Escolar Documentos

Profissional Documentos

Cultura Documentos

Introduction To Production

Enviado por

Farrukh Ali UqailiDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Introduction To Production

Enviado por

Farrukh Ali UqailiDireitos autorais:

Formatos disponíveis

Introduction to Production & Operations Management Management is the study and development of techniques like organizing, planning,staffing, controlling,

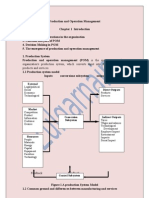

and directing an organization's resources to achieve the policy's objectives. What is POM? Production is the creation of goods and services Production and/or Operations Management are the activities that transform resources into goods and services Why Study POM? It is one of the 3 critical parts of any organization: Marketing generates demand Operations creates the product Finance/accounting tracks organizational performance, pays bills, collects money It shows us how goods and services are produced It shows us what POM managers do It is the most costly part of any organization The Critical Decisions Service and product design What product or service should we offer? How should we design these products and services? Quality management Who is responsible for quality? How do we define quality? Process and capacity design What processes will these products require and in what order? What equipment and technology is necessary for these processes? Location Where should we put the facility On what criteria should we base this location decision? Layout design How should we arrange the facility? How large a facility is required? Human resources and job design How do we provide a reasonable work environment? How much can we expect our employees to produce? Supply chain management

Should we make or buy this item? Who are our good suppliers and how many should we have? Inventory, material requirements planning, How much inventory of each item should we have? When do we re-order? Intermediate, short term, and project scheduling Is subcontracting production a good idea? Are we better off keeping people on the payroll during slowdowns? Maintenance Who is responsible for maintenance? When do we do maintenance? New Challenges in OM From Local or national focus Batch shipments Lengthy product development cycles To Global focus Just-in-time Supply chain Management Rapid product development Goods vs. Services Characteristics of Goods Tangible product Consistent product definition Production usually separate from consumption Can be inventoried Low customer interaction Characteristics of Services Intangible product Produced & consumed at same time Often unique High customer interaction Inconsistent product definition Goods vs. Services Can be resold Reselling unusual Can be inventoried Difficult to inventory

Some aspects of quality measurable Selling is distinct from production Product is transportable Site of facility important for cost Often easy to automate

Quality difficult to measure Selling is part of service Provider, not product is transportable Site of facility important for customer contact Often difficult to automate

Types of production There are 3 basic types of production 1. Job order production 2. Batch production 3. Continuous production Points to Remember Volume of production Variety of product Variety of raw material Nature of work Worker skill level Equipment level Facility utilization factor Volume discount The Productivity Challenge Productivity Measure of process improvement Represents output relative to input stands for elimination of waste of all kinds material, machine,manpower, working apace, building utilization Tools of productivity External factors Internal Factors External factors Natural resources and their mobility Taxation Laws & restrictions imposed by Govt. Availability of water, power & other inputs Technical & training facilities Internal factors Product Design

Input Material Plant Layout Material handling techniques Work study Reason for Low Productivity Product Design Lack of Standardization Improper Equipment Poor Plant layout Frequent change of product design Lack of motivation among workers Factors that help increase Productivity Wastage of material Poor working conditions Poor management Material handling Waiting related to man power/ machine Kinds of Productivity Material Productivity Labor Productivity Capital Productivity Machine Productivity Energy Productivity Technical Method to improve Productivity Task based Techniques Product based Techniques Technology based Techniques Material based Techniques Employee based techniques

Você também pode gostar

- Sap Functionality For Accounting of Prepaid ExpensesDocumento3 páginasSap Functionality For Accounting of Prepaid ExpensesVanshika Narang100% (1)

- Business Meeting ScriptDocumento4 páginasBusiness Meeting Scriptroshelle100% (3)

- Operation ManagementDocumento79 páginasOperation ManagementSumama IkhlasAinda não há avaliações

- Lean PresentationDocumento82 páginasLean PresentationEkasuthan RastaAinda não há avaliações

- Business Plan FinalDocumento16 páginasBusiness Plan FinalItsRenz YTAinda não há avaliações

- Honda Market Mix Final ProjectDocumento75 páginasHonda Market Mix Final ProjectdemulluAinda não há avaliações

- SWOT Mat With ExplanationDocumento3 páginasSWOT Mat With ExplanationHanna SilloAinda não há avaliações

- 03 Bain HealthDocumento6 páginas03 Bain HealthT LiuAinda não há avaliações

- Advanced Accounting NotesDocumento19 páginasAdvanced Accounting NotesTajammul M'd TakiAinda não há avaliações

- Production and Operations ManagementDocumento123 páginasProduction and Operations ManagementJayanth SamavedamAinda não há avaliações

- Opm-Bba-Wk 1-2013Documento29 páginasOpm-Bba-Wk 1-2013afzaalkhnAinda não há avaliações

- CBME1 Practice QuestionsDocumento21 páginasCBME1 Practice QuestionsPhielle MarilenAinda não há avaliações

- Lean MFG PresentationDocumento42 páginasLean MFG PresentationDara RaviAinda não há avaliações

- Production and Operations Management - Introduction (BSBA)Documento48 páginasProduction and Operations Management - Introduction (BSBA)hanna sanchezAinda não há avaliações

- Operations ManagementDocumento54 páginasOperations ManagementShrushti MehtaAinda não há avaliações

- Production/ Operations Management: Estrella Y. Yu, DBMDocumento76 páginasProduction/ Operations Management: Estrella Y. Yu, DBMTristan ZambaleAinda não há avaliações

- DS412:IntroDocumento15 páginasDS412:IntroDavid HuAinda não há avaliações

- Introduction To Operations ManagementDocumento12 páginasIntroduction To Operations ManagementKristine Mae SampuangAinda não há avaliações

- Introduction To Operations Management-Ch 1 (Stevenson)Documento25 páginasIntroduction To Operations Management-Ch 1 (Stevenson)tahmid quayum100% (1)

- Wa0022Documento46 páginasWa0022AswinAinda não há avaliações

- Operation Management: Reviewer in CBMEDocumento9 páginasOperation Management: Reviewer in CBMEmaria cruzAinda não há avaliações

- Management Accounting ReviewerDocumento17 páginasManagement Accounting ReviewerIvan LuzuriagaAinda não há avaliações

- Operational Excellence Through Operational Excellence ThroughDocumento38 páginasOperational Excellence Through Operational Excellence Throughashhad89Ainda não há avaliações

- Lean Manufacturing Presentation 1Documento20 páginasLean Manufacturing Presentation 1AlangAki HanafiahAinda não há avaliações

- Operations MGMT - AIMADocumento549 páginasOperations MGMT - AIMATata SatishkumarAinda não há avaliações

- 3 Competitiveness, Strategy and Productivity-Ch 2 (Stevenson)Documento30 páginas3 Competitiveness, Strategy and Productivity-Ch 2 (Stevenson)sadasdasdasAinda não há avaliações

- Glossary of Lean Manufacturing TermscDocumento13 páginasGlossary of Lean Manufacturing TermscRatjaga TaraAinda não há avaliações

- Term Paper On Production Operation ManagementDocumento4 páginasTerm Paper On Production Operation ManagementaflsmceocAinda não há avaliações

- Pom CH1Documento64 páginasPom CH1Syed Zain AhmadAinda não há avaliações

- Supply Chain and Inventory Management Seminar Paper Presented ToDocumento17 páginasSupply Chain and Inventory Management Seminar Paper Presented Toankitjain1104Ainda não há avaliações

- 16 Lean ManufacturingDocumento75 páginas16 Lean ManufacturingSyed Lissan HaiderAinda não há avaliações

- Operation ManagementDocumento4 páginasOperation Managementxowof70509Ainda não há avaliações

- câu hỏi vật liệu họcDocumento33 páginascâu hỏi vật liệu họcTỊNH LÊ THANHAinda não há avaliações

- Project DataDocumento3 páginasProject DataChampions Martial Art and Sports Academy PuneAinda não há avaliações

- Q2oscm Y1 BoyanaDocumento55 páginasQ2oscm Y1 Boyanasebastian.vduurenAinda não há avaliações

- OperationsManagement Part1Documento121 páginasOperationsManagement Part1nethaji_pAinda não há avaliações

- 2..operation Strategy in Global EnvironmentDocumento32 páginas2..operation Strategy in Global EnvironmentGwen WilliamsAinda não há avaliações

- An Introduction To Lean ManufacturingDocumento45 páginasAn Introduction To Lean ManufacturingSid508Ainda não há avaliações

- 7 Lean Manufacturing 1 1 Five S and Visual ControlDocumento44 páginas7 Lean Manufacturing 1 1 Five S and Visual Controlmax hopus100% (1)

- Total Quality Management Short NoteDocumento4 páginasTotal Quality Management Short NoteHazim IzzatAinda não há avaliações

- Benchmarking Is An Essential Part of TQM For Continuous ImprovementDocumento46 páginasBenchmarking Is An Essential Part of TQM For Continuous Improvementwaqasrashid75Ainda não há avaliações

- Chapter 6Documento21 páginasChapter 6fifisaffiya05Ainda não há avaliações

- OM - CH 1-2 - Spring - 2011Documento63 páginasOM - CH 1-2 - Spring - 2011iyadomar2005Ainda não há avaliações

- Assignment Report ON: " " (451) Unit - IiiDocumento13 páginasAssignment Report ON: " " (451) Unit - IiiRobin GanjooAinda não há avaliações

- Chap 3aDocumento13 páginasChap 3aRehana NaqshbandiAinda não há avaliações

- Finals ReviewerDocumento7 páginasFinals ReviewerDesarollo OrganizacionalAinda não há avaliações

- Chapter 1 - Introduction To Operations ManagementDocumento24 páginasChapter 1 - Introduction To Operations ManagementMonevaAinda não há avaliações

- Lecture 01-20141129Documento36 páginasLecture 01-20141129maria saleemAinda não há avaliações

- 634169410298974830Documento56 páginas634169410298974830Anil BhardwajAinda não há avaliações

- The Basics of Operations ManagementDocumento32 páginasThe Basics of Operations Managementravi_nyseAinda não há avaliações

- Chapter 2 - CompetitivenessDocumento7 páginasChapter 2 - CompetitivenessMurray BorgoniaAinda não há avaliações

- Lean ManufacturingDocumento54 páginasLean ManufacturingPayal Sarupria0% (1)

- LESSON 1 4Ms of OperationsDocumento39 páginasLESSON 1 4Ms of OperationsABM-AKRISTINE DELA CRUZAinda não há avaliações

- Nestle RevisedDocumento56 páginasNestle RevisedAparna Khanna100% (3)

- Pom NotesDocumento16 páginasPom NotesYash MakhijaAinda não há avaliações

- Chapter 1 Production and Operation ManagementDocumento6 páginasChapter 1 Production and Operation Managementzulqarnainhaider450_Ainda não há avaliações

- Operations ManagementDocumento91 páginasOperations ManagementAnup MamenAinda não há avaliações

- Operations and Supply Chain ManagementDocumento61 páginasOperations and Supply Chain ManagementSandeep SonawaneAinda não há avaliações

- Japanese Quality Standards: Ashutosh Dubey Manish BhandhariDocumento48 páginasJapanese Quality Standards: Ashutosh Dubey Manish Bhandharianand5482100% (3)

- Just in TimeDocumento29 páginasJust in Timejobij3Ainda não há avaliações

- Haider Ali Mid TermDocumento6 páginasHaider Ali Mid TermArbaz KhanAinda não há avaliações

- Operations Management: Operations and Productivity Dr. Vaidy Jayaraman Univ of Miami, FL, USADocumento55 páginasOperations Management: Operations and Productivity Dr. Vaidy Jayaraman Univ of Miami, FL, USARahul SachdevaAinda não há avaliações

- Production: - Deepa Patil - Sangita Bhardwaj - Saroj Adhikari - Venkatesh - Jigyasu Yadav - Shailendra S.ThakurDocumento20 páginasProduction: - Deepa Patil - Sangita Bhardwaj - Saroj Adhikari - Venkatesh - Jigyasu Yadav - Shailendra S.Thakursstmech2Ainda não há avaliações

- Operation MGMTDocumento45 páginasOperation MGMTZahid TaqviAinda não há avaliações

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1Ainda não há avaliações

- Assignment On: Developing A Career PlanDocumento2 páginasAssignment On: Developing A Career PlanNazmul HasanAinda não há avaliações

- Online Vs OfflineDocumento3 páginasOnline Vs OfflineAnm AdnanAinda não há avaliações

- Balance Cash HoldingsDocumento34 páginasBalance Cash HoldingsSurafelAinda não há avaliações

- 12 Entrepreneurship Lyp 2013 DelhiDocumento3 páginas12 Entrepreneurship Lyp 2013 DelhiAshish GangwalAinda não há avaliações

- Development of Business PlanDocumento20 páginasDevelopment of Business PlanSuzannePadernaAinda não há avaliações

- Analisis Efisiensi Perbankan. (Dicha Nur Wendha) 85Documento13 páginasAnalisis Efisiensi Perbankan. (Dicha Nur Wendha) 85Ika SwastiAinda não há avaliações

- Wal Mart SwotDocumento19 páginasWal Mart SwotjityendraAinda não há avaliações

- LG CompanyDocumento54 páginasLG CompanyshivavermaAinda não há avaliações

- Micro EconomicDocumento9 páginasMicro EconomicNhật HạAinda não há avaliações

- Ultimate Guide To Cost SavingsDocumento18 páginasUltimate Guide To Cost SavingsSuzana RicAinda não há avaliações

- HW 2 - Ch03 P15 Build A Model - HrncarDocumento2 páginasHW 2 - Ch03 P15 Build A Model - HrncarsusikralovaAinda não há avaliações

- Marketing Plan Dunhill CigaretteDocumento8 páginasMarketing Plan Dunhill CigaretteAreeb JafriAinda não há avaliações

- Ch. 14 Measure of SuccessDocumento22 páginasCh. 14 Measure of SuccessyeyeAinda não há avaliações

- Growth StrategyDocumento2 páginasGrowth StrategyShabana KhanAinda não há avaliações

- 1 Digital EntreprenuershipDocumento32 páginas1 Digital EntreprenuershipJit MukherheeAinda não há avaliações

- FCB MatrixDocumento4 páginasFCB Matrixaaryaman mohattaAinda não há avaliações

- Accounting Policies Changes in Accounting Estimates and Errors IAS 8Documento16 páginasAccounting Policies Changes in Accounting Estimates and Errors IAS 8Akash RanaAinda não há avaliações

- Pe Final Mocktest - Fow9Documento12 páginasPe Final Mocktest - Fow9wwwpa2005Ainda não há avaliações

- Exercise Production N Material Budget Gaeber Industries QDocumento2 páginasExercise Production N Material Budget Gaeber Industries Qwww.harinihariniAinda não há avaliações

- B. Com (CA) SyllabusDocumento70 páginasB. Com (CA) SyllabusBhaskar ReddyAinda não há avaliações

- Reaction Paper To Chater 13Documento2 páginasReaction Paper To Chater 13Steven Sanderson100% (5)

- Sox PDFDocumento8 páginasSox PDFRoland ValAinda não há avaliações

- KPIs in Digital MarketingDocumento2 páginasKPIs in Digital MarketingJ Eduardo LeivaAinda não há avaliações