Escolar Documentos

Profissional Documentos

Cultura Documentos

Pipeline Crossing Plan Requirements

Enviado por

Shams TabrezDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Pipeline Crossing Plan Requirements

Enviado por

Shams TabrezDireitos autorais:

Formatos disponíveis

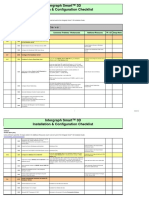

GAS/OIL AND WATER/SEWER PIPELINE CROSSINGS APPLICATIONS

NOTE: Gas and Oil pipeline specific requirements shown in red. Water and Sewer pipeline specific requirements shown in green

Applicants must submit THREE (3) copies of an acceptable plan. Plans must meet TC E-10 and CN Standards. Additionally, Gas and Oil pipelines must meet CSA Standard Z662-07. Cost for reviewing the first plan received shall be included in the basic engineering application fee. The applicant may be charged an additional fee for each review after the initial application due to inadequate or missing information. Plans Must Have: Plan Number & Date Revised plans must have a revision number & date of revision. Full company name & contact information of the owner of the pipeline. o can be on the application letter Land Description (legal description & or CN Subdivision & Mileage) Site Plan & Profile o width of Trillium right-of-way / number of tracks / angle of crossing If encased . . . a cross section or a note advising on spacers, etc. Drawing must be to scale or have all dimensions/measurement noted. Gas/Oil: A note stating: Installation and maintenance to be in accordance with TC E10 and the latest edition of applicable CSA standard (Z-662) . Water/Sewer: A note stating: Installation and maintenance to be in accordance with TC E10. Signed stamp of a Professional Engineer.

SPECS Required on Plan: Contents of pipe must be noted. Crossing angle to be greater than 45 degrees. Warning Markers required on each side of the railway right-of-way Direction of flow. Not required for a gravity sewer pipe. Emergency Shut-off Valve locations noted on each side of track. Not required for a gravity sewer pipe. Method of Installation. Gas/Oil: No gas pipeline under buildings, switches, etc. Gas/Oil: Hoop Strength calculation must be shown on uncased xings. Water/Sewer: 13.7m minimum clearance to any bridges, buildings, switches, etc.

PIPE SPECS Design Loading Cooper E80 (TC E-10) PIPE MATERIAL Water/Sewer Type of Pipe, Wall Thickness, and Pressures (operating & max. test) of carrier & casing pipe. Must be STEEL CASED unless it is a non-pressure (under 700 kpa) gravity feed pipe (sewer) and then the following applies: concrete pipe as per AREMA & CSA, minimum Class 5. Coated corrugated metal pipe as per AREMA & CSA. ALUMINUM PIPE is not acceptable! Gas/Oil Steel pipe is the only acceptable material for a carrier pipe when there is no casing. Steel pipe is the only acceptable material for a casing pipe. Must meet minimum wall thickness. Approved CSA material . . . ie. . . Z245.1, 359.11 o Polyethylene pipe can be used as a carrier pipe if the following conditions are met: If encased the entire width of the right-of-way. Less than 168.3 mm outside diameter. Less than 700 kpa design or test pressure. Approved CSA material. ALUMINUM PIPE is not acceptable! Wall Thickness o minimum 4.8mm . . . unless no protective coat or it is not cathodically protected . . . ADD 1.6 mm. (TC E-10 & AREMA). . . ie . . . YJ-1 = yellow jacket coding o see Table 4.10 CSA Z662-07 for all sizes (Table 4.9 CSA Z662-99) Yield Strength (uncased) o Minimum Yield Strength 241 Mpa (the higher the #, the better). o With a Joint Factor of 1.00 (standard - welded) Less then 50% for all tracks. o With a Joint Factor of less than 1.00 Less than 50% on secondary & industrial tracks. Less than 30% on main tracks. Casings: Carrier pipe less than 168.3 mm O.D. . . . casing pipe must be at least 50 mm O.D. larger. Carrier pipe more than 168.3 mm O.D. . . . casing pipe must be at least 75 mm O.D. larger. Carrier pipe shall be held clear of the casing pipe by properly designed supports, insulators, or centering devices. - CSA Standard 4.12.3.3 (c)

Casing must extend the full width of the Railways core right-of-way and a minimum of 15 m on each side from outside track to accommodate for any future construction. Based on our standard 100 right-of-way. NOTE: TC E-10 & Z662-07 states a 7 m minimum from center outside track. Gas/Oil: Casing pipe must be sealed to the carrier pipe. Water/Sewer: Casing pipe to be left open on the ends (not sealed) when the ends of the casing are at or above ground surface and above high-water level (AREMA 5.1.6.4).

Wall Thickness minimum 4.8mm . . . unless no protective coat or it is not cathodically protected . . . ADD 1.6 mm. (TC E-10 & AREMA) . . ie . . . YJ-1 = yellow jacket coding see Table 4.10 CSA Z662-07 for all sizes (Table 4.9 CSA Z662-99) Water/Sewer protective coat or cathodically protected not required for concrete pipe Minimum Depth of Burial BELOW TRACK Mainline Cased Other Tracks/Uncased BELOW RIGHT OF WAY Mainline Cased Other Tracks/Uncased

Gas/Oil 1.68 m (5.5 ft) 3.05 m (10 ft) Gas/Oil 0.91 m (3.0 ft) 1.83 m (6.0 ft)

Water/Sewer 1.68 m (5.5 ft) 1.37 m (4.5 ft) Water/Sewer 0.91 m (3.0 ft) 0.91 m (3.0 ft)

Geo-technical Report: If installation is known or suspected to be a problem due to soil conditions at location or if this is a large bore pipeline (cased or uncased), a written recommendation from a Geo-technical Engineer, who has reviewed soil testing and water table results, will be required. The written recommendation is to note the following: That the method of installation is appropriate to the soil conditions. There will be no adverse affect to Trillium operations and property. The contingency plan if problems arise during construction at the site. Nearest Point at which digging can take place: Starting 10 (ten) feet from the gauge side of the nearest rail, calculate a slope to the bottom of the proposed pipe at 1.5:1. If a 1.5:1 slope cannot be maintained or more restrictive conditions occur, approved shoring will be required.

Você também pode gostar

- Electric Actautor Valve Damper Technical Catalog PDFDocumento5 páginasElectric Actautor Valve Damper Technical Catalog PDFCair Euromatic Automation Pvt. Ltd.Ainda não há avaliações

- Bolt DesignDocumento1 páginaBolt Designbala_ccc3353Ainda não há avaliações

- API570 Training Book PDFDocumento312 páginasAPI570 Training Book PDFRamziAhmed100% (4)

- Handbook of Weld InspectionDocumento64 páginasHandbook of Weld InspectionAgourame Abderrahmane100% (3)

- 2015-Xii. P&id PDFDocumento71 páginas2015-Xii. P&id PDFFitria Nur HayatiAinda não há avaliações

- Power System Design Basics Tb08104003e PDFDocumento145 páginasPower System Design Basics Tb08104003e PDFRochelle Ciudad BaylonAinda não há avaliações

- Basics of Pipe For Oil & Gas EngineerDocumento12 páginasBasics of Pipe For Oil & Gas EngineerMannuddin KhanAinda não há avaliações

- Command Line Entries for PDMS and DraftDocumento13 páginasCommand Line Entries for PDMS and DraftSasha KatichAinda não há avaliações

- Piping Engineering Certification CourseDocumento22 páginasPiping Engineering Certification Courseshiraz ahmedAinda não há avaliações

- Cadworx Customising Backing SheetDocumento27 páginasCadworx Customising Backing Sheetalan172081100% (1)

- AGIP STD - Valves Specification SheetDocumento1 páginaAGIP STD - Valves Specification Sheethalim_kaAinda não há avaliações

- GTP - 01 Power TransformersDocumento8 páginasGTP - 01 Power Transformersraj_stuff006100% (1)

- Pipe Fittings PDFDocumento164 páginasPipe Fittings PDFjlvega18Ainda não há avaliações

- PipingDocumento4 páginasPipingramthecharm_46098467Ainda não há avaliações

- Overview of GRP PipesDocumento14 páginasOverview of GRP PipesMD IBRARAinda não há avaliações

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocumento2 páginasEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganAinda não há avaliações

- PipingDocumento7 páginasPipingfarhanyazdaniAinda não há avaliações

- About UsDocumento32 páginasAbout UsSubbu Ram PAinda não há avaliações

- August 2012 IssueDocumento56 páginasAugust 2012 IssueGas, Oil & Mining Contractor Magazine100% (1)

- (Offer PDF) - Numerical Index of SHELL DEP Piping Classes Feb. 2012-NEW Standards - Powered by Discuz!Documento11 páginas(Offer PDF) - Numerical Index of SHELL DEP Piping Classes Feb. 2012-NEW Standards - Powered by Discuz!Mathias OnosemuodeAinda não há avaliações

- Saudi Aramco Piping QC Inspector Sample Interview Questions & Answers..Documento5 páginasSaudi Aramco Piping QC Inspector Sample Interview Questions & Answers..Ch SIB100% (1)

- Pds Manual 2Documento54 páginasPds Manual 2agkamalakannan1982@gmail.comAinda não há avaliações

- Piping Engineering Course OverviewDocumento2 páginasPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Design Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintsDocumento14 páginasDesign Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintslumpertAinda não há avaliações

- CDOT Bridge Design Manual - 20180101Documento431 páginasCDOT Bridge Design Manual - 20180101albertoxina100% (1)

- Design Criteria FOR Centrifugal Compressors: Saudi Arabian Oil CompanyDocumento19 páginasDesign Criteria FOR Centrifugal Compressors: Saudi Arabian Oil CompanyNicolaMasteAinda não há avaliações

- PDFDocumento7 páginasPDFAngling DharmaAinda não há avaliações

- Pipe Stress Analysis & Design Services - Openso EngineeringDocumento2 páginasPipe Stress Analysis & Design Services - Openso EngineeringAmit Sharma100% (1)

- Steps For The Procurement of Piping / Mechanical ItemsDocumento2 páginasSteps For The Procurement of Piping / Mechanical ItemsSanjeev KumarAinda não há avaliações

- Plant Shutdown ActivitiesDocumento1 páginaPlant Shutdown ActivitiesHosseinAinda não há avaliações

- Basic PipingDocumento48 páginasBasic Pipingmackoi BalaresAinda não há avaliações

- Majid Piping Supervisor CVDocumento3 páginasMajid Piping Supervisor CVZishan KhanAinda não há avaliações

- Maharashtra Factories Rules, 1963Documento210 páginasMaharashtra Factories Rules, 1963Jatin Shah100% (4)

- Capacity Design of Gas Distribution SystemsDocumento32 páginasCapacity Design of Gas Distribution SystemsErickAinda não há avaliações

- P&id SeminarDocumento30 páginasP&id SeminaryasirvazhikkadavuAinda não há avaliações

- TGE Brochure 2010Documento12 páginasTGE Brochure 2010ankeshkatochAinda não há avaliações

- ASD Metal Services Guide to Tubes, Pipes and FittingsDocumento8 páginasASD Metal Services Guide to Tubes, Pipes and FittingshaggAinda não há avaliações

- Linked inDocumento47 páginasLinked inProcess GeeksAinda não há avaliações

- APT001-S-DS-PI-004 Insulation - Gasket - Data - Sheet - Rev0+Documento10 páginasAPT001-S-DS-PI-004 Insulation - Gasket - Data - Sheet - Rev0+Roy RahadianAinda não há avaliações

- Design code for sour hydrocarbon liquid and vapour pipingDocumento6 páginasDesign code for sour hydrocarbon liquid and vapour pipingprathameshAinda não há avaliações

- Steam Trap and Drain Trap FunctionsDocumento23 páginasSteam Trap and Drain Trap FunctionsMallela Sampath KumarAinda não há avaliações

- Online Piping and Caesar Course SyllabusDocumento10 páginasOnline Piping and Caesar Course Syllabusm 418Ainda não há avaliações

- Training - Successful Project ManagementDocumento34 páginasTraining - Successful Project ManagementWidodo D PrasetyoAinda não há avaliações

- ValveDocumento9 páginasValveAdhie_ginthinkAinda não há avaliações

- Piping Specifications HarrisDocumento27 páginasPiping Specifications Harrisrensieovi100% (2)

- Bestline Mining Supplies LTD - 2010 EditionDocumento50 páginasBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaAinda não há avaliações

- Swagelok Fitting PDFDocumento16 páginasSwagelok Fitting PDFmattuiffAinda não há avaliações

- LWN FlangesDocumento8 páginasLWN Flangesfranckx1960Ainda não há avaliações

- Universal Y StrainerDocumento2 páginasUniversal Y Strainerabdi zakiAinda não há avaliações

- Mount-Rushmore-Brick-Red-Resume TemplateDocumento1 páginaMount-Rushmore-Brick-Red-Resume TemplateRaj Dubey100% (1)

- Plug Valve Specification for Carlsberg BreweryDocumento7 páginasPlug Valve Specification for Carlsberg BreweryNarayana MugalurAinda não há avaliações

- 1 - Training PDS Interface - Generate PCD and PDS RDB FilesDocumento25 páginas1 - Training PDS Interface - Generate PCD and PDS RDB Filesno1139Ainda não há avaliações

- L&T Aquaseal Butterfly Check Valves PDFDocumento28 páginasL&T Aquaseal Butterfly Check Valves PDFSanjay SahulAinda não há avaliações

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Documento84 páginasKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdAinda não há avaliações

- Welker 2Documento2 páginasWelker 2faradbAinda não há avaliações

- PE600 Brochure PipingEngineeringDocumento2 páginasPE600 Brochure PipingEngineeringGowri ShankarAinda não há avaliações

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDocumento8 páginasISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezAinda não há avaliações

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Documento2 páginasDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrAinda não há avaliações

- 2017 03436 01 002 - Bom 320Documento8 páginas2017 03436 01 002 - Bom 320sundyaAinda não há avaliações

- Datasheet of Butterfly ValveDocumento2 páginasDatasheet of Butterfly Valvedhaval3gAinda não há avaliações

- SPLM Licensing InstallDocumento9 páginasSPLM Licensing InstallAbdu AbdoulayeAinda não há avaliações

- The Feasibility of Transporting Hydrogen in Existing Carbon Steel PipelinesDocumento9 páginasThe Feasibility of Transporting Hydrogen in Existing Carbon Steel PipelinesomiitgAinda não há avaliações

- 1 PipelineDocumento69 páginas1 PipelineEhab MohammedAinda não há avaliações

- Annual Report HELLENIC PETROLEUM 2010Documento77 páginasAnnual Report HELLENIC PETROLEUM 2010AbdelmotelbElbannaAinda não há avaliações

- Swagelok Flange AdaptersDocumento6 páginasSwagelok Flange AdapterstotcsabAinda não há avaliações

- Presentation FRP 06Documento10 páginasPresentation FRP 06Mohamed BouchouatAinda não há avaliações

- Weld Spec 2Documento3 páginasWeld Spec 2spstainless316Ainda não há avaliações

- Site ResponsibilitiesDocumento1 páginaSite ResponsibilitiesShams TabrezAinda não há avaliações

- SS 316Documento6 páginasSS 316Shams TabrezAinda não há avaliações

- STD 118Documento22 páginasSTD 118Shams TabrezAinda não há avaliações

- 3 SP3D DisenoDocumento11 páginas3 SP3D DisenoShanmugaraj RamaiahAinda não há avaliações

- SP3D Object Search User Manual Rev4Documento44 páginasSP3D Object Search User Manual Rev4Kodali Naveen Kumar100% (1)

- Plinth & Slab Beam DetailsDocumento1 páginaPlinth & Slab Beam Detailsnandu523Ainda não há avaliações

- Yield Stress Sa 240 304Documento1 páginaYield Stress Sa 240 304faizalAinda não há avaliações

- Updtaed CV - Y.vikas Singla-2018Documento6 páginasUpdtaed CV - Y.vikas Singla-2018yv singlaAinda não há avaliações

- CMP E2FW Flameproof ATEX Cable Glands For Lead Sheathed CablesDocumento1 páginaCMP E2FW Flameproof ATEX Cable Glands For Lead Sheathed CablesrocketvtAinda não há avaliações

- List of UniversitasDocumento40 páginasList of UniversitasMuhamad Erlangga SaputraAinda não há avaliações

- Goud-Umashankar2018 Article InterfaceShearStrengthPropertiDocumento14 páginasGoud-Umashankar2018 Article InterfaceShearStrengthPropertiJPDGLAinda não há avaliações

- Concrete Problems in AI SafetyDocumento29 páginasConcrete Problems in AI SafetyCris D PutnamAinda não há avaliações

- Perspective: Proposed BungalowDocumento1 páginaPerspective: Proposed BungalowZhey GarciaAinda não há avaliações

- Design Hydraulic Pneumatic SystemsDocumento2 páginasDesign Hydraulic Pneumatic SystemsGokul raj SAinda não há avaliações

- Definition and Types of Bridges PDFDocumento34 páginasDefinition and Types of Bridges PDFHivet Jurieta Mamani100% (1)

- ICMSETDocumento9 páginasICMSETPramudyo BayuAinda não há avaliações

- Fib Bulletin 65 ContentsDocumento7 páginasFib Bulletin 65 ContentsMarko ĆećezAinda não há avaliações

- (PPR) Lbycvg1 Field TestsDocumento4 páginas(PPR) Lbycvg1 Field TestsJan Marielle LandichoAinda não há avaliações

- 42 GCSC PDFDocumento6 páginas42 GCSC PDFMary MorseAinda não há avaliações

- END-SEMESTER AND MID-SEMESTER EXAM SCHEDULE July 2021Documento32 páginasEND-SEMESTER AND MID-SEMESTER EXAM SCHEDULE July 2021sunny soniAinda não há avaliações

- Accomplishment Report Arc V1Documento24 páginasAccomplishment Report Arc V1ANO BYNOUUSAinda não há avaliações

- LS - Susol Series PDFDocumento354 páginasLS - Susol Series PDFThinh TranAinda não há avaliações

- I DriveDocumento2 páginasI DriveengineermarkAinda não há avaliações

- PostDocumento203 páginasPostMichael NasiefAinda não há avaliações

- Time Table Even Sem 18-19 (II, III and IV - PT) To WebsiteDocumento42 páginasTime Table Even Sem 18-19 (II, III and IV - PT) To WebsiteAnonymous n7zsf8w7aAinda não há avaliações

- The Easily Mounted Floor System For Large Spans: Hoesch Additive Floor Technical InformationDocumento16 páginasThe Easily Mounted Floor System For Large Spans: Hoesch Additive Floor Technical InformationIvan ŠpacAinda não há avaliações

- College Course Code Data for Andhra PradeshDocumento114 páginasCollege Course Code Data for Andhra Pradeshashok815Ainda não há avaliações

- Summary OM Notes CMA IMPDocumento99 páginasSummary OM Notes CMA IMPtapasAinda não há avaliações

- Electrical Engineer Sample CV 1Documento5 páginasElectrical Engineer Sample CV 1ArnabAinda não há avaliações

- IMP Q BearingsDocumento2 páginasIMP Q BearingsPraveen Kumar100% (1)