Escolar Documentos

Profissional Documentos

Cultura Documentos

Food Waste Aerobic Composting

Enviado por

nurhanamjDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Food Waste Aerobic Composting

Enviado por

nurhanamjDireitos autorais:

Formatos disponíveis

Waste Manage Res 2005: 23: 3947 Printed in UK all right reserved

Copyright ISWA 2005

Waste Management & Research

ISSN 0734242X

Biotechnology for aerobic conversion of food waste into organic fertilizer

A biotechnology for aerobic conversion of food waste into organic fertilizer under controlled aeration, stirring, pH and temperature at 5565C, is proposed. To maintain neutral pH at the beginning of the bioconversion 5% CaCO3 was added to the total solids of the food waste. The addition of 20% horticultural waste compost as a bulking agent to the food wastes (w.w./w.w.), improved the bioconversion and increased the stability of the final product. No starter culture was needed for aerobic bioconversion of food waste into organic fertilizer for 10 days. The low contents of heavy metals in the raw materials used in the bioconversions ensured the safety of fertilizer from food waste for application in agriculture. The addition of 4% organic fertilizer to the subsoil increased the yield and growth of Ipomoea aquatica (Kang Kong) by 1.5 to 2 times. The addition of phosphorus is required to enhance the positive effect of organic fertilizer on plant growth.

Olena Stabnikova Hong-Bo Ding Joo-Hwa Tay Jing-Yuan Wang

School of Civil and Environmental Engineering, Nanyang Technological University, Singapore Keywords: Aerobic bioconversion, fertilizer, food waste, horticultural waste compost, plant growth: wmr 7699

Corresponding author: Dr O. Stabnikova, School of Civil and Environmental Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore 639798. Tel: +65 6790 4740; fax: +65 6792 1650; e-mail: costab@ntu.edu.sg DOI: 10.1177/0734242X05049768 Received 7 June 2004; accepted in revised form 4 October 2004

Introduction

Total food waste, collected in 2002 from food processing companies, restaurants, food courts, markets, and households in Singapore, amounted to approximately 500 000 tonnes (Ministry of the Environment 2002). It comprises the highest portion of all solid wastes generated in Singapore and accounts for about 20% of the total waste stream. Currently, almost all food waste is disposed of by incineration. There is an alternative method of aerobic treatment of food waste, known as composting, which converts waste material into a hygienic, humus-rich, relatively stable product that conditions soils and nourishes plants (Mathur 1992). Composting also leads to reduction in odour and the removal of pathogens. The wastes from wholesale fruit and vegetable markets, supermarkets and food processing are the best materials for composting (Sharma et al. 1997). Other reports describe the application of composts from different food wastes such as leaf compost (Maynard & Hill 2000) and compost from agro-industrial wastes (Garcia-Gomez et al. 2002) which improve the physical properties of the soil and the yields of crops. The optimal conditions for composting of food waste are: moisture content of the composting material must be at least 65%; pH near neutral; the C/N ratio of the material must be between 25 : 1 and 35 : 1. Additional aeration can improve the process; a temperature of 60C must be kept for optimal thermophilic composting (Haug 1993). Aerobic systems of solid composting can be open systems (aerated pile process and windrow process) and in-vessel, or container systems. The main advantages of in-vessel systems are the high speed of the process (1014 days), low land requirement, minimization of any odour problems and complete process control (Mathur 1992). Fresh compost is an intermediate product of the thermophilic stage, but a certain stage of maturation is needed to obtain a stabilized product. Composting of food waste is not suitable in countries with limited land resources such as Singapore. There is one recycling park in Singapore that produces compost and soil fertilizer. However, this practice has not been widely adopted (Bai & Sutanto 2002).

Waste Management & Research

39

O. Stabnikova, H.-B. Ding, J.-H. Tay, J.-Y. Wang

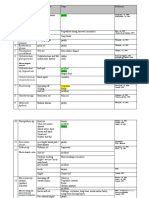

Fig. 1: Schematic diagram of the pilot-scale reactor for intensive aerobic bioconversion of food waste: 1, control panel; 2, air blower and motor chamber; 3, sampling and input gate; 4, cooling tower; 5, heating plate; 6, output gate; 7, air inlet; 8, air outlet; 9, rotation shaft and agitation paddles.

Another aerobic technology for the treatment of food waste is a slurry technology which leads to a complete highrate decomposition of food waste to inorganic carbon (Park et al. 2001). Food waste is an easily degradable material under aerobic conditions. A 91% reduction of food wastes was achieved during treatment in the slurry phase at 30C with the addition of a mixture of micro-organisms used in composting (Yun et al. 2000). The maximum content of microorganisms was 5 1010 cells mL1 at the 20th day (Park et al. 2002). The effect of aeration rate was considered to be a major factor affecting the slurry-phase decomposition of food wastes (Park et al. 2001). The oxygen requirement for decomposition of food wastes was estimated to be 5.0 g O2 g1 dry weight of food wastes. In this slurry-phase decomposition, suspended solids in the reactor disappeared at a maximum rate of 7.9 g dry weight L1 day1 (Yun et al. 2000). It is possible to completely destroy food waste, but this process is not a cheap one and needs special equipment, an intensive air supply, and stirring. Food waste contains important nutrients and it would be more efficient to reuse them in agriculture after they have been treated. The use of aerobic thermophilic treatment to convert a mixture of sewage sludge and food waste into fertilizer has been reported previously (Wang et al. 2003a, b). This process includes biotreatment at high temperature (60C) and an intensive air supply. The aim of present research was to study the applicability of intensive aerobic bioconversion to food waste to produce a fertilizer or soil conditioner.

Materials and methods

Bioconversion process Fresh vegetable processing wastes were collected from a canteen at the university, and shredded into small particles using a Robot-Coupe shredder (CL50 Ultra, France). Shredded food waste was added to the pilot-scale reactor (Figure 1), which was a steel cylinder with a total volume of 500 L. The temperature inside the reactor was maintained at 5565C using the heater located on two sides of reactor. The moisture content was maintained at 7580% to prevent drying in the microzones of the reactor caused by aeration. This process may be considered physically intermediate between conventional solid-phase composting with an optimum moisture content of 5565% and slurry-phase biotreatment of suspended solid wastes in which the moisture content is usually greater than 85%. Water was added daily to the reactor, except during the last 12 h of the process. The material was stirred by the horizontal agitator at a speed of 10 r.p.m. An air supply was provided by an air blower with a rate of 50 L min1 for 10 min every hour. Calcium carbonate was added at 5% of total solids (TS) to maintain neutral pH. To enhance aeration and the structure of the treated organic matter bulking agent (horticultural waste compost with size particles less than 6.4 cm) was added to the food waste at a quantity of 20% (w.w./w.w.). The high temperature and the effect of aeration dried the final matter (organic fertilizer) in the last 12 h. The organic fertilizer was a light substance of

40

Waste Management & Research

Aerobic conversion of food waste into organic fertilizer

yellow or black colour with a moisture content of approximately 5%. Three bioconversions of food waste were conducted to study the process. A mixture of vegetable food waste and soy bean residue from tofu production in a ratio 1 : 1 (w.w./w.w.) was placed into the pilot-scale reactor for every bioconversion. Neither starter culture nor bulking agent was added to the food waste mixture used in bioconversion 1 (B1). Bulking agent (horticultural waste compost) was added to the food waste mixtures used in bioconversions 2 (B2) and 3 (B3). The biomass of starter culture Bacillus thermoamylovorans SW25 (Wang et al. 2003a) was added to bioconversion 3. The bioconversions were operated for 10 days. The final products of bioconversions 1, 2 and 3 were named as organic fertilizers (OF) 1, 2 and 3, respectively. Bacterial starter preparation Bacterial strain Bacillus thermoamylovorans SW25 (Wang et al. 2003a) was used as the starter culture for bioconversion 3. The addition of a microbial biomass ensured an initial content of bacterial cells 1.1 108 cells g1 TS in bioconversion 3. Optimal pH for the growth of this strain was 6.7 to 8.2 and its optimal temperature was 60C. The bacterial biomass for the inoculation of the solid waste was grown on tryptic soy broth (Difco, USA) in a shaker at 130 r.p.m. for 24 h at 60C. Biomass was recovered by centrifugation at 4000 r.p.m. for 5 min in an Eppendorf centrifuge 5810R, and added into the reactor. Chemical analysis Samples from the reactor were taken for microbiological and chemical analysis every day. The pH and electric conductivity (EC) of the samples were measured in a suspension of 1 g of matter in 10 ml of distilled water and in 5 ml of deionized water using a pH meter (Corning 145; UK) and conductivity meter (Horiba ES-14; Japan), respectively. The content of dry matter (total solids, TS) was determined by the standard method (American Public Health Association 1998). The content of organic matter was determined as the percentage of volatile solids (VS) in TS by the weight loss after ignition of approximately 1 g of dried sample at 500C for 20 min. The content of carbon and nitrogen in the samples was determined using an elemental analyser (CHNS/O 2400; Perkin Elmer, USA). Samples were oven-dried at 103C for 24 h, and then ground to a particle size less than 1 mm, and 2 mg of this powder was put into the sample collector of the elemental analyser. The content of K and P was determined using an inductively coupled plasma atomic emission spectrometer (ICP-AES; Perkin-Elmer, UK).

Microbial counts The enumeration of thermophilic bacteria on nutrient and tryptic soy agar (Difco Laboratories, USA) was carried out by a spread-plate method from a serial ten-fold dilution of the suspension produced by vortexing 1 g of material in 9 ml of phosphate-buffered saline (PBS). The Petri dishes were incubated at 60C for 1 day under aerobic conditions. Examination of food waste biodegradation The percentage biodegradation of organic matter () was estimated by the equation = [1 VS2(1 VS1)/VS1(1 VS2)] 100% (1)

where VS1 and VS2 are the initial and final content of volatile solids in the organic matter, respectively (Ivanov et al. 2003). This equation is based on the assumption that the inorganic matter remained unchanged during the biodegradation of food waste. The structure of the initial and treated food waste was observed by scanning electron microscopy (SEM) Stereoscan 420 (Leica Cambridge Instruments). Food waste were prepared for SEM by fixation for 1 to 4 h in 2% (v/v) glutaraldehyde, washed three times for 20 min with 0.10 mol L1 sodium cacodylate buffer (pH 7.2), and were dehydrated in a graded butyl alcohol series (50, 70, 85, 95, 100% v/v). Dehydrated food waste was dried using a freeze-drier (Bal-Tec CPD 030), sputter-coated with gold at 20 mA in a high vacuum (2.8 106 Torr) and low temperature (170C) cryochamber for 90 s, and then viewed with the SEM at 20 kV. Examination of organic fertilizer The fertilizer stability index was evaluated according to the CO2 evolution rate (Q), in mg CO2C g1 organic matter (OM) day1, as being very stable (Q < 2); stable (Q < 4); or unstable (Q > 4) (United States Department of Agriculture and the United States Composting Council, 2001a). The moisture of the samples was adjusted to 7085% and the samples were pre-incubated at room temperature for 24 h. Five grams of the pre-incubated sample were transferred into an incubation vessel containing 20 ml of 1 mol L1 NaOH. The vessel was sealed and kept at 37C for 4 days. The amount of CO2 adsorbed by NaOH was determined daily over a 4-day period by back titration of the residual NaOH with 1 N HCl. The organic fertilizer stability index was evaluated according to the CO2 evolution rate (Q), in mg CO2C g1 organic matter (VS) day1. The effect of organic fertilizer on seed germination was determined by the modified germination and root elongation

Waste Management & Research

41

O. Stabnikova, H.-B. Ding, J.-H. Tay, J.-Y. Wang

Table 1: Characteristics of raw materials used for bioconversions (mean values standard deviations are shown). Raw materials pH Vegetable food waste Soy bean residue Horticultural waste compost 5.9 6.6 6.6 TS (%) 5.6 0.2 16.0 0.1 43.5 1.3 VS (% of TS) 75.2 1.1 96.2 0.1 76.3 1.1 Parameters C (% of TS) 32.2 0.4 45.5 0.2 40.2 2.7 N (% of TS) 3.2 0.3 5.4 0.1 1.4 0.1 Stability index (mg CO2C g1 VS day1) 6.1 0.5 21.3 1.6 1.2 0.1

test (United States Department of Agriculture and the United States Composting Council, 2001b). The extracts from organic fertilizers for this test were prepared by the following procedure. The fertilizer was suspended in water in the ratio 1 : 9 (wet weight/volume) and incubated in a shaker at 50 r.p.m. for 3 h. The extract was separated from the solids by centrifugation at 4000 r.p.m. for 5 min. Cucumber seeds were selected for the germination and root elongation test. Ten cucumber seeds were placed on a 9-cm-diameter paper Whatman No. 3 disc inside a Petri dish. A 10 ml aliquot of extract at various dilutions was added. Germination of the seeds in distilled water was used as control. Petri dishes were placed in a naturally lit area, but not in direct sunlight to avoid rapid evaporation. The percentage of germinated seeds, the length of the sprouts and roots were determined after 5 days. The effect of fertilizer was evaluated by counting the number of germinated seeds and measuring the length of the roots. Germination test (GT) and root length (RL) were calculated by the equations (2) and (3), respectively GT = A/B 100% (2)

where A is the number of germinated seeds for seeds treated by fertilizer and B is the number of germinated seeds in distilled water (control). RL = C/D 100% (3)

and watered daily as required. The products of bioconversions 1 to 3 (organic fertilizers OF1, OF2 and OF3) were added to the experimental pots at application rates of 1.0 to 4.0 (weight of dry matter/weight of subsoil). Commercial organic fertilizer (COM) Horti Bloom (Horti Flora Pte Ltd, Singapore), which was added to the subsoil after seed germination, was used in the plant cultivation experiments as a positive control. The dosages of commercial organic fertilizer contained the same amount of nitrogen as a 2% dosage of OF1, OF2 and OF3. Pots with subsoil only were used as a negative control. Each mixture was incubated for 1 week prior to the plant growth experiments. Ten seeds were placed in every pot, but only the four strongest seedlings were retained after 2 weeks. The growth of the plants was observed and measured over a period of 7 weeks. During the experimental period the temperature varied between 25 and 27C at night and 31 and 33C in the daytime. To increase the effect of organic fertilizer application it was used in combination with additional Na2HPO4, as a source of phosphorus and 8 g Na2HPO4 per pot was added into the subsoil after seed germination. At harvesting, the plants were carefully removed from the soil and rinsed with distilled water. The length of shoots and roots were recorded. The plants were then oven-dried at 60C for 48 h and the dry weight yield of shoots and roots were determined. The dried plant biomass was ground and used for the determination of nitrogen content. All experiments and controls were performed in triplicate to ensure that the data were statistically reliable.

where C is the average root length of seeds treated by fertilizer (mm) and D is the average root length of seeds in distilled water (control) (mm). The germination index (GI) was calculated according to Zucconi et al. (1981) GI = (A C)/(B D) 100% Plant cultivation experiments The test plant was a common local vegetable crop, Ipomoea aquatica (Kang Kong). The cultivation of the Kang Kong plants was performed in ceramic pots (18 cm in diameter and 40 cm in height) with 3 kg of fresh subsoil. The pots, sheltered from direct sunlight and rainfall, were situated outdoor (4)

Results

Three bioconversions of food waste were performed in the pilot-scale aerobic reactor. The characteristics of the raw materials used in bioconversions are shown in Table 1. The content of heavy metals in raw materials were lower than the values for the compost category A according the Compost Standards in Canada (http://www.compost.org/standard.html) (Table 2). The low content of heavy metals in the raw materials used in bioconversions ensured the safety of fertilizer made from food waste for applications in agriculture. The characteristics of the initial material and final products of food waste bioconversions 13 are presented in Table 3. Under aerobic thermophilic conditions the food

42

Waste Management & Research

Aerobic conversion of food waste into organic fertilizer

Table 2: Contents of heavy metals in raw materials used for bioconversions, mg kg1 air-dried material (mean values standard deviations are shown). Raw materials Cu Vegetable food waste Horticultural waste compost Standard compost 85 6 56 0 100 Ni 38 2 40 5 62 Heavy metals Zn 82 6 87 9 500 Cd 51 nd* 3 Cr 31 5 111 1 210 Pb 71 11 1 150

Note: *nd means values are under the detection limit. Table 3: Characteristics of the initial material and final products after different procedures of pilot-scale bioconversion and commercial organic fertilizer (mean values standard deviations are shown). Parameters pH TS (%) VS (%) EC (dS m1) C (% of TS) N (% of TS) P (% of TS) K (% of TS) Stability index (mg CO2C g1 VS day1) Heterotrophic aerobic thermophilic bacteria (CFU g1 TS) Bioconversion N 1 * Initial matter Final product 6.0 10.8 0.4 82.8 0.8 2.64 42.2 0.7 5.2 0.4 ND ND 18.1 (0.9 0.2) 105 5.9 95.1 0.2 70.8 0.4 9.00 38.6 0.3 2.8 0.1 0.34 0.1 2.99 0.3 7.7 (1.8 0.4) 105 Bioconversion N 2* Initial matter 6.2 16.9 0.4 78.4.0 1.0 5.82 41.2 0.5 3.4 0.2 ND ND 11.0 (2.1 0.1) 105 Final product 8.0 97.0 0.05 65.8 0.4 3.92 37.4 0.8 2.2 0.18 0.25 0.2 2.56 0.2 2.9 (1.1 0.2) 108 Bioconversion N 3** Initial matter 6.0 17.1 0.9 80.3 0.5 8.40 41.6 0.4 3.4 0.3 ND ND 10.5 (1.0 0.1) 108 8.1 98.9 .05 67.1 0.4 5.45 37.4 0.8 2.1 0.18 0.23 0.2 3.15 0.3 1.9 (6.8 1.0) 107 Commercial Final product organic fertilizer ND 74.9 0.5 41.2 0.4 20.65 18.2 0.6 7.0 0.4 2.9 0.4 2.4 0.2 14.6 ND

Notes: *Bulking agent was added in bioconversions 2 and 3; **Starter culture was added in bioconversion 3; ND means not determined.

waste lost structure very quickly and was transformed into a thick, almost homogeneous, semi-solid mixture. The SEM images of initial food waste and food waste after 3 days of bioconversion 1 are shown in Figure 2. The cavities appeared in the food waste matter after bioconversion (Figure 2b). The pH dropped rapidly during the first 2 days of the process. For pH buffering, the addition of a 5% dosage of CaCO3 to the total solids of the treated material was recommended. This dosage was used in bioconversions 1 to 3. The product of bioconversion 1, which received no addition of bulking agent or starter culture, was unstable with a stability index of 7.7 mg CO2C g1 VS day1. The highest decrease of the VS content was observed during the first 2 days of bioconversion (Figure 3a). Final VS was high (70.8%), despite the biodegradation efficiency of VS (58.5%). The product of bioconversion 2, which was treated with the addition of bulking agent, but without starter culture, was stable. The stability index was 2.9 mg CO2C g1 VS day1, the final VS was 65.8%, and biodegradation efficiency of VS was 59.8%. The product of bioconversion 3, which was provided with bulking agent and starter culture, was very stable with a stability index of 1.9 mg CO2C g1 VS day1. The final content of VS was 67.1%, and the biodegradation efficiency of VS was 58.1%. The addition of horticultural waste compost improved the processing of food waste aerobic bioconversion and ensured the stability of the end product. Organic fertilizer

Fig. 2: The SEM images of initial food waste (a) and food waste after 3 days of bioconversion 1 (b).

Waste Management & Research

43

O. Stabnikova, H.-B. Ding, J.-H. Tay, J.-Y. Wang

Fig. 3: Changes of VS content, percentage of TS (a), biodegradation, percentage (b) and cell number, log CFU g1 of dry matter (c), with time during bioconversions of food waste without starter culture and horticultural waste compost (B1); without starter culture but with horticultural waste compost (B2); with starter culture Bacillus thermoamylovorans SW25 and horticultural waste compost (B3).

from food waste obtained in bioconversion 1 was unstable, but the organic fertilizers produced in bioconversions 2 and 3 were stable. The use of soya bean residue as a component of food waste ensured a relatively high content of nitrogen (2.1 2.8% of TS) in the organic fertilizer. Biomass of the bacterial strain Bacillus thermoamylovorans SW25 was used as the starter culture for food waste bioconversion 3. The representatives of this species are common inhabitants of food compost (Dees & Ghiorse 2001). The

effectiveness of its application for bioconversion of sewage sludge mixed with food waste into fertilizer has been demonstrated (Wang et al. 2003a, b). In spite of the high initial contents of thermophilic bacterial cells in bioconversion 3, the end content of cells was the same or even lower than in bioconversions without the addition of a starter culture (Figure 3c). The initial content of thermophilic bacteria was 1.1 108 CFU g1 TS in bioconversion 3 (with the addition of starter culture), but it dropped during the first 2 days of bioconversion to 5.67 106 CFU g1 TS and increased only to 6.7 107 CFU g1 TS on day 10 of the process (Figure 3c). The content of thermophilic bacteria decreased during the first 2 days of bioconversion 3, maybe because of the adaptation period. However, the results indicated that the decrease of VS in the treated food waste was high enough during this time (Figure 3a). Probably, the decrease of VS was due not only to the microbial activity, but also to intracellular plant enzyme activity at 60C. The highest content of thermophilic bacteria was observed in bioconversion 2, when horticultural waste compost was added to the initial mixture of food waste. The initial content of thermophilic bacteria was 2.1 105 CFU g 1 TS in bioconversion 2 (without addition of starter culture), but it increased to 1.1 108 CFU g1 TS on day 10 of bioconversion. Similar maxima in the range of 108 to 109 cells g1 of the composted matter were found during composting of organic waste at temperatures from 65 to 82C (Beffa et al. 1996). Therefore, it can be concluded that there is no need to use starter culture for food waste aerobic thermophilic bioconversion. Indigenous thermophilic bacteria that were already present in raw materials grew well and reached a sufficient content in aerobically treated food waste in a short period of time. For the semi-continuous and continuous process it is possible to use part of the final product to enhance the biodegradation of food waste. The results of the germination test, root length and germination index indicate that the end-product of bioconversion 1 had a higher phytotoxicity than the end-products from bioconversions 2 and 3. The addition of horticultural waste compost decreased the phytotoxicity of the organic fertilizer from food waste (Figure 4). The addition of organic fertilizers to subsoil increased the plant growth. The highest improvement for OF1 was observed at its 1% dosage (weight of dry matter/weight of subsoil) (Table 4 and Figure 5). The highest dosage of OF1 decreased the length and weight of Kang Kong stems and roots. These results were in agreement with the toxicity test of OF1. The application of OF2 in dosages from 1 to 4% (weight of dry matter/weight of subsoil) increased the lengths of stems and roots from 30 to 50% and from 70 to 140%, respectively, in comparison with plants grown in subsoil. Very similar results were obtained when subsoil was amended with OF3. The

44

Waste Management & Research

Aerobic conversion of food waste into organic fertilizer

Fig. 4: Germination of seeds (Fig. 2a), length of roots (Fig. 2b) and germination index (Fig. 2c) of cucumber seeds in the presence of extracts from the product of bioconversions 1, 2 and 3.

Fig. 5: Effects of food waste fertilizers added in different dosage to subsoil on Kang Kong plant growth.

lengths of stems increased from 10 to 48% and the length of roots increased from 7 to 100% at application dosage of OF3 from 1 to 4% (weight of dry matter/weight of subsoil). No toxic effects were observed at application of OF2 and OF3 at the 4% dosage (weight of dry matter/weight of subsoil). No significant differences in plant growth were observed at the addition of OF2 and OF3 in the same dosage. Nitrogen content in the plant tissues increased with the dosage of organic fertilizer applied (Table 4). The positive effect on plant growth due to all the organic fertilizers from food waste added to subsoil at a 2% dosage was lower in comparison with the commercial organic fertilizer used in quantity equivalent for nitrogen. One of the reasons for this may be that these organic fertilizers were not balanced by nutrients. For example, the

lack of phosphorus was evident (Table 3). Phosphorus in the form of the salt Na2HPO4 (1 g P2O5 per plant) was added with OF1 and OF3 used at 2% dosage (weight of dry matter/weight of subsoil). The length of stems increased by 32.3 and 36.7%, the length of roots increased by 25.4 and 43.8%, respectively, following application of OF1 and OF3 with the addition of extra phosphorus (Table 4). Therefore, the addition of phosphorus is required to increase the positive effect on plant growth of organic fertilizer from food waste.

Conclusions

A biotechnology for aerobic conversion of food waste into organic fertilizer under controlled aeration, stirring, pH and

Waste Management & Research

45

O. Stabnikova, H.-B. Ding, J.-H. Tay, J.-Y. Wang

Table 4: Comparison of end products of bioconversions on Kang Kong plant growth (mean value standard deviations are shown). Amendments to subsoil Dosage (%) (weight of dry matter/ weight of subsoil) 0 1 2 2* 3 4 COF OF2 Equal by N to 2% of FFW1 1 2 3 4 COF OF3 Equal by N to 2% of FFW2 1 2 2* 3 4 COF Equal by N to 2% of FFW3 Parameters of plants Lengths (mm) Stems 127 22 193 21 161 24 213 16 124 17 100 0 307 34 167 11 170 13 188 13 190 29 300 20 140 0 150 19 205 15 185 5 189 10 230 7 Roots 70 7 150 11 130 19 163 11 116 13 100 0 240 29 122 14 130 16 156 11 170 18 245 15 75 13 80 15 115 22 130 14 140 15 235 22 Dry weights (g) Stems 0.08 0.01 0.20 0.03 0.28 0.05 0.52 0.04 0.18 0.01 0.06 0.00 0.72 0.12 0.19 0.01 0.25 0.01 0.27 0.02 0.30 0.00 0.69 0.13 0.19 0.00 0.20 0.00 0.42 0.01 0.27 0.00 0.30 0.00 0.56 0.12 Roots 0.02 0.00 0.12 0.00 0.10 0.00 0.18 0.01 0.06 0.00 0.03 0.00 0.26 0.03 0.09 0.00 0.10 0.01 0.14 0.01 0.17 0.00 0.22 0.02 0.05 0.00 0.05 0.01 0.06 0.00 0.15 0.00 0.16 0.00 0.23 0.05 Content of N (% of dry matter) 1.32 0.11 1.56 0.1 2.66 0.2 2.63 0.3 2.78 0.1 3.20 0.2 ND 1.45 0.2 1.67 0.1 1.87 0.4 2.54 0.2 ND 2.08 0.2 2.34 0.3 2.33 0.3 2.54 0.1 3.31 0.2 ND

No amendments OF1

Note: * Na2HPO4 (1 g P2O5 per plant) was added; ND means not determined.

temperature at 55oC to 65oC was investigated. To maintain neutral pH, at the beginning of the bioconversion 5% CaCO3 was added to the total solids of the food waste. The addition of 20% horticultural waste compost as a bulking agent to food wastes (w.w./w.w.) improved the bioconversion process and increased the stability of the final product. No starter culture was needed in the aerobic bioconversion of food waste. It took 10 days to convert food waste into organic fertilizer in the pilot scale reactor. The addition of 4% organic fertilizer from food waste to subsoil increased the

yield and growth of the Kang Kong plant by 1.5 to 2 times. The addition of phosphorus is required to enhance the positive effect on plants growth of organic fertilizer from food waste.

Acknowledgements

The research was supported by a grant from the National Environment Agency of the Ministry of the Environment, Republic of Singapore.

References

American Public Health Association. (1998): Standard Methods for the Examination of Water and Wastewater. 20th edn, Clesceri, L.S., Greenberg, A.A., & Eaton, A.D. (eds). American Public Health Association/American Water Works Association/Water Environmental Federation, Washington DC, USA, part 2, 254. Bai, R. & Sutanto, M. (2002): The practice and challenges of solid waste management in Singapore. Waste Management, 22, 557567. Beffa, T., Blanc, M., Lyon, P.-F., Vogt, G., Marchiani, M., & Fisher, J.L. (1996): Isolation of Thermus strains from hot compost (60 to 80C). Applied and Environmental Microbiology, 62, 17231727. Dees, P.M. & Ghiorse, W.C. (2001): Microbial diversity in hot synthetic compost as revealed by PCR-amplified rRNA sequences from cultivated isolates and extracted DNA. FEMS Microbiology & Ecology, 35, 207216. Haug, R.T. (1993): The Practical Handbook of Compost Engineering. Lewis Publishers, Boca Raton, FL, USA. Garcia-Gomez, A., Bernal, M.P., & Roig, A. (2002): Growth of ornamental plants in two composts prepared from agroindustrial wastes. Bioresource Technology, 83, 8187. Ivanov, V.N., Wang, J.Y., Stabnikova, O.V., Tay, S.T.L. & Tay, J.H. (2004): Microbiological monitoring in the biodegradation of sewage sludge and food waste. Journal of Applied Microbiology, 96, 641647. Maynard, A.A. & Hill, D.E. (2000): Cumulative effect of leaf compost on yield and size distribution in onions. Compost Science and Utilization, 8, 1218. Mathur, S.R. (1991): Composting process. In: Bioconversion of Waste Materials to Industrial Products, Martin, A.M. (ed.). Kluwer Academic Publishers, Dordrecht, pp. 147183. Ministry of the Environment, Singapore. (2002): Annual Report. (http:// www.nea.gov.sg). Park, J.I., Yun, Y.S., & Park, J.M. (2002): Long-term operation of slurry bioreactor for decomposition of food wastes. Bioresource Technology, 84, 101104.

46

Waste Management & Research

Aerobic conversion of food waste into organic fertilizer

Park, J.I, Yun, Y.S. & Park, J.M. (2001): Oxygen-limited decomposition of food wastes in a slurry bioreactor. Journal of Industrial Microbiology and Biotechnology, 27, 6771. Sharma, V.K., Candietelli, M., Fortuna, F. & Cornacchia, G. (1997): Process of urban and agro-industrial residues by aerobic composting: review. Energy Conversion and Management, 38, 453478. United States Department of Agriculture and the United States Composting Council. (2001a): Carbon dioxide evolution rate. 05.08-B. In: Test Methods for Examination of Composting and Compost, Thompson, W.H. (ed.); Leege, P.B., Milner, P.D., & Watson, M.E. (co-eds) Jointly Published by the United States Department of Agriculture and the United States Composting Council, 05.08-1105.08-12. United States Department of Agriculture and the United States Composting Council. (2001b) In-vitro germination and root elongation. 05.05B. In: : Test Methods for Examination of Composting and Compost,

Thompson, W.H. (ed.); Leege, P.B., Milner, P.D., & Watson, M.E. (coeds) Jointly Published by the United States Department of Agriculture and the United States Composting Council, 05.05-705.05-8. Wang, J.Y., Stabnikova, O., Tay, S.T.L., Ivanov, V., & Tay, J.H. (2003a): Intensive bioconversion of sewage sludge and food waste by Bacillus thermoamylovorans. World Journal of Microbiology and Biotechnology, 19, 427432. Wang, J.Y., Stabnikova, O., Ivanov, V., Tay, S.T.L., & Tay, J.H. (2003b): Intensive aerobic bioconversion of sewage sludge and food waste into fertilizer. Waste Management & Research, 21, 405415. Yun,Y.-S., Park, J.I., Suh, M.S., & Park J.M. (2000): Treatment of food wastes using slurry-phase decomposition. Bioresource Technology, 73, 2127. Zucconi, F., Forte, M., Monaco, A., & de Bertoldi, M. (1981): Biological evaluation of composte maturity. Biocycle, 22, 2729.

Waste Management & Research

47

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Technical Specifications BD Facsarray™Documento4 páginasTechnical Specifications BD Facsarray™nurhanamjAinda não há avaliações

- Primary Cell Culture 2013 020914Documento40 páginasPrimary Cell Culture 2013 020914nurhanamjAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- WWW - Emtech.upm - Edu.my Document EMTech CalendarDocumento16 páginasWWW - Emtech.upm - Edu.my Document EMTech CalendarnurhanamjAinda não há avaliações

- Drug Common Name ManufacturerDocumento1 páginaDrug Common Name ManufacturernurhanamjAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Multiwell PlatesDocumento1 páginaMultiwell PlatesnurhanamjAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Pathogens Affecting Crops in MalaysiaDocumento4 páginasPathogens Affecting Crops in MalaysianurhanamjAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Animal Farm Quiz CH 5 7Documento3 páginasAnimal Farm Quiz CH 5 7BrennaAinda não há avaliações

- MUNGGODocumento17 páginasMUNGGOJenny Joy B. Fortin100% (2)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Tcs Ninja NQT Previous Year PapersDocumento210 páginasTcs Ninja NQT Previous Year PapersVellasamy karthickAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- NUTRITIONDocumento4 páginasNUTRITIONaira michaella libiran0% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Tematica EnglezaDocumento75 páginasTematica EnglezaAna-Maria GuguAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Sample Integrated Marketing Communications Plan Happy Family Ice Cream MachinesDocumento29 páginasSample Integrated Marketing Communications Plan Happy Family Ice Cream MachinesrodolfoAinda não há avaliações

- Collection of Easy To Follow Salad RecipesDocumento52 páginasCollection of Easy To Follow Salad RecipesmasurimasoodAinda não há avaliações

- Rajasthan: The Incredible State OFDocumento24 páginasRajasthan: The Incredible State OFMohit NegiAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Measure UP! Worksheet: Name - Date - ClassDocumento2 páginasMeasure UP! Worksheet: Name - Date - ClassnangungunaAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Simple Present / Present ContinuousDocumento15 páginasSimple Present / Present Continuousla wea cosmica EspacialAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Simple Present Tense and Simple Past TenseDocumento7 páginasSimple Present Tense and Simple Past TenseResta MahesaAinda não há avaliações

- Folleto de 3 Caras Informativo para Evento Moderno Gradiente MulticolorDocumento2 páginasFolleto de 3 Caras Informativo para Evento Moderno Gradiente MulticolorBernat Gabarro obiolsAinda não há avaliações

- KRON. Food Production - Expanded VersionDocumento47 páginasKRON. Food Production - Expanded Versionliuia drusillaAinda não há avaliações

- Final Copy With Page SetupDocumento37 páginasFinal Copy With Page SetupPankajDhobleAinda não há avaliações

- MicroPro Grill Recipes 2020Documento85 páginasMicroPro Grill Recipes 2020Jayme-Lea VanderschootAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Kenwood - FP698 - User ManualDocumento8 páginasKenwood - FP698 - User ManualianjprAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Ingredients: Ep 18 - Rhubarb Trifle With Champagne Jelly and MascarponeDocumento6 páginasIngredients: Ep 18 - Rhubarb Trifle With Champagne Jelly and Mascarponegrupo077Ainda não há avaliações

- Coffee Recipes - Hot and Cold Coffee and Espresso Beverages To Make at HomeDocumento66 páginasCoffee Recipes - Hot and Cold Coffee and Espresso Beverages To Make at HomeGiancarlo Braccio100% (2)

- Acceptability and Use of Cereal-Based Foods in Refugee Camps: Case-Studies From Nepal, Ethiopia, and TanzaniaDocumento137 páginasAcceptability and Use of Cereal-Based Foods in Refugee Camps: Case-Studies From Nepal, Ethiopia, and TanzaniaOxfamAinda não há avaliações

- Design and Fabrication of Paddy Cleaning MachineDocumento5 páginasDesign and Fabrication of Paddy Cleaning MachineDave RoneAinda não há avaliações

- The Cutting Edge: Inside The Modern Lauter TunDocumento11 páginasThe Cutting Edge: Inside The Modern Lauter TunSatyam Pandya100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Company Profile PT - HMSDocumento10 páginasCompany Profile PT - HMSmasindraAinda não há avaliações

- Sea Shepherd Captain's Log No. 70Documento12 páginasSea Shepherd Captain's Log No. 70Derek BoyceAinda não há avaliações

- Ricetti Ghawdxin Volume 3 SmallDocumento21 páginasRicetti Ghawdxin Volume 3 SmallSGAinda não há avaliações

- US Food System FactsheetDocumento2 páginasUS Food System Factsheetmatthew_hoffman_19Ainda não há avaliações

- Here, There and Everywhere: Unit 5Documento10 páginasHere, There and Everywhere: Unit 5Bernabé Hernández MoguelAinda não há avaliações

- Lactogrow VS Lactogen 2Documento3 páginasLactogrow VS Lactogen 2Mardan Love SunnahAinda não há avaliações

- The Future of Ready-To-Eat Food in IndiaDocumento8 páginasThe Future of Ready-To-Eat Food in IndiaMukesh ManwaniAinda não há avaliações

- EjerciciosPresentTenses 210907 171536Documento10 páginasEjerciciosPresentTenses 210907 171536Andrea Martinez JiménezAinda não há avaliações

- WSM West Salem MachineryDocumento7 páginasWSM West Salem Machinerymostafa sherifAinda não há avaliações