Escolar Documentos

Profissional Documentos

Cultura Documentos

4 Microbial Lipids

Enviado por

Diana López LópezDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

4 Microbial Lipids

Enviado por

Diana López LópezDireitos autorais:

Formatos disponíveis

4 Microbial Lipids

COLIN RATLEDGE

Hull, United Kingdom

1 Introduction 135 1.1 Lipid Nomenclature and Major Lipid Types 138 2 Accumulation of Lipid 139 2.1 Patterns of Accumulation 139 2.2 Efficiency of Accumulation 142 2.3 Biochemistry of Accumulation 143 3 Triacylglycerols and Fatty Acids 146 3.1 Bacteria 147 3.1.1 Polyunsaturated Fatty Acids in Bacteria 147 3.2 Yeasts 148 3.2.1 Production of a Cocoa Butter Equivalent Yeast Fat 148 3.2.1.1 Direct Feeding of Stearic Acid 150 3.2.1.2 Inhibition of Stearoyl Desaturase 151 3.2.1.3 Mutation 152 3.2.1.4 Metabolic Manipulation 154 3.2.1.5 Conclusions 154 3.3 Molds 155 3.3.1 g-Linolenic Acid (GLA, 18:3 v-6) 159 3.3.2 Dihomo-g-Linolenic Acid (DHGLA, 20 : 3 v-6) 160 3.3.3 Arachidonic Acid (ARA, 20 : 4 v-6) 161 3.3.4 Eicosapentaenoic Acid (EPA, 20 : 5 v-3) 162 3.3.5 Docosahexaenoic Acid (DHA, 22 : 6 v-3) 162 3.3.6 Eicosatrienoic Acid (ETA, 20 : 3 v-9, Mead Acid) 163 3.3.7 Conclusions 163 3.4 Algae 164 3.4.1 g-Linolenic Acid (GLA, 18 : 3 v-6) 167 3.4.2 Arachidonic Acid (ARA, 20 : 4 v-6) 167 3.4.3 Eicosapentaenoic Acid (EPA, 20 : 5v-3) 168 3.4.4 Docosahexaenoic Acid (DHA, 22 : 6 v-3) 169 3.4.5 Conclusions 170

134

4 Microbial Lipids

4 Sterols, Carotenoids, and Polyprenes 170 4.1 Sterols 170 4.2 Carotenoids 172 4.3 Polyprenoids 175 5 Wax Esters and Polyesters 176 5.1 Wax Esters 176 5.2 Polyesters Poly-b-Hydroxyalkanoates 6 Other Lipids 180 6.1 Biosurfactants 180 6.2 Ether (Archaebacterial) Lipids 181 6.3 Phospholipids and Sphingolipids 183 6.4 Prostanoid-Type Lipids 184 7 Conclusions 185 8 References 186

177

1 Introduction

135

1 Introduction

Since the publication of the 1st Edition of Biotechnology and the earlier chapter on the biotechnology of lipids in 1986, a considerable number of developments have taken place in this field. Some microbial lipid products have now been produced commercially and prospects for other developments appear to be not too far away. In some cases, as e.g. with the bacterial lipid poly-b-hydroxybutyrate, no counterpart exists from plant or animal sources and consequently the economics of producing this product lie outside the normal oils and fats domain. With most other microbial lipids, these are the equivalent in composition to plant-derived oils and consequently must compete against these in any potential market place. Only the highest valued oils have any chance of being produced by biotechnological means as it is impossible for microorganisms to produce oils and fats as cheaply as the main commodity oils are produced from plant and animal sources. However, there is always the possibility of producing a microbial oil as an adjunct to some waste treatment process in a way similar to that often used to produce microbial proteins (SCP single cell protein) for animal feed from some unwanted substrate. Microbial oils which could then be referred to as single cell oils (SCO) would have the double advantage over SCP in that they could probably sell for a higher price than SCP and, moreover, could be used for a technical purpose should the nature of the substrate prevent the product being returned into the food chain. The major commercial plant oils continue to be dominated by soybean oil (current 1993 production is about 18710 6 t); palm oil, though, continues to be the fastest growing market with 14710 6 t now being produced compared to 6710 6 t in 1983. If the present rate of expansion in palm oil production continues in Malaysia and Indonesia (BASIRON and IBRAHIM, 1994; LEONARD, 1994), then palm oil will overtake soybean oil production by the end of this decade. Rapeseed oil (now 9710 6 t in 1993) is also expanding mainly due to increased cultivation in Europe and Canada. The variety now under cultivation is the

low- (or zero-) erucic acid (20 : 1) oil which is then a permitted oil for food manufacture. Overall production of plant and animal oils is increasing at about 3% per annum; production in 1992/93 was about 85710 6 t and is expected to reach 105710 6 t by the year 2000 (MIELKE, 1992). Pricing of these materials remains highly competitive as most products using oils can switch between the various types according to the price of the day. The average price index for the major commodity oils is about US$ 500550 per t though groundnut oil, e.g., is always significantly higher than the average at $ 800850 per t. The highest priced commodity oil, excluding the speciality materials, is always olive oil at $ 1,5002,000 per t. Its price depends on its quality which includes minor, but very important, flavor components. Animal fats (tallow and lard) have steadily declined in consumption over the past decade and are likely to fall even further to about 20% of the total market by 2001 (SHUKLA, 1994). Their prices are therefore usually at or below the average index level. The trends in world oil and fats supplies are under constant surveillance and are frequently reviewed in various publications: the extensive reviews by SHUKLA (1994) and MIELKE (1992) can be recommended though for current information journals such as Lipid Technology (P. T. Barnes & Associates), Oils and Fats International (Chase Webb, St Ives PLC), INFORM (American Oil Chemists Society, Illinois) provide invaluable and continuously up-dated information in most areas. There are, in addition, a number of specialized trade reviews that provide weekly prices of the traded oils. The fatty acid composition of the major commercial oils is given in Tab. 1. The nomenclature of lipids is given in Sect. 1.1. It will be appreciated that, unlike say animal feed protein, the composition of the fats varies considerably from species to species. In all cases, however, the oil or fat is composed almost entirely (`98%) of triacylglycerols (formerly known as triglycerides) Sect. 1.1. For edible purposes, the oil or fat is retained in this form though the individual fatty acyl groups on the glycerol can be modified usually by chemical means without affecting the triacylglycerol structure per se. Some en-

136

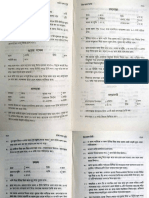

Tab. 1. Fatty Acid Composition of Fats and Oils of Animal and Plant Origin

Fats/Oils 12:0 3 P P 1 P P P P 1 10 P 1 7 1 1 22 b 9b 17 b 70 48 P P P 4.5 P P P P 1 1 P 1 P P P P P P P P P 2 P P P P P P P P P P P 22:0c24:0, 5% P P P P 22:1, 24:0, 39 2.5% 1.5% P P P P P 47 48 P P P P P P P P P P P 1 P P P P P 1 P P P 2 1 9 10 4 16 P P P P P 8 6 P 11 18 16 P P P P P P P 1 9 8 26 13 4 11 7 11 11 22 3 3 35 3 2 2 5 4 2 3 6 15 35 71 62 48 19 24 28 19 2 2 3 10 22 32 68 54 58 54 2 26 3 14 44 10 11 3 27 24 2 4 12 19 29 43 2 3 15:0c17:0, 3% 15:0c17:0, 2%; 14:1c17:1, 2% 14:0 16:0 16:1 18:0 18:1 18:2 18:3 20:0 20:1 Others

Relative Proportion of Fatty Acyl Groups [%(w/w)]

4:010:0

Animal Fats Butterfat Beef tallow

10 P

4 Microbial Lipids

Lard

Plant Oils Coconut oil Palm kernel oil Cocoa butter Olive oil Rapeseed oil Groundnut oil a Sunflower oil Soybean oil Corn oil Cotton seed oil

15 8 P P P P P P P P

Exotic Plant Oils Borage seed oil

Evening primrose seed oil Blackcurrant seed oil

P P

a-18:3,

13%

Also known as peanut oil. g-Linolenic acid, 18:3 (6, 9, 12).

1 Introduction

137

zymatic reformulation of triacylglycerols occurs on an industrial scale using stereospecific lipases to transesterify palm oil fractions into the much more expensive cocoa butter-like triacylglycerols (OWUSU-ANSAH, 1993). With some technical applications of oils, it is the fatty acid that is required; consequently saponification (hydrolysis) of the triacylglycerol is carried out and the fatty acid used either as such, e.g., with soap manufacture, or is modified to an appropriate derivative which is then used in a multitude of products: from detergents to adhesives. The aim of all biotechnological processes is to produce products that are either cheaper than can be obtained from other sources, including possible chemical synthesis, or are not available by any other means. Within the field of lipids, the opportunities to produce triacylglycerol lipids are limited to the highest valued materials. The highest priced bulk (commodity) oil is cocoa butter whose price has varied between $ 8,000 to $ 3,000 per t over the past decade. At the higher price level, the prospects of producing a cocoa butter equivalent oil by yeast technology have looked favorable. This topic is specifically reviewed later (see Sect. 3.2.1). Other very high valued oils are those in the health care market and which have had various claims made on their behalf for the amelioration of various diseases and conditions. Of current interest are oils containing the polyunsaturated fatty acids: g-linolenic acid, 18 : 3 (v-6); arachidonic acid, 20 : 4 (v-6); eicosapentaenoic acid, 20 : 5 (v-3); and docosahexaenoic acid, 22 : 6 (v-3). Oils containing such fatty acids are found in a number of microorganisms and are reviewed in Sects. 3.3 and 3.4. The very highest priced lipids though are probably the prostanoid compounds encompassing the prostaglandins, leukotrienes, and thromboxanes. These are mainly used for treatment of uncommon disorders or for experimental purposes. Consequently, the amounts required per annum are probably at the kilogram stage rather than the ton (or kiloton) stage with other lipid products. Prospects for producing such materials are briefly mentioned in Sect. 6.4. Thus, if we view microorganisms as a po-

tential source of the widest types of lipids then it is possible to identify a number of potentially attractive products. For the purposes of this article, I have therefore used the broad definition of a lipid as any material that is derived from a (micro)organism, is directly soluble in organic solvents, and is essentially a water-insoluble material. However, as there is still considerable interest in the manner in which microorganisms synthesize large quantities of lipids, much of the review will be taken up with the more conventional types of oils and fats that they produce. The entire subject of microbial lipids, encompassing all aspects and not just biotechnology, has been the above subject of a two-volume monograph by RATLEDGE and WILKINSON (1988a, 1989). The industrial applications of microbial lipids have also been the subject of a monograph edited by KYLE and RATLEDGE (1992). Details concerning the degradation of fats, oils, and fatty acids, including the action of lipases and phospholipases, which are not covered here have been recently reviewed elsewhere by the author (RATLEDGE, 1993). It will be appreciated, of course, that although microorganisms remain a potential source of oils and fats, there is considerable effort being put into the production of oils and fats from conventional plant sources. Such efforts include the modification of peanut oils (groundnut oil) to produce changes in the fatty acid composition so that the more desirable oils can be produced more cheaply. The application of genetic engineering is now gathering pace as a means of producing tailor-made oils and fats in plants and is likely to supersede the traditional plant breeding approach as a means of creating what is wanted more quickly and with greater certainty. This review, however, will not include any detailed review of the current developments in plant genetic engineering as applied to the commodity oils and fats. Readers should though be aware that such advances are now likely to be a major influence in the availability of improved oils for everyday use and will undoubtedly ensure that these materials remain highly competitively priced for many years to come. The recent reviews by HARWOOD (1994a, b), MURPHY (1994a) and RATTRAY (1994) and the monographs

138

4 Microbial Lipids

Tab. 2. Developments in Genetic Engineering (by in vitro Mutagenesis and Gene Transfer) Being Applied for the Modification of Plant Oils (adapted from RATTRAY, 1994) Plant Target Soybean and rapeseed Fatty Acid 16:0 16:0 18:0 18:1 a-18:3 Rapeseed Sunflower Linseed Groundnut 22:1 18:1 18:2c18:3 18:3 18:1 Objective increase decrease increase increase decrease increase increase decrease increase increase Application margarine edible oil margarine; cocoa butter substitute(?) improved edible oil improved stability and odor erucic acid for oleochemicals

6 olive oil substitute

oleochemicals improved edible oil

edited by RATTRAY (1991) and by MURPHY (1994b) will be found particularly useful in this respect. Tab. 2 summarizes some of the current developments that are now taking place in this area. The opportunities for microorganisms to produce oils and fats of commercial value for the bulk markets remain doubtful but where the product cannot be obtained from elsewhere then this provides a much better opportunity for a microbial oil than attempting to replicate what is already available from plant sources. Some opportunities nevertheless do exist but they have to be identified with some care. Hopefully, some of the following material may indicate to the astute reader where such opportunities may lie.

1.1 Lipid Nomenclature and Major Lipid Types

Fatty acids are long chain aliphatic acids (alkanoic acids) varying in chain length from, normally, C12 to C22 though both longer and shorter chain-length acids are known. In most cells (microbial, plant, and animal), the predominant chain lengths are 16 and 18. Fatty

acids may be saturated or unsaturated with one or more double bonds which are usually in the cis (or Z) form. The structure of a fatty acid is represented by a simple notation system PX : Y, where X is the total number of C atoms and Y is the number of double bonds. Thus, 18 : 0 is octadecanoic acid, that is stearic acid; 16 : 1 is hexadecenoic acid, that is palmitoleic acid, with one double bond, and 18 : 3 would represent octadecatrienoic acid, a C18 acid with three double bonds. The position of the double bond(s) is indicated by designating the number of the C atom, starting from the COOH terminus, from which the double bond starts: oleic acid is thus 18 : 1 (9) signifying the bond is from the 9th (to the 10th) C atom. If it is necessary to specify the isomer, this is added as c (for cispZ) or t for transpE). In this review, the cis/trans system is used. Thus, cis, cis-linoleic acid is 18 : 2 (c 9, c 12). Most naturally-occurring unsaturated fatty acids are in the cis configuration and, unless it is stated otherwise, this configuration may be assumed. With polyunsaturated fatty acids (PUFA), the double bonds are normally methylene-interrupted: UCHuCHUCH2UCHuCHU. Thus, once the position of one bond is specified all the others are also indicated. In num-

2 Accumulation of Lipid

139

bering PUFAs, a reverse system is used where the position of only the last double bond is given by the number of carbon atoms it is from the CH3 terminus. To denote the counting back system is in operation the notation is given as v-x or n-x; thus the two main isomers of linolenic acid (18 : 3) are given as 18 : 3 (v-3) and 18 : 3 (v-6) or as 18 : 3 (n-3) and 18 : 3 (n-6). In some systems, the minus sign may be omitted giving, for example, 18 : 3 (v3) or 18 : 3 (n3) and 18 : 3 (v6) and 18 : 3 (n6). Respectively, these two isomers are:

18 17 16 15 14 13 12 11

With respect to the monoacylglycerols, there are obviously three possible isomers and similarly for the diacylglycerols. Where different acyl groups are attached to the glycerol moiety, these can then be individually given. For example, 1-stearoyl-2-oleoyl3-palmitoyl-sn-glycerol is the major triacylglycerol of cocoa butter with stearic, oleic, and palmitic acids on the three OH positions. Phospholipids possess two fatty acyl groups at the sn-1 and sn-2 positions of glycerol with a phospho group at sn-3 which is also linked

10 9

CH3U CH2U CHu CHU CH2U CHu CHU CH2U CHu CH F

2 3 4 5 6 7 8

HOOCUH2 CUH2 CUH2 CUH2 CUH2 CUH2 CUH2 C CH3U CH2U CH2U CH2U CH2U CHu CHU CH2UCHuCH F v v-1 v-2 v-3 v-4 v-5 v-6 F n-1 n-2 n-3 n-4 n-5 n-6 n HOOCUH2CUH2CUH2CUH2CUHCuHCUH2C The v-x system will be used in this review. When fatty acids are esterified to glycerol, they give a series of esters: mono-, di-, and triacylglycerols (I, II, III). This is the preferred nomenclature to the older mono-, di-, and triglycerides. CH2UOUCOUR F CHUOH F CH2UOH I CH2UOUCOR F CHUOUCOR F CH2UOH II to a polar head group: choline, serine, ethanolamine, and inositol are the common ones. For the nomenclature and naming of phospholipids and other microbial lipids, the multiauthored treatise Microbial Lipids, edited by RATLEDGE and WILKINSON (1988a, 1989),

CH2UOUCOR F CHUOUCOR F CH2UOUCOR III may be helpful though there are numerous text books on lipids that provide similar information.

where R is a long alkyl chain and RCOU is, therefore, the fatty acyl group. As various isomeric forms are possible, the position of attached acyl group must be specified in most cases. For this, the stereospecific numbering (sn-) system is used so that the two prochiral positions of glycerol (IV) can be distinguished as sn-1 and sn-3.

1 2 3

2 Accumulation of Lipid

2.1 Patterns of Accumulation

Not all microorganisms can be considered as abundant sources of oils and fats, though, like all living cells, microorganisms always contain lipids for the essential functioning of

CH2OH F CHOH F CH2OH IV

140

4 Microbial Lipids

membranes and membranous structures. Those microorganisms that do produce a high content of lipid may be termed oleaginous in parallel with the designation given to oilbearing plant seeds. Of the some 600 different yeast species, only 25 or so are able to accumulate more than 20% lipid; of the 60,000 fungal species fewer than 50 accumulate more than 25% lipid (RATLEDGE, 1989 a). The lipid which accumulates in oleaginous microorganisms is mainly triacylglycerol (see Sect. 1.1). If lipids other than this type are required then considerations other than those expressed here might have to be taken into account to optimize their production. With few exceptions, oleaginous microorganisms are eukaryotes and thus representative species include algae, yeasts, and molds. Bacteria do not usually accumulate significant amounts of triacylglycerol but many do accumulate waxes and polyesters (see Sects. 5.1 and 5.2) which are now of commercial interest. The process of lipid accumulation in yeasts and molds growing in batch culture was elucidated in the 1930s and 1940s (see WOODBINE, 1959, for a review of the early literature, and RATLEDGE, 1982, for an updated review of these aspects). A typical growth pattern is shown in Fig. 1. This pattern is also found with the accumulation of polyester material in bacteria (see Sect. 5). The key to lipid accumulation lies in allowing the amount of nitrogen supplied to the

Fig. 2. Electron micrograph of Cryptococcus curvatus (pCandida curvatapApiotrichum curvatum) strain D grown for 2 days on nitrogen-limiting medium (viz. Fig. 1) showing presence of multiple lipid droplets. Total lipid content approx. 40%, marker bar: 1 mm (from HOLDSWORTH et al., 1988).

Fig. 1. Typical lipid accumulation pattern for a yeast (Rhodotorula glutinispR. gracilis) growing on a high C:N ratio medium in batch culture. Biomass L, % lipid content l, NHc in medium [ 4 (from YOON et al., 1982).

culture to become exhausted within about 2448 h. Exhaustion of nutrients other than nitrogen can also lead to the onset of lipid accumulation (see GRANGER et al., 1993, for a recent reference) but, in practice, cell proliferation is most easily effected by using a limiting amount of N (usually NH4c or urea) in the medium. The excess carbon which is available to the culture after N exhaustion continues to be assimilated by the cells and, by virtue of the oleaginous organism possessing the requisite enzymes (see below), is converted directly into lipid. The essential mechanism which operates is that the organism is unable to synthesize essential cell materials protein, nucleic acids, etc. because of nutrient deprivation and thus cannot continue to produce new cells. Because of the continued uptake of carbon and its conversion to lipid, the cells can then be seen to become engorged with lipid droplets (Fig. 2). It is important to appreciate, however, that the specific rate of lipid biosynthesis does not increase; the cells fatten because other processes slow down or cease altogether and, as lipid biosynthesis is not

2 Accumulation of Lipid

141

linked to growth, this may continue unabated. The process of lipid accumulation (Fig. 1) can be seen as a two-phase batch system: the first phase consists of balanced growth with all nutrients being available; the subsequent fattening or lipogenic stage occurs after the exhaustion of a key nutrient other than carbon and, of course O2. The role of O2 during lipid formation was discussed briefly in the 1st Edition of Biotechnology (RATLEDGE, 1986). Accumulation of lipid has also been achieved in single stage continuous culture (RATLEDGE et al., 1984) and a typical accumulation profile dependent upon the dilution rate (growth rate) is shown in Fig. 3. As with batch cultivation, the medium has to be formulated with a high carbon-to-nitrogen ratio, usually about 50 : 1. The culture must be grown at a rate which is about 2530% of the maximum. Under this condition, the concentration of nitrogen in the medium is virtually nil and the organism then has sufficient residence time within the chemostat to assimilate the excess carbon and convert it into lipid. The rate of lipid production (i.e., g L P1 h P1) is usually faster in continuous cultures than in batch ones (EVANS and RATLEDGE, 1983; FLOETENMEYER et al., 1985).

Fig. 3. Typical lipid accumulation pattern for a yeast (Rhodotorula glutinis) growing on nitrogen limiting medium in continuous culture. Biomass L, % lipid content [ (from YOON and RHEE, 1983).

The exact ratio of C to N chosen for the medium was originally considered to be of little consequence provided N was the limiting nutrient and sufficient carbon remained to ensure good lipid accumulation. However, YKEMA et al. (1986) showed that a range of lipid yields in an oleaginous yeast, Apiotrichum curvatum (originally Candida curvata but now Cryptococcus curvatus; see BARNETT et al., 1990) were traversed in continuous culture by varying the C : N ratio of the growth medium. There was a hyperbolic relationship between the C : N ratio and the maximum growth (dilution) rate that the organism could attain: the lowest growth rate was at the highest C : N ratio of 50 : 1 and this, in turn, controlled the amount of lipid produced and the efficiency of yield (g lipid per g glucose used) with which it was produced. Although the highest lipid contents of the cell (50% w/w) were obtained with a C : N ratio of 50 : 1 or over, the optimum ratio for maximum productivity (g L P1 h P1 lipid) was at a ratio of 25 : 1 with glucose (YKEMA et al., 1986) and at 3035 : 1 when whey permeates were used with same yeast (YKEMA et al., 1988). Similar results for describing the optimum C : N ratio for lipid accumulation have been developed by GRANGER et al. (1993) using Rhodotorula glutinis. Interestingly, YKEMA et al. (1986) commented that Apiotrichum curvatum simultaneously accumulated about 20% carbohydrate in the cells along with the 50% lipid. Such a phenomenon of carbohydrate formation had been conjectured by BOULTON and RATLEDGE (1983a) to be a likely event to account for an observed delay in lipid synthesis after glucose assimilation had been initiated. This carbohydrate was also recognized independently by HOLDSWORTH et al. (1988) in the same yeast and was considered to be glycogen. As YKEMA et al. (1986) pointed out, if the biosynthesis of the polysaccharide which, like lipid, is a reserve storage material, could be prevented then this would enhance the total amount of lipid producible with a cell. Although most studies on microbial lipid accumulation have been conducted using batch cultivation and, for accuracy, in continuous culture, other growth systems have also been explored. In particular, fed-batch cul-

142

4 Microbial Lipids

ture has proved effective in increasing both the cell density and lipid contents of oleaginous yeasts: YAMAUCHI et al. (1983) used ethanol as substrate with Lipomyces starkeyi and achieved a biomass density of 150 g L P1 with a lipid content of 54%. Similarly, PAN and RHEE (1986) achieved 185 g (dry wt.) of Rhodotorula glutinis per liter with a lipid content of 43% using glucose as the fed-batch substrate. In this latter case, O2-enriched air (40% O2 c 60% air) had to be used to sustain the cells. At the density recorded, the packed cell volume was 75% of the total volume of the fermentation medium. Without using additional O2, it seems likely that cell densities of up to 100 g L P1 could be achieved with most oleaginous yeasts (see, e.g., YKEMA et al., 1988) though filamentous molds may pose other problems. Economic considerations, however, would probably be against the use of O2-enriched air for any commercial process. Interestingly, it is suggested that higher rates of lipid formation may occur with fed-batch techniques than with batch- or continuous-culture approaches (YKEMA et al., 1988). At the end of the lipid accumulation phase (see Fig. 1), it is essential that the cells are promptly harvested and processed. If glucose, or other substrate, has become exhausted on the end of the fermentation, then the organism will begin to utilize the lipid as the role of the accumulated material is to act as a reserve store of carbon, energy, and possibly even water. HOLDSWORTH and RATLEDGE (1988) showed with a number of oleaginous yeasts that after carbon exhaustion following lipid accumulation, the lipid began to be utilized within 1.5 h thus indicating the dynamic state of storage lipids in these organisms.

2.2 Efficiency of Accumulation

The efficacy of conversion of substrate to lipid has been examined in some detail in both batch and continuous culture. In general, the latter technique offers the better means of attaining maximum conversions as the cells are operating under steady state conditions and carbon is not used with different efficiencies at each stage of the growth cycle.

Conversions of glucose and other carbohydrates including lactose and starch, to lipid up to 22% (w/w) have been recorded with a variety of yeasts (RATLEDGE, 1982; YKEMA et al., 1988; DAVIES and HOLDSWORTH, 1992; HASSAN et al., 1993) which compares favorably with the theoretical maximum of about 3133% (RATLEDGE, 1988). Somewhat lower yields appear to pertain with molds (WOODBINE, 1959; WEETE, 1980). The reason for this difference is not obvious though it may be due to a somewhat slower growth rate of molds than yeasts. It should be said, however, that there has not been the same amount of detailed work carried out with molds as with yeasts. Claims that microorganisms have achieved higher conversions of glucose or other sugars to lipid should be treated with caution: either there will be found to be additional carbon within the medium and not taken into the mass balance or, as may occasionally happen, the lipid has been improperly extracted and may contain non-lipid material. However, if experimental data are calculated so that the yield of lipid or fatty acids can be based on the fraction of glucose being used solely for lipid biosynthesis, then values close to the theoretical value have been attained in practice (GRANGER et al., 1993). When ethanol is used as substrate, the theoretical yield of lipid is 54% (w/w) (RATLEDGE, 1988). Though only a 21% conversion of ethanol to lipid was recorded by YAMAUCHI et al. (1983) in the fed-batch culture of Lipomyces starkeyi, higher conversions were recorded by EROSHIN and KRYLOVA (1983) also using a fed-batch system for the cultivation of yeasts on ethanol: conversions of 26%, 27%, and 31% were obtained using, respectively, Zygolipomyces lactosus (Lipomyces tetrasporus) and two strains of Cryptococcus albidus var. aerius. The reason for these very high values lies in the efficiency by which ethanol can be converted to acetyl- CoA, the starting substrate for lipid biosynthesis (see below). With glucose, the maximum yield of acetyl-CoA can only be 2 mol per mol utilized whereas with ethanol the yield is 1 mol per mol. On a weight-to-weight basis, therefore, ethanol (MW 46) is almost twice as efficient as glucose (MW 180) in providing C2 units. GRANGER et al. (1993) have recorded direct

Você também pode gostar

- Grant Writers WorkbookDocumento184 páginasGrant Writers WorkbookSharif M Mizanur RahmanAinda não há avaliações

- Production of 120000 MTA Oleochemical Fatty Acids From Sunflower OilsDocumento93 páginasProduction of 120000 MTA Oleochemical Fatty Acids From Sunflower OilsRay LimAinda não há avaliações

- Refinery of Palm OilDocumento36 páginasRefinery of Palm Oildoshi_ritesh100% (6)

- Green Vegetable Oil Processing: Revsied First EditionNo EverandGreen Vegetable Oil Processing: Revsied First EditionWalter E. FarrNota: 3 de 5 estrelas3/5 (1)

- Transgenic OilsDocumento20 páginasTransgenic OilsHerdiwan Novindra0% (1)

- Biomolecules 10 00106Documento9 páginasBiomolecules 10 00106SpidervaitAinda não há avaliações

- For Thesis'Documento3 páginasFor Thesis'Gracilla ElmidoAinda não há avaliações

- 1 Production and Trade of Vegetable Oils: Frank D. GunstoneDocumento5 páginas1 Production and Trade of Vegetable Oils: Frank D. GunstoneAlfonso RuizAinda não há avaliações

- Table of Alimentary OilsDocumento3 páginasTable of Alimentary Oilshonest_loezAinda não há avaliações

- Molecules: Biological and Nutritional Properties of Palm Oil and Palmitic Acid: Effects On HealthDocumento23 páginasMolecules: Biological and Nutritional Properties of Palm Oil and Palmitic Acid: Effects On HealthHyung Sholahuddin AlayAinda não há avaliações

- Palm Oil (Q&A) 2013Documento5 páginasPalm Oil (Q&A) 2013labendetAinda não há avaliações

- Palm Oil in FryingDocumento73 páginasPalm Oil in FryingGenesis Custodio100% (1)

- Fatty Acid CompositionDocumento5 páginasFatty Acid CompositionAnonymous MhTaJsAinda não há avaliações

- Oil and Fat Technology Lectures IDocumento27 páginasOil and Fat Technology Lectures Iaulger100% (4)

- 9559 26617 1 PBDocumento21 páginas9559 26617 1 PBerrisharAinda não há avaliações

- Quality and Functions of Palm Oil - MPOCDocumento117 páginasQuality and Functions of Palm Oil - MPOCAhmad Fadzli Abdul Aziz100% (1)

- KIL 2002 Oleochemicals - 2018Documento41 páginasKIL 2002 Oleochemicals - 2018EdAinda não há avaliações

- Fatty AcidsDocumento9 páginasFatty AcidsQOTRUNNADA AIDAAinda não há avaliações

- Chapter 1.1Documento83 páginasChapter 1.1Hafizuddin AdzharAinda não há avaliações

- Vegetable OilsDocumento7 páginasVegetable OilsJohn FernandezAinda não há avaliações

- A Two-Step Acid-Catalyzed Process For The Production of Biodiesel Fron Rice Bran OilDocumento8 páginasA Two-Step Acid-Catalyzed Process For The Production of Biodiesel Fron Rice Bran OilPablo PaganiAinda não há avaliações

- Soybean OilDocumento77 páginasSoybean OilSabrina LaBlue100% (2)

- Cestaro Dkk. 2017Documento4 páginasCestaro Dkk. 2017Dika CodAinda não há avaliações

- Biodiesel: Ways of Obtaining and ImportanceDocumento40 páginasBiodiesel: Ways of Obtaining and ImportanceCarolina RamirezAinda não há avaliações

- 24 MaizeeeDocumento10 páginas24 MaizeeeRizka ArianiAinda não há avaliações

- Food and Nutritional Analysis Oils and Fats-328-334Documento7 páginasFood and Nutritional Analysis Oils and Fats-328-334fernandoferozAinda não há avaliações

- Oleochemistry - WikipediaDocumento5 páginasOleochemistry - WikipediaSerafeim SakkasAinda não há avaliações

- Oilref-Soybean Oil RefiningDocumento37 páginasOilref-Soybean Oil RefiningirfanAinda não há avaliações

- Enzymatic Synthesisof Biodieselvia Alcoholysisof Palm OilDocumento10 páginasEnzymatic Synthesisof Biodieselvia Alcoholysisof Palm Oilroberto.siregar4002Ainda não há avaliações

- tmp405F TMPDocumento23 páginastmp405F TMPFrontiersAinda não há avaliações

- Corn Oil. An Emerging Industrial Product: January 2012Documento40 páginasCorn Oil. An Emerging Industrial Product: January 2012dimas nuriyan efendiAinda não há avaliações

- Biobased Polyalphaolefin Base Oil Chemical PhysicaDocumento17 páginasBiobased Polyalphaolefin Base Oil Chemical Physicamoneeb buttAinda não há avaliações

- Palm Oil Fractionation: Article April 2007 With 5,542 ReadsDocumento38 páginasPalm Oil Fractionation: Article April 2007 With 5,542 ReadsFadzal Al-MuhandisAinda não há avaliações

- WWW Britannica Com Science Human Nutrition LipidsDocumento6 páginasWWW Britannica Com Science Human Nutrition LipidsJd DiazAinda não há avaliações

- Grasas VacaDocumento17 páginasGrasas VacajulianAinda não há avaliações

- Use of Coconut OilDocumento5 páginasUse of Coconut OilRakeshKumarAinda não há avaliações

- Liu 1997Documento89 páginasLiu 1997Hary PrasetyaAinda não há avaliações

- Palm Oil: Biochemical, Physiological, Nutritional, Hematological, and Toxicological Aspects: A ReviewDocumento24 páginasPalm Oil: Biochemical, Physiological, Nutritional, Hematological, and Toxicological Aspects: A ReviewCarlos RomanAinda não há avaliações

- 2001 Final Report On The Safety Assessment of Hydrogenated Cottonseed Oil Cottonseed (Gossypium) Oil Cottonseed AcidDocumento9 páginas2001 Final Report On The Safety Assessment of Hydrogenated Cottonseed Oil Cottonseed (Gossypium) Oil Cottonseed Acidmgamal1080Ainda não há avaliações

- Fatty Acid Oil CompositionDocumento10 páginasFatty Acid Oil CompositionĀĥMệd HĀşşanAinda não há avaliações

- Research Paper On Vegetable OilDocumento7 páginasResearch Paper On Vegetable Oilefe8zf19100% (1)

- Single Cell Oils: Microbial and Algal OilsNo EverandSingle Cell Oils: Microbial and Algal OilsZvi CohenAinda não há avaliações

- Total Polar Compounds and Acid Values of Repeatedly UsedDocumento8 páginasTotal Polar Compounds and Acid Values of Repeatedly UsedtonicokAinda não há avaliações

- Biodiesel Production From Waste Cooking OilDocumento29 páginasBiodiesel Production From Waste Cooking OilNurhayati SurbaktiAinda não há avaliações

- 3rd Draft - Last VersionDocumento39 páginas3rd Draft - Last VersionParinitha RaoAinda não há avaliações

- Rice Bran OilDocumento8 páginasRice Bran OilAK CúAinda não há avaliações

- Palm Oil and Palm Kernel Oil: Versatile Ingredients For Food ApplicationsDocumento25 páginasPalm Oil and Palm Kernel Oil: Versatile Ingredients For Food ApplicationsFikka RuhaiyaAinda não há avaliações

- Healthy Fats and Oils: Topic HighlightsDocumento11 páginasHealthy Fats and Oils: Topic HighlightsAditia Habibul AkbarAinda não há avaliações

- Chemical Modifications of Lipids For Applications in Chemical Industry PDFDocumento49 páginasChemical Modifications of Lipids For Applications in Chemical Industry PDFAlfonso FuentesAinda não há avaliações

- Dissertation Fan2010 (204-253)Documento50 páginasDissertation Fan2010 (204-253)ابوايمن العمراني ايمنAinda não há avaliações

- Refinery of Palm OilDocumento14 páginasRefinery of Palm OilEvantono Balin Christianto100% (1)

- Transesterification For The Preparation of Biodiesel From Crude-Oil of Pongamia PinnataDocumento6 páginasTransesterification For The Preparation of Biodiesel From Crude-Oil of Pongamia PinnataatulsemiloAinda não há avaliações

- 1-s2.0-S0301679X08000595-Main Experience With Evaluating Biodegradability of Lubricating Base OilsDocumento7 páginas1-s2.0-S0301679X08000595-Main Experience With Evaluating Biodegradability of Lubricating Base OilsJúlio MilitãoAinda não há avaliações

- Trait-Modified Oils in FoodsNo EverandTrait-Modified Oils in FoodsFrank T. OrthoeferAinda não há avaliações

- Olive Oil: Chemistry and TechnologyNo EverandOlive Oil: Chemistry and TechnologyDimitrios BoskouNota: 3.5 de 5 estrelas3.5/5 (2)

- Trans Fats Replacement SolutionsNo EverandTrans Fats Replacement SolutionsDharma R. KodaliNota: 3 de 5 estrelas3/5 (1)

- Edible Oleogels: Structure and Health ImplicationsNo EverandEdible Oleogels: Structure and Health ImplicationsAinda não há avaliações

- Oilseed Crops: Yield and Adaptations under Environmental StressNo EverandOilseed Crops: Yield and Adaptations under Environmental StressAinda não há avaliações

- BlackHoles Thorne StarmusDocumento10 páginasBlackHoles Thorne StarmusSharif M Mizanur RahmanAinda não há avaliações

- Respiration HandoutDocumento9 páginasRespiration HandoutSharif M Mizanur RahmanAinda não há avaliações

- Meraj and ScienceDocumento93 páginasMeraj and ScienceSharif M Mizanur RahmanAinda não há avaliações

- History of Science Fullversion PDFDocumento70 páginasHistory of Science Fullversion PDFSharif M Mizanur RahmanAinda não há avaliações

- Kyokushin TerminologieDocumento13 páginasKyokushin TerminologieSharif M Mizanur RahmanAinda não há avaliações

- Recipetehari PDFDocumento153 páginasRecipetehari PDFSharif M Mizanur RahmanAinda não há avaliações

- Ranna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Documento73 páginasRanna Khaddo O Pusti by Siddika Kabir Part 1 (p50-p189)Sharif M Mizanur RahmanAinda não há avaliações

- U.S. Meat Goat Operations: Veterinary ServicesDocumento4 páginasU.S. Meat Goat Operations: Veterinary ServicesSharif M Mizanur RahmanAinda não há avaliações

- Ranna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Documento48 páginasRanna Khaddo O Pusti by Siddika Kabir Part 4 (p430-p524)Sharif M Mizanur Rahman0% (1)

- Ranna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Documento60 páginasRanna Khaddo O Pusti by Siddika Kabir Part 3 (p310-p429)Sharif M Mizanur RahmanAinda não há avaliações

- What Are The Transport Phenomena?: Wednesday, August 24, 2016 9:39 PMDocumento8 páginasWhat Are The Transport Phenomena?: Wednesday, August 24, 2016 9:39 PMSharif M Mizanur RahmanAinda não há avaliações

- Ranna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Documento60 páginasRanna Khaddo O Pusti by Siddika Kabir Part 2 (p190-p309)Sharif M Mizanur RahmanAinda não há avaliações

- Isoa Hea OMPASS - 2016 - 2017 PDFDocumento13 páginasIsoa Hea OMPASS - 2016 - 2017 PDFSharif M Mizanur RahmanAinda não há avaliações

- Math Prob SP 3Documento2 páginasMath Prob SP 3Sharif M Mizanur RahmanAinda não há avaliações

- Vector Subspace DimDocumento5 páginasVector Subspace DimSharif M Mizanur RahmanAinda não há avaliações

- MIT Artificial LeafDocumento10 páginasMIT Artificial LeafSharif M Mizanur RahmanAinda não há avaliações

- Math24 SolDocumento2 páginasMath24 SolSharif M Mizanur RahmanAinda não há avaliações

- Linear Dependence and Independence (Chapter. 4) : Column SpaceDocumento12 páginasLinear Dependence and Independence (Chapter. 4) : Column SpaceSharif M Mizanur RahmanAinda não há avaliações