Escolar Documentos

Profissional Documentos

Cultura Documentos

Separation Techniques

Enviado por

solangishahidDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Separation Techniques

Enviado por

solangishahidDireitos autorais:

Formatos disponíveis

Isotope Separation:

Isotope separation is the process of concentrating specific isotopes of a chemical element by removing other isotopes, for example separating natural uranium into enriched uranium and depleted uranium. This is a crucial process in the manufacture of uranium fuel for nuclear power stations, and is also required for the creation of uranium based nuclear weapons. Plutonium based weapons use plutonium produced in a nuclear reactor, which must be operated in such a way as to produce plutonium already of suitable isotopic mix or grade. This theory was first recognized by Charles H. Townes. While in general chemical elements can be purified through chemical processes, isotopes of the same element have nearly identical chemical properties, which make this type of separation impractical, except for separation of deuterium.

Practical methods of separation:

1. Mass Spectrograph/Electromagnetic This method uses the fact that charged particles are deflected in a magnetic field and the amount of deflection depends upon the particle's mass. It is very expensive for the quantity produced, as it has an extremely low throughput, but it can allow very high purities to be achieved. This method is often used for processing small amounts of pure isotopes for research or specific use, but is impractical for industrial use. Uranium used in the first United States atomic bomb was enriched by this method. Devices using this principle are named calutrons. After the war the method was largely abandoned as impractical. 2. Gas Diffusion Separation: Often done with gases, but also with liquids, the diffusion method relies on the fact that in thermal equilibrium, two isotopes with the same energy will have different average velocities. The lighter atoms will travel more quickly and be more likely to diffuse through a membrane. The difference in speeds is proportional to the square root of the mass ratio, so the amount of separation is small and many cascaded stages are needed to obtain high purity. This method is expensive due to the work needed to push gas through a membrane and the many stages necessary. The first large-scale separation of uranium isotopes was achieved by the United States in large gaseous diffusion separation plants at Oak Ridge Laboratories. These used uranium hexafluoride gas as the process fluid. Nickel powder and electro-deposited nickel mesh diffusion barriers were pioneered by Edward Adler and Edward Norris. 3. Gas Centrifuge: Centrifugal effect schemes rapidly rotate the material allowing the heavier isotopes to go closer to an outer radial wall. The centrifugal separation of isotopes was first suggested by Aston and Lindemann in 1919 and the first successful experiments were reported by Beams and Haynes on isotopes of chlorine in 1936. In modern times it is the main method used throughout the world to enrich uranium and as a result remains a fairly secretive process, hindering a more widespread uptake of the technology. In general a feed of UF6 gas is connected to a cylinder that is rotated at high speed. Near the outer edge of the cylinder heavier gas molecules containing U-238 collect, while molecules containing U-235 concentrate at the center and are then fed to another cascade stage. Use of gaseous centrifugal technology to enrich isotopes is desirable as power consumption is greatly reduced when compared to more conventional techniques such as

diffusion plants since fewer cascade steps are required to reach similar degrees of separation. In fact, Gas centrifuges using uranium hexafluoride have largely replaced gaseous diffusion technology for uranium enrichment. As well as requiring less energy to achieve the same separation, far smaller scale plants are possible, making them an economic possibility for a small nation attempting to produce a nuclear weapon. Pakistan is believed to have used this method in developing its nuclear weapons. 4. Laser Isotope Separation: a. In this method a laser is tuned to a wavelength which excites only one isotope of the material and ionizes those atoms preferentially. The resonant absorption of light for an isotope is dependent upon its mass and certain hyperfine interactions between electrons and the nucleus, allowing finely tuned lasers to interact with only one isotope. After the atom is ionized it can be removed from the sample by applying an electric field. This method is often abbreviated as AVLIS (atomic vapor laser isotope separation). This method has only recently been developed as laser technology has improved, and is currently not used extensively. However, it is a major concern to those in the field of nuclear proliferation because it may be cheaper and more easily hidden than other methods of isotope separation. Tunable lasers used in AVLIS include the dye laser and more recently diode lasers. One kilogram of enriched product comes from 6 kg of natural uranium. b. A second method of laser separation is known as MLIS, Molecular Laser Isotope Separation. In this method, an infrared laser is directed at uranium hexafluoride gas, exciting molecules that contain a U-235 atom. A second laser frees a fluorine atom, leaving uranium pentafluoride which then precipitates out of the gas. Cascading the MLIS stages is more difficult than with other methods because the UF5 must be refluorinated (back to UF6) before being introduced into the next MLIS stage. Alternative MLIS schemes are currently being developed (using a first laser in the near-infrared or visible region) where an enrichment of over 95% can be obtained in a single stage, but the methods have not (yet) reached industrial feasibility. This method is called OPIRMPD (Overtone Pre-excitation - IR Multiple Photon Dissociation). Finally, the SILEX process, developed by Silex Systems in Australia, has recently been licensed to General Electric for the development of a pilot enrichment plant. The method uses uranium hexafluoride as a feedstock, and uses magnets to separate the isotopes after one isotope is preferentially ionized. Further details of the process are not disclosed. Gravity Isotopes of Carbon, Oxygen, and Nitrogen can be purified by chilling these gases or compounds nearly to their liquefaction temperature in very tall columns (200 to 700 feet tall - 70 to 200 meters). The heavier isotopes sink and the lighter isotopes rise, where they are easily collected. The process was developed in the late 1960s by scientists at Los Alamos. This process is also called "cryogenic distillation".

Você também pode gostar

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Vertical Force Considerations in Differential Space Closure - JCO-OnLINEDocumento5 páginasVertical Force Considerations in Differential Space Closure - JCO-OnLINE김재훈Ainda não há avaliações

- Applyingasuitablerouteforpreparation Fe 3 O4 Nanoparticlesby AmmoniaandinvestigationoftheirphysicalanddifferentmagneticpropertiesDocumento9 páginasApplyingasuitablerouteforpreparation Fe 3 O4 Nanoparticlesby AmmoniaandinvestigationoftheirphysicalanddifferentmagneticpropertiesGurudas VisputeAinda não há avaliações

- Using Jmol To Help Students Better Understand Fluxional ProcessesDocumento1 páginaUsing Jmol To Help Students Better Understand Fluxional Processesdevy ridaAinda não há avaliações

- UntitledDocumento3 páginasUntitledFarah EssidAinda não há avaliações

- Energy Transfer in Electrical CircuitsDocumento5 páginasEnergy Transfer in Electrical CircuitsAnyrchiveAinda não há avaliações

- Torque and Equilibrium (40 charactersDocumento2 páginasTorque and Equilibrium (40 charactersEndai DesuAinda não há avaliações

- MATE464 W4 Tribology v2Documento87 páginasMATE464 W4 Tribology v2Tuna CanAinda não há avaliações

- Chapter 12: Vibrations and Waves: 12.1 Simple Harmonic MotionDocumento5 páginasChapter 12: Vibrations and Waves: 12.1 Simple Harmonic MotionSteven SuAinda não há avaliações

- CO4-Kinetic Theory of GasesDocumento39 páginasCO4-Kinetic Theory of GasesThrishnaa BalasupurManiamAinda não há avaliações

- Question Bank: Ee 1403 - Design of Electrical ApparatusDocumento11 páginasQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshAinda não há avaliações

- Fundamentals of Statistical Mechanics: EnsemblesDocumento10 páginasFundamentals of Statistical Mechanics: EnsemblesRUIVTOMAinda não há avaliações

- Performance of emulsion explosives containing glass micro-balloonsDocumento7 páginasPerformance of emulsion explosives containing glass micro-balloonsOscar PamosAinda não há avaliações

- WWW - Manaresults.Co - In: (Common To ME, AME, MSNT)Documento2 páginasWWW - Manaresults.Co - In: (Common To ME, AME, MSNT)Asheesh KumarAinda não há avaliações

- API Piping PlanDocumento109 páginasAPI Piping PlanSakthikumar ChandrasekaranAinda não há avaliações

- Couette Flow of Micropolar Fluids: Theory GoverningDocumento6 páginasCouette Flow of Micropolar Fluids: Theory GoverningSrinivas JangiliAinda não há avaliações

- SsssDocumento17 páginasSsssPhysicsAinda não há avaliações

- #Part 1 2021 PSM NMRDocumento26 páginas#Part 1 2021 PSM NMRMely Yunior SafitriAinda não há avaliações

- Aqa 84031 W MS Jun13 PDFDocumento18 páginasAqa 84031 W MS Jun13 PDFdadajee420Ainda não há avaliações

- Net Positive Suction HeadDocumento16 páginasNet Positive Suction HeadpandiangvAinda não há avaliações

- 55-1-1 Physics Marking Scheme 2020Documento18 páginas55-1-1 Physics Marking Scheme 2020jyotibhalaAinda não há avaliações

- Air Crew Radiation Exposure - An OverviewDocumento8 páginasAir Crew Radiation Exposure - An OverviewStarxteelAinda não há avaliações

- Skills Sheet F12 - MatricesDocumento2 páginasSkills Sheet F12 - MatricesAlice YipAinda não há avaliações

- Unbalanced Magnetic Pull Forces in Cage Induction Motors with AsymmetryDocumento5 páginasUnbalanced Magnetic Pull Forces in Cage Induction Motors with AsymmetryRohan ChandrashekarAinda não há avaliações

- MicrobiologyDocumento82 páginasMicrobiologyAbhishek SinghAinda não há avaliações

- Classified Examples of Electrical Engineering 1928Documento103 páginasClassified Examples of Electrical Engineering 1928dominicrochford3068Ainda não há avaliações

- Modern Physics OverviewDocumento32 páginasModern Physics OverviewKay LagunaAinda não há avaliações

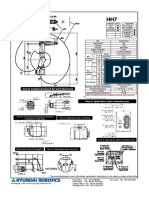

- Hh7 CatalogDocumento1 páginaHh7 Catalogjitender kumarAinda não há avaliações

- 12.elastic ConstantsDocumento18 páginas12.elastic ConstantsaderancAinda não há avaliações

- Energy Transfer in Turbomachines ExplainedDocumento4 páginasEnergy Transfer in Turbomachines Explainedsachintyagi1Ainda não há avaliações

- Separation of HCl-H2SO4 by MDDocumento7 páginasSeparation of HCl-H2SO4 by MDKuldeep BhattAinda não há avaliações