Escolar Documentos

Profissional Documentos

Cultura Documentos

Spec HT Cable

Enviado por

Anonymous vcadX45TD7Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Spec HT Cable

Enviado por

Anonymous vcadX45TD7Direitos autorais:

Formatos disponíveis

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

1.0 1.1

SCOPE The Scope of this specification includes design, manufacture, testing at manufacturer works and supply of HT XLPE cables for as per specification and as required for satisfactory operation of the system. The equipment furnished under this specification shall conform to the standards under respective equipment heads. The design and workmanship shall be in accordance with best engineering practices to ensure satisfactory performance throughout the service life of the equipment. Materials and components not specifically stated in this specification but which are necessary for satisfactory operation of the equipment and accessories specified in this specification shall be deemed to be included unless specifically excluded and shall be supplied without any extra cost. All the equipment shall be inspected at manufacturer works by client / consultant before dispatch. The successful tendered shall provide all test certificates and other necessary documents/ information related to inspection & testing at works. All necessary arrangement for inspection at works shall be organised by the successful tendered.

1.2

1.3

1.4

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 1 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

2.0

STANDARDS The cables shall confirm to the following standards as applicable and as amended up to date.

Sl. No. Standard Description

1.

2. 3. 4. 5. 6.

IS7098-Part-II, Specification for Cross-linked polyethylene insulated 1985 PVC sheathed cables PartII: For working voltage from 6.6kV up to and including 33kV. IS 8130, 1984 Specification for conductors for insulated electric cables and flexible cords. IS 5831, 1984 Specification for PVC insulation and sheath of electric cables. IS 3975, 1999 Specification for low carbon galvanized steel wires, formed wires and tapes for armoring of cable. IS 10810- Part Methods of test for cables 1 to 64, 1984 IS 10462 Fictitious calculation method for determination of Part-1, 1983 dimensions of protective covering of cable, Part-1: Elastometic and thermoplastic insulated cables.

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 2 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

3.0 3.1

GENERAL REQUIREMENT The cables shall be suitable for laying in trays, trenches, ducts and conduits and for underground buried installation with backfill and possibility of flooding by water and chemicals. Outer sheath of all XLPE cables shall be black in colour and suitable chemicals shall be added into the PVC compound of the outer sheath to protect the cable against rodent and termite attack. Sequential marking of the length of the cable in metres and ISI marking shall be provided on the outer sheath of the cable at every one metre. The embossing / engraving shall be legible and indelible. The overall diameter of the cables shall be strictly as per the values declared in the technical information furnished along with bids subject to the maximum tolerance applicable as per IS 1554 / IS 7098. PVC / Rubber end caps shall be supplied free of cost for each drum with a minimum of eight per thousand metre length. In addition, ends of the cables shall be properly sealed with caps to avoid ingress of water during transportation and storage. The cables used in installations under the jurisdiction of Director General of Mines and Safety shall be of copper conductor only.

3.2

3.3

3.4

3.5

3.6

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 3 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

4.0 4.1

6.6 kV TO 33 kV XLPE POWER CABLE Power cables for 6.6 kV up to and including 33 kV system shall be Aluminium/ copper conductor, XLPE insulated, PVC inner sheathed, armoured and overall PVC outer sheathed. The conductors shall be stranded and compacted circular for all cables. All cables rated 6.6 / 6.6 kV and above shall be provided with both conductor screening and insulation screening the conductors shall be provided with nonmetallic extruded semi conducting compound screen. The semi conducting compound shall be suitable for operating temperature of the cable and compatible with the insulating material. The core insulation shall be with cross linked polyethylene insulating compound dry cured, applied by extrusion. It shall be free from voids and shall withstand all mechanical and thermal stresses under steady state and transient operating conditions. It shall conform to the properties given in table 1 of IS: 7098 (Part-2). The insulation screen shall consist of non-metallic extruded semi-conducting compound in combination with a non-magnetic metallic copper screen. Unless specified otherwise, the copper screen for all the three cores together shall be capable of carrying the single line to ground fault current value and the duration specified in the technical particulars. Vendor shall furnish calculation in support of selection of the size of copper screen along with bids. The copper screen shall be suitable to carry 1 kA earth fault current for 1 Sec. The conductor screen, XLPE insulation and insulation screen shall all be extruded in one operation to ensure perfect bonding between the layers. The core identification shall be by coloured strips or by printed numerals in line with IS - 7098. The inner sheath shall be extruded and shall conform to the requirements of type ST 2 compound as per IS: 5831. The extruded inner sheath shall be of uniform thickness. In case of single core cables, there shall be extruded inner sheath between insulation metallic screen and armoring. For multi-core cables, the armoring shall be by galvanized steel strips as per IS: 7098. If armoring is specified for single core cables in the technical particulars, the same shall be with hard drawn aluminium round wire.

4.2 4.3

4.4

4.5

4.6 4.7

4.8

4.9

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 4 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

4.10

The outer sheath of the cables shall be extruded over the armoring and shall be of PVC compound conforming to the requirements of Type ST 2 compound as per IS: 5831. The thickness of the insulation, inner sheath & outer sheath, dimension of armoring and tolerances shall be governed by values given in IS: 7098, unless specified otherwise.

4.11

5.0 5.1

TESTING AND INSPECTION The cables shall be tested and inspected at the manufacturers works. All the materials used in the manufacture of the cable shall be subjected, both before and after manufacture, to testing and approval by Purchaser / Consultant. Manufacturer shall furnish all necessary information concerning the supply to Purchaser / Consultant. The inspector shall have free access to the manufacturers works for the purpose of inspecting the process of manufacture in all its stages and he will have the power to reject any material which appears to be unsuitable description or of unsatisfactory quality. The vendor shall give at least 2 weeks advance notice to the purchaser, regarding the date of testing to enable him or his representative to witness the tests. After completion of manufacture of cables and prior to dispatch, the cables shall be subjected to type, routine, acceptance and special tests as per the approved QAP. Purchaser / Consultant reserve the right to witness all tests with sufficient advance notice from vendor. Inspection call shall be given by the manufacturer for association of purchaser or his representative during inspection in line with the inspection call proforma no. 11.20(DQM) F-05/2 Rev.-0 enclosed with the specification. Inspection call shall be given minimum 15 days in advance from the proposed date of inspection. Four sets of relevant manufacturer test certificates, test certificate for major bought out components, internal inspection report of contractor (if applicable) etc. as per the approved QAP shall be enclosed with each inspection call. Filled up Quality Assurance Plan (QAP) shall be submitted by the manufacturer for approval for all the equipment as per the enclosed MECONs

5.2

5.3

5.4

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 5 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

QAP format no. 11.20 (DQM) F10 Rev.-0. Inspection shall be carried out as per approved data sheet/ Specification and QAP. 5.5 All routine tests, acceptance tests, type tests and additional type tests for improved fire performance shall be carried out on cables as per IS:1554 Part 1 and IS:7098 Part 2 and international standards as may be applicable. The inner and outer sheath of XLPE cables shall be subjected to all the tests applicable for PVC cables. The test requirements for insulation and sheath of PVC cables shall be as per IS: 5831. Acceptance tests as per IS-1554 (Part-1) and IS: 7098 (Part-2) shall be performed on all cables. The tendered shall submit type test certificates for similar equipment supplied by him elsewhere. In case type test certificates for similar equipment is not available, the same shall be conducted in presence of Purchaser or his representative if Purchaser so desires, without any financial implications to purchaser. The following special tests may be performed on the cables as per sampling plan and as may be applicable as per approved QAP. These tests shall be witnessed by Purchaser / Consultant before dispatch of cables. a. Accelerated water absorption test for insulation as per NEMA WC 5. (For PVC insulated cables) and as per NEMA WC 7 (for XLPE insulated cables). Sampling for this test to be done randomly and once for each size per order wise provided outer sheath remains same. Dielectric Retention Test: The dielectric strength of the cable insulation tested in accordance with NEMA WC 5 at 75 +/- 1 deg C shall not be less than 50% of the original dielectric strength (For PVC insulated cables.) Test certificates with respect to this test from recognised testing laboratory to be furnished for review by purchaser/ consultant before inspection of cables. In case test certificates are not available, test to be conducted by the manufacturer at his own cost in any recognised test laboratory before inspection of cables.

5.6

5.7

5.8

5.9

b.

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 6 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

c.

Oxygen index test: The test shall be carried out as per ASTMD 2863 or applicable Indian Standard. Sampling to be done for every offered lot / size as per sampling plan. Flammability test: The test shall be carried out on finished cable as per IS-10810 (Part 61 & 62). Sampling for these tests to be done randomly once for each size per lot provided outer sheath remains same. Test for rodent and termite repulsion property: The vendors shall furnish the test details to analyse the property by chemical method. Sampling shall be done for every offered lot / size as per sampling plan.

d.

e.

6.0 6.1

PACKING AND MARKING Cables shall be dispatched in non-returnable wooden or steel drums of suitable barrel diameter, securely battened, with the take-off end fully protected against mechanical damage. The wood used for construction of the drum shall be properly seasoned, sound and free from defects. Wood preservatives shall be applied to the entire drum. Ferrous parts used shall be treated with a suitable rust preventive finish or coating to avoid rusting during transit or storage. On the flange of the drum, necessary information in line with Indian Standards such as project title, manufacturers name, type size, voltage grade of cable, length of cable in metres, drum no, cable code, BIS certification mark, gross weight, etc. shall be printed. An arrow shall be printed on the drum with suitable instructions to show the direction of rotation of the drum

6.2

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 7 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

7.0 7.1

TECHNICAL PARTICULARS HV XLPE Power Cable 3 Core Cable Sl. Description Requirement No. 1. Applicable Standard IS-7098 Part II,1985 2. Voltage grade As per schedule of quantities 3. Conductor Stranded and compacted circular aluminium (AL) conductor of grade H2 & class 2 as per IS.8130 4. Conductor Screen Non-metallic extruded semi-conducting compound. 5. Insulation Extruded cross-linked polyethylene (XLPE) as per IS-7098 6. Insulation Screen Non-metallic extruded semi-conducting compound in combination of copper screen as per IS-7098. 7. Copper Screen rating 1kA for 1 Sec. 8. Inner Sheath Extruded PVC compound confirms to ST-2 as per IS-5831 9. Armour Galvanized steel strip armour as per IS 3975 10. Outer Sheath Extruded PVC compound confirming to ST-2 as per IS-5831. 11. Core Identification With coloured strips or by numerals for three core cables applied on core. HV XLPE Power Cable 1 Core Cable Sl. No. 1. 2. 3. Description Applicable Standard Voltage grade Conductor Requirement IS-7098 Part II,1985 As per schedule of quantities Stranded and compacted circular aluminium (AL) conductor of grade H2 & class 2 as per IS.8130 Non-metallic extruded semi-conducting compound. Extruded cross-linked polyethylene (XLPE) as per IS-7098 Non-metallic extruded semi-conducting compound in combination of copper screen as per IS-7098.

7.2

4. 5. 6.

Conductor Screen Insulation Insulation Screen

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 8 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

7. 8. 9. 10. 11.

Copper Screen rating Inner Sheath Armour Outer Sheath Core Identification

1kA for 1 Sec. Extruded PVC compound confirms to ST-2 as per IS-5831 Hard drawn aluminium round wire. Extruded PVC compound confirming to ST-2 as per IS-5831. With coloured strips or by numerals for three core cables applied on core.

8.0

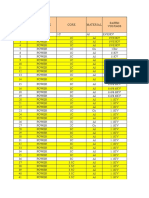

SCHEDULE OF QUANTITIES The following schedule of quantities takes care of cables pertaining to following areas: Outgoing cables from 220/34KV Transformer to 33KV Indoor switchboard at MSDS:-01. Outgoing cables of indoor type 33 kV switchboards at MSDS:-01 to Respective Plant. Incoming and outgoing cables of 6.6 kV & 11 kV Switchboards Located at various HT Sub Station. 19/33 kV grade, XLPE power cables, AL conductor, Conductor Screen, XLPE insulation, Insulation screen, Extruded inner sheath, Armour, Extruded outer sheath confirming to clause 4.0 & 7.2 of this TS above, of following sizes shall be used for Incoming and out going cable: Sl. No. No. of Cores x Size 1. 1 x 1000 sq. mm 2. 1 x 630 sq. mm

8.1

8.2

19/33 kV grade, XLPE power cables, AL conductor, Conductor Screen, XLPE insulation, Insulation screen, Extruded inner sheath, Armour, Extruded outer sheath confirming to clause 4.0 and 7.1 of this TS above, of following sizes shall be used for out going cable:

Sl. No. No. of Cores x Size 1. 3 x 300 sq. mm

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 9 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

8.3

6.6/6.6 kV grade, Un Earth XLPE power cables, AL conductor, Conductor Screen, XLPE insulation, Insulation screen, Extruded inner sheath, Armour, Extruded outer sheath confirming to clause 4.0 and 7.1 of this TS above, of following sizes shall be used for out going cable for :

: Sl. No. 1. 2. 3. 4. 8.4 No. of Cores x Size 3X95 sq. mm 3X185 sq. mm 3X240 sq. mm 3X300 sq. mm

6.6/6.6 kV grade, Un Earth XLPE power cables, AL conductor, Conductor Screen, XLPE insulation, Insulation screen, Extruded inner sheath, Armour, Extruded outer sheath confirming to clause 4.0 and 7.2 of this TS above, of following sizes shall be used for out going cable: Sl. No. No. of Cores x Size 1. 1X630 sq. mm

8.4

11/11 kV grade, Un Earth XLPE power cables, AL conductor, Conductor Screen, XLPE insulation, Insulation screen, Extruded inner sheath, Armour, Extruded outer sheath confirming to clause 4.0 and 7.2 of this TS above, of following sizes used for out going cable: Sl. No. No. of Cores x Size 1. 1 x 630 sq. mm

8.5

11/11 kV grade, Un Earth XLPE power cables, AL conductor, Conductor Screen, XLPE insulation, Insulation screen, Extruded inner sheath, Armour, Extruded outer sheath confirming to clause 4.0 and 7.1 of this TS above, of following sizes used for out going cable: Sl. No. No. of Cores x Size 1. 3 x 240 sq. mm

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 10 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

9.0 9.1

DOCUMENTS TO BE SUPPLIED BY THE SUCCESSFUL TENDERER For Approval i) ii) Quality Assurance Plan (QAP) as per enclosed format. Data sheet in line with the format enclosed.

9.2

For Reference Calculation for conductor temperature during short circuit

9.3

Manuals / Others Documents Four sets of the following documents shall be provided along each equipment : i) ii) iii) Instruction manuals catering procedures for operation, erection, testing, commissioning, maintenance and repair. Catalogues and technical data sheet. Internal Test Certificates and Inspection Certificates

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 11 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

10.0

DATA SHEET Data sheet containing the following details shall be furnished for each type and size of cable for approval by the manufacturer. Sl. No. 1.0 1.1 1.2 2.0 2.1 2.2 2.3 2.4 2.5 3.0 3.1 3.2 3.3 4.0 4.1 4.2 4.3 5.0 6.0 7.0 7.1 7.2 7.3 7.4 8.0 8.1 a) b) c) d) e) f) Description General Name of Manufacturer Place of Manufacture Standards Applicable General construction Conductor material Sheath material Armour material Test methods Permissible Variations Voltage Frequency Combined (Voltage & Frequency) Permissible variations For continuous operation For emergency operation For short circuit operation Permissible (Maximum) Overload Manufacturing process Type of Cable Voltage grade Earthed/ Unearthed Number of cores Type Designation (As per IS) Construction Details Conductor Material Grade/ Class Type (Solid / Stranded) No. & nominal diameter of strands Shape Nominal size Unit Value

% % % Deg.C Deg.C Deg.C %

kV

Sq.mm

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 12 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

Sl. No. 8.2 a) b) c) 8.3 a) b) c) 8.4 a) b) c) 8.5 a) b) c) d) 8.6 8.7 8.8 a) b) c) d) e) 8.9 a) b) c) d) 8.10 a) b) c) d) e)

Description Conductor Screen Material Minimum thickness Application process Insulation Material Minimum thickness Tolerance on thickness of insulation Insulation screen Material Minimum thickness Application process Metallic screen Material No. of layers Nominal thickness of each layer Width Material of fillers if any Calculated diameter over laid up cores Inner Sheath Material Type Minimum thickness Tolerance on thickness of sheath Calculated diameter under armour Armour Material No. of layers Dimension of each wire/ strip Calculated diameter under outer sheath Outer Sheath Material Type as per IS:5831 Minimum thickness Tolerance on thickness of sheath Colour

Unit

Value

mm

mm

mm

mm mm

mm

No. mm

mm

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 13 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

Sl. No. 9.0 9.1 9.2 9.3 9.4 9.5 9.6 9.7 10.0 10.1 a) b) 10.2 10.3 10.4 10.5 10.6 11.0 a) b) c) d) e) 10.0

Description

Unit

Value

Mechanical Data Approx. overall diameter (O.D.) Approx. net weight Standard packing length Tolerance on drum length Tolerance on total quantity Minimum bending radius Safe pulling force (with pulling eye) Electrical Data Current carrying capacity In air at 40C In ground at 30C Short circuit rating (For 1 sec.) Maximum DC resistance of conductor at 20C AC resistance of conductor at operating temperature of 90C Reactance at 50Hz Capacitance Cable drum details Flange dia Barrel dia. Traverse Weight Shipping weight

mm Kg./Km Mtr % % N/ sq.mm

Amp Amp KA Ohm/km Ohm/km Ohm/km MicroF/ Km mm mm mm Kg Kg

PREFERRED MAKE LIST:1) 2) 3) 4) 5) 6) 7) 8) 9) 10) HAVELLS INDIA LTD NOIDA. INDUSTRIAL CABLE (INDIA) LTD CHANDIGARH. UNIVERSAL CABLES LTD SATNA. KEI INDUSTRIES LTD NEW DELHI. CRYSTAL CABLE INDUSTRIES LTD KOLKATA.(UPTO 11KV) PARAMOUNT COMMUNICATION LTD NEW DELHI.(UPTO 33KV) UNIFLEX CABLE LTD MUMBAI (UPTO 33KV) POLYCAB WIRES PVT.LTD MUMBAI.(UPTO 33KV) KRISHNA ELECTRICAL INDUSTRIES LTD GWALIOR.(UPTO 33KV) CLOT CABLE PVT LTD MUMBAI.

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 14 of 14

JINDAL STEEL & POWER LIMITED ANGUL (ORISSA)

TECHNICAL SPECIFICATION FOR 6.6KV, 11KV AND 33KV HT XLPE CABLE.

TS No.: MEC/11/TS/Q6LL/00/E-1/01512

2009, MECON Limited. All rights reserved Page 15 of 14

Você também pode gostar

- OHL DRG - Annexure CDocumento8 páginasOHL DRG - Annexure CAnonymous vcadX45TD7Ainda não há avaliações

- 1400 Kva DG SetDocumento1 página1400 Kva DG SetAnonymous vcadX45TD7Ainda não há avaliações

- ACE Pilot User GuideDocumento109 páginasACE Pilot User GuideEnrique Tejada FarfanAinda não há avaliações

- Checklist IslandingDocumento2 páginasChecklist IslandingAnonymous vcadX45TD7Ainda não há avaliações

- Turbine Performance Curves Midrex Stage 1 & 2Documento15 páginasTurbine Performance Curves Midrex Stage 1 & 2Anonymous vcadX45TD7Ainda não há avaliações

- Energy Reading March-17 CompareativeDocumento64 páginasEnergy Reading March-17 CompareativeAnonymous vcadX45TD7Ainda não há avaliações

- Shift SH Engr MAYDocumento1 páginaShift SH Engr MAYAnonymous vcadX45TD7Ainda não há avaliações

- To Whom So Ever It May ConcernDocumento2 páginasTo Whom So Ever It May ConcernAnonymous vcadX45TD7Ainda não há avaliações

- 33 KV Multifunc Meter - 33KV SBDocumento2 páginas33 KV Multifunc Meter - 33KV SBAnonymous vcadX45TD7Ainda não há avaliações

- Transformer Efficiency and Regulation CalculationDocumento1 páginaTransformer Efficiency and Regulation CalculationAnonymous vcadX45TD7Ainda não há avaliações

- TBEA ENERGY PROPOSED VENDOR LISTDocumento4 páginasTBEA ENERGY PROPOSED VENDOR LISTAnonymous vcadX45TD7Ainda não há avaliações

- ChecklistDocumento13 páginasChecklistAnonymous vcadX45TD7Ainda não há avaliações

- Commissioning Certificate 4561001627Documento1 páginaCommissioning Certificate 4561001627Anonymous vcadX45TD7Ainda não há avaliações

- Emax ACBDocumento280 páginasEmax ACBFreddy SuhartonoAinda não há avaliações

- 000411034202Documento1 página000411034202Anonymous vcadX45TD7Ainda não há avaliações

- Checklist IslandingDocumento2 páginasChecklist IslandingAnonymous vcadX45TD7Ainda não há avaliações

- Digital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartDocumento13 páginasDigital Motor Protection Relays: Electronic Protection Type Up To 60A With Micro Controller Unit & Digital Display PartAnagha Deb100% (1)

- SMS SLDDocumento1 páginaSMS SLDAnonymous vcadX45TD7Ainda não há avaliações

- Improving Island Detection with Enhanced Vector Shift RelayingDocumento4 páginasImproving Island Detection with Enhanced Vector Shift RelayingPablo ArancibiaAinda não há avaliações

- Balance Items of TowerDocumento2 páginasBalance Items of TowerAnonymous vcadX45TD7Ainda não há avaliações

- Switchyard - Cable YardDocumento11 páginasSwitchyard - Cable YardAnonymous vcadX45TD7Ainda não há avaliações

- Adhar LinkDocumento1 páginaAdhar LinkAnonymous vcadX45TD7Ainda não há avaliações

- Satya Exp - CertificateDocumento1 páginaSatya Exp - CertificateAnonymous vcadX45TD7Ainda não há avaliações

- Circuit Breaker BomDocumento4 páginasCircuit Breaker BomAnonymous vcadX45TD7Ainda não há avaliações

- Tasklists MDS 11-1-16Documento20 páginasTasklists MDS 11-1-16Anonymous vcadX45TD7Ainda não há avaliações

- 2 RPM Sources and Sinks MNMDocumento29 páginas2 RPM Sources and Sinks MNMRohit VyasAinda não há avaliações

- TR#3Documento12 páginasTR#3Anonymous vcadX45TD7Ainda não há avaliações

- Ge Shunt ReleaseDocumento4 páginasGe Shunt ReleaseAnonymous vcadX45TD7Ainda não há avaliações

- Elbo ApplicationDocumento2 páginasElbo ApplicationAnonymous vcadX45TD7Ainda não há avaliações

- Sub Station Design EngineerDocumento3 páginasSub Station Design EngineerAnonymous vcadX45TD7Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Person On The StreetDocumento12 páginasPerson On The StreetalyssajdorazioAinda não há avaliações

- 7 Day Diet AnalysisDocumento5 páginas7 Day Diet AnalysislipakevinAinda não há avaliações

- Aguerra - Resume 2021 1Documento1 páginaAguerra - Resume 2021 1api-547475674Ainda não há avaliações

- Summary of Verb TensesDocumento4 páginasSummary of Verb TensesRamir Y. LiamusAinda não há avaliações

- Fiber Optics: By: Engr. Syed Asad AliDocumento20 páginasFiber Optics: By: Engr. Syed Asad Alisyedasad114Ainda não há avaliações

- Fano - Description of States in Qunatum Mechanics by Density Matrix and OperatorsDocumento20 páginasFano - Description of States in Qunatum Mechanics by Density Matrix and OperatorsAlexAinda não há avaliações

- Review Notes in ABG Interpretation - NCLEXDocumento1 páginaReview Notes in ABG Interpretation - NCLEXFilipino Nurses CentralAinda não há avaliações

- Extension Worksheet For Week 5Documento4 páginasExtension Worksheet For Week 5PRAVITHA SHINEAinda não há avaliações

- RICS Research On NECDocumento9 páginasRICS Research On NECAhmad MajedAinda não há avaliações

- National Competency Based Teachers StandardDocumento34 páginasNational Competency Based Teachers Standarddanebantilan100% (3)

- Types of Errors and Coding TechniquesDocumento11 páginasTypes of Errors and Coding TechniquesTiffany KagsAinda não há avaliações

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocumento26 páginasReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaAinda não há avaliações

- Bonaventure Sentences Doctorisseraphic11bonaDocumento1.014 páginasBonaventure Sentences Doctorisseraphic11bonaChad Deffler100% (1)

- KMBS RRDocumento147 páginasKMBS RRNicole Athena Sofia MiranoAinda não há avaliações

- Hamlet Act 3 Scene 1Documento4 páginasHamlet Act 3 Scene 1Αθηνουλα ΑθηναAinda não há avaliações

- DIASS - Quarter3 - Module1 - Week1 - Pure and Applied Social Sciences - V2Documento18 páginasDIASS - Quarter3 - Module1 - Week1 - Pure and Applied Social Sciences - V2Stephanie Tamayao Lumbo100% (1)

- UBD PlantDocumento8 páginasUBD PlantMahmoud DibAinda não há avaliações

- BSIA - Access ControlDocumento16 páginasBSIA - Access ControlSayed HashemAinda não há avaliações

- Department of Information TechnologyDocumento1 páginaDepartment of Information TechnologyMuhammad ZeerakAinda não há avaliações

- Games and Sports As Man's Cultural HeritageDocumento5 páginasGames and Sports As Man's Cultural Heritagesimransabir152004Ainda não há avaliações

- Certification 5Documento10 páginasCertification 5juliet.clementeAinda não há avaliações

- Objective/Multiple Type QuestionDocumento14 páginasObjective/Multiple Type QuestionMITALI TAKIAR100% (1)

- Genealogy On June 09-2003Documento25 páginasGenealogy On June 09-2003syedyusufsam92100% (3)

- HPLC Method for Simultaneous Determination of DrugsDocumento7 páginasHPLC Method for Simultaneous Determination of DrugsWidya Dwi Arini100% (1)

- As Work: Self Perceptions and Perceptions of Group Climate Predictors of Individual Innovation atDocumento17 páginasAs Work: Self Perceptions and Perceptions of Group Climate Predictors of Individual Innovation atMuqadas KhanAinda não há avaliações

- Code of Ethics in 40 CharactersDocumento8 páginasCode of Ethics in 40 Charactersvasu bansalAinda não há avaliações

- Establishing Te Lesson 6Documento36 páginasEstablishing Te Lesson 6SARAH JANE CAPSAAinda não há avaliações

- New Tribological WaysDocumento516 páginasNew Tribological Waysskippytheclown100% (2)

- Empt Forming Welding Crimping and CuttingDocumento13 páginasEmpt Forming Welding Crimping and CuttingEmil MariusAinda não há avaliações