Escolar Documentos

Profissional Documentos

Cultura Documentos

Improving Procurement Performance

Enviado por

Joju JohnyDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Improving Procurement Performance

Enviado por

Joju JohnyDireitos autorais:

Formatos disponíveis

21.

BRIDGING THE PROCUREMENT-PERFORMANCE GAP

Improving the Bottom Line

Manufacturing companies spend, on an average, 60 percent of total sales income on procurement of materials, supplies of components, and outside services. Savings made in procurement expenditure flow directly to profit. Profits are the lifeblood of the business operations and necessary for survival. Thus there is a need for appraisal of procurement performance with the purpose of improving the efficiency, effectiveness and profitability of the company. A large number of buyers, spending the whole day in solving yesterday's or today's problems, do not find time to understand and take proactive actions to solve future problems which are equally important for the survival of their company. Success in business today is based on the assumption that no matter how we are today, we can and must be better tomorrow. That is because the competition is constantly expecting more and more. We must forget our glorious past and should address the future. Many procurement strategies have often been criticized as short- sighted and focused on the near term. One manifestation of this syndrome is the excessive attention to 'fire-fighting'. Planning for performance improvement in procurement function, regardless of complexity or size of the company is a courageous step which sometimes involves not only a major attitude change but also active participatory involvement of the top management and commitment procurement and cross-functional staff. 'To be a world-class manufacturer, a company needs to challenge everything it has done in the past. It has to change dramatically from the way it selects and develops suppliers to the way it meets the next customer requirements and manages supply chains. This demands a change in mind-set, which searches for opportunities defining what a procurement function can contribute to the company's competitive advantage, survival, and growth. It needs actions to improve performance focused on the vision of the company and everyone in the procurement department

working on a clear, complete, and measurable set of goals. Unfocused activities may not result in positive performance. The traditional drive on the single-point formula of cost reduction through supplier price reduction alone can make companies vulnerable when they fail to add value to the supply chain. Cost reduction and simultaneous value addition is the route to competitive advantage. The efficiency of the procurement function at procuring products and services may include elements such as: Speed of working. Efficiency of the work flow. Management of procurement administration. Ability to use procurement resources efficiently. Use of information technology to improve efficiency. In-bound supply chain. Continuous improvement of processes. Adaptability to respond to changing requirements.

It is generally accepted that companies exist to create added value for customers by transforming inputs through a number of activities to produce outputs. The transformation process costs money and other resources. It is important for the procurement manager to ensure that the procurement activities for which he is responsible are:

1. 2.

Effective: Meeting next customer needs, on time, every time. Efficient: Keeping costs and inputs to minimum, efficient in using the suppliers and company's resources. Responsive: Adapting to changes in supply market and internal customer requirements.

3.

4. 5.

Elimination: Eliminating non-value-adding activities. Focused on suppliers' competence and releasing their potential.

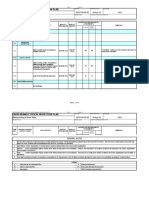

Chart 1 :Some Examples of Procurement Weakness 1. Inclination not to see end-to-end process. 2. Inclination to complacency. 3. 4. 5. 6. 7. 8. Inclination to think only of procurement function while acting. Inclination not to use data, information, and facts. Inclination not to foster supplier abilities or potential. Inclination not to do root cause analysis Inclination to neglect quality. Inclination to solve problems with fire-fighting approach and end with patch-up solutions.

9. Inclination to playing a safe game, not to take challenges 10. Inclination to work on short-term problems.

Features of Purchasing Performance

Procurement performance improvement has to be targeted at meeting customer requirements by doing the right things right the first time. It begins with strategic procurement decisions that must be made and fully supported by the top management. It is a top- down affair and it needs to encourage a balanced approach based on the following features. 1. Focus on retrospective performance assessment and concentration on future performance planning and improvement. 2. Identification and recognition of skills and competences associated with higher level of performance. 3. Identification and recognition of outputs, which are defined in qualitative terms and not just quantitative ones. 4. Recognition of the need to get thoroughly trained in the skills required for agreeing on goals and objectives of the procurement function and providing feedback on them to review performance. 5. Obtaining better results from building cross-functional teams internally and teaming up with suppliers for understanding and managing joint performance within an agreed framework of planned goals, standards, and attitude and competence requirements.

6. Establishing a culture in which both buyer and supplier take responsibility for improvement in their processes and contribute to shared vision and each other's growth. 7. Listening to suppliers' suggestions very closely and evaluating them carefully, in whatever way they can contribute towards performance improvement. 8. Linked to corporate strategy. 9. Providing methods to measure and report on performance. 10. Providing feedback and allowing corrective action to meet goals. 11. Linking rewards to results.

Chart 2. Ten Tendencies which Make for Poor Procurement performance

1. Tendency to depend only on buyer's own judgement. 2. Tendency to think of only procurement department. 3. Tendency not to utilize data and information. 4. Tendency not to accept and use suggestion from others. 5. Tendency not to look out of box. 6. Tendency not to take difficult challenge. 7. Tendency to neglect quality. 8. Tendency to evaluate bids on price. 9. Tendency to sweep problems under the rug.

10. Tendency to act without a strategy.

Elements of Procurement Performance Improvement

Today processes outlive products. In many industries the life cycle of a product may be measured in months, while business processes for design, production, sales, and service functions will exist as long as the company continues in operation. This underlines the

significance of process thinking and process optimization. A company may mess up a product or two, but if it messes up a process for too long it may not stay in business (Watson 1994).

For performance improvement through process thinking, a buyer must understand a group of either related or unrelated activities that together create value for an internal customer. For example, fulfilment of release of procurement purchase order and the receipt of goods is a process. It involves not only the requistioner but also various levels of approvals and routing, depending on the product requirement and value involved. Unless the work flow is understood and the need for each activity is questioned it cannot be ideally improved. .

Chart 10.3. Reasons for Poor Procurement Performance

1. Misplaced priorities. 2. A lack of focus. 3. Top management not taking interest in improvement activities. 4. Lack of resources to perform job. 5. Underestimating external pressures like opportunities, and threats in the supply environment. 6. Internal weaknesses such as unskilled people, inefficient bureaucratic processes, outdated technologies, culture or management style of the company. 7. Lack of awareness of what is happening outside and inside the industry. 8. Preoccupation with day-to-day problems. 9. Improper leadership and communication. 10. Arm's-length relations between procurement staff and next customer.

For example, releasing a purchase order comprises the following series of tasks: sending an enquiry, receiving a reply, selection of suppliers, comparing of quotations, negotiation with suppliers, placing an order, booking materials with carriers, receiving, etc. None of these activities is of the slightest interest or value to the requisition raiser. He is not interested how many suppliers the buyer has, how he selects them, how he awards or deletes them from the

approved list. He is just interested in how material procured meets his specified needs on time at the right location. Whether it is a production or procurement process, improvement would be easy if the buyer continuously improves every activity, every task and sub-task which affects the vision. For this, he must get his procurement system under control, and work to eliminate wasteful activities. The basic elements of procurement improvement process fall into eight areas of activity described below. These can be used as the foundation stone for building performance improvement activity. CUSTOMER-CENTRED APPROACH The vital area in performance improvement is creating a passion for customer-centred approach. Without this, little else matters. The customer is where it all starts. The focus should be on value. That means knowing what the next customer needs and wants, and successfully translating that knowledge into the operating requirements of day today actions.

Chart 10.4. Possible Reasons for Need to Improve Procurement Performance

1. Disastrous existing performance. 2. Signals of impending decrease in productivity, efficiency, and effectiveness. 3. A desire to leap further ahead of competitor to become world class and set an example.

. Centre means 'a hub of activities'. Customer-centred approach is about bringing the next customer to the hub of the buyer's day- to-day actions. When this happens, the customer's needs are understood, evaluated, assessed. It becomes easy for the buyer to know precisely what has to be done to satisfy him. He aligns his every task, every decision by asking just one vital question: how will my actions add value to the next customer?

Listening to the voice of the internal customer must become a feature of everyday working. The customer-centred approach involves identifying customer's needs, meeting their expectations, and matching or exceeding the performance of the competitor. Recognizing the supplier-customer chain is pivotal to procurement performance improvement and forms the basis for leveraging competitive advantage. Hence awareness of who are the internal customers and what are their needs is vital. Unless buyers satisfy the next customers, the customer-supplier chain within the company will not be able to satisfy external customers. In business, external customers are the final judge of how well the company performs and what they say counts. Customer-centred performance needs an enquiry of fundamental questions about the purpose of the buyer's function and how it can add the buyer's value to the supply chain. Such an approach leverages innovation in many ways: it will provide the fuel for identifying new opportunities, motivate staff and provide direction and focus for speedy proactive improvement efforts. This needs frequent listening to the next customer, and focused, two-way, collaborative problem solving, ideally face to face. Customer-centred approach may sometimes need the procurement department's culture to be characterized by speed, pro-action, and risk taking. The department needs to grasp new ideas, knowledge, imagination, continuous regeneration, flexibility, and innovation and discard old assumptions. These attributes are necessary but not sufficient. Directionless efforts can simply exhaust the procurement department's resources. The buyer therefore must be ever watchful to capitalize immediately on the fleeting opportunities the supply market continuously provides.

Chart 5. Action Checklist on Performance Improvement

1. How is our existing performance? 2. Can we make it OK? 3. Are we making it OK? 4. Have we made it OK? 5. Could we make it better? 6. How should be our future performance? 7. What future requirements will have to be handled?

8. What would be the cost-benefit of improvement projects? 9. What procurement or other issues preoccupy us most? 10. Are they essential to keep us busy and neglect other issues? 11. On what criteria and benchmarks do the competitors measure supplier Performance and their own performance? 12. What is our next customer's vision about our role? 13. How would procurement strategies be in the next ten or fifteen years from now in our industry? 14. Does future management reflect in our current strategies? 15. Are we fully alert to competitor strategies to substitute traditional raw materials being used in the industry? 16. What types of threats may cause our company to be out of competition? 17. Are we keen on the urgency to reinvent the current procurement strategies? 18. Are we clear about where the next 5-10 per cent compulsory saving will come from? 19. What percentage of our improvement efforts on lead-time reduction, Quality improvement, on-time deliveries, and price reductions focus on creating value improvement opportunity to our next customer? 20. Do our benchmark parameters tally with the competitor's method of benchmarking? 21. Are our actions directed towards preventive measures or crisis management?

Chart 6. Essentials of Improvement Plan

1. Finding and using out-of-industry examples for benchmarking. 2. Creating a 'bounded vision' with suppliers but always keeping the company's vision intact.

3. Being aware of the hidden agendas and political implications for other functional areas. 4. Spending a of time solving issues in other activities which surround one's activities because the1r output is critical to one s Important " objective. 5. Keeping vigilance on symptoms of problems appearing on any activities that appear to be related to procurement inaction but the causes are actually generated further back on related activities. 6. Simplifying processes and correspondingly the competences of suppliers to be broadened and enriched. 7. Redesigning of processes to be targeted at customer satisfaction. 8. Appropriate use of information technology. 9. Providing and obtaining of information wherever required. 10. A fundamental thinking of procurement processes with the aim of drastically improving value addition. 11. Cost and lead-time reduction. 12. Redesigning of activities aiming at breaking functional barriers into cross-functional teams. 13. Continually being ready for obsolescence. 14. Practising out-of-box thinking. 15. Refusing to be shackled by familiar supply markets. 16. Treating previous failures in improvement plans as learning opportunities for future success. 17. Making the buyers aware of the implications of delay in decision- making in terms of cost.

Peter Drucker says that the difference between efficiency effectiveness is: Efficiency is 'doing things right'; Effectiveness is 'doing the right things'. Many of those who strive to become efficient do not realize that they spend much of their time doing wrong things. So organizations are full of people who spend a large proportion of their working lives producing outputs that are accurate, on time, well presented, and so on; but unfortunately are neither necessary nor used by the people for whom they were produced

Improving performance in a competitive environment needs severe reforms in the way buyers act to meet future demands and respond to them quickly. This can only be achieved by developing listening and communication skills extensively, so that they can perfectly deliver what their next customer actually needs. CON11NUOUS IMPROVEMENT In the past, the game of survival and making profits was simple for companies. There were a few rules to remain in the competition, but as we head into the twenty-first century the rules and umpires will be more and winning will be possible only if a company makes the right moves at the right time. Opportunities for continuous improvement are points of concern or dissatisfaction which have been expressed by someone, whether end-customers, suppliers, or internal customers. These concerns may be caused by a need for improved quality, lower cost, adversarial relationship, or the availability of new technology. A measure of continuous improvement is the rate at which the procurement function is continuously renewing its know-how and regenerating its capabilities in anticipation of uncertainties. Adopting new ways and discarding old baggage must become a top priority. Understanding the concerns is not enough. Searching for ways to improve should be a non-stop process. When implementing best solutions in one area is over, the next advance should be incorporated in the improvement process with a new benchmark and formal performance standard. Once this cycle begins, improvement breeds improvement. Continuous improvement refers to the buyer's unceasing efforts to upgrade supplies, suppliers, procurement process and other related areas in order to meet the next customer's needs, while concurrently reducing inefficiency, costs and wastage. To achieve significant improvements in procurement, the buyer must work holistically. There are no quick fixes. The buyer must also get the low hanging fruit rather than big fruit. His next customer would be so much happier if he solves his immediate problems. The buyer must also solve problems his customer points out and not the ones that he himself feels are important.

Continuous improvement helps prevent recurrence and occurrence of mistakes. Preventing occurrence means doing it right: the first time for all actions. The buyer must understand how to analyse defects, find root causes, and eliminate problems for good by improving the process. Preventive recurrence means not putting out the same fires over and over again, but tracing and correcting the root causes of each error or defect in the process. Improving procurement performance needs a systematic approach rather than a situational solution specific to a particular problem. The latter does not add long-term value to the value chain. A similar problem may crop up at any moment, making the buyers spend extra resources. Continuous improvement is facilitated by focusing on end-to- end process rather than the outputs coming out of the small process link. The approach needs a redefinition of success, unlearning the past, offloading outdated old baggage. Some improvement actions can force the buyer to discard old practices of keeping suppliers at the arm's length, squeezing them to the last drop, or doing price reductions based on comparisons of quotations, working on areas conforming to the buyer's ways, working always jn fire-fighting mood, and neglecting preventive style of working. Continuous improvement is distinguished from other attempts to improve efficiency and effectiveness by its emphasis on daily, incremental forms of improvement. The purpose of all these efforts is to enhance supply chain value, a concept that refers not only to price reductions but also to quality, delivery, and flexibility in supply. Every internal meeting agenda, memo, report, supplier visit, evaluation and improvement effort should have a bifocal dimension, explicitly considering the impact of today's and future issues. The buyer should not put in efforts to scratch the surface activities to obtain improvements. He needs to go deeper, and spend resources, if required, to drastically improve performance and move in the direction of the vision. The most important requirement is to become nimble to adjust rapidly to environmental changes and gain from opportunities as they arise. Continuous improvement should be seen as a dynamic process. The buyer has to fight to achieve and sustain best performance. It requires long-term planning and constancy of purpose. It is the result of teamwork within the whole company.

MANAGEMENT BY FACT Management by fact is the cornerstone of effective procurement performance planning, decision-making, and improvement. Decisions, if based on intuition or gut feel, and not hard data, will have enormous consequences, not only on the performance of procurement function but also on the next customer's performance. It is a recipe for disaster. Buyers must be able to aggregate, correlate, and creatively synthesize from the mass of data to identify concrete opportunities. It requires a disciplined and refined approach to information analysis and a high-order acquaintance with analytic tools. Once the buyer starts dealing with problems, people within the company and supplier's company will try to hide the problems and divert attention. By managing such problems with information, data, and facts, it becomes possible to bring them into the open and tackle them. Collection and arrangement of data often leads to the discovery of hitherto unseen facts or clarification of otherwise vague subjects, which in turn results in matters being handled better. Management by fact will allow openness expose problems and create an awareness to deal with them. The procurement performance will be improved considerably if problems are isolated and measures adopted to prevent them rather than cure them later. Obviously, this starts from having a clear vision for improvement and actions centred on internal customer needs. It should never be forgotten that internal customer satisfaction is the topmost priority item that contributes to competitive advantage. Several good books explain in detail how to use various statistical and other methods to improve performance by fact analysis. A few methods require measurement of data. Some of the tools used are: Brainstorming, Histogram, Process flow diagram, Fishbone, or cause-andeffect diagram, Parrot diagram, etc. TRAINING AND DEVELOPMENT Training is necessary to improve performance. It provides a disciplined organized approach to dealing with performance issues and problem solving. Training requires collection and evaluation of qualitative, and quantitative information. Buyers must under stand what to measure, how to interpret the data, use them to /improve performance, how to search for improvement goals and where to start. Experience shows that training and development of

procurement staff not only helps to become more flexible, proactive, and customer focused but also acts as a prime motivational tool.

Today the emphasis on procurement staff training has changed from just skill-based training to bring attitudinal and cultural value change. Every staff member of the procurement function, whatever his status, should be trained to remain constantly aware of the company's mission to its customers and strive to beat their previous best performances. Training can influence the attitude towards the internal customer. It can leverage performance that hinges on creativity and innovation applied to the procurement process. Continuously getting training in correcting weaknesses is the best for improvement. It improves the ability to learn faster and climb the learning curve speedily. The first step in developing a training programme is to chart core procurement activities, then build in measures that will at first enable the achievement of consistent results and improve performance gradually, reducing failures and mistakes. This allows acquiring knowledge that will enable the buyer to do the right things and develop skills necessary to enable him to do the right things right the first time. QUICK RESPONSE Quick response is usually driven by pressing internal customer requirement and desire to improve performance. Improving response needs buyers to eliminate communication barriers and non-value-adding activities: and continuously improve delivery and quality of incoming supply. Quick response means several things. It means being committed to and being able to meet internal customer needs faster than the competitor buyers. Today time is very important in improving performance, along with price, delivery , and flexibility, and the consequent competitive advantage. Products and services procured fast determine how the internal customer can meet external customer needs faster. Quick response leads to focus on the creation of value through every action, built on a process orientation that recognizes the impact ~f bottlenecks on system effectiveness and tolerates no

wastage. Such an approach may be seen as curious for a buyer to adopt, since buyers generally prefer to work in a stable and predictable environment. Nevertheless, their ability to adapt to the volatile conditions in today's turbulent markets requires that buyers and their procurement processes are extremely flexible. Quick response proceeds through a constant stream of alterations or adaptations in the procurement process, decision-making practices and procurement methods. Some will have widespread repercussions and may require resources. The vast majority, however, are tiny, costless modifications. It is their cumulative effect which is the true source of competitive advantage.

To achieve perfection in quick response buyers should practise understanding of: What their internal customers want. Communicate with internal customers to discuss problems. Listen to internal customer complaints and comment sympathetically. Resolve internal customer problems.

CREATING A CLEAR PICTURE Creating a clear picture of the current activity for improvement and future value-added activity is vital for performance improvement. A critical element here is to understand the definition and identification of value addition from the buyer's point of view. It consists of two parts: The first, how much he can reduce quality costs. This is a rigid requirement, but it highlights the few activities the buyers should concentrate on to develop anew platform for improvement. Second, how much the improvement can meet end customer satisfaction. This criterion is based on benchmark data. If the current activities are studied effectively, it will become a valuable case for performance improvement action by highlighting the quality costs and non-value-added steps. Among the many problems, it is important to select those that need to be addressed first. Not ~l the factors can be treated at one time, because of limited resources, but one can look for those factors that can have the greatest impact and opportunity to tackle those.

In other words, it is important to take care of the vital few rather than the trivial many. Buyers should list the activities and evaluate their relative importance. There are numerous techniques to test the importance of an activity. The. simplest way is to get the procurement staff and the internal customer to rate the important activities from one to five (1 = least important, 5 = most important) and ask the internal customer to rate the performance on each of them. Based on this information the buyer can concentrate his efforts and resources. Following are a few additional guidelines to determine priority items: Identify areas for maximum improvements. Identify difference between the present and the vision. Identify challenging opportunities. Identify problematic issues. Identify procurement issues that are vital for deciding corporate strategy . Identify cost-sensitive operations. Identify areas which are unique, special, and different for procurement performance. Identify issues of strategic and competitive importance to the company. Identify issues having a significant impact on quality, cost, delivery, or lead-time. Identify those activities, which represent (or support) procurement activity as success factor. LONG-RANGE VIEW OF GOAL To become the best in a class, procurement activities must be guided by a set of measurable goals that emerge from procurement strategy that will serve t~ align the work of buyers with the company's vision. Measurable goals allow evaluating performance and deciding how and where they are going from the predetermined path. Without measurable goals, buyers may still work hard, but go in different directions and miss the target. Focusing on goals helps the buyers monitor actual performance, make adjustment in priorities, and reallocate resources, without losing focus. A long-range view of goals helps to integrate and strengthen efforts towards achieving broad objectives relevant to the entire company with the increased outsourcing trends.

The role of the buyer is changing from merely bringing goods and services as per the requirements decided by someone to a leadership role, playing a proactive role in buying quality goods and services at competitive prices. A long-range view gives meaning to his work and can guide actions in a rapidly changing competitive environment to confront current issues and, at the same time, develop competitive strategies for the future. A source of valuable inforl1lation on how well a procurement function is performing is internal customers and suppliers. They provide the best opportunity for performance improvement and to become more effective. The long-range view goes a long way in preventing internal customer dissatisfaction. TEAM WORK Procurement performance improvement needs teamwork. The buyer's actions should be aligned with the actions of individuals working in own company and supplier's company. Such a synergy of team work will produce more effective results than the isolated efforts of procurement staff only.

Jeffrey Funk defines team work as extensive cooperation between employees in a business process (Funk 1992). A business process is performed by a number of different employees on a specific product or technology. Since these processes involve multiple people and multiple business functions {e.g. engineering, manufacturing, and marketing) team work is an important part of these processes. Team work is not cooperation; it is just not working together. It is creatively producing better solutions than those produced independently. This requires deep empathetic listening and courage in expressing perspectives and opinions in ways that show respect for the views of others. Out of that genuine interaction come insight, trust, interdependence and learning actions that are truly synergistic with the company's vision. Once buyers start working in a team they will develop competence to see their work in the overall context and develop an ability to seek and offer collaboration unflinchingly. With the increased product complexity, product diversity, component complexity, technology changes,

and drastic fall in product life cycle, team-based solution to various problems has become essential to improve performance. Breakthroughs can be obtained by adopting new mind-sets about possibilities overcoming established paradigms. Xerox Corporation, winner of the Malcolm Baldrige National Quality Award in 1989, conceives of its business as 'Team Xerox', explicitly including its suppliers in its definition of that team. Xerox knew it could never expect to achieve the significant cost saving it had estimated when implementing its just-in-time inventory systems. Accordingly, Xerox reduced the number of its suppliers from 5000 to 480, seeking to become one of the top five customers for each supplier. Further, Xerox requires that every supplier be 'process qualified'. The vendor certification process involves extensive training for each supplier in quality management, and it permits Xerox to quantify and analyse each supplier's performance (Snyder et al. 1993).

Procurement Performance Measurement

In order to compare or determine the results of a process, some kind of measurement is carried out. Fundamentally, measurement is an act or result of either qualitative or quantitative comparison between the goal or a predefined standard and actual results. If the result is to be meaningful, the act of measurement must satisfy the following requirements. 1. The standard or goal must be accurately known. 2. The procedure or method adopted for comparison must be provable. 3. Measurement should be proactive and able to manage the future, part of a procurement strategy and goal setting role. Measurement is a fluid, ever-changing process that is constantly re-evaluated and recalibrated as the activities and realities of organizational life evolve. It is a language of progress, which provides a sense of where we are and, more important, where we are going. It can guide steady advancement towards established goals and identify shortfalls or stagnation. To achieve these ends, it is important to measure the right things for the right reasons. Many companies can honestly claim that they have tracked cost reductions, supplier quality improvements, deliveries, and other measures for years. Tracking these measures is one thing but giving them equal status in determining overall corporate strategy is another-. Measurement becomes a waste of time with little or no competitive value when a company measures items

that have no influence on its competitive advantage. Measuring the right thing is a good beginning, but it must be done systematically. Remaining strategies rapidly. Goals and objectives are quantitative. They define what is to be achieved, as well as the amount of achievement. Goals define long- term quantifiable targets; objectives establish short-term quantifiable achievements. Both are performance indicators or critical success factors and are measurable. Procurement performance can be measured in various ways: reduced prices, increased response time, quality improvements, inward acceptance figures, delivery reliability, etc. The choice is wide, depending upon what is important to the company. Generally, performance measures are cross-functional. They must provide focus on critical processes, enable proactive problem identification and correction and promote continuous improvement and provide feedback on how well the procurement strategies and objectives are being met. Buyers in future will have to redesign procurement performance measurement system to reinforce cross- functional collaboration and continuously improve their customer responsiveness. When management fails to sort out strategic priorities, different goals can pull people in different directions. If production is concerned about large lot sizes and procurement is concerned about small lots and multiple deliveries, progress toward both goals may be slow and conflicts will occur. Sometimes, the aim is cost or quality. At other times, customer satisfaction is the focus. It would be much easier if one could simply focus on one need, but competitiveness is a moving target. One rival beaten, another crops up, and then we need a new goal. low many goals are too many? No one is sure. It depends on level and complexity. Most experts say that five specific goals are the maximum. Since too many goals can distract, they should be consolidated and prioritised (Denton 1995). The radical decision of changing measurement parameters involves a shift from treating financial figures as the foundation of performance measurement to treating them as one among a basket of measures. Recent literature is eloquent about the shortcomings f traditional financial matrices. They might be entirely appropriate for financial goals, but the large issue is whether the company's overall strategy can be expressed in only financial goals, which is probably not the case. Some fundamental characteristics of procurement performance in terms of measurability are: competitive requires adjusting

1. All the purchasing activities can be described, measured, studied, evaluated, and improved. 2. Inputs can be obtained from suppliers, internal customers and output provided to next customers. 3. It enables understanding of what one's next customer thinks one is supposed to do. 4. All activities consume resources (cost). 5. All purchasing activities can be improved through both corrective and preventive actions. 6. A majority of purchasing activities can be benchmarked either internally or externally. 7. Every procurement output can be described with a set of performance characteristics. 8. Next customer needs may be identified with a set of characteristics applicable to their performance and the relative improvement they attach to the changing level of each. Aims of Procurement Performance Improvement The buyer should take a strategic approach towards designing performance improvement actions towards internal or external customers. They should identify key customers, key outputs, and performance matrices and measure customer satisfaction. Some of the important aims are given below: 1. Acting as a catalyst for change in developing a more performance-oriented culture. 2. Developing of supplier partnership. 3. Developing and carrying out tactics (actions) to implement strategies. 4. Elimination of non-value-added work. 5. Enhancing flexibility to deal with rapid changes in market. 6. Fostering team work by linking cross-functions together and focusing on results of the entire company. 7. Monitoring and controlling number of defective goods to be sent back to supplier. 8. Providing for accurate and objective measurement and assessment of performance in relation to agreed targets and standards so that procurement staff receive feedback on how well they are doing. 9. Providing timely and effective solutions to problems. 10. Placing customer needs and requirements at the forefront of a procurement strategy . 11. Identifying and eliminating waste. 12. Identifying and adding focus to early indicators that are correlated to desired results.

13. Improving ratio of purchase value / purchase staff. 14. Improving on internal customer satisfaction. 15. Improving efficiency and effectiveness. 16. Improving delivery consistency. 17. Improving quality. 18. Improving creativity, innovation, flexibility, information sharing, number of suggestions, productivity. 19. Improving supplier performance. 20. Increasing percentage of discount orders by consolidating. 21. Increasing delivery reliability. 22. Increasing number of hours procurement staff invests in training sessions. 23. Increasing number of supplier certifications. 24. Increasing number of long-term contracts. 25. Increasing motivation and commitment of procurement staff. 26. Lowering inventories/ costs. 27. Increasing number and frequency of delivery. 28. Reducing number of amendments to purchase orders/supplier instructions. 29. Reducing time cost owing to non-availability of products for processing or maintenance. 30. Reducing loss of suppliers from approved list. 31. Reducing damages in incoming supply. 32. Reducing time taken to clear non-moving inventory. 33. Reducing cost of quality. 34. Reducing number of oral orders without hard purchase orders. 35. Reducing product development time by supplier involvement. 36. Reducing purchase order release lead-time. 37. Reducing number of non-compliances to ISO-9000, QS-9000 standards in a specified period. 38. Reducing number of items on hot shortage lists. 39. Reducing supplier rejections. 40. Reducing errors in purchase orders. 41. Reducing cost

42. Reducing number of suppliers. 43. Reducing internal customer complaints. 44. Reducing expediting situations. 45. Reducing time taken to meet emergency internal customer requirement. 46. Reducing material handling. 47. Reducing backlog of purchase orders, supplier payments, etc. 48. Reducing variance against budgeted performance.

Benchmarking

Benchmarking, a term used in land surveying, is in the Concise Oxford Dictionary defined as a 'mark cut in rock etc. by surveyors or to mark point in line of levels; criterion or point of reference', Benchmarking in land survey is therefore the process of establishing a benchmark, a reference point against which others can be compared (Lema and Price 1995). Benchmarking is the search for the best practices that will lead to superior performance of an organization (Camp 1989). Benchmarking is gaining wide popularity and interest among executives and senior managers around the globe for its potential in enhancing performance of the company and gaining a competitive edge. Benchmarking is a continuous process of identifying, comparing, understanding, adopting, improving or using as is, implementing, arid reviewing outstanding practices from and within the same company or group of companies or from other companies to help improve performance and achieve excellence. It involves a process of comparing the methods, practices and procedures to those of best-in-class companies, in order to learn how they have achieved excellence so that similar goals and performance standards can be set, which will better help satisfy customer requirements in various parameters. NEED TO UNDERSTAND BENCHMARKING Traditionally, companies have been comparing competition on the basis of financial results, prices, product, and features, marketing and sales strategies.. They have realized, however, that comparison of outcomes alone is not enough: they should also focus attention on the outputs of various internal processes, which leads to outcomes. They have to understand how each function and process is managed not only by a competitor but also in other industries.

As no individual or company can be best in all processes companies must understand they will always be in short supply with respect to talented men, adequate finances, competitive technology, versatile machines, competent suppliers, and enough materials that can meet the needs. Benchmarking can effectively be used to understand, learn and adopt the practices of others, how effectively they transform and leverage limited resources to gain competitive advantage. Every time there is an effort to step up benchmarking efforts, it brings in enthusiasm and motivation and productivity improvements. Benchmarking does four things: it sets goals by using the company's vision and mission and allows learning and unlearning from others, opens doors for continuous improvement and prepares one to deal effectively with the future. The continuous on-going changes in the company's markets and at the supplier's end do not allow the buyers to be complacent. Among the more wide-ranging trends in procurement thinking are: the recent shift from traditional arm's-length supplier relationship, extensive use of information technology, supplier base reduction, involving suppliers in design and development, continuous improvement, and meeting internal customer needs in exactly the same manner as with external customers. A benchmarking standard acts as a useful decision-making tool to design a procurement strategy in compliance with the procurement resource constraints. It can also deal with trade-off evaluation and other circumstances encountered during the normal improvement activities. This provides the buyer added flexibility to cope with the anticipated problems and unanticipated uncertainties and map out proper strategy .It reinforces performance improvement activities and displays clearly the opportunity for plenty more . Benchmarking is a non-stop process. The goal is never ending. Once the target is achieved there is an immediate search for another . Buyers of world-class companies do not rest on their laurels when one target is achieved. When they come close to it they start working for another they had already searched, so there is no waste of time.

Benchmarking is a long-term activity without scope for complacency. The road is a perfect circle with no ends. How fast a company completes the circle is a matter of its efficiency. BENEFITS OF BENCHMARKING Benchmarking helps focus attention out of the box and encourages looking for improvement areas, with a different mind-set and direction; allows setting performance indicators to assess whether the present purchasing performance standards are achieving the objectives set; helps set specific goals needed for the chosen performance area; helps measure and review goals, milestones, indicators, and ultimately develop procurement strategy itself for review and upgrading continuously; helps learn best practices and motivate staff, to set out the match or surpass it; prepares the company for quality certification and quality awards; .develops goals and strategies appropriate to the company whatever. may be the size, its customers, or its place in the competitive space; accelerates and manages change; helps in realistically understanding one's weaknesses, and capabilities, and opens up opportunities. Prompts deciding on priorities right the first time helps in reassessing one's strength and helps to draw a real picture of one's performance; helps create a sense of urgency; promotes the training of procurement staff with tools such as problem solving and value analysis; and gives particular attention to management leadership, human resource management, business process management, customer and market focus, information utilization, and problem solving tools.

Performance Improvement Actions and Feedback

Many procurement strategies have been criticized as being short- sighted and focused on the near term. One manifestation of this syndrome is the excessive attention to 'fire-fighting' and achievement of immediate results. One key to breaking this pattern and building a strategic perspective is to strengthen the underlying activities instead of each specific output and deviation.

Three failings which can prevent a procurement function from systemically improving its performance are: 1. Failure to identify critical success factors of procurement function leading to a company's competitive advantage. 2. Failure to measure the right things. 3. Failure to apply a robust improvement approach that builds an understanding of fundamental root causes for poor performance. Generally, performance improvement can be simplified through the application of three simple concepts: By focusing on the customer. Continuously improving work processes. Providing a supportive environment for building the commitment of everyone with the procurement function. Once these requirements are understood and an appropriate environment is established, improvement becomes the core of any activity, typically through cross-functional teams with continuous improvement and with the Plan-Do-Check-Act (PDCA) model serving as a road map. Normally, failure to improve competitive advantage through procurement actions does not come from failure to do hard work. It stems from the fact that buyers do not know how to increase advantage through improving relationship between buyer and supplier on one side and internal customer on the other side. Buyers can measure performance and satisfy the next customer , provided they know what and why they are measuring and the output they measure is acceptable to the next customer. In fact,

since we know that next-customer orientation is the key to procurement performance improvement and quality cost, buyers should have a scoreboard to measure their process outputs in relation to these objectives. They must also remember that: 1. Objectives should be measurable. 2. The number of key objectives should be manageable, for example, four to five. 3. They should acquire proper tools and appropriate support to work on these objectives.

4. Any improvement in efficiency and effectiveness which does not contribute to the vision is not an improvement but a change for the worse. 5. Data are important; data collected on procurement process ~l within the plan can give more importance to facts rather than qualitative judgement. 6. If one accepts the premise that cross-functional team members' involvement is essential to the improvement-process, one must know what role each must play in this game and how to play it as a team member . 7. One also needs a scoreboard to see how one is doing and record one's progress. If result cannot be obtained through these acts, it can be concluded that improvement activities have been done without much thought given to them. When we verify results with set objectives, we do not merely look them over. The verification activates a process through which we rethink and reflect on our own actions.

Actions

to

Ensure

Effective

and

Systematic

Procurement

Performance Improvement

1. Conduct an assessment to establish the need for procurement performance improvement. 2. Develop a clear idea of the outcome of the performance improvement effort. 3. Analyse the current situation to understand what changes are needed. 4. Prepare a systematic plan to discern how the performance improvement effort will be managed with the outgoing demands of the operation. 5. Design methods to evaluate, learn from, and stabilize the new procurement improvement process.

A Seven-step Approach to Procurement Performance Improvement STEP 1: DEFINE THE OBJECT1VE i. Define the problem in terms of a gap between what is and what should be (For example, manufacturing reports on excessive number of supply rejections. The buyer's objective is to reduce the number of defects in the incoming supply). ii. Document why it is important to be working on a particular problem. iii. Explain how you know it is a problem, providing any data you might have that supports this. iv. List the next customer's key performance characteristics. v. State how closing the gap will benefit the next customer in terms of these characteristics. vi. Decide what data you will use to provide a baseline against which improvement can be measured. vii. Develop any operational definitions you will need to collect the data. STEP 2: STUDY THE CURRENT SITUATION i. Map the process ii. Identify any variable that might have a bearing on the problem. iii. Collect the data and summarize what you have learned about the variable's effect. on the problem. iv. Determine what additional information would be helpful at this time. STEP 3: ANALYSE THE POTENTIAL CAUSES i. ii. Determine the potential cause of the current condition. ii. Determine whether more data are needed.

STEP 4: IMPLEMENT A SOLUTION i. Develop a list of solutions to be considered. ii. Be creative. iii. Decide which solution should be tried. iv. Carefully assess the feasibility of each solution, and the likelihood of success.

v. Determine how the preferred solution will be implemented. vi. Implement the preferred solution. STEP 5: CHECK THE RESULTS i. Determine whether the actions in Step 4 were sufficient. ii. Analyse the results; determine whether the solution tested was effective:. iii. Repeat prior steps as necessary . iv. Describe any deviations from the plan and what was learned STEP 6: STANDARDIZE THE IMPROVEMENT i. Institutionalize the improvement. ii. Develop a strategy for institutionalizing the improvement. iii. Implement the strategy for and check to see that it has been successful. iv. Determine whether the improvement should be applied elsewhere and plan for its implementation STEP 7: ESTABUSH PLANS i. Determine your plans for the future, decide whether the gap should be narrowed further, and if so, how another objective should be approached. ii. Identify related problems that should be addressed.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Sap 3Documento29 páginasSap 3Joju JohnyAinda não há avaliações

- Quantitative Techniques - TheoryDocumento2 páginasQuantitative Techniques - TheoryJoju JohnyAinda não há avaliações

- Internal and External ConsistencyDocumento35 páginasInternal and External ConsistencyAakriti ChAinda não há avaliações

- Technology Management 3Documento6 páginasTechnology Management 3Joju JohnyAinda não há avaliações

- GATPDocumento14 páginasGATPJoju JohnyAinda não há avaliações

- Warehouse Management: Submitted To Prof. Sham Chaugule by Ajinkya J Bhavsar Roll No. 06Documento11 páginasWarehouse Management: Submitted To Prof. Sham Chaugule by Ajinkya J Bhavsar Roll No. 06Joju JohnyAinda não há avaliações

- Materials Requirement PlanningDocumento12 páginasMaterials Requirement PlanningJoju JohnyAinda não há avaliações

- OPC - LectureDocumento70 páginasOPC - LectureJoju JohnyAinda não há avaliações

- Joju - World Class Manufacturing (Learnings)Documento8 páginasJoju - World Class Manufacturing (Learnings)Joju JohnyAinda não há avaliações

- Presentation - International Logistics & Supply Chain ManagementDocumento25 páginasPresentation - International Logistics & Supply Chain ManagementJoju Johny100% (3)

- Joju - BPR 4Documento12 páginasJoju - BPR 4Joju JohnyAinda não há avaliações

- Joju - BPR 3Documento7 páginasJoju - BPR 3Joju Johny100% (1)

- Business Process Re - Engineering: Product Development Case of KodakDocumento8 páginasBusiness Process Re - Engineering: Product Development Case of KodakJoju JohnyAinda não há avaliações

- Joju - BPR 1Documento4 páginasJoju - BPR 1Joju JohnyAinda não há avaliações

- Joju Johny - ADSCM - SPL Case StudyDocumento15 páginasJoju Johny - ADSCM - SPL Case StudyJoju JohnyAinda não há avaliações

- Value AnalysisDocumento32 páginasValue AnalysisJoju JohnyAinda não há avaliações

- Vendor DevelopmentDocumento13 páginasVendor DevelopmentJoju Johny100% (1)

- Joju - International ProcurementDocumento9 páginasJoju - International ProcurementJoju JohnyAinda não há avaliações

- Spare Parts ManagementDocumento18 páginasSpare Parts ManagementJoju Johny100% (1)

- Lecture - Materials ManagementDocumento48 páginasLecture - Materials ManagementJoju Johny100% (1)

- Purchasing PrinciplesDocumento10 páginasPurchasing PrinciplesJoju Johny100% (1)

- MM EfficiencyDocumento5 páginasMM EfficiencyJoju JohnyAinda não há avaliações

- Standard Is at IonDocumento8 páginasStandard Is at IonJoju JohnyAinda não há avaliações

- Surplus, Salvage & Scrap DisposalDocumento5 páginasSurplus, Salvage & Scrap DisposalJoju Johny100% (1)

- Selecting A Right SupplierDocumento7 páginasSelecting A Right SupplierJoju JohnyAinda não há avaliações

- Planning & Prog, Inventory, ReplenishingDocumento18 páginasPlanning & Prog, Inventory, ReplenishingJoju JohnyAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Project PresentationDocumento19 páginasProject PresentationRaushan KumarAinda não há avaliações

- Forming Process ReportDocumento4 páginasForming Process ReportAqib ZamanAinda não há avaliações

- 01 - Machinery OEM Catalogue - MoellerDocumento228 páginas01 - Machinery OEM Catalogue - MoellerPhaniAinda não há avaliações

- Saudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilDocumento2 páginasSaudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilSatheesh Rama SamyAinda não há avaliações

- Sessions 3 and 4: Business Process Re-EngineeringDocumento48 páginasSessions 3 and 4: Business Process Re-Engineeringpick YourpetAinda não há avaliações

- ANPQP 2.3 - Phase DiagramDocumento2 páginasANPQP 2.3 - Phase DiagramM80% (5)

- The Impact of New Nigerian Petroleum Industry Bill PIB 2021 On Government andDocumento39 páginasThe Impact of New Nigerian Petroleum Industry Bill PIB 2021 On Government andIbrahim SalahudinAinda não há avaliações

- Paver Brochure 1 ZenbesDocumento2 páginasPaver Brochure 1 ZenbesOng Ju EeAinda não há avaliações

- Market Study On Maruti Suzuki SwiftDocumento63 páginasMarket Study On Maruti Suzuki SwiftNikesh BeradiyaAinda não há avaliações

- E46 AirbagDocumento6 páginasE46 AirbagTutzu99Ainda não há avaliações

- Chapter1 - Technology ManagementDocumento16 páginasChapter1 - Technology ManagementJawad Ahmad SahibzadaAinda não há avaliações

- HCI 534E/544E - Winding 311: Technical Data SheetDocumento9 páginasHCI 534E/544E - Winding 311: Technical Data SheetMd ShAinda não há avaliações

- Creating VOFM Custom RoutineDocumento16 páginasCreating VOFM Custom RoutineSergio Martín Cordero100% (1)

- Checklist For Rope Suspended Platform HSE OCP 16Documento1 páginaChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalAinda não há avaliações

- Autonomous TransactionsDocumento9 páginasAutonomous TransactionsdkmdipeshAinda não há avaliações

- Automated Metal Cutting MachineDocumento14 páginasAutomated Metal Cutting MachineAmlan pandaAinda não há avaliações

- Markets For Air Transport ServicesDocumento26 páginasMarkets For Air Transport ServicesMohasin85100% (1)

- Hyscan II IomDocumento33 páginasHyscan II Ioma1gulesAinda não há avaliações

- Sop Piling WorkDocumento2 páginasSop Piling WorkamirAinda não há avaliações

- Sensible Chinese Characters To WordsDocumento27 páginasSensible Chinese Characters To WordsrajualnAinda não há avaliações

- EM531 531 RathodH 2Documento60 páginasEM531 531 RathodH 2Santosh Kumar SurineediAinda não há avaliações

- Including Files and Applets in JSP PagesDocumento23 páginasIncluding Files and Applets in JSP PagesSireeshaAinda não há avaliações

- Catálogo Taylor and FrancisDocumento48 páginasCatálogo Taylor and Francismkr1980100% (1)

- 8991 7428 00 Diagrams and Drawings PDFDocumento66 páginas8991 7428 00 Diagrams and Drawings PDFjuangomezsanAinda não há avaliações

- GT-50 Module 1 Introduction 82 SlidesDocumento81 páginasGT-50 Module 1 Introduction 82 SlideslucholadeAinda não há avaliações

- Pihak Berkuasa Penerbangan Awam Malaysia (Civil Aviation Authority of Malaysia) Application For Unmanned Aircraft System (Uas) / DroneDocumento11 páginasPihak Berkuasa Penerbangan Awam Malaysia (Civil Aviation Authority of Malaysia) Application For Unmanned Aircraft System (Uas) / DroneMuhammad Fahmi MahmudAinda não há avaliações

- A 2020 Insights IAS Subjectwise Test 23Documento62 páginasA 2020 Insights IAS Subjectwise Test 23Sandeep SoniAinda não há avaliações

- TR Rhel7 Rhel8 Learning Path Infographic f17058 201905 enDocumento1 páginaTR Rhel7 Rhel8 Learning Path Infographic f17058 201905 enHabiburrokhman SjarbiniAinda não há avaliações

- WPS-PQR ListDocumento1 páginaWPS-PQR ListSandra SandersAinda não há avaliações