Escolar Documentos

Profissional Documentos

Cultura Documentos

Downstream Processing Assignment

Enviado por

Anupriya KhareDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Downstream Processing Assignment

Enviado por

Anupriya KhareDireitos autorais:

Formatos disponíveis

DOWNSTREAM PROCESSING ASSIGNMENT on

SOLVENT EXTRACTION PRINCIPLE

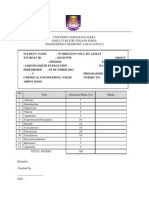

Submitted to: Mr. S.P. Singh Lecturer AIB

Submitted by: Anupriya Khare B.Tech (BT) 7A Roll no. 32 A7104108033 NOVEMBER, 2011

PRINCIPLE OF SOLVENT EXTRACTION

Extraction is the process of separating the constituents (solutes) of a liquid solution (feed) by contact with another insoluble liquid (solvent). During the liquid-liquid contact, the solutes will be distributed differently between the two liquid phases. By choosing a suitable solvent, you can selectively extract the desired products out of the feed solution into the solvent phase. Extraction is the removal of a soluble constituent from one liquid into another. By convention, the first liquid is the feed (F) which contains the solute at an initial concentration Xf. The second liquid is the solvent (S) which is at least partially immiscible with the feed. The solvent may also have some solute present at an initial concentration of Ys, but usually Ys is essentially zero. The solvent does the extraction, so the solvent-rich liquid leaving the extractor is the extract (E). With the solute partially or completely removed from the feed, the feed has become rejned so the feed-rich liquid leaving the extractor is the raffinate (R). When the feed and solvent are brought together, the solute (A) will distribute itself between the two liquid phases. At equilibrium, the ratio of this distribution is called the distribution coeficient (m):

The distribution coefficient, m, is a measure of the affinity of the solute (A) for one phase (E, S) over the other phase (F, R). The concentration of A may be expressed in various units, but for ease of subsequent calculations, it is preferable to express the concentration on a solutefree basis for both phases. For example, in the extraction of acetone from water with toluene:

Although the units of m appear to be dimensionless, they actually are (weight acetone-free water)/(weight acetone-free toluene). If more than one solute is present, the preference, or selectivity, of the solvent for one (A) over the other (B) is the separation factor ().

The separation factor (AB) must be greater than unity in order to separate A from B by solvent extraction, just as the relative volatility must be greater than unity to separate A from B by distillation. The analogy with distillation can be carried a step further. The extract phase is like the vapor distillate, a second phase wherein the equilibrium distribution of A with respect to B is higher than it is in the feed liquid (liquid bottoms). Extraction requires that the solvent and feed liquor be at least partially immiscible (two liquid phases), just as distillation requires both a vapor and a liquid phase. Extraction requires that the solvent and feed phases be of different densities. Even though extraction may successfully remove the solute from the feed, a further separation is required in order to recover the solute from the solvent, and to make the solvent suitable for reuse in the extractor. This recovery may be by any other unit operation, such as distillation, evaporation, crystallization and filtration, or by further extraction. Extraction is frequently chosen as the desired primary mode of separation or purification for one or more of the following reasons: 1. Where the heat of distillation is undesirable or the temperature would be damaging to the product (for example, in the recovery of penicillin from filtered broth). 2. Where the solute is present in low concentration and the bulk feed liquor would have to be taken overhead (most fermentation products). 3. Where extraction selectivity is favorable because of chemical differences, but where relative volatilities overlap. 4. Where extraction selectivity is favorable in ionic form, but not in the natural state (such as citric acid). 5. Where a lower form or less energy can be used. The latent heat of most organic solvents is less than 20% that of water, so recovery of solute from an organic extract may require far less energy than recovery from an aqueous feed.

The combinations of mixing both feed and solvent until the equilibrium distribution of the solute has occurred, and the subsequent complete separation of the two phases is defined as one theoretical stage (Fig. 1). The two functions may be carried out sequentially in the same vessel, simultaneously in two different zones of the same vessel, or in separate vessels (mixers and settlers).

Extraction may also be performed in a continuous differential fashion (Fig. 2), or in a sequential contact and separation where the solvent and feed phases flow counter currently to each other between stages (Fig. 3).

Você também pode gostar

- Liquid Liquid ExtractionDocumento40 páginasLiquid Liquid ExtractionApurba Sarker Apu93% (29)

- Table 1: Comparing Extraction and DistillationDocumento23 páginasTable 1: Comparing Extraction and DistillationAnonymous QM0NLqZOAinda não há avaliações

- Liquid LiquidDocumento8 páginasLiquid LiquidAnonymous b9fcR5Ainda não há avaliações

- Liquid-Liquid Extraction FundamentalsDocumento67 páginasLiquid-Liquid Extraction FundamentalsMuhammad Farhan100% (1)

- Liquid Liquid ExtractionDocumento25 páginasLiquid Liquid ExtractionsyafiqAinda não há avaliações

- Exp 6 Lab ReportDocumento15 páginasExp 6 Lab ReportNur Syuhaidah100% (1)

- Chapter 2 - LleDocumento56 páginasChapter 2 - LleShahrizatSmailKassim100% (3)

- Solvent Extraction Updated 14.02.2012Documento5 páginasSolvent Extraction Updated 14.02.2012Loveena SteadmanAinda não há avaliações

- CheDocumento15 páginasChenelsonAinda não há avaliações

- FractionationDocumento19 páginasFractionationnovitariaAinda não há avaliações

- Pressure Swing DistillationDocumento7 páginasPressure Swing DistillationgongweejieAinda não há avaliações

- Liquid Liquid ExtractionDocumento16 páginasLiquid Liquid ExtractionShahrizatSmailKassimAinda não há avaliações

- Liquid Liquid ExtractionDocumento19 páginasLiquid Liquid ExtractionNiteshmeeAinda não há avaliações

- Liquid-Liquid Extraction (LLE)Documento26 páginasLiquid-Liquid Extraction (LLE)soran najebAinda não há avaliações

- Lab LleDocumento20 páginasLab LleMuhamad Baihakhi Shamsudin100% (1)

- 09 01 24 CHE 411 Extraction-1Documento27 páginas09 01 24 CHE 411 Extraction-1olawale.olamide19Ainda não há avaliações

- Experiment 6 ExtractionDocumento10 páginasExperiment 6 Extractionwallace120Ainda não há avaliações

- CCB 3062 – Unit Operation Laboratory 2 January 2014 Experiment ReportDocumento11 páginasCCB 3062 – Unit Operation Laboratory 2 January 2014 Experiment Reporteelya93Ainda não há avaliações

- Laboratory Experiment 4 ExtractionDocumento4 páginasLaboratory Experiment 4 ExtractionPytharix CaineAinda não há avaliações

- Liquid-Liquid Extraction: Principle of SeparationDocumento11 páginasLiquid-Liquid Extraction: Principle of SeparationinamAinda não há avaliações

- AstDocumento33 páginasAstpradip katariyaAinda não há avaliações

- Organic Compound Separation Using Liquid-Liquid ExtractionDocumento8 páginasOrganic Compound Separation Using Liquid-Liquid ExtractionShyam BhaktaAinda não há avaliações

- Partition ExtractionDocumento5 páginasPartition ExtractionWhoZz DizAinda não há avaliações

- Liquid-Liquid Extraction: Frederick F. Cantwell and Manon LosierDocumento44 páginasLiquid-Liquid Extraction: Frederick F. Cantwell and Manon Losierاصيل اسامهAinda não há avaliações

- Liquid Extraction OperationDocumento19 páginasLiquid Extraction OperationOky TresiaAinda não há avaliações

- 4.liquid2 Extraction FullDocumento17 páginas4.liquid2 Extraction FullMuhammad Zaidi MisniAinda não há avaliações

- Module 2 - Extraction Note - DR Akinsiku PDFDocumento4 páginasModule 2 - Extraction Note - DR Akinsiku PDFGlory UsoroAinda não há avaliações

- CHE435 Week 5 LabDocumento19 páginasCHE435 Week 5 LabStolen RememberAinda não há avaliações

- Liquid Liquid ExtractionDocumento20 páginasLiquid Liquid ExtractionRavi JoshiAinda não há avaliações

- Liquid Liquid ExtractionDocumento25 páginasLiquid Liquid ExtractionAllensius Karelsta HarefaAinda não há avaliações

- LleDocumento17 páginasLlemirdza94Ainda não há avaliações

- Batch Distillation ExperimentsDocumento29 páginasBatch Distillation Experimentsytconstance50% (4)

- Simulation of liquid-liquid extractionDocumento16 páginasSimulation of liquid-liquid extractionKaaya GodfreyAinda não há avaliações

- Liquid/Liquid Extraction HandoutDocumento28 páginasLiquid/Liquid Extraction HandoutTINOTENDA TERAAinda não há avaliações

- Azeotropic and Extractive DistillationDocumento9 páginasAzeotropic and Extractive DistillationShahzaib IqbalAinda não há avaliações

- Extraction ExperimentDocumento6 páginasExtraction ExperimentFatima SaavedraAinda não há avaliações

- Distillation EkstraktifDocumento17 páginasDistillation EkstraktifIrlin AfrianingsihAinda não há avaliações

- Lec 10Documento14 páginasLec 10Anugrah SyaifullahAinda não há avaliações

- Liquid Liquid Extraction ExperimentDocumento22 páginasLiquid Liquid Extraction ExperimentMohd Sharu Mamat67% (12)

- Extractive Distillation ReportDocumento17 páginasExtractive Distillation ReportAmanda Brown100% (1)

- Physical Chemistry Chemical EquilibriumDocumento19 páginasPhysical Chemistry Chemical EquilibriumAdilla Rizka YonitaAinda não há avaliações

- Separation Process LLEDocumento59 páginasSeparation Process LLEmazayaAinda não há avaliações

- Solid-Liquid Extraction Lecture NotesDocumento21 páginasSolid-Liquid Extraction Lecture NotesDarren100% (1)

- Liquid Liquid ExtractionDocumento73 páginasLiquid Liquid ExtractionUbaid RaanAinda não há avaliações

- Expt B ManualDocumento10 páginasExpt B Manualwanbin zhuAinda não há avaliações

- This Study Resource WasDocumento8 páginasThis Study Resource WasDaniellaAinda não há avaliações

- Extraction TheoryDocumento32 páginasExtraction TheoryFida RoinikaAinda não há avaliações

- Liquid Extraction Process Design and TechniquesDocumento7 páginasLiquid Extraction Process Design and TechniquesIR Ika EtyEtyka DoraAinda não há avaliações

- Exp 4 Extraction 300LDocumento29 páginasExp 4 Extraction 300LAli MansourAinda não há avaliações

- 2210 - ExtractionDocumento13 páginas2210 - ExtractionChandra Icha KurniauanAinda não há avaliações

- 2423L6Documento11 páginas2423L6Salman Dinani100% (1)

- Experiment No. 8 - 203144254 - TIBDocumento4 páginasExperiment No. 8 - 203144254 - TIBBokutoAinda não há avaliações

- Separatory Funnel Extraction BackgroundDocumento3 páginasSeparatory Funnel Extraction BackgroundCelrose FernandezAinda não há avaliações

- Extraction Is A Terminology Used in The Mass Transfer Operations When A Desired Solute IsDocumento3 páginasExtraction Is A Terminology Used in The Mass Transfer Operations When A Desired Solute IsmadhujayarajAinda não há avaliações

- Extraction TechniquesDocumento40 páginasExtraction TechniquesAlexander Robert JennerAinda não há avaliações

- Relative volatility in distillation separationDocumento2 páginasRelative volatility in distillation separationChua RhickAinda não há avaliações

- Azeotropic Mixtures and Their Separation - PPT Outline Seminar 2Documento6 páginasAzeotropic Mixtures and Their Separation - PPT Outline Seminar 2Ben Anthony JosephsAinda não há avaliações

- O Level Biology Practice Questions And Answers Movement of substancesNo EverandO Level Biology Practice Questions And Answers Movement of substancesAinda não há avaliações

- BP406P Medicinal Chemistry1Documento30 páginasBP406P Medicinal Chemistry1Anit DubeyAinda não há avaliações

- BCS PrácticaDocumento17 páginasBCS PrácticaEarvin GonzálezAinda não há avaliações

- Aqueous Two Phase Extraction For Purification of C-PhycocyaninDocumento9 páginasAqueous Two Phase Extraction For Purification of C-PhycocyaninRuxandra SimionAinda não há avaliações

- Automatic Creation of Missing Groups Through Connectivity Index For Pure-Component Property PredictionDocumento8 páginasAutomatic Creation of Missing Groups Through Connectivity Index For Pure-Component Property Predictionmarco_ravelo_10Ainda não há avaliações

- Biochemistry Laboratory - Modern Theory and Techniques (2nd Edition) - Rodney F. Boyer-01360430Documento240 páginasBiochemistry Laboratory - Modern Theory and Techniques (2nd Edition) - Rodney F. Boyer-01360430M Azeneth JJAinda não há avaliações

- Medicinal Chemistry: Physicochemical Properties of Medicinal AgentsDocumento32 páginasMedicinal Chemistry: Physicochemical Properties of Medicinal AgentsakkimipadmaAinda não há avaliações

- Lipinski Rule of 5Documento23 páginasLipinski Rule of 5Ah BoonAinda não há avaliações

- Persistence of Carbon Dioxide Corrosion InhibitorsDocumento10 páginasPersistence of Carbon Dioxide Corrosion InhibitorsINRO IngeníeriaAinda não há avaliações

- Drug Design STEPS PDFDocumento26 páginasDrug Design STEPS PDFal_marton100% (1)

- LogP—Understanding How Chemicals PartitionDocumento4 páginasLogP—Understanding How Chemicals Partitionmbugua simon ngigiAinda não há avaliações

- AtenololDocumento21 páginasAtenololAbdul QadirAinda não há avaliações

- Rectal Drug Delivery: A Promising Route For Enhancing Drug AbsorptionDocumento7 páginasRectal Drug Delivery: A Promising Route For Enhancing Drug AbsorptionDwi Puspita AyuuAinda não há avaliações

- Liquid-Liquid Extraction Experiment (LLEDocumento5 páginasLiquid-Liquid Extraction Experiment (LLEMuhamad Baihakhi Shamsudin100% (1)

- Anish Nag Nikhil Dhull Ashmita Gupta: Original ArticleDocumento23 páginasAnish Nag Nikhil Dhull Ashmita Gupta: Original ArticleFajri FebrianAinda não há avaliações

- Solubility of Flavonoids in Organic SolventsDocumento5 páginasSolubility of Flavonoids in Organic SolventsJonatas LopesAinda não há avaliações

- Pharmaceutical Preformulation: The Physicochemical Properties of Drug SubstancesDocumento26 páginasPharmaceutical Preformulation: The Physicochemical Properties of Drug SubstancesChandrashekhar SinghAinda não há avaliações

- Exp-9 - Liquid Liquid Extraction in A Packed ColumnDocumento5 páginasExp-9 - Liquid Liquid Extraction in A Packed ColumnSiddharth MohapatraAinda não há avaliações

- Multi Author General Pharmacology PDFDocumento98 páginasMulti Author General Pharmacology PDFAamir Ali63% (8)

- Preformulation Studies: Characterizing New Drug MoleculesDocumento49 páginasPreformulation Studies: Characterizing New Drug MoleculesAnas AlamAinda não há avaliações

- Gardner 1980Documento10 páginasGardner 1980thomas cookAinda não há avaliações

- Complexation and Protein BindingDocumento15 páginasComplexation and Protein BindingShivraj JadhavAinda não há avaliações

- Manual On Fungicides and Fungicide Resistance Monitoring in BananaDocumento69 páginasManual On Fungicides and Fungicide Resistance Monitoring in BananaEiluj Lee PalamianoAinda não há avaliações

- Universiti Kuala Lumpur Royal College of Medicine Perak Bachelor of Science (Honours) in Pharmaceutical TechnologyDocumento10 páginasUniversiti Kuala Lumpur Royal College of Medicine Perak Bachelor of Science (Honours) in Pharmaceutical TechnologyAzel OthmanAinda não há avaliações

- Determination of Distribution Coefficient of Acetic AcidDocumento4 páginasDetermination of Distribution Coefficient of Acetic AcidPurnima NaskarAinda não há avaliações

- TRD Rar Uk MCCP enDocumento234 páginasTRD Rar Uk MCCP enusman khalidAinda não há avaliações

- Intro To Med Chem - Lecture 2Documento43 páginasIntro To Med Chem - Lecture 2lukehongAinda não há avaliações

- IPP-I As Per Generic Curriculum-LidetaDocumento416 páginasIPP-I As Per Generic Curriculum-Lidetaredhat56964Ainda não há avaliações

- CMC Ophthalmic FormulationsDocumento28 páginasCMC Ophthalmic FormulationsFagner CruzAinda não há avaliações

- LleDocumento30 páginasLlefirstlove_492_736373Ainda não há avaliações