15100 Basic-N EN - 2018 - 03Documento8 páginasDUPLEX 1400 - 15100 Basic-N EN - 2018 - 03Constantin CilibiuAinda não há avaliações

- Part I.A - Fundamentals of Fluid DynamicsDocumento38 páginasPart I.A - Fundamentals of Fluid Dynamicswiggly18Ainda não há avaliações

- 1 Hvac-Refrigeration CycleDocumento5 páginas1 Hvac-Refrigeration CycleAkshaye VaidAinda não há avaliações

- 2016 Practical Guide PDFDocumento9 páginas2016 Practical Guide PDFPromiseDoringtenNkosiAinda não há avaliações

- EQUIPMENT DESIGN by DR NORIN ZAMIAH PDFDocumento104 páginasEQUIPMENT DESIGN by DR NORIN ZAMIAH PDFAimanAinda não há avaliações

- Chapter 2 - Reservoir Performance Analysis (Updated)Documento51 páginasChapter 2 - Reservoir Performance Analysis (Updated)Tu Dang TrongAinda não há avaliações

- 2105ENG FE ProjectDocumento18 páginas2105ENG FE ProjectDylan Perera0% (1)

- Borgnakke's Fundamentals of Thermodynamics: Global EditionDocumento94 páginasBorgnakke's Fundamentals of Thermodynamics: Global Edition정윤서Ainda não há avaliações

- Autodeskrobotstructuralanalysisprofessional2013 190105071907 PDFDocumento9 páginasAutodeskrobotstructuralanalysisprofessional2013 190105071907 PDFmaheshbandhamAinda não há avaliações

- Solution Tuto 6Documento13 páginasSolution Tuto 6Abood AtiyatAinda não há avaliações

- Thermal Analysis of Thrust Chambers: RPA: Tool For Rocket Propulsion AnalysisDocumento26 páginasThermal Analysis of Thrust Chambers: RPA: Tool For Rocket Propulsion AnalysisBill M. SpragueAinda não há avaliações

- IMVF Engineering Data Manual 20150213Documento245 páginasIMVF Engineering Data Manual 20150213Beatriz A. Marulanda100% (2)

- Impeller DesignDocumento6 páginasImpeller Design19MECH052 SYED YOUNUS100% (1)

- BCS TheoryDocumento56 páginasBCS TheoryhitupyAinda não há avaliações

- Anaerobic Digester - QasimDocumento35 páginasAnaerobic Digester - Qasimawaluddin nurmiyantoAinda não há avaliações

- 112106196Documento1 página112106196Abison RajuAinda não há avaliações

- Staad Output: St-2ADocumento12 páginasStaad Output: St-2ASaipem Rel2Ainda não há avaliações

- Sag Tension Calculation-765 KVDocumento13 páginasSag Tension Calculation-765 KVHugh cabAinda não há avaliações

- Flixborough: The Disaster and Its Aftermath: J. E. S. VenartDocumento31 páginasFlixborough: The Disaster and Its Aftermath: J. E. S. VenartabuahnfAinda não há avaliações

- Fluid Mechanics 7th Edition CH 3 SolutionsDocumento129 páginasFluid Mechanics 7th Edition CH 3 Solutionsimmery1892% (13)

- Moduli and Damping Factors For Dynamic Analyses of Cohesionless Soils - Seed, Wong, Idriss and TokimatsuDocumento40 páginasModuli and Damping Factors For Dynamic Analyses of Cohesionless Soils - Seed, Wong, Idriss and TokimatsuAA_BB_HHAinda não há avaliações

- Phase and Phase EquilibriumDocumento40 páginasPhase and Phase EquilibriumNyanda MadiliAinda não há avaliações