Escolar Documentos

Profissional Documentos

Cultura Documentos

Exec Shirt Comp

Enviado por

Ashish AdikeDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Exec Shirt Comp

Enviado por

Ashish AdikeDireitos autorais:

Formatos disponíveis

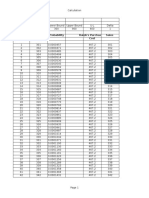

1. Current Process Regular Shirts Labor content Operation Min/shirt Cutting 1. Make collar 2. Make Cuff 3.

. Make Sleeve 4. Make Front 5. Make Back 6. Join Shoulder 7. Attach collar 8. Attach Sleeve 9. Stitch down sleeve 10. Sew side seem 11. Attach cuff 12. Hem bottom 13. Inspect 14. Iron 15.Packaging 120*4/480=1 3.9 2 0.65 2.5 1.7 0.66 1.65 1.55 0.65 1.8 1.55 1.7 1.5 1.95 1.75 Capacity Shirts/day 1920 985 960 1477 1152 1129 1455 1164 1239 1477 1067 1239 1129 1280 985 1097 Capacity Utilization 0.42 0.81 0.83 0.54 0.69 0.71 0.55 0.69 0.65 0.54 0.75 0.65 0.71 0.63 0.81 0.73

No of workers 4 8 4 2 6 4 2 4 4 2 4 4 4 4 4 4

Cycle Time min/shirt 0.25 0.49 0.50 0.33 0.42 0.43 0.33 0.41 0.39 0.33 0.45 0.39 0.43 0.38 0.49 0.44

Analysis of the current plan Bottleneck Bottleneck Production Capacity(shirts/day) Bottleneck Cycle Time(min/shirt) = based on above capacity Actual Production Rate(shirts/day) Actual Cycle Time(min./shirts) Capacity Utilization WIP Inventory(shirts) =16000(total shirts)/20(days) = based on actual capacity (480/800) =A.C./ R.C = 800/960 =196*60 (Exhibit 3) =0.6*11760/480 Manufacturing Lead Time(days) or =11760/800 Direct Labor Content(min./shirts) Sum(all Process time) Direct Labor Utilization Direct Labor Cost($/shirts) =(26.51*800)/(64*8*60) =64*8*6/800 26.51 0.69 3.84 14.7 Make cuffs 960 0.5 800

0.6 0.83 11760

Mikes Plan Regular + Exclusive shirts (800 + 100 = 900 shirts) Operation Labor content Min/shirt New Cutting m/c Cutting 1. Make coller 2. Make Cuff 2.5 / 5 120* 4 / 480 3.9 2 1 4 8 4 2 6 4 2 4 4 No. of workers Cycle time min/shirt 0.50 0.25 0.49 0.50 0.33 0.42 0.43 0.33 0.41 0.39 Capacity shirts/day 960 1920 985 960 1477 1152 1129 1455 1164 1239 Capacity Utilization 0.10 0.42 0.91 0.94 0.61 0.78 0.80 0.62 0.77 0.73

3. Make Sleeve 0.65 4. Make Front 5. Make Back 2.5 1.7

6. Join Shoulder 0.66 7. Attach coller 1.65 8. Attache Sleeve 9. Stich down sleeve 10. Sew side seem 11. Attach cuff 1.55

0.65

0.33

1477

0.61

1.8 1.55

4 4 4 4 4 4

0.45 0.39 0.43 0.38 0.49 0.44

1067 1239 1129 1280 985 1097

0.84 0.73 0.80 0.70 0.91 0.82

12. Hem bottom 1.7 13. Inspect 14. Iron 15. Packaging 1.5 1.95 1.75

Analysis of Mikes Plan Bottleneck Bottleneck Production Capacity(shirts/day) Bottleneck Cycle Time(min/shirt) Actual Prodcution Rate(shirts/day) Actual Cycle Time(min./shirt) Capacity Utilization WIP Inventory(shirts) Manufacturing Lead Time(days) Direct Labor Content(min./shirt) Direct Labor Utilization Direct Labor Cost($/shirt) = based on above capacity =800 regular shirts + 100 custom shirts = based on actual capacity (480/900) =A.C./ R.C = 900/960 =396*5 (Exhibit 5) =0.53*1980 or =1980/900 Make Cuff 960

0.5

900

0.53 0.94 1980 2.2

Sum(all Process time) =(27.01*900)/(65*8*60) =65*6*8/900

27.01 0.7791 3.466

Ikes Plan for 100 custom shirts Operation Labor content Min/shirt New Cutting m/c 2.5 1. Make collar 2. Make Cuff 3. Make Sleeve 4. Make Front 5. Make Back 6. Join Shoulder 7. Attach coller 3.9 2 0.65 2.5 1.7 0.66 1.65 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 No. of workers Cycle time min/shirt 0.5 3.90 2.00 0.65 2.50 1.70 0.66 1.65 1.55 0.65 1.80 1.55 1.70 1.50 1.95 1.75 Capacity shirts/day 960 123 240 738 192 282 727 291 310 738 267 310 282 320 246 274 Capacity Utilization 0.10 0.81 0.42 0.14 0.52 0.35 0.14 0.34 0.32 0.14 0.38 0.32 0.35 0.31 0.41 0.36

8. Attache Sleeve 1.55 9. Stich down sleeve 0.65

10. Sew side seem 1.8 11. Attach cuff 12. Hem bottom 13. Inspect 14. Iron 15. Packaging 1.55 1.7 1.5 1.95 1.75

Analysis of Ikes Plan Bottleneck Bottleneck Production Capacity(shirts/day) Bottleneck Cycle Time(min/shirt) Actual Production Rate(shirts/day) = based on above capacity Make collar 123

3.9

=100 custom shirts

100 4.8 0.81 45 0.45

Actual Cycle Time(min./shirt) = based on actual capacity Capacity Utilization WIP Inventory(shirts) Manufacturing Lead Time(days) Direct Labor Content(min./shirt) Direct Labor Utilization Direct Labor Cost($/shirt) =A.C./ R.C = 100/123 =3*15 (Ike's Plan) =4.8*45 or =45/100

Sum(all Process time) =(26.01*100)/(16*8*60) =16*8*6/100

26.01 0.3386 7.68

Ikes Plan for 800 regular shirts Operation Labor content no. of workers Min/shirt Old cutting m/c 120*4/480 1. Make coller 2. Make Cuff 3.9 2 4 7 3 1 5 3 1 3 3 min/shirt 1 0.56 0.67 0.65 0.50 0.57 0.66 0.55 0.52 shirts/day 1920 862 720 738 960 847 727 873 929 Utilization 0.42 0.93 1.11 1.08 0.83 0.94 1.10 0.92 0.86 Cycle time Capacity Capacity

3. Make Sleeve 0.65 4. Make Front 5. Make Back 2.5 1.7

6. Join Shoulder 0.66 7. Attach coller 1.65 8. Attache Sleeve 9. Stich down sleeve 10. Sew side seem 11. Attach cuff 1.55

0.65

0.65

738

1.08

1.8 1.55

3 3 3 3 3 3

0.60 0.52 0.57 0.50 0.65 0.58

800 929 847 960 738 823

1.00 0.86 0.94 0.83 1.08 0.97

12. Hem bottom 1.7 13. Inspect 14. Iron 15. Packaging 1.5 1.95 1.75

Analysis of Ikes Plan for 800 regular shirts Bottleneck Bottleneck Production Capacity(shirts/day) Bottleneck Cycle Time(min/shirt) Actual Production Rate(shirts/day) Actual Cycle Time(min./shirt) Capacity Utilization WIP Inventory(shirts) Manufacturing Lead Time(days) Direct Labor Content(min./shirt) Direct Labor Utilization Direct Labor Cost(Rs/shirt) Aditinal labor Cost (Rs/shirt) for 80 shirts Actual Cost /shirt with overtime = based on above capacity (480/720) = 800 shirts (required) = based on actual capacity =A.C./ R.C = 720/720 =151*60 (Exhibit 5) =0.66*9060 or =9060/720 (800) Sum(all Process time) =(26.51*720)/(49*8*60) =49*8*6/720 Make cuff 720 0.66 720 0.66 1.00 9060 12.58 (11.32) 26.51 0.81 3.266

=49*1*9/80 =(3.26*720+5.51*80)/800

5.51 3.49

Comparison of Current process, Mikes and Ikes Plan Current Process Regular Shirts Actual Cycle Time (min/shirt) M.L.T. (days) WIP Inventory (shirts) Production Capacity (shirts/day) Capacity Utilization Direct Labor Content(min/shirt) 0.6 14.7 11760 960 0.83 26.51 Mikes Plan Regular & Custom Shirts 0.53 2.2 1980 960 0.94 25.51 without cutting 26.01/26.51 0.78 3.46 Regular Shirts 0.67 12.58 9060 720 1 26.51 Custom Shirts 4.8 0.45 45 123 0.81 26.01 Ikes Plan

Direct Labor Utilization Direct Labor Cost($/shirt)

0.69 3.84

0.81 3.49

0.33 7.68

Normal Process Flow Diagram

Make Collars

Make Cuffs

Cutting

Make Front Join Shoulder Make Back Inspect Attach Collar Attach Sleeves

Stitch down sleeves

Sew Side Seam

Attach cuffs

Hem Bottom

Make Sleeves

Iron

Folding, Package

Mikes Plan Flow Diagram

Make Collars

Make Cuffs

Cutting

Make Front Join Shoulder Make Back Inspect Attach Collar Attach Sleeves

Stitch down sleeves

Sew Side Seam

Attach cuffs

Hem Bottom

Make Sleeves

Iron

Folding, Package

Ikes Plan Flow Diagram

Make Collars

Make Cuffs

Cutting

Make Front Join Shoulder Make Back Inspect Attach Collar Attach Sleeves

Stitch down sleeves

Sew Side Seam

Attach cuffs

Hem Bottom

Make Sleeves

Iron

Folding, Package

2. Suggestion to Dwight Collier: From the table we observe that, the Direct Labor Cost for manufacturing Custom shirts using Mikes plan is less by an amount of 4.22 per shirt when compared to that of Ikes plan. It can also be inferred that the Labor costs for Regular shirts using Ikes plan costs 0.03 per shirt which is very minimal when compared to 4.22. Hence, by using Mikes plan a labor cost of 4.17 per shirt can be saved over Ikes plan. Moreover in Mikes plan the Capacity utilization is 94% whereas, for Ikes plan it is 81%. In Mikes plan Maximum utilization is achieved as both types of shirts are manufactured under the same process, whereas, in Ikes process the utilization is over used in Regular process and under used in Exclusive shirt process.i.e. In regular process the workers need to work in additional shifts and in Exclusive shirt process the workers are free for a large amount of time. In addition, the Initial cost of setting up the equipment in Ikes process would be more because it requires the Exclusive Shirt process to be arranged separately. This requires a lot of removing and fixing the Machines form their present positions, whereas, in Mikes process the Exclusive shirts can be manufactured in the current set up. Hence, we recommend Dwight Collier to go for Mikes plan as it seems to be more beneficial when compared to Ikes plan.

An operation is composed of processes designed to add value by transforming inputs into useful outputs. Operations deal with process aspects such as cost, quality, flexibility, and speed. Some of the process performance measures that communicate these aspects include:

Process capacity - The capacity of the process is its maximum output rate, measured in units produced per unit of time. The capacity of a series of tasks is determined by the lowest capacity task in the string Capacity utilization - the percentage of the process capacity that actually is being used. Throughput rate (flow rate ) - the average rate at which units flow past a specific point in the process. The maximum throughput rate is the process capacity. Flow time (throughput time or lead time) - the average time that a unit requires to flow through the process from the entry point to the exit point. Cycle time - the time between successive units as they are output from the process. Cycle time for the process is equal to the inverse of the throughput rateProcess time - the average time that a unit is worked on. Process time is flow time less idle time. Direct labor content - the amount of labor (in units of time) actually contained in the product. Excludes idle time when workers are not working directly on the product. Also excludes time spent maintaining machines, transporting materials, etc. Direct labor utilization - the fraction of labor capacity that actually is utilized as direct labor.

Little's Law The inventory in the process is related to the throughput rate and throughput time by the following equation: W.I.P. Inventory = Throughput Rate x Flow Time The Process Bottleneck The process capacity is determined by the slowest series task in the process; that is, having the slowest throughput rate or longest cycle time. This slowest task is known as the bottleneck. Identification of the bottleneck is a critical aspect of process analysis since it not only determines the process capacity, but also provides the opportunity to increase that capacity. Saving time in the bottleneck activity saves time for the entire process. Saving time in a non-bottleneck activity does not help the process since the throughput rate is limited by the bottleneck. It is only when the bottleneck is eliminated that another activity will become the new bottleneck and present a new opportunity to improve the process.

Você também pode gostar

- Executive Shirt Company, Inc.: Group No 3 Section BDocumento14 páginasExecutive Shirt Company, Inc.: Group No 3 Section Byuveesp5207Ainda não há avaliações

- Executive Shirts - HBSDocumento4 páginasExecutive Shirts - HBSDeepika ChainaniAinda não há avaliações

- Case StudyDocumento4 páginasCase Studyhemel dddAinda não há avaliações

- 21PGDM152 - RACHIT MRINAL - Executive Shirt Co. Inc. AssignmentDocumento8 páginas21PGDM152 - RACHIT MRINAL - Executive Shirt Co. Inc. AssignmentRachit MrinalAinda não há avaliações

- BottleneckDocumento5 páginasBottleneckAkanksha GuptaAinda não há avaliações

- Taylor Shirts Inc. - Operations ManagementDocumento8 páginasTaylor Shirts Inc. - Operations ManagementGeneAinda não há avaliações

- Executive Shirt Company IncDocumento13 páginasExecutive Shirt Company Incp11rupsacAinda não há avaliações

- Executive Shirt Company - Group 6Documento8 páginasExecutive Shirt Company - Group 6Puneet Agarwal100% (1)

- Executive Shirt Company: Case Study Analysis by Lg-4Documento9 páginasExecutive Shirt Company: Case Study Analysis by Lg-4AD RAinda não há avaliações

- Executive Shirts - Solution 2Documento10 páginasExecutive Shirts - Solution 2Bernard EugineAinda não há avaliações

- 12 Six Basic Strategies PDFDocumento6 páginas12 Six Basic Strategies PDFAishvarya GuptaAinda não há avaliações

- Strategicmgmt1 - What Is StrategyDocumento21 páginasStrategicmgmt1 - What Is Strategymonish147852Ainda não há avaliações

- Process Re-EngineeringDocumento54 páginasProcess Re-EngineeringAkanksha GuptaAinda não há avaliações

- A.SAI GAURAV (06) - Chitrangada Roy (07) - Nitin Kumar (14) - Saumya SaksenaDocumento31 páginasA.SAI GAURAV (06) - Chitrangada Roy (07) - Nitin Kumar (14) - Saumya SaksenaAnkita RanjanAinda não há avaliações

- Chapter 4 Process AnalysisDocumento6 páginasChapter 4 Process Analysispbpotter43100% (1)

- CHAPTER 7 - Work MeasurementDocumento29 páginasCHAPTER 7 - Work MeasurementmeeyaAinda não há avaliações

- Our Six Specific Objectives: How We're DoingDocumento8 páginasOur Six Specific Objectives: How We're Doingking_jsrAinda não há avaliações

- Assignment Toyota Case Study MsbeDocumento2 páginasAssignment Toyota Case Study MsbeAmodh SehgalAinda não há avaliações

- Welcome To The Capstone Rehearsal Tutorial!Documento10 páginasWelcome To The Capstone Rehearsal Tutorial!Abhishek Singh ChauhanAinda não há avaliações

- Midterm Case FinalDocumento6 páginasMidterm Case FinalChristina Parillo100% (1)

- Just in Time System: A Study and ReviewDocumento5 páginasJust in Time System: A Study and ReviewVIVA-TECH IJRIAinda não há avaliações

- Manzana Insurance: The Business ProblemDocumento8 páginasManzana Insurance: The Business ProblemDeepti AgarwalAinda não há avaliações

- Carr and Latham's Technology of Clothing ManufactureNo EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerNota: 4 de 5 estrelas4/5 (1)

- Coin-Operated Coffee Vending Machine: A Project Proposal By: Pinili, Ellen Gold B. Ponce, Mary Rosechelle SDocumento14 páginasCoin-Operated Coffee Vending Machine: A Project Proposal By: Pinili, Ellen Gold B. Ponce, Mary Rosechelle SPauline Ermeje GozoAinda não há avaliações

- Assignment # 3Documento1 páginaAssignment # 3naila khan0% (1)

- 2.beating The Odds When You Launch A New VentureDocumento13 páginas2.beating The Odds When You Launch A New VentureHithai ShreeAinda não há avaliações

- What Changes Are Required To Ensure Successful Implementation of Cellular Manufacturing? Is Worker Cross-Training Necessary?Documento4 páginasWhat Changes Are Required To Ensure Successful Implementation of Cellular Manufacturing? Is Worker Cross-Training Necessary?isaavedracastroAinda não há avaliações

- OPIM101 - Spring 2012 - Extra Study Problems With Solutions PDFDocumento17 páginasOPIM101 - Spring 2012 - Extra Study Problems With Solutions PDFjoe91bmw100% (1)

- Lean ManufacturingDocumento3 páginasLean ManufacturinganurajAinda não há avaliações

- Blitz Process FlowDocumento6 páginasBlitz Process FlowPrashant DhayalAinda não há avaliações

- Case Analysis Form - Fletcher ElectronicsDocumento2 páginasCase Analysis Form - Fletcher ElectronicsAmir YousafAinda não há avaliações

- Discopress Case SolutionDocumento4 páginasDiscopress Case SolutionumarzAinda não há avaliações

- OM - Dont Bother MeDocumento4 páginasOM - Dont Bother MePrakarsh ArenAinda não há avaliações

- Using Value Stream Mapping at Apparel Industry: A Case StudyDocumento7 páginasUsing Value Stream Mapping at Apparel Industry: A Case StudySANNITH VARIKOTIAinda não há avaliações

- Berkshire Toy Case - Calculation Groupe 4 18 FevDocumento9 páginasBerkshire Toy Case - Calculation Groupe 4 18 FevchandrakumaranAinda não há avaliações

- IEMS Module 5Documento31 páginasIEMS Module 5VenkatramananAinda não há avaliações

- Lean Six Sigma (Part A)Documento17 páginasLean Six Sigma (Part A)Punniavel PAinda não há avaliações

- Problem #3Documento28 páginasProblem #3Kevin RaderAinda não há avaliações

- PEn CaseDocumento3 páginasPEn Casemayank kumarAinda não há avaliações

- Week 5 Balancing Process Capacity Simulation Slides Challenge1 and Challenge 2 HHv2Documento23 páginasWeek 5 Balancing Process Capacity Simulation Slides Challenge1 and Challenge 2 HHv2Mariam AlraeesiAinda não há avaliações

- CH 10Documento23 páginasCH 10monel_24671Ainda não há avaliações

- Strategies To Reduce Wastage in A Garment Export HouseDocumento8 páginasStrategies To Reduce Wastage in A Garment Export Houseanshushah_144850168Ainda não há avaliações

- Tls ReportDocumento19 páginasTls Reportsharanabasava malipatilAinda não há avaliações

- Executive Shirts CompanyDocumento12 páginasExecutive Shirts CompanyAnonymous thwanV100% (1)

- Beer GameDocumento2 páginasBeer Gameemuro001Ainda não há avaliações

- Sports Obermeyer WACCDocumento10 páginasSports Obermeyer WACCAyesha TahirAinda não há avaliações

- Group3 SectionC Mapleleaf AssignmentDocumento9 páginasGroup3 SectionC Mapleleaf AssignmentUtkarsh SinghAinda não há avaliações

- Sport Obermeyer PaperDocumento10 páginasSport Obermeyer PaperagarwalankurkAinda não há avaliações

- Gentle Electric Company AssignmentDocumento2 páginasGentle Electric Company AssignmentSakshi ShardaAinda não há avaliações

- A Study On Total Quality ManagementDocumento121 páginasA Study On Total Quality ManagementranjithAinda não há avaliações

- Managerial AccountingDocumento23 páginasManagerial AccountingErum AnwerAinda não há avaliações

- SUMMARY Linking The Balanced Scorecard To Strategy SummaryDocumento4 páginasSUMMARY Linking The Balanced Scorecard To Strategy SummaryCamilleAinda não há avaliações

- Module 1Documento12 páginasModule 1viky5rajput45Ainda não há avaliações

- Fast React Evolve Case Study MaduraDocumento2 páginasFast React Evolve Case Study MaduraNt93100% (1)

- 9 Ways To Increase Sewing Operator EfficiencyDocumento47 páginas9 Ways To Increase Sewing Operator EfficiencyNitta MallikAinda não há avaliações

- Time Study of A Furniture Industry A Case StudyDocumento5 páginasTime Study of A Furniture Industry A Case StudyKhalfi PipinAinda não há avaliações

- Executive Shirt Company, Inc.: Group No 3 Section BDocumento14 páginasExecutive Shirt Company, Inc.: Group No 3 Section BAbhishek KumarAinda não há avaliações

- Executive Shirt Company IncDocumento14 páginasExecutive Shirt Company IncUtkarsh Singh50% (2)

- Case Analysis - Executive Shirt Company, IncDocumento6 páginasCase Analysis - Executive Shirt Company, IncSaptarshee ChatterjeeAinda não há avaliações

- Executive Shirts CompanyDocumento8 páginasExecutive Shirts Companysouravreachesout7112Ainda não há avaliações

- Exec ShirtDocumento1 páginaExec ShirtAshish AdikeAinda não há avaliações

- Executive Shirt CompanyDocumento9 páginasExecutive Shirt CompanyAshish Adike0% (1)

- TheoryDocumento1 páginaTheoryAshish AdikeAinda não há avaliações

- Exec Shirt CompDocumento14 páginasExec Shirt CompAshish AdikeAinda não há avaliações

- Exec ShirtDocumento1 páginaExec ShirtAshish AdikeAinda não há avaliações

- DonnerDocumento1 páginaDonnerAshish AdikeAinda não há avaliações