Escolar Documentos

Profissional Documentos

Cultura Documentos

04.343-Ago-2005 critério de aceitação solda

Enviado por

aldairlopes0 notas0% acharam este documento útil (0 voto)

4 visualizações8 páginas04.343-Ago-2005 critério de aceitação solda

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documento04.343-Ago-2005 critério de aceitação solda

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

4 visualizações8 páginas04.343-Ago-2005 critério de aceitação solda

Enviado por

aldairlopes04.343-Ago-2005 critério de aceitação solda

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 8

ICONTROLLED.

(2005)

(Continued)

we Eilanaton offem KES indie

Nef Hens (Definition) Glass Class 2 Casa]. Stal nates

ory Ei Thin jmmia itn dram in No palation Bead WR

£ = od width svidth cans the width

2.| 8 Toint flference _fiffeence 3 the postion of

2t/ 2 mm fom the

Z|” ppiterenceotbeat joint.

a: th WW

33 eight of bead ihn Tama Witkin mm in No ipalaion ead height

23 “ ight (eps) fi op) fens

33 Be it the position of

23/3¢ cue Omum from the

gj eo joint.

i

a a in pisces Within Spiess Pin hoks oF

onthe surface of et weld line of fer weld line of p2tam or more

welded portion [sn fm in length fbal ot be

lowed

7 : Trait—mnNo stipulation effective eg

=| . Bee Pee |=s gt dimension

z ae pe boar shall met leg

= pe jength L indicated

Re ae oper

Dimensions of the 4 — ~ =i |»

weld enforcement

4 SLOT O10 RELOFIROIS fReTOeIROD

However, the | However, tie | However, te

ing fx shall filing of x shall filing of x

30mm. fe .0mm. hall be 5.0mm

2|» ay Kees)

2 | 3 6 : ano

#| 3 is

| Eh Dimensions ofthe

E | weld reinforcement

i of [feos — iz aI — We

: However, the | However, the | However, thefhat the concave

: foiling etd shalt being of @shal being of degrades the

a e1.0mm fe 1Smm. hall be 2.0mm fippearance

juality (such as

be dump vessel),

ay nt be

llowed.-Thea it

Dimensions of the all be so noted

concave pte

DOCUMENTS

(DOCUMENTS CONTROLARO

CONTROLADC

— 8 MAR 2007

14 man 7008 T

7 ENG® DE PRODUTO

Established: August 1, 1991 Revised: August 31,2005

ONTROLLED

(2005)

6. DRAWING INDICATION Conform to Table 4.

Table 4

‘Application

Unitized lication

ems =o Point of indication Example of indicati

drawing

Quality fAllparts Welding quality shall be indicated on an [WELDING QUALITY TO CONFORM

per of left-hand portion in the ttle [TO KES 04.343,

lum.

f@sT [Required [The required class shall be indicated on APPEARANCE QUALITY OF WELD.

.g|2}0l8552_ parts only fn upper or left-hand portion inthe title [TO CLASS 2. ON ALL CHECK ITEMS.

lun.

8° Gass _| —— No inition aie naga ale =

S| [Class 1 [Required |The required class shall be indicated at [CLASS 1 ON STRENGTH QUALITY

3] E[Class2 parts only fhe end of a leader line fromthe weld [CLASS 1 ON APPEARANCE QUALITY

Ff required.

[Glass 3_| = No indication in the drawing as a rule, =

Remarks The actual class indication in part shall be determined after due consultation with the

department

involved.

7. INSPECTION AND TEST METHODS Conform to the following,

(1) Internal quality inspection of welds Conforming to KES 86.501

(2) Radiograph test Conform to KES 86.503 (RADIOGRAPHIC TESTING METHODS OF STEEL

WELDING), when a radiographic testis especially required.

Crack inspection for the external quality of welds Conform tothe following.

KES 86.505 (MAGNETIC PARTICLE TESTING METHODS)

@)

KES 86.504 (DYE PENETRANT TESTING METHODS)

4

Others The other standards forthe test methods of welds are as follows, which shall be used for

checking the welding quality of prototypes, and analyzing problem goods, a required.

KES 86.502 (DRILLING INSPECTION METHODS OF WELDING PENETRATION)

KES 86.500 (DESTRUCTIVE INSPECTION FOR INTERNAL DEFECTS OF STEEL WELDED.

PORTIONS)

DOCUMENT«

CONTR?

oo

14 ano 2008,

DOCUMENTO

CONTROLADO

8 MAR 2007

ENG®° DE PRODUTO

KOMATSU DO BRASIL LTDA

oabinid: Ang, 991 KOMATSU

Revised: August 31, 2005

Reference 1. Revised in 1988

DO}

CONTROLADO

14 wat 2008

2. Revised in 1990 (90-037)

3. Revised in 1991 (90-269)

4. Revised in 1998. (95-299)

5. Items revised in 2000 The leg length to be increased by the gap of fillet welding has been revised.

nd a note concemed with the gap limit for quality assurance bas been added in the remark column

(00-159),

Revised by ‘Tadashi Egawa, Hydraulic Excavator Development Group, Construction Equipment

Technical Center 1, Technical Division

6. Items revised in 2002 ‘The contents and descriptions have been reviewed according to the current

‘weld technology (01-032).

Revised by Liaison meeting of total welding quality masters

7. tems revised in 2005

(1) Inorder to prevent defects in the welding quality, notes on the effective throat depth have been.

added to the column for the gap in fillet welding in Table 2 (05-014),

(2) Regarding No. 11 “Shape of bead” in Table 3, the allowable width ofthe dimensions of the weld

reinforcement in butt and comer welding has been revised according to the current weld

technology (05-258).

‘The allowable width has been specified with reference to values of level B and level C in ISO.

5817:2003(Welding — Fusion-welded joints in steel nickel titanium and their alloys (beam

welding excluded) ~ Quality levels for imperfections).

8.Revised by Tetsuo Toda, Inspection Section, Quality Assurance Department, Osaka Plant,

Production Division

Kanji Katada, Manufacturing Engineering Development Center, Production Division

‘Mitsuhiro Kuroki, Technology Group, Material Technical Center, Development

Division

9. Keywords WELDING and QUALITY

UMENTO

DOCUMENTO

CONTROLADO

8 Mar 2007

ENG® DE PRODUTO

KOMATSU DO BRASIL LTDA

Col oH ser SoTOToOON ABE TSENT

KES QUALITY OF WELDS 343

w) (2005)

1. SCOPE This standard stipulates the quality of welds (heat-affected zones) as specified by KES 04.354

(STANDARD GROOVE DIMENSIONS AND FILLET LEG LENGTH OF WELDED JOINT).

However, in the case of spot welding and pulse TIG welding, the quality shall conform to KES 04. 344. 4

(QUALITY OF SPOT WELDED AREA) and KES 04. 341, 2 (QUALITY OF PULSED TIG WELDING

PORTION), respectively.

Moreover, this standard is not necessarily used when there isa technical foundation,

2. QUALITY DIVISION The quality division of welds is as follows.

2.1 Quality before welding Quality (quality of base metal and tack weld, etc.) in dimensional accuracy

controlled in weld processing.

2.2 Quality after welding To be divided into strength quality and appearance quality; the former specifies

guality to guarantee reliability and durability, and the latter specifies quality which would affect the product value

3. QUALITY GRADE Conform to Table 1

Table 4

_Examples of applicable portions

fo stipulation

[Functionally more important weld line (including safety items)

fWeld Hine important in strenggy

[Weld line i tin strength

eld fine other than in Class 1 and

‘onspicuous weld line on the cab, the machine cover, and the main fame,

1¢ am, the boom, the bucket, ec: of machine models requiring especially

sood appearance quality

for application, the approval of related de

‘Cualiy sion

Quay before weld

Strength quality of

welds

after welding,

Appearance quality

of welds

;ppearance quality, such asthe cab, the machine cover, the main frame, the

sm, the boom and bucket

eld line on the parts and portion of which the appearance Ts not especially

tant

4. PRECAUTIONS FOR QUALITY CLASS ASSIGNMENT When assigning the quality Class, ay

attention to the following items.

4.1 Dimensional accuracy influencing the quality before welding Conform to KES 04.052.4

(STANDARD GENERAL TOLERANCES FOR MACHINING DIMENSIONS) and KES 04.052.3 [GENERAL

DIMENSION TOLERANCE (STEEL PLATE, WELDMENT)].

4.2 Base metal quality influencing the quality after welding Conform to KES 04.052.75

[QUALITIES OF CASTING SURFACE (OF CAST STEEL PRODUCTS), KES 04.052.76 [QUALITY OF

MACHINED SURFACE (CASTING)] and KES 07.011 (GENERAL SPECIFICATIONS OF THE STEEL

MATERIAL),

Qual

ITO

CONTROLADO

14 Ma 2008

SUPRIMENTOS

KOMATSU 00 BRASIL LTDA

DOCUMENTO

CONTROLADO

8 MAR 2007

ENG? DE PRODUTO.

KOMATSU DO BRASIL LTDA

DOCUMENTO

CONTROLADO

18 MAI 2012

* DE PROCESSOS

gno

ecas.

[ett Ant KOMATSU

CONTROLLED.

(2005)

5. QUALITY The details of quality shall conform to Table 2.

Table 2

Unit_mm

os Dimen=

Cos lnems} Drawings |Welding method] Dimensions | sional Remarks

tolerance

ned electrode | aco] a2

« elding WE

mmi-automatic | 0

Você também pode gostar

- FICHA CADASTRAL EDITÁVEL CURYDocumento3 páginasFICHA CADASTRAL EDITÁVEL CURYaldairlopesAinda não há avaliações

- Dados Do Veículo: Esta Pesquisa Tem Caráter Apenas Informativo. Não É Válida Como CertidãoDocumento3 páginasDados Do Veículo: Esta Pesquisa Tem Caráter Apenas Informativo. Não É Válida Como Certidãoaxl153314Ainda não há avaliações

- Comprovante de EndereçoDocumento1 páginaComprovante de EndereçoNataliaasantosAinda não há avaliações

- Do Livro "Abrindo Portas Interiores" de Eileen CaddyDocumento40 páginasDo Livro "Abrindo Portas Interiores" de Eileen CaddyaldairlopesAinda não há avaliações

- Ensaio de Exposição À Luz para Componentes Do Habitáculo Do VeículoDocumento10 páginasEnsaio de Exposição À Luz para Componentes Do Habitáculo Do VeículoaldairlopesAinda não há avaliações

- Apostila de FeTrans - Parte 01Documento20 páginasApostila de FeTrans - Parte 01aldairlopesAinda não há avaliações

- Mensagens diárias de esperança e féDocumento40 páginasMensagens diárias de esperança e féaldairlopes75% (4)

- Mudar Cor Do Componente - CatiaDocumento2 páginasMudar Cor Do Componente - CatiaaldairlopesAinda não há avaliações

- Lista de Exercícios 01 FTBDocumento7 páginasLista de Exercícios 01 FTBaldairlopesAinda não há avaliações

- Proposta - Servi - o de Monitoramento de Normas.Documento1 páginaProposta - Servi - o de Monitoramento de Normas.aldairlopesAinda não há avaliações

- Lista de Exercícios 02 FTBDocumento2 páginasLista de Exercícios 02 FTBaldairlopesAinda não há avaliações

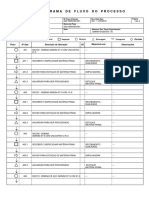

- Processo de recebimento e armazenamento de bobinasDocumento2 páginasProcesso de recebimento e armazenamento de bobinasaldairlopesAinda não há avaliações

- Exercícios de Transferência de Calor - Parte 2Documento2 páginasExercícios de Transferência de Calor - Parte 2aldairlopesAinda não há avaliações

- UntitledDocumento40 páginasUntitledaldairlopesAinda não há avaliações

- Resumo Abrindo Portas Interiores Eileen CaddyDocumento2 páginasResumo Abrindo Portas Interiores Eileen CaddyArthur Calaza0% (1)

- InstrucoesDocumento1 páginaInstrucoesAna Clara Feitosa TavaresAinda não há avaliações

- DIN 50125 Norma de Corpo de ProvaDocumento14 páginasDIN 50125 Norma de Corpo de ProvaNatan1912Ainda não há avaliações

- Cálculo ExatoDocumento1 páginaCálculo ExatoaldairlopesAinda não há avaliações

- Lista Materiais Elétricos - 01.09.22Documento1 páginaLista Materiais Elétricos - 01.09.22aldairlopesAinda não há avaliações

- Cálculo PPMDocumento1 páginaCálculo PPMaldairlopesAinda não há avaliações

- Folha de CadernoDocumento1 páginaFolha de CadernoaldairlopesAinda não há avaliações

- Cantares 1Documento1 páginaCantares 1aldairlopesAinda não há avaliações

- Declaração de união estável modeloDocumento1 páginaDeclaração de união estável modelorosevieiraAinda não há avaliações

- Tarefas - 12.09.2022Documento1 páginaTarefas - 12.09.2022aldairlopesAinda não há avaliações

- Apostila MS Project 2010Documento113 páginasApostila MS Project 2010Tharssia Baldasso100% (3)

- Última ConversaDocumento1 páginaÚltima ConversaaldairlopesAinda não há avaliações

- Uliana - 02-2013Documento1 páginaUliana - 02-2013aldairlopesAinda não há avaliações

- Uliana 01-2011Documento1 páginaUliana 01-2011aldairlopesAinda não há avaliações

- Processo de recebimento e armazenamento de bobinasDocumento2 páginasProcesso de recebimento e armazenamento de bobinasaldairlopesAinda não há avaliações