Escolar Documentos

Profissional Documentos

Cultura Documentos

Introduction To Internal Combustion Engines.: Fundamentals of Engineering Thermodynamics ME 1052

Enviado por

Supun AmarasingheDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Introduction To Internal Combustion Engines.: Fundamentals of Engineering Thermodynamics ME 1052

Enviado por

Supun AmarasingheDireitos autorais:

Formatos disponíveis

Fundamentals of Engineering Thermodynamics ME 1052

Introduction to Internal Combustion Engines.

Name

: S.W.Amarasinghe

Index No.: 090019X Field : EE

Date of Practical : 30/09/2011

Introduction. The heat engines which are used in the world are mainly divided in to two main categories. They are external combustion engines and internal combustion engines. The external combustion engines burns the fuel outside the engine and the working fluid (ex: steam) is heated through a heat exchanger. The steam engines are external engines in which the steam is generated by the heat taken from a combustion chamber situated outside the engine. A fuel (eg: coal) is burned inside the furnace or combustion chamber. The external combustion engine is widely used in steam engine applications such as steam locomotives, steam boats, nuclear submarines.

In internal combustion engines the process of burning fuel is done with in the engine. The internal combustion engines are powered by petrol, diesel, hydrogen, methane, propane and etc. In the petrol engine the petrol gas mixture is sprayed to the cylinder, then compressed and then ignited by a spark caused by the spark plug. In the diesel powered IC engine the fuel is injected to the high pressured air. Due to the very high temperature in the pressured air, the fuel is self ignited.

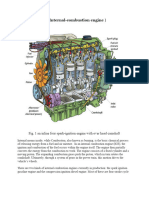

4 Stroke Spark Ignited Internal Combustion Engine

The main components of a 4 stroke engine are shown in the above diagram. Intake valve Allow the air fuel mixture to enter the cylinder. Exhaust valve Allow the exhaust gas to exit from the cylinder. Head The upper part of the engine which contains the valve assembly and spark plug. Coolant Remove the excess heat out from the cylinder. Usually water is used as coolant. Engine block The lower part of the engine which contains the crank shaft assembly. Oil sump The bottom of the engine which contains the lubricant. Cam shaft The asymmetric shaft used to trigger rocker arms to open and close the valves. Spark plug Produce the spark to ignite the fuel air mixture. Crank shaft Converts the vertical movement of the piston to a rotary movement. Connecting rod Connects the piston and crank shaft. Rocker arm Open and close the valves.

A single vertical movement of the piston in the cylinder is known as stroke. The 4 stroke cycle is consisting of four main strokes. Intake stroke This is also known as suction stroke. In this stroke the piston is moving downwards. The intake valve is opened during this stroke and hence the air fuel mixture is sucked in to the cylinder. The system is open in this stroke. Compression stroke The piston moves upwards in this stroke. The intake and exhaust valves are closed. The fuel air mixture captured in the cylinder is compressed to a volume 7:1 in this stroke. The mixture is compressed to the clearance space of the cylinder at the end of this stroke. The system is close in this state. Power stroke The compressed fuel air mixture is ignited by the spark from the spark plug. The spark is generated before the piston is reached to the top dead center. Then the ignition is occurred and the power produced by the blast drives the piston downwards. Valves are closed and system is close in this state. Exhaust stroke. The piston moves upwards. The exhaust valve is opened and the exhaust gas in the cylinder is going out. It takes two cycles to complete the four strokes. The power stroke is occurring only once within these two cycles. The ignition of spark plug is coordinated with the piston movement from a separate ignition system. The petrol is usually used as the fuel in this type engines. These engines are used to low power applications with low vibration levels.

In this compressed ignition engine, the air is drawn to the cylinder in the intake stroke and air is compressed. The diesel is injected to the compressed air. Due to the high temperature in the compressed air the diesel is self ignited within the cylinder causing the power stroke. The air is compressed to a volume ratio of 15:1 in order to get the high pressure. Special fuel injecting mechanism is employed in these engines. When the engine is starting a preheating of the cylinder is needed in order to achieve the ignition temperature. The basic components of the engine are same as in the spark ignited engine. The spark plug is replaced by a diesel injector in compression ignition engine. The engine parts are made much stronger because the power of ignition is much higher than the spark ignited petrol engine. The main advantage of diesel engine is the inexpensive fuel. Then the cost difference between diesel fuel and petrol reaches the 20% level even the owners of expensive cars start to save. The fuel efficiency of diesel engines is 36% and higher. The efficiency of petrolpowered engine is only 25% that means that the diesel engine wastes less fuel than the petrolpowered engine. The diesel engine as compared to the petrol-powered engine of the equal volume of combustion chamber has advantage of higher torque. It is critically important for minivans and station wagons. No alternative engines are mounted now on trucks. High torque helps in the city traffic; it allows moving on minimal engine turnover in traffic jams.

Two Stroke engine

The two stroke engine cylinder has no valves as in a conventional four stroke engine. Intake and exhaust are accomplished by means of ports - special holes cut into the cylinder wall which allow fuel-air mixture to enter from the crankcase, and exhaust to exit the engine. These ports are uncovered when the piston is in the down position. Air-fuel mixture is drawn into the crankcase from the carburetor. When the piston is forced down, the exhaust port is uncovered first, and hot exhaust gases begin to leave the cylinder. As the piston is now in the down position, the crankcase becomes pressurized, and when the intake port into the cylinder is uncovered, pressurized air-fuel mixture enters the chamber. Both the intake and exhaust ports are open at the same time, which means the timing and air flow dynamics are critical to proper operation. As the piston begins to move up, the ports are closed off, and the air-fuel mixture compresses and is ignited; the hot gases increase in pressure, pushing the piston down with great force and creating work for the engine. The two-stroke type of internal combustion engine is typically used in utility or recreational applications which require relatively small, inexpensive, and mechanically simple motors (chainsaws, jet skis, small motorcycles, etc).

Reference [1] http://www.animatedengines.com

[2] http://en.wikipedia.org/wiki/Two-stroke_engine

Você também pode gostar

- Diesel Automotive Engines: Energy and Power Technology TextbookDocumento32 páginasDiesel Automotive Engines: Energy and Power Technology TextbookSrinivas EedaraAinda não há avaliações

- Internal Combustion EnginesDocumento32 páginasInternal Combustion Enginespramodkb_cusatAinda não há avaliações

- Diesel and Petrol Engines ReportDocumento8 páginasDiesel and Petrol Engines ReportJonathan MalamulaAinda não há avaliações

- 4 Stroke Petrol Engine Cut ModelDocumento9 páginas4 Stroke Petrol Engine Cut ModelZahid MughalAinda não há avaliações

- Internal Combustion Engine ProcessesDocumento80 páginasInternal Combustion Engine Processeschoongwenkang100% (1)

- ICE (Internal Combustion Engine)Documento22 páginasICE (Internal Combustion Engine)johnlloydsantossssAinda não há avaliações

- IC EnginesDocumento8 páginasIC EnginesNo MIAinda não há avaliações

- First Semester:-Course Title: Applied Thermodynamics TopicDocumento8 páginasFirst Semester:-Course Title: Applied Thermodynamics TopicHafeez AliAinda não há avaliações

- Asi Unit 3Documento21 páginasAsi Unit 3Raja RamAinda não há avaliações

- How Does An Internal Combustion Engine Work?Documento5 páginasHow Does An Internal Combustion Engine Work?AsraAinda não há avaliações

- Diesel Automotive Engines Chapter 14Documento32 páginasDiesel Automotive Engines Chapter 14Abdallah MansourAinda não há avaliações

- Lesson V Automobile Engine, and The Four-Stroke CycleDocumento5 páginasLesson V Automobile Engine, and The Four-Stroke CycleNicolas AntiguaAinda não há avaliações

- Assignment-1: Types of EngineDocumento14 páginasAssignment-1: Types of EngineRaj SinghAinda não há avaliações

- Working of I.C EnginesDocumento14 páginasWorking of I.C EnginesHammad Hassan100% (5)

- Gasoline EngineDocumento6 páginasGasoline EngineJonan TutaanAinda não há avaliações

- Applied Thermal Engineering: Prof. K. K.SHARMADocumento69 páginasApplied Thermal Engineering: Prof. K. K.SHARMAKaran100% (1)

- Artifact 4 Parts Small Engines PowerpointDocumento56 páginasArtifact 4 Parts Small Engines Powerpointapi-240922530Ainda não há avaliações

- Unit-3: Diesel Power Plant LayoutDocumento12 páginasUnit-3: Diesel Power Plant LayoutPavankumar PavankumarpvAinda não há avaliações

- 4 STROKE PETROL ENGINE ArsalDocumento5 páginas4 STROKE PETROL ENGINE ArsalMuhammad Arslan AfzalAinda não há avaliações

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocumento9 páginasPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalAinda não há avaliações

- Diesel Engine Tune Up GuideDocumento10 páginasDiesel Engine Tune Up GuideMaher MarquezAinda não há avaliações

- Parts and Working of Four Stroke Petrol EngineDocumento6 páginasParts and Working of Four Stroke Petrol EngineHafeez AliAinda não há avaliações

- Ic Engines: Four Stroke Cycle Diesel EnginesDocumento11 páginasIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meAinda não há avaliações

- Experiment # 6Documento5 páginasExperiment # 6Farhan AliAinda não há avaliações

- Experiment 1Documento9 páginasExperiment 1Mehar HamzaAinda não há avaliações

- Motori e Biofuel ENGDocumento3 páginasMotori e Biofuel ENGIrene FranchinAinda não há avaliações

- Diesel Power PlantDocumento47 páginasDiesel Power PlantRajput Divyapratap Singh Chauhan0% (1)

- Lab ReportDocumento7 páginasLab Reportshah_gen89Ainda não há avaliações

- Thermodynamics Lab ReportDocumento49 páginasThermodynamics Lab Reportjawad60% (5)

- Auto Material EngineDocumento36 páginasAuto Material EngineHardik ShahAinda não há avaliações

- 2-stroke petrol engine seminar reportDocumento13 páginas2-stroke petrol engine seminar reportEr Raghvendra SinghAinda não há avaliações

- Lect 2Documento13 páginasLect 2khalid mustafaAinda não há avaliações

- Meec Prelim CompilationDocumento16 páginasMeec Prelim CompilationBen Aldrian IbañezAinda não há avaliações

- Me 56Documento9 páginasMe 56RhizhailAinda não há avaliações

- Final Project Mechanical PowerDocumento163 páginasFinal Project Mechanical PowerVikrant KumarAinda não há avaliações

- Theory of Engine OperationDocumento19 páginasTheory of Engine OperationGabriel Dela Cruz LagmanAinda não há avaliações

- Engine Part IDocumento39 páginasEngine Part Iaashish koiralaAinda não há avaliações

- Farm Machinery Internal Combustion EnginesDocumento67 páginasFarm Machinery Internal Combustion Engineschoongwenkang100% (2)

- Ic EngineDocumento27 páginasIc EngineSRL MECHAinda não há avaliações

- 4 Stroke Diesel Engine ArslanDocumento5 páginas4 Stroke Diesel Engine ArslanMuhammad Arslan AfzalAinda não há avaliações

- 1514285118329-Notes ALP InductionDocumento97 páginas1514285118329-Notes ALP InductionKhirod SahuAinda não há avaliações

- Below Is An Overview of The Fuel System Intake OperationDocumento8 páginasBelow Is An Overview of The Fuel System Intake OperationchigauAinda não há avaliações

- 4-2-SDocumento142 páginas4-2-SMuhammad RazaAinda não há avaliações

- Assign#1 Thermo Lab. 2019p-ME-18Documento8 páginasAssign#1 Thermo Lab. 2019p-ME-18Abdul Rasheed GhaziAinda não há avaliações

- 1.FSAE Turbocharger Design and ImplementationDocumento27 páginas1.FSAE Turbocharger Design and ImplementationJoy NagAinda não há avaliações

- Experiment No 11Documento6 páginasExperiment No 11ayesha amjadAinda não há avaliações

- I.C EnginesDocumento23 páginasI.C EngineskolappanAinda não há avaliações

- Four Stroke Petrol Engine: What Is An Engine?Documento4 páginasFour Stroke Petrol Engine: What Is An Engine?UsamaAinda não há avaliações

- Engine and TransmissionDocumento26 páginasEngine and TransmissionWFilmy STARAinda não há avaliações

- Lab Report 12Documento8 páginasLab Report 12mamoona noreenAinda não há avaliações

- Differences Between Petrol and Diesel EnginesDocumento48 páginasDifferences Between Petrol and Diesel EnginesSafiullah MangrioAinda não há avaliações

- Propulsion Lab 1Documento4 páginasPropulsion Lab 1Muhammad Ishaq KhanAinda não há avaliações

- Operating Principle of Diesel and Petrol EnginesDocumento8 páginasOperating Principle of Diesel and Petrol EnginesJonathan MalamulaAinda não há avaliações

- Prepared By: Muhammad Hilmi Bin ZaidDocumento44 páginasPrepared By: Muhammad Hilmi Bin ZaidTimothy Del Valle100% (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiNo EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiAinda não há avaliações

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)No EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Ainda não há avaliações

- Learn to Drive: Everything New Drivers Need to KnowNo EverandLearn to Drive: Everything New Drivers Need to KnowNota: 4 de 5 estrelas4/5 (1)

- Pneumatic Control SystemsDocumento4 páginasPneumatic Control SystemsSupun AmarasingheAinda não há avaliações

- Breakdown Characteristics of Air GapsDocumento9 páginasBreakdown Characteristics of Air GapsSupun Amarasinghe100% (6)

- Breakdown Characteristics of Air GapsDocumento9 páginasBreakdown Characteristics of Air GapsSupun Amarasinghe100% (6)

- Numarical RelayDocumento4 páginasNumarical RelaySupun AmarasingheAinda não há avaliações

- Shimano Tourney Rear and Knob AdjustmentDocumento1 páginaShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetAinda não há avaliações

- Bell430 MM CH07Documento10 páginasBell430 MM CH07ame.venkyAinda não há avaliações

- Spare Parts Manual 059459 - LTM - 1070!4!1Documento960 páginasSpare Parts Manual 059459 - LTM - 1070!4!1Dmitrij Lukin100% (1)

- Emerson Spur Gear Selection GuideDocumento25 páginasEmerson Spur Gear Selection GuideIneedsolutionsAinda não há avaliações

- Wet SumpingDocumento3 páginasWet SumpingBimal Amarnath MenonAinda não há avaliações

- Yamaha - Rabeta PDFDocumento41 páginasYamaha - Rabeta PDFDiogo RibeiroAinda não há avaliações

- Iso 1585 2020 en PDFDocumento11 páginasIso 1585 2020 en PDFBraulio Gutierrez PimentaAinda não há avaliações

- Unit 1 Clutch and Gearbox GuideDocumento5 páginasUnit 1 Clutch and Gearbox GuideSathis Kumar67% (12)

- Ef1000b 7XD2 2003Documento25 páginasEf1000b 7XD2 2003CRISTIAN BARRIOSAinda não há avaliações

- Winchester Model 61Documento23 páginasWinchester Model 61Herbert Menendez HuezoAinda não há avaliações

- Catalogo E60HDocumento68 páginasCatalogo E60Hjorge alonsoAinda não há avaliações

- Yamaha R6 2003 Workshop ManualDocumento434 páginasYamaha R6 2003 Workshop ManualLeonard Gingell100% (2)

- OEM National 9-P-100Documento8 páginasOEM National 9-P-100David VilchesAinda não há avaliações

- Price List of Newage CablesDocumento1 páginaPrice List of Newage CablesAmeer HamzaAinda não há avaliações

- Huafengdongli 495 4100 Series OperationmanualDocumento7 páginasHuafengdongli 495 4100 Series Operationmanualdaryl100% (26)

- Pump ToolsDocumento1 páginaPump ToolsNaing Min HtunAinda não há avaliações

- Abstract of ASME B1.13M 1995Documento26 páginasAbstract of ASME B1.13M 1995Jesse ChenAinda não há avaliações

- 5.3 Cruise Control: 5.3.1 OperationDocumento9 páginas5.3 Cruise Control: 5.3.1 OperationdinhvuAinda não há avaliações

- Construction STD DWG Part OneDocumento52 páginasConstruction STD DWG Part Oneinsan_soft6498Ainda não há avaliações

- Xr5 JK 2021 VersionDocumento18 páginasXr5 JK 2021 VersionLuis CuberoAinda não há avaliações

- Front Carrier AssembliesDocumento213 páginasFront Carrier AssembliesESRAAinda não há avaliações

- 01-10 Crank MechanismDocumento2 páginas01-10 Crank MechanismGem RAinda não há avaliações

- Kubota Tractor B21 Parts CatalogDocumento200 páginasKubota Tractor B21 Parts CatalogSAGAR GUPTAAinda não há avaliações

- Manual Instalacion de Transmisiones Evinrude E Tec 2010Documento50 páginasManual Instalacion de Transmisiones Evinrude E Tec 2010URIEL CABALLEROAinda não há avaliações

- MCC # 1N-B AutoCAD PDFDocumento52 páginasMCC # 1N-B AutoCAD PDFzmAinda não há avaliações

- Supporti Collari e U-BoltsDocumento28 páginasSupporti Collari e U-BoltsLupul50Ainda não há avaliações

- Range Rover Manual Service ToolsDocumento10 páginasRange Rover Manual Service ToolsLouise RogersAinda não há avaliações

- Gri Handbook InstallationDocumento2 páginasGri Handbook InstallationYetkin ErdoğanAinda não há avaliações

- Harga Baru 2022Documento46 páginasHarga Baru 2022Yudo bsskoroAinda não há avaliações

- PEUGEOT PARTS SPECIALISTSDocumento399 páginasPEUGEOT PARTS SPECIALISTShuynh lamaAinda não há avaliações