Escolar Documentos

Profissional Documentos

Cultura Documentos

Principles Equipment and Operation of Two Laboratory Scale Bio Dig Esters

Enviado por

Anonymous MVHQ97KEoPDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Principles Equipment and Operation of Two Laboratory Scale Bio Dig Esters

Enviado por

Anonymous MVHQ97KEoPDireitos autorais:

Formatos disponíveis

NASA-TM-IOB060

_7" ;-- (L. L

/t//V -c//

I

{

;z_/-v6L T/'_j ' _ leo e, ?;_ >

BIOSOUBC DIGEST"

? -, and .. 1 Materials

A JournalonBiotnass

Utilizalio,l

Chemicals

0 C T. 1979

I (NASA-TM-108060) PRINCIPLES, ,__UIPHENT, AND OPERATION OF LABORATORY SCALF BIOOIGESTERS (NASA) 13 p TWO

Vl

No.

N93-70417

Uncles

Zg/G5

0130478

PRINCIPLES,

EQUIPMENT, SCALE

AND OPERATION BIODIGESTERS

OF

TWO LABORATORY

BY:

REBECCA RESEARCH

C.

MCDONAI_

e

CHEHIST

NATIONAL

AERONAUTICS EARTH

AND SPACE

ADMINISTRATION

RESOURCES

LABORATORY LABORATORIES 39529

NATIONAL

SPACE NSTL

TECI_NOLOGY MS

STATION,

SUBMITTED BIOSOURCES SEPTEMBER,

TO: DIGEST 1979

d.

Note:

This is the second in a series to and written especially for

of the

laboratory scale experiments BIOSOURCES DIGEST.

submitted

PRECEDING 233

P,_.GE

PLANK

P_OT Fi[_._ED

ABSTRACT

The are

major

factors

influencing These

the

rate

and

efficiency type of

of

biogas

production carbon to nitrogen Ioad-

briefly

discussed. pH,

variables

include

substrate,

ratio,

temperature,

agitation,

influent

solids

concentration,

and

organic

ing

rate. Two laboratory batch an scale blodigesters with a water are described in detail. gas collector. the overall One system The is a systime

simple, tem of uses fresh

biodlgester aneroblc

displacemeRt which can

second

filter up

technique to 757_.

reduce

dlgest[on

plant

material

2_

INTRODUCTION Biogas microbial contains gen. waste similar process. Fresh by organic material that is fed into a_ anaerobic hydrolyze sugars , into bound which digester the is first attacked mainly organics. removing refers degradation carbon can dioxide be to gas of containing organic and small from a high in of percentage the absence of methane of oxygen. produced This by gas and and the also hydro-

material amounts

nitrogen, of

hydrogen from

sulflde_ animal

Biogas to crop for

generated and

a variety The

substrates

human is natural

residues

green

plants.

method that

of microbial are amenable

degradation to this

all

the different

organic

substrates

facultative

microorganisms

which

enzymatlcally proteins, free and and

polymers,

cellulose, These the the vert acids The These gas

hemicellulose, microbes and the

llplds, can use

simple, oxygen, inhibits

soluble thereby or

facultatlve atmospheric growth the are of

chemically digester Next, the

dissolved

oxygen

from

the

prevents con-

strict organics for

anaerobic into the

bacteria. acids, of

acld-forming acetic as the acid.

bacteria The

soluble

organic set the

primarily known

organic bacteria. dioxide. hydrogen

substrates

last

bacteria

methanogenlc and carbon or

methanogenlc bacteria which is

bacteria can also

ferment reduce

organic dioxide during

acids

to methane using

carbon quantities

to methane the

formate stage.

formed

in small BIOGAS

acld-forming

FACTORS The factors. nitrogen solids bic A i.

INFLUENCING rate The ratio, concentrations. and most

PRODUCTION of anaerobic are digestion the type is of influenced substrate, rate, by the and has Academy a number carbon tnfluent on of the anaero2 of to

efficiency important

para_ters pH, impact agitation, that by

temperature, The is for

organic each of 1 and is these the listed

loading

parameters National below.::

digestion brief Type The

process

discussed of these

Singh

Sciences.

guideline of substrate

each

factors

facultative

and

acld-produclng

bacteria

must

hydrolyze

the

polymers,

235

mainly

cellulose

and

hemlcellulos_ to

into

simple last

sugars step of is

and the

monomers digestion which by

in order and

for

the methanogenic methane. gradable. cellulose tial Another High from

bacteria major lignin bacterial results cellulose.

complete of

the plant the

produce

component content

material available

lignin

is nonbiodeprotecting in the the potenavail-

reduces

cellulose llgnln

degradation. in poor blogas

Therefore, and methane

hLgh

content due

substrate of the

production

to reduced

ability 2.

Carbon Most

to nitrogen raw materials

ratio contain adequate amounts

f

of

nutrients it the at reduce a

for

complete

digestion. The

If

the

starting C:N

substrate is 30:1.

is deficient A higher will the

in a nutrient, ratio will slow

is usually process, lower the

nitrogen. and digestion however, content

optimal will some the 3. be

ratio

incomplete. may be

Digestion lost during

proceed

normally and

ratio;

nitrogen remaining Temperature Anaerobic

digestion

nitrogen

of

sludge.

digestion and

proceeds

most

efficiently 54-600C. will in

in two The either

temperature should or

ranges: not be

mesophillc, allowed to

330-38 fluctuate control

thermophilic, or

temperature slow down

suddenly

digestion important

even

stop.

Temperature 4. pH The 7.6. usually teria to The by

is especially

the

thermophilic

range.

pH of

a balanced pH range new

digestion Is 7.0 to

process 7.2.

will If the and

naturally system causing

stay

between and

6.6 the

and

optimal

is upset the

pH drops, bacmay be

introducing

substrate_too acid pH and and

fast

acld-formlng bacteria, llme

produce added

excessive until the

inhibit

the

methanogenic is restored to

carefully 5.

buffer

system

normal.

Agitation Minor agitation is desirable, especially with vegetable matter in order

I

to

2_

prevent scum build-up and prolonged settling 6. Influent solids concentration

of 7 to 9% is

of the heavier material

on the bottom.

An optimal solids range

7. Organic This acid ing loading paramter in rate is the

desirable.

important system. on several

in continous No general variables, An

feed

digesters

in

order

to the

prevent organic

an loadsolids

imbalance rate

guide

is available the

since type of is

is dependent pH, for and

especially for

substrate, the

concentration, loading LABORATORY I. Batch Simple bility in this and rate

temperature. municipal

example,

guidance, kg per

recoa=nended day.

standard

digesters:

0.48-1.6

m 3 per

BIODIGESTERS Biodigester laboratory methane was batch digesters of various et can be easily set up to evaluate The system water in the digesti-

production used

organic al.3

substrates. methane is

described hyacinths I. sysa ontrolle(

paper

by Wolverton The complete

to produce

from shown

(Eichhornia The tem system to

crasslpes). consists the of

experimental the substrate digestion mesophilic or blended amount of the

set-up and

Figure

a container All of in chopped area.

for the the

a water is 36_ to

displacement in

collect

biogas.

equipment range in of order water st

incubated lC. the added volume a

temperature The with tem a

chamber substrate substrate on the the

maintained should be surface Inital In fresh facultatlve bacterial plant sollds the

provide that is the

bacteria to the systo mass

large

The

depends

content first materlal and

substrate with The water

and

needed 1:1

disperse ratio with vessel. manure blcslly or of

bacteria. to of initial a for

experiments was used. bacteria be that the

hyacinths, should sealing a fresh been the

water

substrate before from

be

inoculated

a mixture An

anaerobic

substrste of to cow anaero-

inoculumcan the weeks. substrate After

prepared has first

slurry allowed

from

slurry several

of

previously successful

digest

anaerobic

digestion,

237

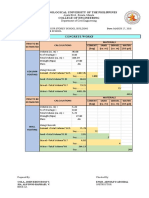

GAS SAMPLING SEPTUM TUBING FLEXIBLE PINCH CLAMP RUBBER STOPPER WATER DISPLACEMENT VES SUBSTRATE VESSEL

/

STOPPER RUBBER

FLEXIBLE TUBING

WATER

WATER SUBSTRATE

GLASS TUBING

WATER

Fih, urc

1.

Laboratory

Batch

Bio-Digcster

238

approximately to of inoculate the saved

one the

fourth next

of

the

remaining Great because the

sludge care

and

supernatant be used

should

be

saved exposure

experiment. to oxygen can

should

to minimize are or the extremely even kill

the

material Oxygen

anaerobic anaerobic cause

bacteria activity a delay in

sensia large of the

tive

to oxygen. of

suppress population

percentage next

the bacterial fermentation. the substrate,

and

initiation

anaerobic After all the

water, the left

and vessel

inoculating should vessel, be it

bacteria tightly

have sealed

been to

thoroughly the atmosphere. the the wastes up air facul-

mixed If a

in large with

substrate air

vessel, is

dead an

space gas

in this

is preferable the time

to purge for

space tative

inert

such up all

as nitrogen the free

to minimize oxygen. Batch of

required of

bacteria

to use

digestion plant

animal

generally to three The prior is to

requires months. water

three

weeks;

whereas,

digestion

material

requires

displacement it and

system

should it to off

also the as

be

completely vessel.

filled The the

with pinch

water clamp tubing into volume and Methane the

to sealing loose gas

connecting to close

substrate as

left the

until

needed vessel

close

possible

connecting of by air the

collection vessel. The

in order of for total

to minimize blogas

the

introduction is measured Sparks, gas

substrate of water heat

volume

produced and

displaced, should

corrected be

temperature avoided when

pressure. the

flames,

sources

carefully mixed

refilling

collector.

is highly

explosive

when

with

air. up the blogas limewater and can and be installed iron in the system prior to

Scrubbing if desired. collection Hydrogen metal

systems Passing

for

cleanlng

the blogas the carbon

through dioxide

then

filings

will sulfide H2S

reduce re_bval

hydrogen in

sulfide gas

content, collectors prior the

respectively. made to of

is especially If water

desirable vapor

large

since

is corrosive. containing

removal be

is desired in

burning, llne.

a drying

system

calcium

chloride

may

included

outlet

239

II.

Anaerobic A new

Filters 4 system is currently a substrate gas collector. flow being evaluated by Wolverton filter is still are being and McDonald.

biodigestion shown and water and

This

system

in Figure

2 has

vessel, This

anaerobic system etc.

(reaction in the varied experiin

chamber), mental order

displacement the the substrate efficiency

stage,

preparation, of this

rates,

to optimize The initial the

system. manners. Another constructed separated One method involves only the

substrate with a

is prepared a minimum

in several of water. and

blending juices

plants with

volume

method by

uses Dr.

obtained of with juices the provide

squeeze A third

press, method

designed uses

Larry and

Bagnall, solids

University obtained The through rocks the never

Florida. the press. the

both

the

juices

from

substrate which area

vessel is for

are

circulated vessel

via

peristalic small come in

pump rocks. contact filter The with is

anaerobic a large After to the is

filter surface

a large the

filled to grow in

with and

bacteria is

substrate. exposed

anaerobic atmosphere from

digestion and

initiated

the

filter,

the

continues

to maintain

a high

anaerobic this

bacterial indi-

population cate days GAS that even

that the with

used

digestion digestion

to digestion. time is reduced

Results to

from

system 21 to 28

average fresh

total plant

approximately

material.

ANALYSIS Methane alone A can six be foot analyzed column using packed

\

a gas with

chromatograph Porapak Q

with

flame will

ionizagive

tion good

detector. results. Nitrogen,

150-200

mesh

carbon

dioxide, fltted packed C02

oxygen, with with all mesh

and

methane

can thermal

be

analyzed conductivity (DEHS)

with

a dual

column The

gas

chromatograph 6'x_" column the

a 2-channel

detector. 60-80 mesh column

first

di-2-ethylhexylsebacate other components. Sieve 13X The and

on

Columpak in series

separates is packed

from

second absorbs

6_'x3/16" the

with

42-60

Molecular

CO 2 and

240

GAS SAMPLING SEPTUM

ANAEROBIC FILTER

PEA GRAVEL J

r,

WATER DISPLACEMENT GAS COLLECTOR

CIRCULATION PUMP ANAEROBIC DIGESTER CONTAINING WATER HYACINTH JUICE, FIBER AND PEA GRAVL

l.'il4_are ;_.

"l'xvu-,_t:t_v At_terobi_. l_letl_u_e irom Water

IJil_estvr lly:_eintbs,

System 4

for

l)r_)(lucing

241

separates adapted PLANT

all for

other

major

gas are

components. commercially

Small

gas

chromatographs

that

are

especially

this

purpose

available.

ANALYSIS for 5 analyzing the initial substrate potassium, and carbon, are be final sludge can ash, be found

Procedures in the A.O.A.C. and

Nitrogen, are the the Etzel

phosphorus, important digestion and

moisture, normally using

volatile Volatile

solids, acid

fiber

parameters'whlch process 6 can

monitored. the

formation

through by

followed

analytical

procedure SUMMARY Far The simple

outlined

Pohland. ..

more

elaborate

blodigesters that These in order have

than been

described here can

in this can be

paper

are

available. from standard

blodlgesters equipment. parameters of interest. assortment animal wastes

outlined models the

assembled modlfied for

laboratory different substrate A sludge New marine potential organic

laboratory

be

easily

to vary a particular

to determine

optimum

conditions

large and

of to

substrates agricultural

from

the more

common wastes

ones

such

as munlcipal investigated. kudzu, must and have of high the

products include

and

have

been

substrates algae

receiving (giant kelp).

current All of

interest the order economically

the water under

hyacinth,

substrates for the

consideration

annual materlal

productivities to methane accounts can be to of

in be the found

microbiologlcal attractive. processes, reading.

conversion

More tlonal

detailed

microbiological in the suggested

equipment,

and

opera-

considerations

REFERENCES 1. Singh, Gobar 2. Ram Gas Bux. 1971. Bio-gas Plant, AJi_mal, 1977. Generatin_ Etawah Methane Academy of Hethan_____efro.___m Organic (U.P.) India. 70 pp. Animal, D.C. 131 pp. Wastes.

Research Academy of

Station, Sciences.

National

Generation Sciences,

from_Human, Washington,

an___ddAgrlcultural

Wastes.

National

242

3.

Wolverton, Water 72725.

B.

C.,

McDonald, Methane

R.

C.

and Part

Gordon, I."

J.

1975.

"Bio-converslon Memorandum

of TM-X-

Hyacinths

into

Gas:

NASA

Technical

4.

Wo!verton Wastewater

, B. C.

and

McDonald, Systems." of

Rebecca NASA the

C.

1979.

"Energy

from

Aquatic

Plant

Treatment Methods Ed.

Technical Assoclatlon

Memorandum

TM-X-72733. Analytical Washington, Chemists. D.C.

5.

Official 1975. 1094

of Analysis Association

of Official Chemists,

12th pp. J.

of Official

Analytical

6.

Etzel,

E.

and Public

Pohland, Works.

F. G.

1960.

"Volatile

Acld

Formation

Durfng

Sludge

Digestion." SUGGESTED I. READING L.

7:105-108.

Anderson, Quantities of

1972.

"Energy

Potential Bureau

from

Organic

Wastes:

A Review 8549,

of

the Dept.

and

Sources."

of Mines

Information

Circular

U.S.

Interior. H. A.

16 pp. 1956. "Biological Formation of Methane." Ind_____. EnKin. Chem. 48:

2.

Barker,

1438-1442. 3. Buswell, J. 4. Am. A. Chem. C. and S. D. M. and Sollo, F. W. 1948. '_The Mechanism of the Methane Formation."

Soc. and

70:1778-1780. Evans, of R. S. 1975. "Anaerobic Science. Digestion: The Rate-Limltlng

Flnney, Process

the

Nature

Inhibition." 1971.

190:1088-1089. Dynamics in in Continuous Industrial Cultures Microbiology.

5.

Ghosh, of

and

Pohland,

F. C.

"Population

Heterogenous

Microbial

Populations."

Developments

12:295-311. 6. Ghosh, genesLs 7. Coleuke, Co qmpost Sambhunath, of Sewage Conrad, Sludge." C. 1974. John Journ. R., and Klass, D. L. 1974. "Anaerobic l_6:1-12. Recovery Systems." Acldo-

_ater

Poll.___.ConCrolFed. Reactions

Clarence Science.

"Biological

in SolldWaste

15(2):2-6.

243

8.

Klass, of

Donald

L.,

Ghosh, Gas for and

Sambhunath, Captive

and

Conrad,

John of

R.

1976.

"The

Conversion Biomass,

Grass

to Fuel Urban R. by D.

Use."

Proceedings

Clean FL.

Fuels 1-24. of

from

Sewage, 9. Laura, Cowdung 164-167. 10. Leese,

Refuse and

A_rlcultural M. A. 1971.

Wast______e, Orlando, "Increased Waste

Idnanl, Other

Production

Biogas Fd. _

from 22:

Adding

Agricultural

Materials."

J__.Scl.

Thomas

M.

1976.

"The of

Conversion Fuels 50-64. 1960.

of Ocean from

Farm

Kelp

to Methane

and

Other

Products." A_rlcultural II. Oswald, Energy." 12. Oswald, W.

Proceedings

Clean FL. C. G.

Biomass

, Sew._,

Urba___n_nRefuse and

Wast.__e,Orlando, J. and Goleuke, in Applied Goleuke, 40-43. S. C.

"Biological

Transformation

of

Solar

Advances W. J. and

MicrobioloEy. G. 1964.

_:223-262. Power Via a Botanical Process."

"Solar

Mechanical 13. Pohland, Organic 14. Sanders, Ratio 1752. 15. Wolverton, Vascular on F.

Engineers. G. and - _e and

Ghosh,

1971_

"Developments Environ. "The Water

In Anaerobic Letters. of

Stabilization

of

Wastes F. A.

_o-Phase Bloodgood,

Concept." D. E. 1965. Journ.

_(4):255-266. Nitrogen Fed. to Carbon 37(12):1741-

Effect Poll.

Anaerobic

Decomposition."

Control

B. C., Aquatic

Barlow, Plants

R. for

M.,

and

McDonald, Removal, of

R. C. Energy,

1976. and

"Application Food

of in

Pollution

Production of Penn.

a Biological Press. 16.

System."

Biological

Control

x

Water

Pollution,

Univ.

141-149. B. Pest C. to and McDonald, Rebecca C. 1979. '_rhe Water Royal Hyacinth: Academy From of

Wolverton, Prolific Sciences.

Potential

Provider."

Ambl.____o, The

Swedish

_(I) :2-9.

2_

Você também pode gostar

- Livestock FormsDocumento37 páginasLivestock FormsddpuruliaAinda não há avaliações

- Popovers Recipe - Food NetworkDocumento1 páginaPopovers Recipe - Food NetworkAnonymous MVHQ97KEoPAinda não há avaliações

- Organic Orchard, Vineyard, and Berry Crop Documentation FormsDocumento22 páginasOrganic Orchard, Vineyard, and Berry Crop Documentation FormsAnonymous MVHQ97KEoPAinda não há avaliações

- Triple Standards Quick Reference GuideDocumento9 páginasTriple Standards Quick Reference GuideAnonymous MVHQ97KEoPAinda não há avaliações

- Popovers - King Arthur Flour PDFDocumento1 páginaPopovers - King Arthur Flour PDFAnonymous MVHQ97KEoPAinda não há avaliações

- Guide To Production Information For Commercial Floriculture GrowersDocumento13 páginasGuide To Production Information For Commercial Floriculture GrowersAnonymous MVHQ97KEoPAinda não há avaliações

- NOSB Processing Materials Decisions June 2001Documento11 páginasNOSB Processing Materials Decisions June 2001Anonymous MVHQ97KEoPAinda não há avaliações

- What Are The Basic Requirements For Organic Certification?Documento2 páginasWhat Are The Basic Requirements For Organic Certification?Anonymous MVHQ97KEoPAinda não há avaliações

- What Are The Basic Requirements For Organic Certification?Documento2 páginasWhat Are The Basic Requirements For Organic Certification?Anonymous MVHQ97KEoPAinda não há avaliações

- Cold Protection For Nursery CropsDocumento9 páginasCold Protection For Nursery CropsAnonymous MVHQ97KEoPAinda não há avaliações

- Home & Garden Information Center: JasmineDocumento2 páginasHome & Garden Information Center: JasmineAnonymous MVHQ97KEoPAinda não há avaliações

- PopoversDocumento1 páginaPopoversAnonymous MVHQ97KEoPAinda não há avaliações

- Easy Care Hydrangeas GuideDocumento2 páginasEasy Care Hydrangeas GuideAnonymous MVHQ97KEoPAinda não há avaliações

- Home & Garden Information Center: VinesDocumento4 páginasHome & Garden Information Center: VinesAnonymous MVHQ97KEoPAinda não há avaliações

- Chapati Recipe SearchDocumento11 páginasChapati Recipe SearchAnonymous MVHQ97KEoPAinda não há avaliações

- 15 Min Stinging Nettle SoupDocumento2 páginas15 Min Stinging Nettle SoupAnonymous MVHQ97KEoPAinda não há avaliações

- HTTP 301Documento2 páginasHTTP 301Anonymous MVHQ97KEoPAinda não há avaliações

- Muesli SML PDFDocumento4 páginasMuesli SML PDFAnonymous MVHQ97KEoPAinda não há avaliações

- Engaging in A Conversation About Race - Louhelen Compilation - 2010Documento44 páginasEngaging in A Conversation About Race - Louhelen Compilation - 2010Anonymous MVHQ97KEoPAinda não há avaliações

- Arduino Tutorial - Learn Electronics and Microcontrollers Using Arduino!Documento3 páginasArduino Tutorial - Learn Electronics and Microcontrollers Using Arduino!Anonymous MVHQ97KEoPAinda não há avaliações

- SAWG Organic Farmer Network - EquipmentDocumento4 páginasSAWG Organic Farmer Network - EquipmentAnonymous MVHQ97KEoPAinda não há avaliações

- Popovers - King Arthur FlourDocumento1 páginaPopovers - King Arthur FlourAnonymous MVHQ97KEoPAinda não há avaliações

- Ishi in Two Worlds A Biography of The Last Wild Indian in North AmericaDocumento6 páginasIshi in Two Worlds A Biography of The Last Wild Indian in North AmericaAnonymous MVHQ97KEoPAinda não há avaliações

- Muesli SML PDFDocumento4 páginasMuesli SML PDFAnonymous MVHQ97KEoPAinda não há avaliações

- BT Style Guide July 2018Documento9 páginasBT Style Guide July 2018Anonymous MVHQ97KEoPAinda não há avaliações

- The Problems and Possible Solutions in The Development of A Chinese Deaf IdentityDocumento15 páginasThe Problems and Possible Solutions in The Development of A Chinese Deaf IdentityAnonymous MVHQ97KEoPAinda não há avaliações

- Pitch Discrimination in The Cat Through Electrical Stimulation of The Terminal Auditory Nerve FiberDocumento6 páginasPitch Discrimination in The Cat Through Electrical Stimulation of The Terminal Auditory Nerve FiberAnonymous MVHQ97KEoPAinda não há avaliações

- A Matched Pairs Comparison of Single and Multichannel Cochlear Implants in Children Chute 1990Documento4 páginasA Matched Pairs Comparison of Single and Multichannel Cochlear Implants in Children Chute 1990Anonymous MVHQ97KEoPAinda não há avaliações

- A Model of Safe Levels for Electrical StimulationDocumento3 páginasA Model of Safe Levels for Electrical StimulationAnonymous MVHQ97KEoPAinda não há avaliações

- Bioresource Technology: Su Yun Xu, Obuli P. Karthikeyan, Ammaiyappan Selvam, Jonathan W.C. WongDocumento6 páginasBioresource Technology: Su Yun Xu, Obuli P. Karthikeyan, Ammaiyappan Selvam, Jonathan W.C. WongAnonymous MVHQ97KEoPAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Lab Manual Foundation EngineeringDocumento39 páginasLab Manual Foundation Engineeringartiraha100% (1)

- Rha GGBS 27 4Documento12 páginasRha GGBS 27 4KhaDeja MawraAinda não há avaliações

- Resina AOC K022 - Series - UsDocumento3 páginasResina AOC K022 - Series - UsChristian HinostrozaAinda não há avaliações

- Elevator Buckets CatalogueDocumento30 páginasElevator Buckets CatalogueYeffreyn EscalonaAinda não há avaliações

- Requirement For Crown Industrial ParkDocumento1 páginaRequirement For Crown Industrial ParkAbdul RafaeAinda não há avaliações

- Historical Structural Steelwork HandbookDocumento76 páginasHistorical Structural Steelwork Handbookjimmyoftheworld100% (1)

- Densiphalt® - Densitop® - Ferrotop™: FerroDocumento2 páginasDensiphalt® - Densitop® - Ferrotop™: FerroGerardo Humberto Lamas AguilaAinda não há avaliações

- Me 322Documento56 páginasMe 322faisalAinda não há avaliações

- Environmental Health and Vessel Sanitation Preventive Procedure Instruction #11Documento1 páginaEnvironmental Health and Vessel Sanitation Preventive Procedure Instruction #11VizitiuAnisoaraAinda não há avaliações

- Daily Overtime & Night Shift Permit SummaryDocumento23 páginasDaily Overtime & Night Shift Permit SummaryDwi Agung AriyonoAinda não há avaliações

- Magnetocaloric effect and magnetic refrigerationDocumento6 páginasMagnetocaloric effect and magnetic refrigerationMirza MesanovicAinda não há avaliações

- Low-Bias Transport in Graphene:an IntroductionDocumento57 páginasLow-Bias Transport in Graphene:an IntroductionLIAKMANAinda não há avaliações

- Bachmann Process For RDXDocumento4 páginasBachmann Process For RDXjoshuaericksonAinda não há avaliações

- CS2 - Carbon Steel Bars For The Reinforcement of Concrete (1995)Documento36 páginasCS2 - Carbon Steel Bars For The Reinforcement of Concrete (1995)don2hmrAinda não há avaliações

- Marvin Elevate-Catalog Feb 2023 19981914Documento27 páginasMarvin Elevate-Catalog Feb 2023 19981914DiegoAinda não há avaliações

- 2023宣传册最终版 修改3Documento16 páginas2023宣传册最终版 修改3CAMILA ESTAY TORRESAinda não há avaliações

- Interactions and Incompatibilities of Pharmaceutical ExcipientsDocumento24 páginasInteractions and Incompatibilities of Pharmaceutical ExcipientsEmmanuel Vachon LachanceAinda não há avaliações

- Thermal Issues in Materials Processing: Yogesh JaluriaDocumento14 páginasThermal Issues in Materials Processing: Yogesh JaluriarahulAinda não há avaliações

- Thin Cylinder Experiment: Apparatus We Have Used A Thin Cylinder SM1007Documento8 páginasThin Cylinder Experiment: Apparatus We Have Used A Thin Cylinder SM1007Rohan Kumar0% (1)

- 2 Concrete Works CompuDocumento14 páginas2 Concrete Works CompuALFONSO RAPHAEL SIAAinda não há avaliações

- Electroplating: Conducting The Electroplating ExperimentDocumento4 páginasElectroplating: Conducting The Electroplating Experimentapi-32133818Ainda não há avaliações

- MyTiCon Screws Design Guide VU 1.2Documento52 páginasMyTiCon Screws Design Guide VU 1.2TomAinda não há avaliações

- Asme BPVC - Ssc.i.ii.v.ix - Xiii-2023Documento42 páginasAsme BPVC - Ssc.i.ii.v.ix - Xiii-2023mmendozagAinda não há avaliações

- Conduits and FittingsDocumento285 páginasConduits and FittingsNashwanAinda não há avaliações

- Material Turbine - 2 PDFDocumento6 páginasMaterial Turbine - 2 PDFMonikaAinda não há avaliações

- LJF Installation Manual ACQA36-00270Documento11 páginasLJF Installation Manual ACQA36-00270Raymundo Rangel RdzAinda não há avaliações

- Evacuated Tube Collector SpecificationDocumento5 páginasEvacuated Tube Collector SpecificationJaswinder SinghAinda não há avaliações

- Pyrolsyis ppt-1Documento15 páginasPyrolsyis ppt-1Aswin MAinda não há avaliações

- List of notifications prepared as of 22 March 2018Documento13 páginasList of notifications prepared as of 22 March 2018Anonymous F1xtU2RAinda não há avaliações

- Superfrac BrochureDocumento16 páginasSuperfrac Brochureunknownx_XAinda não há avaliações