Escolar Documentos

Profissional Documentos

Cultura Documentos

Wind Mil

Enviado por

Abhi ChatterjeeDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Wind Mil

Enviado por

Abhi ChatterjeeDireitos autorais:

Formatos disponíveis

WindmiII

Background

A windmill is a structure or machine that converts wind into usable energy through

the rotation of a wheel made up of adjustable blades. Traditionally, the energy

generated by a windmill has been used to grind grain into flour. Windmills are

designed by skilled craftsmen and can be constructed on site using hand tools.

Windmills developed steadily over the centuries and achieved their most prominence

in Europe during the eighteenth century. They were largely replaced as a power

generating structure when steam power was harnessed during the nineteenth

century. Today, windmill technology is experiencing a renaissance and the wind

turbine promises to be an important alternative to fossil fuels in the future.

History

Man has used wind to power machines for centuries. The earliest use was most

likely as a power source for sail boats, propelling them across the water. The exact

date that people constructed windmills specifically for doing work is unknown, but the

first recorded windmill design originated in Persia around a.d. 500-900. This machine

was originally used for pumping water then it was adapted for grinding grain. t had

vertical sails made from bundles of lightweight wood attached to a vertical shaft by

horizontal struts. The design, known as the panemone, is one of the least efficient

windmill structures invented. t should be noted that windmills may have been used

in China over 2,000 years ago making it the actual birthplace for vertical-axis

windmills. However, the earliest recorded use found by archeologists in China is a.d.

1219.

The concept of the windmill spread to Europe after the Crusades. The earliest

European designs, documented in a.d. 1270, had horizontal axes instead of vertical

ones. The reason for this discrepancy is unknown, but it is likely a result of two

factors. First, the European windmills may have been patterned after water wheels

that had a horizontal axis. The water wheel had been known in Europe for long

before this. Second, the horizontal axis design was more efficient and worked better.

n general, these mills had four blades mounted on a central post. They had a cog

and ring gear that translated the horizontal motion of the central shaft into vertical

motion for the grindstone or wheel which would then be used for pumping water or

grinding grain.

The European millwrights improved windmill technology immensely over the

centuries. Most of the innovation came from the Dutch and the English. One of the

most important improvements was the introduction of the tower mill. This design

allowed for the mill's blades to be moved into the wind as required and the main

body to be permanently fixed in place. The Dutch created multi-story towers where

mill operators could work and also live. The English introduced a number of

automatic controls that made windmills more efficient.

During the pre-industrial world, windmills were the electric motors of Europe. n

addition to water pumping and grain grinding, they were used for powering saw mills

and processing spices, dyes, and tobacco. However, the development of steam

power during the nineteenth century, and the uncertain nature of windmill power

resulted in a steady decline of the use of large windmill structures. Today, only a

small fraction of the windmills that used to power the world are still standing.

Even as larger windmills were abandoned, smaller fan-type windmills were thriving.

These windmills were used primarily for pumping water on farms. n America, these

designs were perfected during the nineteenth century. The Halladay windmill was

introduced in 1854 followed by the Aermotor and Dempster designs. The later two

designs are still in use today. n fact, between 1850 and 1970 in the United States

over six million were constructed.

0sign

There are two classes of windmill, horizontal axis and vertical axis. The vertical axis

design was popular during the early development of the windmill. However, its

inefficiency of operation led to the development of the numerous horizontal axis

designs.

Of the horizontal axes versions, there are a variety of these including the post mill,

smock mill, tower mill, and the fan mill. The earliest design is the post mill. t is

named for the large, upright post to which the body of the mill is balanced. This

design gives flexibility to the mill operator because the windmill can be turned to

catch the most wind depending on the direction it is blowing. To keep the post stable

a support structure is built around it. Typically, this structure is elevated off the

ground with brick or stone to prevent rotting.

The post mill has four blades mounted on a central post. The horizontal shaft of the

blades is connected to a large break wheel. The break wheel interacts with a gear

system, called the wallower, which rotates a central, vertical shaft. This motion can

then be used to power water pumping or grain grinding activities.

The smock mill is similar to the post mill but has included some significant

improvements. The name is derived from the fact that the body looks vaguely like a

dress or smock as they were called. One advantage is the fact that only the top of

the mill is moveable. This allows the main body structure to be more permanent

while the rest could be adjusted to collect wind no matter what direction it is blowing.

Since it does not move, the main body can be made larger and taller. This means

that more equipment can be housed in the mill, and that taller sails can be used to

collect even more wind. Most smock mills are eight sided although this can vary from

six to 12.

Tower mills are further improvements on smock mills. They have a rotating cap and

permanent body, but this body is made of brick or stone. This fact makes it possible

for the towers to be rounded. A round structure allows for even larger and taller

towers. Additionally, brick and stone make the tower windmills the most weather

resistant design.

While the previous windmill designs are for larger structures that could service entire

towns, the fan-type windmill is made specifically for individuals. t is much smaller

and used primarily for pumping water. t consists of a fixed tower (mast), a wheel and

tail assembly (fan), a head assembly, and a pump. The masts can be 10-15 ft (3-15

m) high. The number of blades can range from four to 20 and have a diameter

between 6 and 16 ft (1.8-4.9 m).

#aw Mat0riaIs

Windmills can be made with a variety of materials. Post mills are made almost

entirely of wood. A lightweight wood, like balsa wood, is used for the fan blades and

a stronger, heavier wood is used for the rest of the structure. The wood is coated

with paint or a resin to protect it from the outside environment. The smock and tower

mills, built by the Dutch and British prior to the twentieth century, use many of the

same materials used for the construction of houses including wood, bricks and

stones.

The main body of the fan-type mills is made with galvanized steel. This process of

treating steel makes it weather resistant and strong. The blades of the fan are made

with a lightweight, galvanized steel or aluminum. The pump is made of bronze and

brass that inhibits freezing. Leather or synthetic polymers are used for washers and

o-rings.

%0 Manufacturing

Proc0ss

Windmills are always erected on site using pre-made parts. The following description

relates to the fan-type windmill. The basic steps include making the parts and then

assembling the structure.

Making t0 tow0r parts

O 1 The tower parts are made from galvanized steel. This process begins with a

roll of coiled sheet metal. The coils are put on a de-spooling device and fed

to the production line. They are run under a straightener to remove any

kinks or twists. The pieces are cut to the appropriate size and shape. n

some cases, pieces may be put on a machine that rolls them and welds the

seam. The ends are passed under a crimping machine and the pieces are

moved to the finishing station.

O 2 At the finishing station, holes are drilled in the metal parts at specific places

as required by the windmill design. The parts may also be painted or coated

before being arranged in the final windmill kit.

Making t0 g0arbox

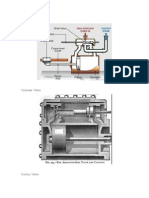

O 3 The gearbox is an intricate assembly made up of various gears, axles,

rotors, and wheels. The parts are die cast and assembled by hand. The are

placed in an weather resistant housing that is designed to accommodate

the gearbox parts and the attached wheel and tail assembly.

Making t0 fan

O 4 The fan is made up of a metal rim with slightly curved blades attached. The

rim is produced on a machine that rolls steel strips into circular hoops. A

hole is drilled in both ends, and they are connected with a small clamp and

screw after the fan blades are attached. A center axle is then connected to

the rim and attached with small steel spokes. A typical design will have five

pairs of spokes attached a evenly spaced intervals along the rim.

O 5 The fan blades and tail are cut from pieces of sheet metal. The blades are

then run through a machine that gives them a slight curve. They are

attached to the metal rim with small bolts and metal clamps. They are

attached in such a way that they can be raised or lowered depending on the

wind conditions.

Pr0paring t0 sit0

O 6 Finding and preparing the construction site is a crucial step in creating a

functional windmill. First, an area with a prevailing wind of at least 15 mph

(24 km/hr) is needed. Then the area needs to be cleared of trees and other

structures that may block wind. n some cases, a dirt mound or concrete

base is erected to raise the windmill off the surface to catch more wind.

inaI ass0mbIy

O 7 The parts of the main body are connected first. They are bolted together on

the ground and then raised up vertically. The outer poles are joined with the

connecting rods. Clamps are bolted at each joint for stability. After the tower

is raised it is loosely bolted to the solid base. Next stay wires are strung

from the frame down to the ground and attached to tensioners and ground

anchors. When the structure is level, the bolts are tightened and the

structure integrity is tested. n some cases a ladder is built into the frame

design to allow access to the fan on top which makes cleaning an

maintenance easier.

O 8 The fan wheel, gearbox, and main shaft are next attached. The gearbox is

first clamped and bolted to the top of the tower. The main shaft is then

inserted into the bottom of the gearbox. Next, the fan and its attached axle

are connected to the gearbox. Finally, the tail section is attached to the

gearbox. The pump is then hooked up to the main shaft and the windmill is

operational.

"uaIity ControI

'arious tests may be done to ensure that each part of the windmill meets the

specifications laid out in the design phase. The most basic of these are simple visual

inspections. These will catch most of the obvious production flaws. Since windmills

are erected by hand, the quality of each part goes through an additional visual

inspection. The quality of workmanship that goes into construction of the windmill will

be primarily responsible for the quality of the finished product. To ensure that it

remains efficient during operation, regular maintenance checks are necessary.

%0 utur0

Windmills have changed little over the last hundred years. n fact, one basic design

conceived in the 1870s is still sold today. The major improvements have come in the

types of materials used in construction. This trend will likely continue in future

windmill products. However, the future of harnessing wind power is not in traditional

windmills at all. The United States government has spent millions of dollars

researching and developing wind turbines for electricity generation. n California,

numerous wind farms are already in operation. 'arious other states and cities have

plans for creating similar wind farms. n the future, wind power promises to be an

environmentally friendly substitute for fossil fuels.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Certificate of Analysis BIRKOSIT 021208Documento1 páginaCertificate of Analysis BIRKOSIT 021208Project Sales CorpAinda não há avaliações

- 9961 Spider SC1000 Operator Manual V1-EnglishDocumento34 páginas9961 Spider SC1000 Operator Manual V1-EnglishdavidrockAinda não há avaliações

- Problems in Material BalanceDocumento28 páginasProblems in Material BalanceKent GardoseAinda não há avaliações

- CV Template For Mechanical EngineerDocumento3 páginasCV Template For Mechanical EngineerSyedZainAli0% (1)

- Megasan Catalog enDocumento108 páginasMegasan Catalog enMhd Maher Al BairoutiAinda não há avaliações

- Vakuumbandfilter enDocumento14 páginasVakuumbandfilter enFrank Vega OrtegaAinda não há avaliações

- Bgrim Oppday 2q2021Documento77 páginasBgrim Oppday 2q2021faroukaliasAinda não há avaliações

- A Study of Different Multi Effect EvaporatorsDocumento4 páginasA Study of Different Multi Effect EvaporatorsdafratuffAinda não há avaliações

- Segmenting The Energy Market: Problems and SuccessesDocumento13 páginasSegmenting The Energy Market: Problems and SuccessesNaveen AmarasingheAinda não há avaliações

- JS Nek606Documento40 páginasJS Nek606nokarajuAinda não há avaliações

- Micro Distillery Ecounit BrazilDocumento13 páginasMicro Distillery Ecounit BrazilgeotechjohnAinda não há avaliações

- ACS800-104-0510-3+E205+Q950+V991: General InformationDocumento2 páginasACS800-104-0510-3+E205+Q950+V991: General InformationDeepak JainAinda não há avaliações

- Kazakhstan National Innovation FundDocumento8 páginasKazakhstan National Innovation FundAchaemenidAdvisorsAinda não há avaliações

- An Jar Ulna NoDocumento14 páginasAn Jar Ulna NoMd Afzal NasirAinda não há avaliações

- 1) 3ua50-52-55 - 42Documento4 páginas1) 3ua50-52-55 - 42deepak2628Ainda não há avaliações

- Decision Tree ExampleDocumento2 páginasDecision Tree Examplemuhammad saadAinda não há avaliações

- Steam ValveDocumento6 páginasSteam ValveuaisouauAinda não há avaliações

- Phil Government Procument Policy BoardDocumento4 páginasPhil Government Procument Policy BoardRyan JD LimAinda não há avaliações

- Seal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDocumento5 páginasSeal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDikaAnindyajatiAinda não há avaliações

- Sop-40-Start Up of Loss in Weight Type Schenck UnitDocumento2 páginasSop-40-Start Up of Loss in Weight Type Schenck UnitOSAMAAinda não há avaliações

- Analysis of O & G Contract in GOMDocumento208 páginasAnalysis of O & G Contract in GOMRuslan ZakirovAinda não há avaliações

- Sinopec Engineering PresentationDocumento83 páginasSinopec Engineering Presentationstavros7Ainda não há avaliações

- Steel Asia - Company Case StudyDocumento3 páginasSteel Asia - Company Case StudyRaymond VillegasAinda não há avaliações

- REPRISM 2021 - UNIT START UP TIME REDUCTION FinalDocumento12 páginasREPRISM 2021 - UNIT START UP TIME REDUCTION Finalravi singhAinda não há avaliações

- "An Insight Into Production-Sharing Agreements: How They Prevent States From Achieving Maximum Control Over Their Hydrocarbon Resource" by Mary Sabina Peters and Manu KumarDocumento8 páginas"An Insight Into Production-Sharing Agreements: How They Prevent States From Achieving Maximum Control Over Their Hydrocarbon Resource" by Mary Sabina Peters and Manu KumarThe International Research Center for Energy and Economic Development (ICEED)Ainda não há avaliações

- 60% LDTDocumento63 páginas60% LDTChirag ShahAinda não há avaliações

- August 2015Documento112 páginasAugust 2015Gas, Oil & Mining Contractor MagazineAinda não há avaliações

- Daewoo DWC-054R Air ConditionerDocumento20 páginasDaewoo DWC-054R Air ConditionerericAinda não há avaliações

- Argus CoalDocumento5 páginasArgus Coalahong100Ainda não há avaliações

- BD 20231126Documento58 páginasBD 20231126amit mathurAinda não há avaliações