Escolar Documentos

Profissional Documentos

Cultura Documentos

Water Resources Engineering

Enviado por

nourDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Water Resources Engineering

Enviado por

nourDireitos autorais:

Formatos disponíveis

CVE 471 WATER RESOURCES ENGINEERING

DAMS

Assist. Prof. Dr. Bertu Akntu

Civil Engineering Program Middle East Technical University Northern Cyprus Campus

CVE 471 Water Resources Engineering

1/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

2/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

3/101

3. DAMS

Classification of Dams

A dam is an impervious barrier built across a watercourse to store water for several purposes:

water supply, creating head (energy generation), forming a lake, sediment control, flood control, recharging of groundwater, etc.

There are disadvantages of dams as well:

imbalance of ecosystem, decrease amount of downstream water, reduction in the fertility of farmlands, etc.

Therefore, detailed survey should be carried out to ensure that the relative weights of advantages over disadvantages are higher.

CVE 471 Water Resources Engineering 4/101

3. DAMS

Classification of Dams

Dams can be classified into a number of different categories depending upon the purpose of classifications. A classification based on the type and materials of construction:

Gravity Dams

Concrete gravity dams Prestressed concrete gravity dams Roller compacted concrete (RCC) gravity dams

Arch Dams

Constant-angle arch dams Constant-center arch dams Variable-angel, variable-cemter arch dams

Buttress Dams

Flat-slab buttress dams Multiple-arch buttress dams

Embankment (Fill) Dams

CVE 471 Water Resources Engineering 5/101

3. DAMS

Classification of Dams

Gravity Dams

Concrete gravity dams Pre-stressed concrete gravity dams Roller compacted concrete (RCC) gravity dams

Karun Dam, Iran http://en.wikipedia.org/wiki/Dam Shasta Dam, California, USA

CVE 471 Water Resources Engineering 6/101

3. DAMS

Classification of Dams

Arch Dams

Constant-angle arch dams Constant-center arch dams Variable-angel arch dams Variable-center arch dams

Monticello Dam, California, USA

CVE 471 Water Resources Engineering

Gordon Dam, Tasmania

http://en.wikipedia.org/wiki/Dam

7/101

3. DAMS

Classification of Dams

Buttress Dams

Used mainly in wide valleys, it consists of an impermeable wall, which is shored up by a series of buttresses to transmit the thrust of the water to the foundation. Flat-slab buttress dams Multiple-arch buttress dams

CVE 471 Water Resources Engineering

8/101

3. DAMS

Classification of Dams

Buttress Dams

Flat-slab buttress dams

Lake Tahoe Dam, California, USA

CVE 471 Water Resources Engineering 9/101

3. DAMS

Classification of Dams

Buttress Dams

Multiple-arch buttress dams

Bartlett Dam , Phoenix, Arizona, USA

CVE 471 Water Resources Engineering 10/101

3. DAMS

Classification of Dams

Embankment (Fill) Dams

Earth-fill dams

Simple embankment Zoned embankment Diaphragm type embankment

Upstream of Ataturk Dam, Turkey

Embankment (Fill) Dams

Rock-fill dams

Downstream of Ataturk Dam, Turkey

Impermeable-face Impermeable-earth core

11/101

CVE 471 Water Resources Engineering

3. DAMS

Classification of Dams

A classifications based on purpose, such as

storage diversion flood control hydropower generation

A classification based on hydraulic design such as

overflow dams, non-overflow dams

Gilboa Dam, New York State, USA

http://en.wikipedia.org/wiki/Dam

CVE 471 Water Resources Engineering

12/101

3. DAMS

Classification of Dams

A timber crib dam in Michigan, USA 1978 http://en.wikipedia.org/wiki/Dam

Liberty Dam, USA

CVE 471 Water Resources Engineering

13/101

3. DAMS

Classification of Dams

A classification based on dam height: According to the International Commission on Large Dams (ICOLD):

Large Dam Large Dam if height > 15 m if 10 m < height < 15 m reservoir storage > 106 m3 crest length > 500 m height > 50 m height < 10 m

High Dam Small Dam

Distribution of dam heights in Turkey as of 2002.

CVE 471 Water Resources Engineering 14/101

3. DAMS

Classification of Dams

Percent distribution of dams in Turkey according to purpose

CVE 471 Water Resources Engineering 15/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

16/101

3. DAMS

Parts of Dams

A dam is composed of the following structural components

Body forms the main part of a dam as an impervious barrier. Reservoir is the artificial lake behind a dam body. Spillway is that part of a dam to evacuate the flood wave from the reservoir. Water intake is a facility to withdraw water from a reservoir. Outlet facilities are those appurtenances to withdraw water from the reservoir to meet the demands or to discharge the excess water in the reservoir to the downstream during high flows.

sluiceways, penstocks, diversion tunnels, bottom outlets, and water intake structures

Others: Hydropower station, site installations, roads, ship locks, fish passages, etc.

CVE 471 Water Resources Engineering 17/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

18/101

3. DAMS

Planning of Dams

There are commonly three steps in the planning and design:

reconnaissance survey, feasibility study, and planning study.

In reconnaissance surveys, the alternatives, which seem infeasible without performing intensive study, are eliminated. Feasibility Study:

Estimation of water demand Determination of water potential Optimal plans Determination of dam site

Topography Geologic information Foundation conditions Flood hazard

CVE 471 Water Resources Engineering 19/101

3. DAMS

Planning of Dams

Feasibility Study:

Determination of dam site (contd)

Spillway location and possibility Climate Diversion facilities Sediment problem Water quality Transportation facilities Right of way cost

Determination of type of dams Project design

Hydrologic design Hydraulic design Structural design

CVE 471 Water Resources Engineering

20/101

3. DAMS

Planning of Dams

Planning Study:

Topographic surveys Foundation studies Details on materials and constructional facilities Hydrologic study Reservoir operation study

CVE 471 Water Resources Engineering

21/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

22/101

3. DAMS

Construction of Dams

Details of dam construction are beyond the scope of this course. The principal steps to be followed during the construction of any type of dam briefly:

Evaluation of time schedule and required equipment. Diversion of river flow Foundation treatment

Evaluation of Time Schedule and Required Equipment. Items to be considered:

the characteristics of dam site the approximate quantities of work the preservation of construction equipment and materials diversion facilities and urgency of work

CVE 471 Water Resources Engineering 23/101

3. DAMS

Construction of Dams

Diversion of River Flow

Diversion of the river flow is may be accomplished in one of the following ways 1. Water is diverted through a side tunnel or channel.

(Applicable for low flow depths ~1.5 m) Diversion by side tunnel or channel

CVE 471 Water Resources Engineering 24/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

Typical cross-section of earth cofferdams

f: free board f=0.2(1+h) h: flow depth (meters) G=z/5 + 3 (meters) Cofferdams should be constructed during the low flow season. For fill type dams, embankment cofferdam may be kept in place as part of the embankment (e.g. Keban Dam and Ataturk Dam). For concrete dams, embankment cofferdam should be demolished after the dam has been constructed.

Earth cofferdam on impervious foundation

CVE 471 Water Resources Engineering

Earth cofferdam on pervious foundation

25/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

Hoover Dam, USA

CVE 471 Water Resources Engineering 26/101

3. DAMS

Diversion of River Flow (contd)

Construction of Dams

Hoover Dam Overflow Tunnels (spillways), USA

CVE 471 Water Resources Engineering

27/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

Hoover Dam Overflow Tunnels (spillways), USA

CVE 471 Water Resources Engineering

28/101

Diversion of River Flow (contd)

Construction of Dams

Hoover Dam Overflow Tunnels (spillways), USA

3. DAMS

CVE 471 Water Resources Engineering

29/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

2. Water is discharged through the construction, which takes place in two stages. This type of diversion is normally practiced in wider valleys.

Two-stage diversion

CVE 471 Water Resources Engineering 30/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

Two-stage diversion

CVE 471 Water Resources Engineering 31/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

A cofferdam on the Ohio River, Illinois, USA, built for the purpose of constructing the lock and dam.

CVE 471 Water Resources Engineering 32/101

3. DAMS

Construction of Dams

Diversion of River Flow (contd)

Selection of a proper diversion scheme is based on the joint consideration of

hydrologic characteristics of river flow, type of dam and its height, availability of materials, characteristics of spilling arrangements.

The optimum design is based on cost minimization. The cost analysis is carried out for various sizes of diversion tunnels or channels to determine the corresponding total costs. The optimum tunnel diameter or bottom width of a lined trapezoidal channel is then determined according to the minimum total cost of the facility.

CVE 471 Water Resources Engineering 33/101

3. DAMS

Construction of Dams

Foundation Treatment

Foundation treatment for dams is essential

to achieve less deformation under high loads, to decrease permeability and seepage, to increase shearing strength, and to satisfy slope stability for the side hills.

Highly porous foundation material causes excessive seepage, uplift and considerable settlement. Such problems can be improved by a grouting operation. In this operation, the grout mix is injected under pressure to decrease the porosity, and hence to solidify the formations underlying the dam and reservoir.

CVE 471 Water Resources Engineering

34/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

35/101

3. DAMS

Gravity Dams

Gravity dams are satisfactorily adopted for narrow valleys having stiff geological formations. Their own weight resists the forces exerted upon them. They must have sufficient weight against overturning tendency about the toe. The base width of gravity dams must be large enough to prevent sliding. These types of dams are susceptible to settlement, overturning, sliding and severe earthquake shocks.

CVE 471 Water Resources Engineering

36/101

3. DAMS

Gravity Dams

Concrete Gravity Dams

Concrete gravity dams area built of mainly plain concrete to take compressive stresses.

Shasta Dam, California, USA

CVE 471 Water Resources Engineering 37/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Concrete gravity dams have lower maintenance and operation costs compared to the other types of dams. In the design of these structures, the following criteria should be satisfied:

Dimensions of the dam are chosen such that only compressive stresses develop under all loading conditions. The dam must be safe against overturning, shear and sliding.

CVE 471 Water Resources Engineering

38/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

In the construction of concrete gravity dams special care is required for the problems due to shrinkage and expansion.

Formation of the body of the concrete gravity dam

CVE 471 Water Resources Engineering

39/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Forces Acting on Gravity Dams

The weight: Wc= dead load Hydrostatic forces:

Uplift Force:

: uplift reduction coefficient Moment arm of Fu=B(2h1+3h2) / 3(h1+h2) Actual uplift pressures are determined by pressure gauges installed at the bottom of the dam.

CVE 471 Water Resources Engineering

Free body diagram. Forces acting on a concrete gravity dam

40/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Forces Acting on Gravity Dams

Sediment Force:

s: submerged specific weight of soil Ka: active earth pressure coefficient according to the Rankine theory. Ka = (1-sin)/(1+sin)

Ice Load (Fi):

Free body diagram. Forces acting on a concrete gravity dam

CVE 471 Water Resources Engineering 41/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Forces Acting on Gravity Dams

Earthquake Force:

Fd = kWc

k: earthquake coefficient

Dynamic Force in the reservoir induced by earthquake

2 Fw = 0.726Ckh1

C = 0.71 90 Dynamic Force acting on a spillways

F = Qu

obtained using momentum equation Free body diagram. Forces acting on a concrete gravity dam

CVE 471 Water Resources Engineering 42/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Forces Acting on Gravity Dams

Wave Force may be considered for wide and long reservoirs.

Temperature Loads may be severe during construction because of hydration reactions

Free body diagram. Forces acting on a concrete gravity dam

CVE 471 Water Resources Engineering 43/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

Stability analyses are performed for various loading conditions The structure must prove its safety and stability under all loading conditions. Since the probability of occurrence of extreme events is relatively small, the joint probability of the independent extreme events is negligible. In other word, the probability that two extreme events occur at the same time is relatively very low. Therefore, combination of extreme events are not considered in the stability criteria.

Floods (spring and summer) Ice load (winter). No need to consider these two forces at the same time.

CVE 471 Water Resources Engineering

44/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

Usual Loading

Hydrostatic force (normal operating level) Uplift force Temperature stress (normal temperature) Dead loads Ice loads Silt load

Unusual Loading

Hydrostatic force (reservoir full) Uplift force Stress produced by minimum temperature at full level Dead loads Silt load

Extreme (severe) Loading

Forces in Usual Loading and earthquake forces

CVE 471 Water Resources Engineering

45/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The ability of a dam to resist the applied loads is measured by some safety factors. To offset the uncertainties in the loads, safety criteria are chosen sufficiently beyond the static equilibrium condition. Recommended safety factors: (USBR, 1976 and 1987)

F.S0: Safety factor against overturning. F.Ss: Safety factor against sliding. F.Sss: Safety factor against shear and sliding.

However, since each dam site has unique features, different safety factors may be derived considering the local condition.

CVE 471 Water Resources Engineering 46/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The factor of safety against overturning:

F .S0 =

Mr M0

where Mr: total resisting moment about the toe. M0: total overturning moment about the toe.

The factor of safety against sliding:

F .S s = f V

where f: coefficient of friction between any two planes V: vectorial summation of vertical forces. H: vectorial summation of horizontal forces.

CVE 471 Water Resources Engineering 47/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The factor of safety against sliding and shear: F .S ss = f V + rA s

(in the dam)

F .S ss =

f V + cA

(at foundation level)

where A: Area of the shear plane, s: shear strength of concrete r: factor to express max allowable average shear stress r=0.33, 0.50, and 1.0 for usual, unusual, and extreme loading, respectively. f: coefficient of friction between any two planes V: vectorial summation of vertical forces. H: vectorial summation of horizontal forces.

CVE 471 Water Resources Engineering 48/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The contact stress between the foundation and the dam or the internal stress in the dam body must be compressive:

=

V A

Normal stress

Mc I

Bending or flexural stress Base pressure distribution

where : vertical normal base pressure A: Area of the shear plane, M: net moment about the centerline of the base (M = V.e) e: eccentricity ( B / 2 x ) c: B/2 I : Moment of inertia (B3/12) V: vectorial summation of vertical forces.

CVE 471 Water Resources Engineering 49/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The contact stress between the foundation and the dam or the internal stress in the dam body must be compressive:

In order to maintain compressive stresses in the dam or at the foundation level, the minimum pressure min 0. This can be achieved with a certain range of eccentricity.

V Mc A I

for a unit width

min =

V V e B / 2 V 6e = 1 0 3 A B B B / 12

min 0 can be achieved if e B/6 Full reservoir max at the downstream face Empty reservoir max at the upstream face

Base pressure distribution

CVE 471 Water Resources Engineering 50/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The contact stress between the foundation and the dam or the internal stress in the dam body must be compressive:

Tension along the upstream face of a gravity dam is possible under reservoir operating conditions.

z = 1.0 (if there is no drainage in the dam body) z = 0.4 (if drains are used) P: hydrostatic pressure at the level under consideration

CVE 471 Water Resources Engineering

51/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

Concrete gravity dams have varying thickness. Hence the inclined compressive stresses parallel to the face of the dam need to be computed.

For a concrete gravity dam with slopes of 1V:mH at the upstream face and 1V:nH at the down stream face, the major principle compressive stresses, iu (parallel to the upstream face) and id (parallel to the downstream face) are obtained from the static equilibrium of forces in the vertical direction as: (Fy=0)

CVE 471 Water Resources Engineering

where u and d vertical normal compressive stresses and pu and pd hydrostatic pressures at the upstream and downstream faces, respectively. 52/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

Internal horizontal and vertical shear stresses at the upstream and downstream faces are obtained by equating the total moment to zero as (MA=0, MB=0):

where hu, hd, vu, and vd are the horizontal and vertical internal shear stresses at the upstream and downstream faces, respectively.

CVE 471 Water Resources Engineering

53/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

The maximum compressive stress, max ,must be smaller than a certain fraction of the compressive strength of concrete, c, and foundation material, f.

Unconfined compressive strength, f for foundation materials

Safety criteria for concrete gravity dams

CVE 471 Water Resources Engineering

54/101

3. DAMS

Gravity Dams

Concrete Gravity Dams (contd)

Stability Criteria

Excessive care must be taken during the filling of the reservoir. Initially 1/3 of the dam height may be filled first. After waiting for several weeks and assuring that the dam is safe, further filling is performed. Since safety levels change with respect to upstream water depth, gravity dams must be analyzed for various operating levels and empty reservoir cases, separately. For the empty reservoir case, the overturning tendency must be checked with respect to the toe and heel, separately. The stability against sliding may be improved by providing a cut off wall in the foundation at the upstream side.

CVE 471 Water Resources Engineering

55/101

3. DAMS

Gravity Dams

Prestressed Concrete Gravity Dams

In a prestress concrete dam, forces are applied to the dam before the reservoir is filled in order to counter undesirable stress that would develop in the absence of the prestressing forces. For prestressing, either small-diameter high-tensile wires or hightensile steel bars can be used.

Roller Compacted Concrete (RCC) Gravity Dams

RCC dam is constructed using cement, water, fine and course aggregates, and fly ash which are mixed in certain proportions to have a no-slump, rather dry composition. Construction is based on the compaction of this mixture by heavy static or vibrating rollers. Construction period of RCC dams is shorter than that of conventional concrete gravity dams.

CVE 471 Water Resources Engineering 56/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

57/101

3. DAMS

Arch Dams

Arch dams are thin concrete structures.

Gokcekaya, Oymapinar, Karakaya, Gezende, and Berke dams in Turkey.

Gokcekaya Dam

Berke Dam

Karakaya Dam

CVE 471 Water Resources Engineering

58/101

3. DAMS

Arch Dams

Arch dams: Oymapinar Dam, Turkey

CVE 471 Water Resources Engineering

59/101

3. DAMS

Arch Dams

Hoover Dam, USA

CVE 471 Water Resources Engineering 60/101

3. DAMS

Arch Dams

Arch dams are thin concrete structures. Stability of an arch dam is based on its self weight and its ability to transmit most of the imposed water loads into the valley walls. At the sites of arch dams, the side formations and foundations should be very stiff to resist the applied load. For effective arching action, the radius of the arch should be as small as possible. They are formed by concrete blocks having base dimensions of approximately 15 m by 15 m and height of 1.5 m Reinforcement is not generally required in thick arch dams because it increases the cost drastically. Arch dams have normally higher structural safety than conventional gravity dams.

CVE 471 Water Resources Engineering 61/101

3. DAMS

Arch Dams

Types of Arch Dams

Arch dams are classified according to geometric characteristics of the valley where they are adopted. Arch dams are classified according to the location of the center and magnitude of the central angle

Constant-center (variable angle) arch dams are suitable for medium-high dams in U-shape valleys. They have single curvature in plan with vertical upstream face.

CVE 471 Water Resources Engineering 62/101

3. DAMS

Arch Dams

Types of Arch Dams

Variable-center (constant angle) arch dams are suitable for V-shape valleys.

Radius of the arc reduces with respect to depth. So arching action is more pronounced at low depths. Since these types of dams are normally thinner than constant-center dams, they are more elastic and safer.

Variable-center (constant angle) arch dams

CVE 471 Water Resources Engineering

63/101

3. DAMS

Arch Dams

Types of Arch Dams

Variable-center (variable angle) arch dams are composed of the combination of two types described above.

Load distribution in vertical direction governs the cross-sectional shape of the dam. This type has a pronounced double curvature They utilized the concrete strength more compared the other types resulting in thinner and more efficient structure. However, tensile stresses may develop in the dam body.

CVE 471 Water Resources Engineering

Variable-center (variable angle) arch dams

Gokcekaya Dam

64/101

3. DAMS

Arch Dams

Types of Arch Dams

Variable-center (variable angle) arch dams

Gokcekaya Dam

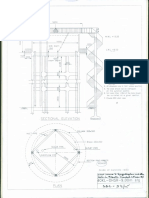

Cross-section of Gokcekaya Dam

CVE 471 Water Resources Engineering 65/101

3. DAMS

Arch Dams

Design of Arch Dams

Structural design of an arch dam requires the determination of load distribution in the dam body using the trial load method and applications of the theory of elasticity and the theory of shells. Structural design is beyond the scope of this course. Simplified design:

The determination of the thickness at any elevation of an arch dam whose crest elevation has already been determined in the hydrologic design step.

In the arch dams, the total load is shared by arch and cantilever actions and transmitted to the sides and foundation, respectively. Therefore, the base width of arch dams is usually much narrower than that of concrete gravity dams having almost the same height. Hence, the effect of uplift pressure can be ignored.

CVE 471 Water Resources Engineering 66/101

3. DAMS

Arch Dams

Design of Arch Dams

However, effect of temperature stresses should be checked to ensure that they are smaller than tensile strength. Near the crest of the dam, most of the loads taken by arches and transmitted to the side abutments. Near the bottom of the dam, cantilevers take most of the load and transmit to the foundation.

Gokcekaya Dam

CVE 471 Water Resources Engineering

67/101

3. DAMS

Arch Dams

Design of Arch Dams

In the following analysis, the water thrust induced by hydrostatic pressure is assumed to be taken by arch action only and transmitted to the sides.

The differential force acting on a differential element having a central angle of d is dFv= P r d The vertical component of this force is dF'v= P r d sin

CVE 471 Water Resources Engineering

Free-body diagram for arch dam analysis

68/101

3. DAMS

Arch Dams

Design of Arch Dams

Integration of this force along the arc length gives the total horizontal force, Hh.

2

Hh = 2

a 2 2

hr sin d = 2hr cos cos a = 2hr sin a 2 2 2 2

Free-body diagram for arch dam analysis

where h: the height of the arch rib relative to the reservoir surface r: the radius of arch a: the central angle

CVE 471 Water Resources Engineering

69/101

3. DAMS

Arch Dams

Design of Arch Dams

The equilibrium of forces in ydirection involves

H h = 2Ry R y = R sin a 2 Therefore 2hr sin a = 2 R sin a 2 2 R = hr

where

Free-body diagram for arch dam analysis

where R: the reaction offered by the sides against the transmission of water thrust. As observed from the R = hr, the reaction at the sides is directly proportional to the arc radius at a given height. Therefore, narrow valleys having stiff geological formations and small r-values are suitable for arch dams.

CVE 471 Water Resources Engineering 70/101

3. DAMS

Arch Dams

Design of Arch Dams

If the thickness of the arch rib, t, is relatively small as compared with r, there is small difference between the average and maximum compressive stresses in the rib and R/t. The required thickness of the rib is then

t=

hr all

(the thickness varies linearly with depth.)

where all: the allowable working stress for concrete in compression.

CVE 471 Water Resources Engineering

71/101

3. DAMS

Arch Dams

Design of Arch Dams

The volume of concrete per unit height of a single arch rib across a canyon of width of Ba is V=Lt where L is the arch length which is equal to ra (a in radians). Inserting the values of L and t into the equation above

V=

h 2 r a all

CVE 471 Water Resources Engineering

72/101

3. DAMS

Arch Dams

Design of Arch Dams

The optimum central angle a for a minimum volume of arch rib can be determined as 13334 by differentiating V with respect to a and equating the result to zero. This is the reason why a constant-angle arch dam can be design to require less concrete than a constant-center dam. In practice, the central angles of arch dams vary from 100 to 140. However, the formwork of a constant-angle dam is more difficult.

CVE 471 Water Resources Engineering

73/101

3. DAMS

Arch Dams

Design of Arch Dams

The optimum central angle a for a minimum volume of arch rib can be determined as 13334 by differentiating V with respect to a and equating the result to zero. This is the reason why a constant-angle arch dam can be design to require less concrete than a constant-center dam. In practice, the central angles of arch dams vary from 100 to 140. However, the formwork of a constant-angle dam is more difficult.

CVE 471 Water Resources Engineering

74/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

75/101

3. DAMS

Buttress Dams

A buttress dam consists of a sloping slab. Depending on the orientation of slab, a buttress dam may be classified as

flat-slab buttress dam multiple-arch buttress dam

Elmali Dam construction, Istanbul, 1941

A typical buttress dam.

CVE 471 Water Resources Engineering

Elmali Dam

76/101

3. DAMS

Buttress Dams

Flat-slab buttress dams

Lake Tahoe Dam, California, USA

CVE 471 Water Resources Engineering 77/101

3. DAMS

Buttress Dams

Multiple-arch buttress dams

Bartlett Dam , Phoenix, Arizona, USA

CVE 471 Water Resources Engineering 78/101

3. DAMS

Buttress Dams

Some advantages of buttress dams over conventional gravity dams:

They can be constructed on foundations having smaller bearing capacity then required for gravity dams. Since they have thinner slabs, possibility of development of vertical cracks is less. Problems encountered during the setting of concrete are reduced. Unless a mat foundation is used, uplift forces are negligibly small because of hollow spaces provided between the buttresses. Ice pressures are also small as the ice sheet slides up the inclined slab.

Main disadvantage of buttress dams:

May have comparable costs, because of increased formwork and reinforcement .

There is only one buttress dam in Turkey (Elmali 2 Dam).

Elmali 2 Dam

CVE 471 Water Resources Engineering 79/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

80/101

3. DAMS

Embankment (Fill) Dams

They composed of fill of suitable earth materials at the dam site.

Coarse-grained soils (gravel and coarse sand)

relatively pervious, easily compacted, resistant to moisture,

Clay is considered as a core material (impermeable)

unstable when saturated (expands due to wetting, hard to compact)

Therefore, clay mixed with sand and fine gravel is used as a core. Core must be compacted in thinner layers with fairly accurate moisture control. Compacted asphalt may also be used as an economical core material in case of loose foundations. Asphalt can absorb earthquake shocks effectively.

CVE 471 Water Resources Engineering

81/101

3. DAMS

Embankment (Fill) Dams

Embankment dams are usually safer against deformations and settlements. Embankment dams

Earth-fill dams Rock-fill dams (More than 50% of the total material is of rock.) Earth-fill dams in Turkey Seyhan Dam Demirkopru Dam Cubuk 2 Dam Bayindir Dam Rock-fill dams in Turkey Keban Dam Ataturk Dam Hasan Ugurlu Dam

CVE 471 Water Resources Engineering

Hasan Ugurlu Dam

82/101

3. DAMS

Embankment (Fill) Dams

Body volume of embankment dams is relatively greater than the other types of dams. Normally cheaper than the other types where there is enough fill material in the close vicinity. Fill dams comprise more than 70% of the dams in the world and 90% in Turkey.

Keban Dam

CVE 471 Water Resources Engineering

83/101

3. DAMS

Embankment (Fill) Dams

Earth-fill Dams

Construction:

Placement of selected material on layers of 50 cm thick and compaction. Non-organic and non-plastic soils are needed. The embankment soil is usually irrigated at the borrow area. Piezometers can be placed in the embankment at various depths during the construction to measure the pore water pressure. A typical earth-fill dam is constructed in a multi-layer formation.

CVE 471 Water Resources Engineering

84/101

3. DAMS

Embankment (Fill) Dams

Earth-fill Dams

A typical earth-fill dam is constructed in a multi-layer formation.

Earth dam on pervious foundation

CVE 471 Water Resources Engineering 85/101

3. DAMS

Embankment (Fill) Dams

Earth-fill Dams

Seepage through an earth-fill dam.

The flow rate, q, between two flow lines can be expressed using the Darcy law as

The total flow rate, q

h q = KAi = KD L Kh q = N N

K: the hydraulic conductivity i : the hydraulic gradient h: head loss (h/N) N : number of equipotential drops N: the number of stream tubes

86/101

CVE 471 Water Resources Engineering

3. DAMS

Embankment (Fill) Dams

Earth-fill Dams

Drainage systems in an earth-fill dam. Chimney drains, in the embankment as well as enlarged toe drains are effective in controlling the seepage through the dam.

CVE 471 Water Resources Engineering

87/101

3. DAMS

Embankment (Fill) Dams

Rock-fill Dams

Having relatively high pore space Can be adopted to weaker foundations where a gravity dam cannot be constructed.

Cross-sections of typical rock-fill dams

CVE 471 Water Resources Engineering 88/101

3. DAMS

Embankment (Fill) Dams

Rock-fill Dams (Ataturk Dam)

Largest dam in Turkey Reservoir Volume: 48.7 x 109 m3 Installed capacity: 2400 MW Annual energy production: 8.9 x 109kWh Irrigated land: 874200 ha (with the completion of the project)

A cross-sections of the Ataturk Dam

CVE 471 Water Resources Engineering 89/101

3. DAMS

Embankment (Fill) Dams

Rock-fill Dams (Ataturk Dam)

A cross-sections of the Ataturk Dam

CVE 471 Water Resources Engineering

90/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

91/101

3. DAMS

Cross-sectional Layout Design of Dams

A suitable dam cross-section should be provided such that both safety and desired functionality concerning service requirement are attained. Sufficient crest width, tc must be provided.

a width of two lane traffic may be selected. For small embankment dams up to Hf=15 m. tc=0.2Hf+3 For large embankment dams up to Hf=150 m. tc=3.6 (Hf )1/3 where tc and Hf are in meter.

CVE 471 Water Resources Engineering

92/101

3. DAMS

Cross-sectional Layout Design of Dams

By examining some existing muti-purpose concrete gravity dams throughout the world, Yanmaz et al. (1999) proposed the following regression equations to define the shape of a gravity dam. H*=0.1075 Ht tc=0.0475 Ht +2.392 where all variables are in meter

CVE 471 Water Resources Engineering

93/101

3. DAMS

Cross-sectional Layout Design of Dams

United States Bureau of Reclamation (USBR) propose the following formulas for cross-sectional layout of arch dams:

tc = 0.01(H t + 1.2 Ba )

H t / 400

H tb = 3 0.0012 H t Ba B0.15 t 400 t0.45 H t = 0.95tb

where

All the dimensions are in ft

Ba: the span width at the crest B0.15: the span width at 15% of the dam height above the base t0.45Ht: the dam thickness at 45% of the dam height above the base.

CVE 471 Water Resources Engineering

94/101

3. DAMS

Cross-sectional Layout Design of Dams

The crest elevation of a dam is to be determined such that there is almost no overtopping danger of the flood wave during the occurance of the design flood.

Freeboards on flood levels for concrete and embankment dams

Greater freeboards are required for embankment dams since they are susceptible to erosion at the downstream face due to overtopping from their crest. The required side slopes of concrete gravity dams are determined from stability analyses. The maximum downstream slope of gravity dams is 45. Side slopes of embankment dams are determined on the basis of seepage and slope stability analyses.

CVE 471 Water Resources Engineering 95/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

96/101

3. DAMS

Local Scour at the Downstream of Dams

Excessive kinetic energy of the flowing water at the downstream of outlet works (spillways, sluiceways etc.) should be dissipated in order to prevent the erosion of the streambed and the banks below the dam.

Local scour at the downstream of the dam and sluice gates

Excessive scours at the downstream of Keban Dam have resulted in serious foundation stability problems (depth of approx 30 m).

CVE 471 Water Resources Engineering 97/101

3. DAMS

Local Scour at the Downstream of Dams

Some of the scour prediction equations are given in the table.

Scour prediction equations for the downstream of dams.

ds: the maximum depth of scour hole in m. b: the thickness of the jet in m. : the side inclination for the scour hole, Fr: Jet Froude number. U: the velocity of the jet in m/s =(s- )/, s: : specific weight of sediment in kN/m3 : specific weight of water in kN/m3. Wf: Fall velocity in m/s q: unit discharge in m3/s/m Hg: gross head in m h: tailwater depth in m D50: median size of bed material in m.

CVE 471 Water Resources Engineering 98/101

3. DAMS

Overview

Classification of Dams Parts of Dams Planning of Dams Construction of Dams Concrete Gravity Dams Arch Dams Buttress Dams Embankment (Fill Dams) Cross-sectional Layout Design of Dams Local Scour at the Downstream of Dams Dam Safety and Rehabilitation

CVE 471 Water Resources Engineering

99/101

3. DAMS

Dam Safety and Rehabilitation

Excessive care must be taken in planning, design, and construction stages of a dam. Major causes for a dam break:

Inadequate spillway capacity, Improper construction of any type of dam, Insufficient compaction of embankment dams or compaction with undesirable water content, Improper protective measures, Excessive settlements, etc

Continuous inspection and monitoring are required to assess the safety level of the dam throughout the lifetime.

CVE 471 Water Resources Engineering

100/101

3. DAMS

Dam Safety and Rehabilitation

Upon periodic inspection, the following deficiencies may be observed that are indicators of problems:

Large horizontal and vertical movements of crest, Tilting of the roadway along the crest, Deformation of embankment slope, Higher than usual pore water pressure in embankment dams, Unusual seepage at the toe or edges of an embankment dam, Seepage flows with not decreasing with low flow conditions, Turbit outflow through the embankment, Tilting of the spillway crest Increased leakage into inspection galleries in concrete dams, etc.

CVE 471 Water Resources Engineering

101/101

Você também pode gostar

- 10KL Sump DrawingDocumento1 página10KL Sump DrawingAbdul Mateen MahammadAinda não há avaliações

- G.O.Ms - No. 97 Dated: 03-10-2018 Read The FollowingDocumento2 páginasG.O.Ms - No. 97 Dated: 03-10-2018 Read The FollowingAbdul Mateen MahammadAinda não há avaliações

- Ohsr40kl WP69Documento11 páginasOhsr40kl WP69Abdul Mateen MahammadAinda não há avaliações

- Labour Cess - RecoveryDocumento6 páginasLabour Cess - RecoveryAbdul Mateen MahammadAinda não há avaliações

- Kirloskar PumpDocumento24 páginasKirloskar PumpAmit Patel0% (1)

- Municipal Corporation of Greater Mumbai: (Hydraulic Engineer's Department)Documento2 páginasMunicipal Corporation of Greater Mumbai: (Hydraulic Engineer's Department)Abdul Mateen MahammadAinda não há avaliações

- APED Vol - IDocumento475 páginasAPED Vol - Im_surendra100% (1)

- JettingDocumento61 páginasJettingAbdul Mateen MahammadAinda não há avaliações

- DEEs Int Egrated Seniority ListDocumento24 páginasDEEs Int Egrated Seniority ListAbdul Mateen MahammadAinda não há avaliações

- Earth DamsDocumento124 páginasEarth DamsTheodore Teddy Kahi100% (3)

- Awc, DWF Go134Documento277 páginasAwc, DWF Go134Abdul Mateen MahammadAinda não há avaliações

- Government of Andhra Pradesh: Panchayat Raj and Rural Development (Rws Ii) DepartmentDocumento5 páginasGovernment of Andhra Pradesh: Panchayat Raj and Rural Development (Rws Ii) DepartmentAbdul Mateen MahammadAinda não há avaliações

- Government of Andhra Pradesh: Panchayat Raj and Rural Development (Rws Ii) DepartmentDocumento5 páginasGovernment of Andhra Pradesh: Panchayat Raj and Rural Development (Rws Ii) DepartmentAbdul Mateen MahammadAinda não há avaliações

- 9 KanyakumariDocumento3 páginas9 KanyakumariAbdul Mateen MahammadAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)