Escolar Documentos

Profissional Documentos

Cultura Documentos

Neeraj Latest CV

Enviado por

neerajpuranikDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Neeraj Latest CV

Enviado por

neerajpuranikDireitos autorais:

Formatos disponíveis

NEERAJ SHASHIKANT PURANIK

Mobile: + 91-9805964450 (India) ~ Residence: + 91-9407409284 (India) E-Mail: neerajpuranik@yahoo.co.in

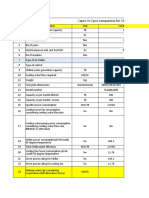

Seeking senior level assignments in Edible Oil Refinery, Fatty Acid Distillation Plants & Soap Plant of Project Management, Instrumentation, Operations & Maintenance with an organization of repute. Proffesional Synopsis A result driven professional with around 12 years of rich experience in the key areas of Project Operations, Maintenance Matrices Operations, Instrumentation & various types control instruments. Insightful experience in project management activities including Project project scoping, estimation, planning, risk management, finalization of technical / functional specifications, resource administration and Management quality management of the product / software application. Sound knowledge of Edible Oil Refinery, Soap Plant, Cement Plant Safety Controls, Figured Glass Plant & Controls. Demonstrated proficiency in interacting with the production department for understanding their requirements and needs for Scheduling carrying out engineering and software development/ modifications. Familiar with the International codes & standards; deft in reviewing the ISO quality assurance & inspection procedure, site installation procedure, power up and commissioning. Documentation Skilled in coordinating with purchase department for ordering all bought outs at optimum price and ensuring their timely delivery. Maintenance Proficient in understanding and coordinating production departments needs / enhancements, customization of product accordingly and Management consulting with technical team/ OEMs for providing solutions in adherence to delivery schedules. Strong problem solving skills, confident decision making based on PLC extensive experience and technical skill enables effective solutions that Programming positively impact customer satisfaction and operational costs.

Profficiency

Carrer Recital May2011 Till date VVF Limited, India Manager - Instrumentation Notable Highlights Project & Maintenance related work in a Fatty Acid Distillation Plant, Splitting Column & Glycerine Concentration Plant.

Project & Maintenance related work in a Noodle Plant, Soap packing & finishing lines.

Control Valve Sizing, Selection of PLC, Selection of AC drives, Selection of transmitters, Cable Schedule & other project related jobs. Leading a team of Instrument Engineers & technicians. Looking after Preventive maintenance, Calibration, Instrument spare parts management & shift schedules. Working on Foxboro DCS, Allen Bradley PLCs, Siemens PLCs, AC drives of various makes, Servo Drives of various makes. Fault finding in HP & MP boiler automation, Chillers & utilities automation. QMS system related Documentation work. November2009 May2011 with Gujarat Borosil Limited, India Senior Manager - Instrumentation Notable Highlights

Commissioning & Maintenance of Figured Glass Plant with Batch house.

Commissioning & Maintenance of Glass Tempering line with Glass grinding & washing machines. Leading a team of Instrument Engineers & technicians.

Looking after Preventive maintenance, Calibration, Instrument spare parts management & shift schedules.

Working on Siemens PCS7 DCS, S7 PLC & Wincc SCADA. ISO 9001:2008 Documentation work. November2008 September2009 with United Millers Limited, Kenya Refinery Engineer

Notable Highlights Handled the overall maintenance & production related functions in a Desmet Make Fully automated Physical Refinery for Palm Oil with fractionation having utilities like Chiller ( TRANE/ ANGELANTONIE), Atlas Copco Compressors, Cooling Tower, Wood & Saw dust fired Boilers & FO Fired High Pressure Boiler.

Handled the overall maintenance & production related functions in a Mazzoni & Precision India make Soap Plant having 10 Ton capacity crutchers, Vacuum Dryer, Plodder, Automatic Cutters, Stamper with chiller & Samarpan Flow Wrap Machine.

Handled the overall maintenance & production related functions in a Fully Automatic Gerstenberg Schroder make Shortening Plant having Ammonia compressor.

Handled the overall maintenance & production related functions in a semi automatic volumetric Oil Filling & load cell based Fat Filling line. Made production/ shift schedules for Refinery, Soap & Shortening Plant, ensuring strict quality control. Looked after Engineering spare parts management & Procurement and In charge of Safety, Occupational Health & Fire fighting. Leading a team of Electrical/ Mechanical & Production technocrats. Working on Siemens S5 PLC & Wizcon SCADA. September2006 September2008 with Marsavco S.A.R.L, Democratic Republic of Congo Manager Instrumentation Notable Highlights Handled the maintenance related functions in a 100 TPD Lurgi Make Semi Automatic Physical Refinery for Palm Oil with fractionation having utilities like Chiller ( RTAD TRANE), Atlas Copco Compressors, Cooling Tower, Electric Boiler (16TPH) & FO Fired High Pressure Boiler.

Commisioned successfully state of art fully automatic 300 TPD DESMET Palm Oil Refinery with fractionation consisting RTAD & RTHD Trane Chiller, High Pressure Boiler, Cooling Tower, Atlas Copco Compressor with air dryers.

Handled the maintenance related functions in a 200 TPD Soap Plant having crutchers, Vacuum Dryers, Plodders, IMSA/ TVE Cutters from Mazzoni ITALY

Commisioned successfully state of art fully automatic 72 TPD Mazzoni fully automatic Toilet Soap Line having individual PLC controlled stations for Crutchers, Vacuum Spray Dryers, Colour & Fregnance Mixing with weight control, Primary & seconry Plodder, TVE Cutters, Stamper with Chiller & integrated high speed ACMA soap wrapping machine.

Troubleshooting of Instrumentation related problems in: Waukesha Cherry Burrell make margarine plant & Benhil/ Boash filling machines for Unilever Product Blue Band Margarine. Nichrom India make Washing Powder packing Machine for Unilever product OMO.

Commissioning & maintenance of detergent Packing plant having PLC based powder packing machines from Nichrom, India & Betapack, South Africa.

Commisioned successfully HDPE & PET Bottelling Plant supplied by Mega Machineries China. Led a team of Instrument / Electrical / Mechanical / Refrigeration engineers & Technicians.

Worked on Siemens S7 PLC/ Allen Bradley PLC/ Mitsubishi PLC/ Honeywell HC900 & Wizcon SCADA/ Automation Direct MMI/ E200 MMI & F-GOT 900 series MMI. February2006 August2006 with DCM Engineering Products Limited, India Assistant Manager Instrumentation -Project & Maintenance (Foundry) Notable Highlights

Implemented the automation project for conversion of relay logic based foundry line to Siemens S7-314 2DP PLC.

Selected PLC / instruments for Automation of Core making machineries & commissioning.

Looked after preventive maintenance, trouble shooting & fault finding in process equipment at a 4500 TPD Grey Iron Foundry supplied by KNKEL WAGNER Germany. July2004 February2006 with Ambuja Cement Eastern Limited, India Senior Engineer Instrumentation Notable Highlights Looked after preventive maintenance, trouble shooting & fault finding in process equipment at a 4400 TPD Polysius Cement Plant.

Worked on Allen Bradley PLC & FLS MMI ( ECS OPSTATION ) system , with AC/DC drives of ABB, AMTECH, YASKAWA as well as ABB/H&B make online analyzers & laboratory instruments. Calibration & fault finding in Transmitters Rosemount/ABB/H&B. Feb01 June04 with Birla Cement Works, India Assistant Engineer Instrumentation Notable Highlights Looked after preventive maintenance, trouble shooting & fault finding in process equipment at a 2000 TPD FLS Cement Plant having ISO 9001 : 2000 & ISO 14 001.

Worked on YASKAWA U84 PLC & Taylor MMI system. of 30 channel

Helped in Commissioning & Maintenance of 300 lines EPABX system and CATV system. June99 Jan01 with Sales Of Penumatic Products, India Sales Engineer Education

Bachelor in Instrumentation Engineering from Rajiv Gandhi Institute Of Technology, Mumbai University in the year 1999. Addiditional Qualification Diploma in Instrumentation from Government Polytechnic College, Kota, Board Of Technical Education in the year 1996. Project Summary Successfully commissioned the following projects:

300 TPD Palm Oil Refinery supplied by DESMET, Belgium. PET & HDPE Plant machineries supplied by China. 72 TPD Toilet soap line & Soap Wrapping machine, supplied by Mazzoni & ACMA, Italy. Detergent Powder Packing machine supplied by Nichrom, India. SIEMENS S7-314-2DP PLC for automation of relay logic based Moulding line for DCM

Engineering.

Core making machines based on Allen Bradley / Siemens PLCs for DCM Engineering. 120 TPD Vertical Roller Mill for Birla Cement Plant.

Personal Details Date of Birth: Permanent Address: India Present Address: 12th August, 1975 120, ROSHNI, Shivshakti Nagar, Off Kanadia Road, Indore (MP)- 452016, Same

Languages Known: Passport:

English , French, Hindi, Marathi F4778113 (Exp. Date 01.11.2015)

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Dunham Bush Air Cooled Screw Chiller AFVX B 6SR SeriesDocumento33 páginasDunham Bush Air Cooled Screw Chiller AFVX B 6SR SeriesazAinda não há avaliações

- Capex Vs Opex Compariosn For Chiller YorkDocumento9 páginasCapex Vs Opex Compariosn For Chiller Yorker_bhavinAinda não há avaliações

- TC Manual Air Cooled ChillersDocumento26 páginasTC Manual Air Cooled Chillersvickers100% (1)

- Refrigration Saving HeatDocumento39 páginasRefrigration Saving HeatTanviAinda não há avaliações

- Monthly Progress ReportDocumento14 páginasMonthly Progress Reportfatin haziqAinda não há avaliações

- Chiller GLAC 0751 8404BA2 - DF - 2007 06 - 150dpiDocumento92 páginasChiller GLAC 0751 8404BA2 - DF - 2007 06 - 150dpifaffs100% (1)

- Recovery of Asphalt From Solution Using Toluene and The Rotary EvaporatorDocumento4 páginasRecovery of Asphalt From Solution Using Toluene and The Rotary EvaporatorasmaAinda não há avaliações

- Start-Up Checklist For 30Xv Liquid Chillers (Remove and Use For Job File)Documento8 páginasStart-Up Checklist For 30Xv Liquid Chillers (Remove and Use For Job File)MauricioAinda não há avaliações

- Energyplus Hvac Global TestsDocumento58 páginasEnergyplus Hvac Global TestsDavid O. AlmeidaAinda não há avaliações

- Coldroom User ManualDocumento6 páginasColdroom User Manualirmansyah1978Ainda não há avaliações

- Selection of Water Cooled Screw ChillerDocumento1 páginaSelection of Water Cooled Screw Chillercalvin.bloodaxe4478Ainda não há avaliações

- Integration of CCGT Plant and LNG TerminalDocumento28 páginasIntegration of CCGT Plant and LNG Terminalcicko45100% (1)

- IBMS Control SchematicDocumento57 páginasIBMS Control SchematicaungwinnaingAinda não há avaliações

- CCTV - CVHG780-CN123 - Product ReportDocumento2 páginasCCTV - CVHG780-CN123 - Product ReportTân NguyễnAinda não há avaliações

- Boq (Addendum#2) March 10, 2016Documento36 páginasBoq (Addendum#2) March 10, 2016Sheriyar ChAinda não há avaliações

- High-Efficiency Turbo Chiller (NART Series) : Wataru Seki Kenji Ueda Jyou Masutani Yoichirou IritaniDocumento6 páginasHigh-Efficiency Turbo Chiller (NART Series) : Wataru Seki Kenji Ueda Jyou Masutani Yoichirou Iritanihessam_seifiAinda não há avaliações

- Mems Report in Iit KanpurDocumento24 páginasMems Report in Iit KanpurbillalaxmanAinda não há avaliações

- SYS-APM001-En Chiller System Design and ControlDocumento2 páginasSYS-APM001-En Chiller System Design and ControlAtiqAinda não há avaliações

- Pump Tanks PDFDocumento37 páginasPump Tanks PDFOrlando MediavillaAinda não há avaliações

- Experimental Determination of The ZIP Coefficients For Modern Residential, Commercial, and Industrial LoadsDocumento10 páginasExperimental Determination of The ZIP Coefficients For Modern Residential, Commercial, and Industrial LoadsAhmed WestministerAinda não há avaliações

- Noise in High Rise Buildings: Ross H. Palmer Cpeng Rpeq Principal Palmer Acoustics (Australia) Pty LTDDocumento9 páginasNoise in High Rise Buildings: Ross H. Palmer Cpeng Rpeq Principal Palmer Acoustics (Australia) Pty LTDzaheeruddin_mohdAinda não há avaliações

- K17014en Rhoss Applied Systems 2012 2013Documento159 páginasK17014en Rhoss Applied Systems 2012 2013nibasicAinda não há avaliações

- Method of Testing Absorbtion Water Chilling & Heating Packages - ASHRAEDocumento12 páginasMethod of Testing Absorbtion Water Chilling & Heating Packages - ASHRAEDeepak JoyAinda não há avaliações

- FAR Master File-MD v1Documento1.015 páginasFAR Master File-MD v1AhmerAinda não há avaliações

- Expression of Interest: Prepared byDocumento9 páginasExpression of Interest: Prepared byAnonymous dFIemPqrAinda não há avaliações

- Catalog TetrisDocumento156 páginasCatalog TetrisAlberto BastosAinda não há avaliações

- Chillers Screw ScrollDocumento8 páginasChillers Screw ScrollAhmed Mohamed AliAinda não há avaliações

- Bhit Field OptimizationDocumento19 páginasBhit Field OptimizationBurhan AyubAinda não há avaliações

- Experiments To Accompany A First Engineering Thermodynamics CourseDocumento10 páginasExperiments To Accompany A First Engineering Thermodynamics CourseDavid Camilo Guerrero GonzalezAinda não há avaliações

- 30xw-7pd CARRIER Water Cooled Chillers PDFDocumento60 páginas30xw-7pd CARRIER Water Cooled Chillers PDFViral PatelAinda não há avaliações