Escolar Documentos

Profissional Documentos

Cultura Documentos

Design of The SR20

Enviado por

hugostvDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Design of The SR20

Enviado por

hugostvDireitos autorais:

Formatos disponíveis

The Engineering Society For Advancing Mobility Land Sea Air and Space

INTERNATIONAL

400 COMMONWEALTH DRIVE, WARRENDALE, PA 15096-0001 U.S.A.

SAE Technical Paper Series

901714

Development of Four Cylinder SR Engine

Akihiko Sobue, Tamio Kawamura and Toshihiro Ninomiya

Nissan Motor Co., Ltd.

Passenger Car Meeting and Exposition Dearborn, Michigan September 17-20, 1990

The appearance of the ISSN code at the bottom of this page indicates SAE's consent that copies of the paper may be made for personal or internal use of specific clients. This consent is given on the condition, however, that the copier pay a $5.00 per article copy fee through the Copyright Clearance Center, Inc. Operations Center, 27 Congress St., Salem, MA 01970 for copying beyond that permitted by Sections 107 or 108 of the U.S. Copyright Law. This consent does not extend to other kinds of copying such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale. SAE routinely stocks printed papers for a period of three years following date of publication. Direct your orders to SAE Customer Service Department. To obtain quantity reprint rates, permission to reprint a technical paper or permission to use copyrighted SAE publications in other works, contact the SAE Publications Group.

All SAE papers are abstracted and indexed in the SAE Global Mobility Database.

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher. ISSN 0148-7191 Copyright 1990 Society of Automotive Engineers, Inc. Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE. The author is solely responsible for the content of the paper. A process is available by which discussions will be printed with the paper if it is published in SAE Transactions. For permission to publish this paper in full or in part, contact the SAE Publications Group. Persons wishing to submit papers to be considered for presentation or publication through SAE should send the manuscript or a 300 word abstract of a proposed manuscript to: Secretary, Engineering Activity Board, SAE.

Printed in USA

901714

Development of Four Cylinder SR Engine

Akihiko Sobue, Tamio Kawamura and Toshihiro Ninomiya

Nissan Motor Co., Ltd.

Abstract

The SR engine is a new medium-size, all aluminum (cylinder block, head, rocker cover and oil pan) in-line 4-cylinder gasoline powerplant developed as a replacement for CA engine in Nissans compact passenger cars. The development aim set for this engine was to achieve excellent power output and ample torque in the middle-and high-speed ranges, as well as a clear, linear engine sound up to the red zone. These performance targets have been achieved through the use of the 4-valve-per-cylinder DOHC design featuring a Y-shaped valve rocker arm system. This system allows a straight intake port for high power output and a narrow valve angle for a compact combustion chamber. The result is ample torque output as well as good fuel economy.

Engine Design Concept

In the last few years, the tendency was to increase the displacement of power unit for compact passenger car to 2.2 to 2.4 1 to increase the driving power. However, we dared to choose 2.0 1 for the G20. This was an excellent choice because it allowed its highly efficient 2.0 1 engine to be combined with compact design, good adaptability to future emission control regulation, and a high degree of driving pleasure. In the development of this engine, special emphasis was placed on the two following points. 1. A good balance between high output and fuel economy. 2. A pleasant engine sound at all stages from idling to its highest rpm. To achieve these goals, Nissan spared no effort, even going beyond their most modem technologies, to design an engine and to select outstanding: parts; thus, a car was created which completey satisfies the above requirements.

THE G20 is added INFINITI channel sthird 1991 model to the North American and Canada area. The G20 concept centers on driving pleasurs, and the model was designed as a sport/luxury sedan. lie main aim was to develop an outstanding power unit with low fuel consumption, ample torque and a pleasant engine sound. This was realized by the SR20DE engine, which was designed simultaneously with the G20 model.

2 Table 1. MAJOR SPECIFICATIONS

Type :Water cooling gasoline 4 cycle Number of cylinder, arrangent Type of combrustion chamber Valve mechanism Displacement Bore x stroke Bore pitch Block height Compression ratio Crankshaft journal dia Crankpin dia Connecting rod length Valve dia Fuel system Recommended fuel Emission control system Max power Max torque Dimension(LxWxH) :Cross flow, pent roof type :DOHC4 valve per cylinder,chain drive :1998cc(l22cuin) :86.0x86.0 :97.0 :211.3 :9.5 :55.0 :48.0 :136.3 :Int 34.0,Exh30.0 :Multi point injection,ECCS :Unleaded regular :TWC+ramda control +EGR+EM :140hp/6400rpm(SAE net) :1321b.ft/4800rpm(SAE net) :685x610x615 :4, in line

901714

Overview of the SR20DE engine

A cross-section of the SR20DE engine is shown in Fig.2. Its basic construction and special features are described below. To achieve light weight, an aluminum cylinder block is used. The upper deck is closed, and the skirt is deep. The combustion chamber is of the compact pentroof type with crossflow, and the spark plug is located in the center of the chamber. Two valves each have been provided for intake and exhaust. The valve angle is a narrow 29 degrees. The intake

Fig. 1. 3-VIEW OUTLINE DRAWINGS

901714 port is straight, mid an aerodynamic intake port (AD port) is provided. To achieve the highest possible valve lift in the valve train, a rocker arm system adopted, and as the end pivot interferes due to the straight configuration of the intake port, Y-shaped rocker arms were used. The camshafts are driven by single roller chains; the tensioner achieve high reliability and exceptional quietness by the combined use of oil pressure and springs. To enhance the rigidity of the coupling between the cylinder block and the transmission, an oil pan made from aluminum is used. To prevent damage to the bottom part it is divided and formed from sheet metal. This also facilitates maintenance considerably. The thermostat was placed ahead of the water pump and keeps the water temperature at the engine inlet at a fixed level. By employing a special passage to return oil in the aluminum oil pan and a large oil separator, it was possible to obtain excellent separation of the oil and the blowby gas even at high rpms and under heavy loads. It is prevents oil deterioration and extends the time interval between oil changes.

Output Performance and Fuel Economy 1.Combustion Chamber Design

To combine high power with good fuel economy we started with our design of combustion chamber. To improve thermal efficiency and to attain steady combustion, a compact pentroof shape was selected for the combustion chamber, and for uniform propagation of the flame, the spark plug was located in the center. To make the area of the valve openings as large as possible, 4 valves-namely two valves for the intake and two valves for exhaust were provided; to reduce heat losses, efforts were made to reduce the valve angle. The angle was made as small as 29 degrees. (for the result refer to Fig.4)

2.Intake Port Design

After designing the combustion chamber, me designed the intake port. The straight intake port was selected to reduce resistance and to allow intake of the largest possible amount of air. This is the so-called high port configuration which serves

Fig. 3. Fig. 2. CUTWAY VIEW 3-D VIEW OF COMBUSTION CHAMBER AND VALVE GEAR TRAIN

901714

Fig. 4. EFFECTS ON FUEL CONSUMPTION BY VALVE ANGLE to narrow the angle formed by the valve center and port center lines. The comparatively great length of the port is effective in improving torque in the low and medium speed ranges. (for the result refer to Fig.5) It was possible to make the port 450 mm long without increasing the overall hight of the engine by the designing it as a downward port holding the collector. At the same time, the overhang of heavy weight items could be reduced, and so vibrations could be lessened. An aerodynamic reduced, port (AD port) was used as it reduces the port diameter in the direction from the collector towards the valve. This is the same method as applied for 300ZX,VG30DE and Q45,VH45DE.

Fig. 5. EFFECTS ON OUTPUT TORQUE BY INTAKE PORT DESIGN

4. Exhaust design

The exhaust system was designed last. An increase in the opening area was made possible by two exhaust valves and increased lift induced by the rocker arm. To suppress the influence of exhaust pulsation, exhaust manifolds 1 and 4, and manifolds 2 and 3 were combined into a dual manifold. The dual part of the exhaust pipe extends until the rear part of the oil pan.

3.Design of the Valve Gear Train

The lift of the intake valve was increased to raise the efficiency of the air intake. For this purpose the rocker arm type was selected, because direct drive valves limit the tappet size. To make a small valve angle possible, the end pivot has to be placed outside the valve. However, this leads to interference with the intake port. This problem was overcome by using a Y-shaped rocker arm and by placing the end pivot between the intake ports. This Y-shaped rocker arm has another advantage: it reduce the contact area of the cam followers and also allows a reduction of the inertial weight so that the friction of the valve gear train is lowered.

Fig. 6. Y-SHAPED ROCKER ARM

901714

Table 2. COMPARISON OF GAINS AND LOSSES BY TYPE OF VALVE OPERTING SYSTEM

All these details enable the SR20DE engine to attain high output of 140 HP / 6400rpm and 132 lb ft / 4800 rpm while registering simutaneously favorable consumption figures of 32 mpg in highway mode and 24mpg in city mode. (G20,M/T, 91my)

Fig. 7. OUTPUT POWER AND TORQUE

901714

Fig. 8. 0-60mph ACCELERATING TIME (SEC)

Comfortable Sound Characteristics

During the development of the SR20DE engine, great importance was placed not only on reducing the sound pressure level but also an improvement the sound tone and quality, which are important for sensory impressions. To create a pleasant engine sound, the sound components produced by the even-number order (2nd,4th,6th...) in a 4-cylinder in-line engine are of great importance. If the difference between the sound component levels of the odd-numberd and evennumberd order is a flat, a unpleasant feeling is obtained. If in addition the level of the intermediate components is high, a rumbling sound is generated. For this reason, during the design of the SR20DE special care was taken to enhance the rigidity of the engine itself as well as the rigidity of die power train which consists of the connected engine and a transmission. Concretely, a closed-deck aluminum cylinder block, a bearing beam, and an aluminum oil pan were adopted and die engine itself made of closed contruction to improve rigidity. Thanks to these measures, it was possible to reduce the intermediate sound components and those from the odd numberd order. (for the results, refer to Fig. 11) To enhance the power train rigidity even further, the transmission was connected over its whole Fig. 9. MAIN PARTS FOR PROVIDING PLEASING SOUND

Fig. 10. COMPARISON OF FREQUENCY RESPONSE OF POWER PLANT

901714

Fig. 11. 3-D MAP OF VIBRATION

circumference to the engine by 10 bolts togther with giving a conical shape to the extreme end of the cylinder block and of the alumnium oil pan. Through these measures, the resonance frequency could be raised to more than 250 Hz and sudden increases in sound pressure were suppressed up to 7500 rpm. (for the results, refer to ihg. 10) To reduce the basic vibration, the crank-shaft has been fully balanced by 8 counter weghts and by forged steel. Crank pully with dynamic damper has been used to suppress die twisting resonance of the crank-shaft. Besides, in line with the efforts for precise tuning, the air cleaner capacity was enlarged, and one Helmholtz type resonatir each was placed before and after the air cleaner to reduce intake noise.

of the distributor, the necessary secondary voltage for up to 7500 rpm is amply available, and to the use of platinum tips spark piugs, dont have to be changed and gaps need not be adjusted for up to 60,000miles. Cylinder head bolts are tightened in the plastic zone to reduce variations in axial force, thus raising reliability. Beside, high reliability in the water or oil seal parts was obtained by liquid packings, which were used nearly everywhere. Blowby gas is perfectly processed even a high rpm and under heavy loads so that the interval between oil changes could be extanded. 7000-->7500 miles.

2.Engine Control and Fuel System Other Features 1.Reliability and Maintenance Free Operation

Because a single roller chain with hydraulic tensioner drives the camshaft, adjustment and change have become superfluous. It has become standard practice to use a timing belt as the camshaft driving method but Nissan selected the roller chain drive for greater reliability. This has also been use in the VH45DE for the INFINITI Q45. Thanks to the large size A fully sequential, multipoint injection system for 4 cylinders with centraized electronic control (ECCS) was adopted. Bottom feed type injectors with high heal resistance were used, and a hot film type and bypass system air flow meter used. The emission controls consist of a three-way catalyzer plus a closed loop lamda control and EGR+EAI system. The 16-bit central controller unit reguiates all of the following; the air-fuel ratio with learning control by O2 senser and air frow meter. the ignition timing control, knock control, and the supplementary air during idling with learning control included. (Fig. 12)

901714

Conclusion

Nissan spent about 3 years developing the SR20DE engine. At the same time, several variation (SR20DET, SR20DI, SR18DE, and SRI8DI) were also developed. All these will be the main engine for compact passenger car produced by Nissan in the 1990s. Amongst all these engines, SR20DE, which will be installed in the INFINITI G20, is the best balbnced engine in the SR series. We believe that the goal of this development, namely a good balance between high performance and fuel economy combined with a pleasant engine sound, has been attained by the design technique of the 4 valve DOHC engine which Nissan has been cultivating over many years, and by the solid reliability built into this car by Nissans production technology. It is expected that in line with the CAFE regulations, new requests for better fuel utilization and for cleaner emissions will be made to this type of car, and we shall continue to meet these demands to supply the market with better and improved engines. Thank you giving us this opportunity to introduce the SR20DE engine.

Acknowledgment

The authors would like to express thier appreciation for being given this opportunity to introduce the new SR engines. The development of these new engines owe much to the enormous efforts and enthusiasm of many people in Nissans R&D division both in Japan and overseas as well as in the manufacturing, sales and public relations departments. The successful development of these high-performance engines depended to a great extent on their hard work and wealth of experience, engineering skills and expertise. The authors would like to take this opportunity to thank everyone within and outside the company who contributed so much to the development, manufacture and marketing publicity for the new SR engines.

Fig. 12. ENGINE CONTROL SYSTEM

This paper is subject to revision. Statements and opinions advanced in papers or discussion are the authors and are his responsibility, not SAEs; however, the paper has been edited by SAE for uniform styling and formal. Discussion will be printed with the paper if it is published in SAE Transactions. For permission to publish this paper in full or in part, contact the SAE Publications Division.

Persons wishing to submit papers to be considered for presentation or publication through SAE should send the manuscript or a 300 word abstract of a proposed manuscript to: Secretary, Engineering Activity Board, SAE. Printed in U.S.A.

Você também pode gostar

- Hormone Replacement Therapy Real Concerns and FalsDocumento13 páginasHormone Replacement Therapy Real Concerns and FalsDxng 1Ainda não há avaliações

- Torque Specifications For 1990-1994 DSMS: Picture From: Http://Rebelautoworxs - Ca/Index/Index - Php?Main - Page Index&Cpath 18Documento55 páginasTorque Specifications For 1990-1994 DSMS: Picture From: Http://Rebelautoworxs - Ca/Index/Index - Php?Main - Page Index&Cpath 18Oswaldo Castillo H.Ainda não há avaliações

- Acura RSX (02-06) Service Manual - Brakes OnlyDocumento27 páginasAcura RSX (02-06) Service Manual - Brakes OnlyWill Wolff-Myren67% (3)

- Haltech Platinum Sprint 500 ManualDocumento19 páginasHaltech Platinum Sprint 500 ManualDaniel Kurniawan67% (3)

- Honda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025Documento8 páginasHonda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025izalirunk100% (1)

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarNo EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarAinda não há avaliações

- Acura TSX 2004 Multiplex Integrated Control SystemDocumento55 páginasAcura TSX 2004 Multiplex Integrated Control Systemjorge antonio guillenAinda não há avaliações

- SM 43 PDFDocumento108 páginasSM 43 PDFsimon_someone217100% (1)

- Dodge Journey 2017 - Owner's ManualDocumento510 páginasDodge Journey 2017 - Owner's Manualandres camachin100% (1)

- Ek3 TovDocumento7 páginasEk3 TovJohn Patrick Sevilla100% (1)

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesAinda não há avaliações

- Aj6 Engineering IgnitionDocumento9 páginasAj6 Engineering IgnitionBo BoboAinda não há avaliações

- K - Series EngineDocumento10 páginasK - Series EngineMubeen Ahmed SiddiqueAinda não há avaliações

- Microsquirt Hardware 3.3Documento152 páginasMicrosquirt Hardware 3.3Amin Rolando Barraza LauraAinda não há avaliações

- Timing Belt Installation Honda CivicDocumento13 páginasTiming Belt Installation Honda Civickilofome05100% (1)

- Quality: Why Koni? Koni PhilosophyDocumento34 páginasQuality: Why Koni? Koni Philosophykreuzschluessel518100% (1)

- Evo7 GtaDocumento9 páginasEvo7 GtaBhirawich PholpokeAinda não há avaliações

- Rb30 Dohc: R32 & R33 Skyline Specific Last Update - This Guide Has Originated From The Following HUGE Thread On SAUDocumento10 páginasRb30 Dohc: R32 & R33 Skyline Specific Last Update - This Guide Has Originated From The Following HUGE Thread On SAUChris Mi-e Dor RomâniaAinda não há avaliações

- Macro Economics A2 Level Notes Book PDFDocumento33 páginasMacro Economics A2 Level Notes Book PDFMustafa Bilal50% (2)

- DTC P1381 Honda Civic PDFDocumento7 páginasDTC P1381 Honda Civic PDFHenrique CoelhoAinda não há avaliações

- Bilstein Off Road ShocksDocumento28 páginasBilstein Off Road ShocksBluEyedTigerAinda não há avaliações

- Bedienungsanleitung Owner'S Handbook Manuel D'Utilisation: ART. NR. 320531 2/98Documento32 páginasBedienungsanleitung Owner'S Handbook Manuel D'Utilisation: ART. NR. 320531 2/98josit31415Ainda não há avaliações

- TURBO-Buick V6 Turbo Intro 780413Documento21 páginasTURBO-Buick V6 Turbo Intro 780413T Smi100% (1)

- LOMA FLMI CoursesDocumento4 páginasLOMA FLMI CoursesCeleste Joy C. LinsanganAinda não há avaliações

- Esp-2000 BSDocumento6 páginasEsp-2000 BSByron LopezAinda não há avaliações

- 2001 EM To 2004 EM Front Conversion - Honda Civic ForumDocumento5 páginas2001 EM To 2004 EM Front Conversion - Honda Civic ForumoneshashpleaseAinda não há avaliações

- MTX-L Digital Air/Fuel Ratio Gauge User ManualDocumento16 páginasMTX-L Digital Air/Fuel Ratio Gauge User ManualSebastian Esteban Cordova ToroAinda não há avaliações

- VISCOLAM202 D20 Acrylic 20 Thickeners 202017Documento33 páginasVISCOLAM202 D20 Acrylic 20 Thickeners 202017Oswaldo Manuel Ramirez MarinAinda não há avaliações

- Honda Accord Tourer 7th Gen Facelift AccessoriesDocumento16 páginasHonda Accord Tourer 7th Gen Facelift AccessoriesAOCUKAinda não há avaliações

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocumento13 páginasAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyAinda não há avaliações

- Mazda RX 8 Series II Workshop Manual (Preview)Documento6 páginasMazda RX 8 Series II Workshop Manual (Preview)Amip FolkAinda não há avaliações

- Suzuki DT15 (1986-1988)Documento39 páginasSuzuki DT15 (1986-1988)Suministros Lasser100% (1)

- 4-Door Except Si Model: Component Location IndexDocumento35 páginas4-Door Except Si Model: Component Location IndexPIKO MOBAinda não há avaliações

- Yaris: It Can Run. But It Can't HideDocumento14 páginasYaris: It Can Run. But It Can't HideabyzenAinda não há avaliações

- Lotustoyota2zz FinalDocumento8 páginasLotustoyota2zz FinalManuel Elias Espinoza HuamanAinda não há avaliações

- Building a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendNo EverandBuilding a WWII Jeep: Finding, Restoring, & Rebuilding a Wartime LegendAinda não há avaliações

- CHAPTER I KyleDocumento13 páginasCHAPTER I KyleCresiel Pontijon100% (1)

- Mathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenDocumento7 páginasMathematical Method For Physicists Ch. 1 & 2 Selected Solutions Webber and ArfkenJosh Brewer100% (3)

- Search Results: Screen Reader Users, Click Here To Turn Off Google InstantDocumento4 páginasSearch Results: Screen Reader Users, Click Here To Turn Off Google InstantMohammad Nazreen100% (1)

- Zspeedracing Master Catalogue 2008Documento13 páginasZspeedracing Master Catalogue 2008api-3863246100% (1)

- Mitsubishi Model IdentificationDocumento8 páginasMitsubishi Model IdentificationHameed100% (1)

- HONDA 2007 Civic Sedan Owner's Manual (Unlinked)Documento314 páginasHONDA 2007 Civic Sedan Owner's Manual (Unlinked)UndertakerAinda não há avaliações

- 2007 Impreza WRXDocumento21 páginas2007 Impreza WRXEdgar Gomez GarciaAinda não há avaliações

- Design Specifications: Item Measurement Qualification SpecificationDocumento6 páginasDesign Specifications: Item Measurement Qualification SpecificationDoc ImportAinda não há avaliações

- Transmission/Transaxle Technical DataDocumento3 páginasTransmission/Transaxle Technical DataDany MartiinezAinda não há avaliações

- 2002 Suzuki XL-7 4wd WagonDocumento1 página2002 Suzuki XL-7 4wd WagonAnon BoletusAinda não há avaliações

- 4AG TuneDocumento9 páginas4AG TuneMohd Hatta100% (1)

- 2000 Buick Regal Diagramas de VacioDocumento23 páginas2000 Buick Regal Diagramas de VacioRubenAinda não há avaliações

- R33 GTR Workshop FAST Search AbleDocumento255 páginasR33 GTR Workshop FAST Search AbleNikel87Ainda não há avaliações

- HKS EVC 6 ManualDocumento52 páginasHKS EVC 6 Manualkai_isman67% (3)

- Fog Ligth Toyota Corolla 2006Documento2 páginasFog Ligth Toyota Corolla 2006tsuelectronicoAinda não há avaliações

- Rear Light Removal & Earthing FixDocumento6 páginasRear Light Removal & Earthing FixKároly Dávid NyulasiAinda não há avaliações

- DSM Tuning Sheet v2.1Documento15 páginasDSM Tuning Sheet v2.1Ultraman NexusAinda não há avaliações

- WRX Glass AdjustmentDocumento6 páginasWRX Glass AdjustmentsoulmobileAinda não há avaliações

- Gearboxes CodesDocumento1 páginaGearboxes CodesAzlan Ahmad100% (1)

- Specifications: Standards and Service LimitsDocumento22 páginasSpecifications: Standards and Service Limitscarlosm6669Ainda não há avaliações

- DC2 Spoon Spec SheetDocumento4 páginasDC2 Spoon Spec SheetDave_BAinda não há avaliações

- Manual Transmission Unit OverhaulingDocumento13 páginasManual Transmission Unit OverhaulingNadhirah Joha100% (1)

- Super Sel e - G (Iai 038C - V7) eDocumento266 páginasSuper Sel e - G (Iai 038C - V7) eEudel TeyAinda não há avaliações

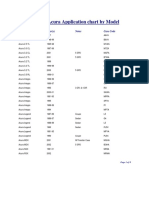

- Acura Honda Application Chart by ModelDocumento4 páginasAcura Honda Application Chart by Modeljesus perezAinda não há avaliações

- Volkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPDocumento33 páginasVolkswagen Jetta, Golf, GTI 1999, 2000 2.8 Liter VR6 2V Engine Mechanical, Engine Code(s) : AFPBoris StoyanovAinda não há avaliações

- Alfa 33 Workshop Manual EngDocumento378 páginasAlfa 33 Workshop Manual Engwi$ardAinda não há avaliações

- Dragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)No EverandDragon Days: The story of Miss Bardahl and the 1960s kids who loved hydros (2020 edition)Ainda não há avaliações

- Project Charger: The Step-By-Step Restoration of a Popular Vintage CarNo EverandProject Charger: The Step-By-Step Restoration of a Popular Vintage CarAinda não há avaliações

- Acm Queue PDFDocumento12 páginasAcm Queue PDFShubham Anil ShahareAinda não há avaliações

- English ExerciseDocumento2 páginasEnglish ExercisePankhuri Agarwal100% (1)

- 2062 TSSR Site Sharing - Rev02Documento44 páginas2062 TSSR Site Sharing - Rev02Rio DefragAinda não há avaliações

- English Literature Coursework Aqa GcseDocumento6 páginasEnglish Literature Coursework Aqa Gcsef5d17e05100% (2)

- Lab 08: SR Flip Flop FundamentalsDocumento6 páginasLab 08: SR Flip Flop Fundamentalsjitu123456789Ainda não há avaliações

- Asin URL Index URL/keyword DomainDocumento30 páginasAsin URL Index URL/keyword DomainStart AmazonAinda não há avaliações

- Miso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsDocumento8 páginasMiso Soup Miso Soup Miso Soup: Ingredients Ingredients IngredientsEllie M.Ainda não há avaliações

- I. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SADocumento2 páginasI. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SAMuhamad KhoerulAinda não há avaliações

- Steinecker Boreas: Wort Stripping of The New GenerationDocumento16 páginasSteinecker Boreas: Wort Stripping of The New GenerationAlejandro Javier Delgado AraujoAinda não há avaliações

- Strategi Meningkatkan Kapasitas Penangkar Benih Padi Sawah (Oriza Sativa L) Dengan Optimalisasi Peran Kelompok TaniDocumento24 páginasStrategi Meningkatkan Kapasitas Penangkar Benih Padi Sawah (Oriza Sativa L) Dengan Optimalisasi Peran Kelompok TaniHilmyTafantoAinda não há avaliações

- Preprints201808 0216 v1Documento15 páginasPreprints201808 0216 v1Baptista Jaime MilioneAinda não há avaliações

- Standards Guide 1021 1407Documento8 páginasStandards Guide 1021 1407Anjur SiAinda não há avaliações

- CivilCAD2014 English Rev1Documento443 páginasCivilCAD2014 English Rev1Nathan BisAinda não há avaliações

- W1 - V1 MultipleWorksheets SolnDocumento3 páginasW1 - V1 MultipleWorksheets SolnAKHIL RAJ SAinda não há avaliações

- Bylaws of A Texas CorporationDocumento34 páginasBylaws of A Texas CorporationDiego AntoliniAinda não há avaliações

- Topic 3 - Analyzing The Marketing EnvironmentDocumento28 páginasTopic 3 - Analyzing The Marketing Environmentmelissa chlAinda não há avaliações

- Copy - of - Commonlit - Meet The Fearless Cook Who Secretly Fed and Funded The Civil Rights Movement - StudentDocumento6 páginasCopy - of - Commonlit - Meet The Fearless Cook Who Secretly Fed and Funded The Civil Rights Movement - Studentlilywright08Ainda não há avaliações

- Digital Economy 1Documento11 páginasDigital Economy 1Khizer SikanderAinda não há avaliações

- MC0085 MQPDocumento20 páginasMC0085 MQPUtpal KantAinda não há avaliações

- Nodal Mesh AnalysisDocumento20 páginasNodal Mesh Analysisjaspreet964Ainda não há avaliações

- Kharrat Et Al., 2007 (Energy - Fuels)Documento4 páginasKharrat Et Al., 2007 (Energy - Fuels)Leticia SakaiAinda não há avaliações

- Pinto pm5 Tif 02Documento24 páginasPinto pm5 Tif 02Salem BawazirAinda não há avaliações

- How To Measure Light Levels and Lux LevelsDocumento4 páginasHow To Measure Light Levels and Lux LevelsAngelo PalamingAinda não há avaliações