Escolar Documentos

Profissional Documentos

Cultura Documentos

Hira 2

Enviado por

Mp ShamnadTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hira 2

Enviado por

Mp ShamnadDireitos autorais:

Formatos disponíveis

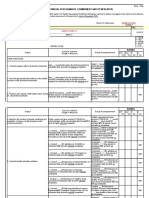

Hazard Identification & Risk Analysis

Sr . N o. Name of Activity Potential Hazard Co ndi tio n N/ Ab /E N Legal Issue Yes (Y) / No (N) N List Before Control of Measures Potential Seve Prob Frequ Injury rity abilit ency y Ris k lev el List of control measures After control Measures Severit Proba y bility Risk level Freq uenc y Remarks

Steel rod cutting by Hand operated m/c.

Caught in between Contact with sharp objects

Body Injury Fract ure

Major

28

1) Proper level of work place. 2) Periodic checking & maintenance of m/c. 3) Use of proper tools in good condition. 4) Trained person to do the work. 5) Strict supervision on work. 6) Use of S. Helmet, S.Shoes, cotton Handloves.S.goggles.

Minor

15

Refer QRA. Follow BEB / SP/04 (PPE)

Steel rod bending Manuall y

Fall of Person at same level Caught in between

Ab

Body Injury Fract ure

Major

24 11) Proper firm level to work place. 2) Use of proper tools in good condition. 3) Restricted entry. 4) Trained person to do the work. 5) Strict supervision on work. 6) Use of S. Helmet, S.Shoes, cotton Handloves. 32 11) Restricted entry to work place 22) Speed limit 15 Km. / hr. 3) Communication with signalman. 4) Trained person to do the work. 5) Strict supervision on work. 6) Use of Stopper at safe distance from excavation.

Minor

Refer QRA. Follow BEB / SP/04 (PPE)

Backfilling by vehicle

Fall of Material Hit by vehicle Toppling of vehicle

N E Ab

Body Injury may be fatal Fract ure Prop erty dama ge

Major

Minor

Refer QRA.

Sr . N o.

Name of Activity

Potential Hazard

Co ndi tio n N/ Ab /E E N

Legal List Issue of Potential Yes Injury (Y) / No (N) Y

Before Control Measures Sever Probab ity ility

Fre que ncy

Ris k lev el

List of control measures

After control Measures Severit Proba y bility

Risk level Freq uenc y

Remar ks

Wood cutting by Portable circular saw

Ele. Shock Contact with Sharp Objects & Flying particles Breaking of cutting blade Noise

Ele. Shock Major burn injury May be fatal Eye injury NIHL

45

Ab

Body injury

N Ab N Body Injury Fracture N N Health hazards Body injury N Major 7 5 Major 7 5 35

1) Proper firm level of work place. 2) Ele. Connections by electrician 3) Use of ELCB. 4) Ele. Cables not passing over floor. 5) Use of Proper tool in good condition. 6) use of standard quality of blade. 2) Trained person to do the work. 3) Strict supervision on work. 4) Use of S. Helmet, S.Shoes,S.Goggles & ear plugs. 1) Proper access to bath place. 2) Floor must be hacked. 3) Daily cleaning of floor.

Minor

10

Refer QRA. Follow BEB / SP/04 (PPE)

Bathing / Washing

Fall of Person (at same level) Contact with Sharp objects Contact With Dust / waste

Minor

10

Refer QRA.

Labor Camp cleaning

35 11) Use of dust bins. 2) Awareness of using dustbins 3) Use of trolly to carry waste. 4) Use of Gumboots, cotton hand gloves, Face mask.

Minor

10

Refer QRA. Follow BEB / SP/04 (PPE)

Sr . N o. 7

Name of Activity

Potential Hazard

Toilet Fall of Cleaning Person (at same level) Contact With human waste Contact With Cleaning liquids Scaffold Fall of Erection & Material dismantlin g Fall of Person Collapse of structure

Co nd. N/ Ab /E Ab

Legal Issue Yes / No N

List of Potential Injury Health hazard Chemical burn Injury Eye injury

Before Control Measures Sever Probab ity ility Major 7

Fre que ncy 5

Ris k lev el 35

List of control measures

After control Measures Severit Proba y bility Minor 2

Risk level Freq uenc y 4

Remar ks

1) Availability of water 2) Use of toilet brush. 3) Daily cleaning. 4) Use of gumboots , PVC 6) Use of S. Helmet, S.Shoes, cotton Handloves.

Refer QRA. Follow BEB / SP/04 (PPE)

Body injury Y Body Injury Fracture May be fatal Major 9 4 36 1) Proper firm & level of base. 2) Check quality of material before erection. 3) Use cross bracing, support bracing as scaffold work progress. 4) Use 20 mm PP rope to shift material. 5) Trained person to do the work. 6) Strict supervision on work. 7) Tool box Talk 8) Use of S. helmet, S.Shoes, S.Harness 1) Proper firm & level of base. 2) Check quality of material before erection. 3) Use support bracing as ramp work progress. 4) Use Ms planks for ramp & tie them by binding wires. 5) Provide Railing & toe board. 6) Trained person to do the work. 7) Strict supervision on work. 8) Use of S. helmet, S.Shoes, Minor 4 4 16 Refer QRA. Follow BEB / SP/04 (PPE)

N E

Ramp Erection & Dismantli ng

Fall of Material Fall of Person Collapse of structure

N E

Body Injury Fracture May be fatal

Major

36

Minor

16

Refer QRA. Follow BEB / SP/04 (PPE)

Sr . N o. 10

Name of Activity

Potential Hazard

Cooking

Contact with hot object Contact with Smoke & fumes Fire & Explosion

Co nd. N/ Ab /E N

Legal Issue Yes / No Y

List of Potential Injury Burn Injury may be fatal Health hazard

Before Control Measures Sever Probab ity ility Major 9

Fre que ncy 5

Ris k lev el 45

List of control measures

After control Measures Severit Proba y bility Minor 2

Risk level Freq uenc y 5

Remar ks

1)Proper work platform to keep stove & cook. 2)Good ventilation 3)Good housekeeping- stacking of wood away from fire/stove. Cloths, bags away from stove. Flammable material oil, kerosene to be stored away. 4)Periodic checking of gas connections. 5) Proper place to put hot utensils. 6) Use appropriate length of cotton cloth to shift hot utensil. 7) Availability of fire Extinguisher. 8)No unauthorized entry in cooking area. 9) Ware cotton cloth while cooking. 1)Proper work plat form to cut raw material. 2)Use of correct tool in correct way. 3)Sufficient illumination at work place. 4) Ele. Connections by electrician 5) Use of ELCB. 6) Periodic checking & maintenance of Mixer / Grinder. 7)Knives must have handle in good condition.

10

Refer QRA. Follow BEB / SP/

11 Cutting of raw material for cooking & serving

Contact with sharp objects Ele. Shock

Minor /major Injury May be fatal

Major

45

Minor

10

Refer QRA.

Hazard Identification & Risk Analysis May 2010

BEB

Sr . N o. 12

Name of Activity

Potential Hazard

Serving of food / Tea / Cold drink

Contact with hot / Cold object Fall of material, Fall of person (at same level) Hit by / Struck by Contact with sharp objects Contact with hot objects Contact with waste food & water Fall of material Fall of person ( at same level)

Co nd. N/ Ab /E N

Legal Issue Yes / No Y

List of Potential Injury Burn Injury Body Injury

Before Control Measures Sever Probab ity ility Major 8

Fre que ncy 5

Ris k lev el 40

List of control measures

After control Measures Severit Proba y bility Minor 2

Risk level Freq uenc y 5

Remar ks

1) Use of proper tray, thermos

to carrey Servings. 2) Trained person to do the work. 3) Follow traffic rules while walking / crossing road. 4) Use S.helmet , Shoes while serving out side canteen.

10

Refer QRA.

N Ab

Ab N Y Minor /major Injury Health Hazard Major 7 5 35

13 Washing of Utensils

1)

N Ab

Proper work plat form for washing. 2)Access to work place without obstruction. 3)Sufficient illumination at work place. 4)Floor non slippery. 5)Proper drain of waste water, 6)Use of dust bin to collect food waste. 7) Wash utensils immediately. 8)Check temp of utensil before 9) Washing. Cool it by water & then wash. 10) Ergonomics Way to carry & lift the load. 11) Wash hands & legs with soap & dry them with napkin immediately after the work .

Minor

10

Refer QRA.

Hazard Identification & Risk Analysis

Sr . N o. 14

Name of Activity

Potential Hazard

Staggerin g of Mivan plate & Stacking

Contact with sharp object Fall of material, Caught in between

Co nd. N/ Ab /E N

Legal Issue Yes / No N

List of Potential Injury Body Injury Facture

Before Control Measures Sever Probab ity ility Major 7

Fre que ncy 4

Ris k lev el 28

List of control measures

After control Measures Severit Proba y bility Minor 2

Risk level Freq uenc y 4

Remar ks

N N N Y Ele. Shock Major burn injury May be fatal Eye injury N E NIHL Body injury 8 5

15 Cleaning of Mivan plate

Contact with sharp objects Flying particles Noise Ele.Shock

16 Cutting of Mivan plate

Contact with sharp objects Flying particles Noise Ele.Shock

Ele. Shock Major burn injury May be fatal Eye injury

N N E NIHL Body injury

1)Proper place & access for keeping staggered material. 2)Good housekeeping.- stacking similar parts separately. 3) Stacking upto one met. height 4)Trained person to do the work. 5) Use S.helmet , Shoes, and cotton hand gloves. 40 1) Proper work platform to keep material. 2)Use of proper tool in good condition. 3) Ele. Connections by electrician 4) Use of ELCB. 5) Periodic checking & maintenance of Grinder. 6) Restricted entry. 77) Trained person to do the work. 8) Strict supervision on work. 9) Use of S.Helmet,S.Shoes,S.Goggles, Ear muff / plugs. 40 1) Proper work platform to keep cutting material. 2) Check m/c condition, guards. 3) Ele. Connections by electrician 4) Use of ELCB. 5) Restricted entry. 76) Trained person to do the work. 7) Strict supervision on work. 8) Use of S.Helmet,S.Shoes,S.Goggles, Ear muff / plugs.

Refer QRA. Follow BEB/ SP/ Houske eping

Minor

10

Refer QRA.

Hazard Identification & Risk Analysis

Sr . N o. 17

Name of Activity

Potential Hazard

Welding of Mivan plate

Contact with Hot object Contact with U V rays Ele. Shock

Co nd. N/ Ab /E N

Legal Issue Yes / No E

List of Potential Injury

Before Control Measures Sever Probab ity ility 9

Ele. Shock Major burn injury May be fatal Eye injury Body Injury Health hazard

Fre que ncy 4

Ris k lev el 36

List of control measures

After control Measures Severit Proba y bility Minor 4

Risk level Freq uenc y 4

Remar ks

N E

18

Contact with hazards fumes Steel rod Noise straining by m/c. Ele.Shock Caught in between

N N E N Y

Ele. Shock Major burn injury May be fatal Hand injury NIHL

Steel rod cutting (Ele. Operated m/c.)

Contact with sharp objects Caught in between Ele.Shock

Ele. Shock Major burn injury May be fatal Hand injury

20 Pile chiping

Fall from the pile. Chance for slip the hammer Probablity for sharpnels from the

Y Y

Body inju Major Ry. Fracture

1) Use of proper tools & equipments in good condition. 2)Ele. Connections by electrician 3) Use of ELCB. 4) Periodic checking & maintenance of equipments. 5) Restricted entry. 76) Trained person to do the work. 7) Strict supervision on work. 8)Use of S.Shoes, Welding Goggles, respiratory mask, leather apron, Boiler suit, Ear muff. 32 1) Ele. Connections by electrician 2) Use of ELCB. 3) Periodic checking & maintenance of m/c. 4) Proper guarding of rotating parts, V belts. 6) Barrication--Restricted entry. 77) Trained person to do the work. 8) Strict supervision on work. 9) Use of S.Helmet, S.Shoes, cotton hand gloves, Ear muff. 32 1) Ele. Connections by electrician 2) Use of ELCB. 3) Periodic checking & maintenance of m/c. 4) Proper guarding of moving parts. 6) Restricted entry. 77) Trained person to do the work. 8) Strict supervision on work. 9) Use of S.Helmet, S.Shoes, cotton hand gloves, S goggles. 36 1)Wear helmet, goggles ,gloves,boot etc. 2)Use fall arrestor. 3)Use grip on the hammer. 4) Use proper platforms.

16

Refer QRA. Follow BEB/ SP/ 04 PPE

Minor

16

Refer QRA. Follow BEB/ SP/ 04 PPE

Minor

16

Refer QRA. Follow BEB/ SP/ 04 PPE

16

Refer QRA. Follow BEB / SP/04 (PPE)

Eye injury

5)Trined person to do work.

Você também pode gostar

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- 1st Hrpta AgendaDocumento3 páginas1st Hrpta AgendaJomarAinda não há avaliações

- Fon Unit - 5 Elimination NeedsDocumento106 páginasFon Unit - 5 Elimination NeedsAshwathy ThomasAinda não há avaliações

- Diagnostic Cytopathology: Dr. Sanjiv Kumar Asstt. Professor, Deptt. of Pathology, BVC, PatnaDocumento51 páginasDiagnostic Cytopathology: Dr. Sanjiv Kumar Asstt. Professor, Deptt. of Pathology, BVC, PatnaMemeowwAinda não há avaliações

- African Herbal Medicines Adverse Effects and CytotDocumento20 páginasAfrican Herbal Medicines Adverse Effects and Cytotmenziwa01Ainda não há avaliações

- Clean Premises & Equipment PDFDocumento11 páginasClean Premises & Equipment PDFGiabell100% (2)

- METABOLISM AND THERMOREGULATIONDocumento44 páginasMETABOLISM AND THERMOREGULATIONriezanurdinsyahAinda não há avaliações

- SenateDocumento261 páginasSenateTinsae Mulatu86% (7)

- Diary Card VorlageDocumento3 páginasDiary Card Vorlagelaraschindlerhotmail.comAinda não há avaliações

- Nurs208 Qa Practice Reflection Worksheet 1Documento1 páginaNurs208 Qa Practice Reflection Worksheet 1api-34714578980% (5)

- Urban HydrologyDocumento39 páginasUrban Hydrologyca rodriguez100% (1)

- Test Bank For The Labor Relations Process 10th Edition HolleyDocumento36 páginasTest Bank For The Labor Relations Process 10th Edition Holleyjakraging7odbt100% (43)

- LANTUS XR Label InformationDocumento17 páginasLANTUS XR Label InformationMichaelJonatanAinda não há avaliações

- 2014 Annual 4question...Documento76 páginas2014 Annual 4question...VanroAinda não há avaliações

- 5 GRAM-Positive - Cocci - Staphylococci 5 GRAM - Positive - Cocci - StaphylococciDocumento5 páginas5 GRAM-Positive - Cocci - Staphylococci 5 GRAM - Positive - Cocci - StaphylococciJoseline SorianoAinda não há avaliações

- Medical AspectsofBiologicalWarfareDocumento633 páginasMedical AspectsofBiologicalWarfaredennyreno100% (2)

- WCC Career Focus Magazine: Spring Summer 2011Documento28 páginasWCC Career Focus Magazine: Spring Summer 2011Washtenaw Community CollegeAinda não há avaliações

- FIP Statement on Continuing Professional DevelopmentDocumento4 páginasFIP Statement on Continuing Professional DevelopmentCesly Jewel Acosta AvilesAinda não há avaliações

- FC Script-1lv8zpiDocumento149 páginasFC Script-1lv8zpiPaulo CamiloAinda não há avaliações

- 10 English Lang SP 01Documento10 páginas10 English Lang SP 01naveen_halkAinda não há avaliações

- Seychelles Travel GuideDocumento5 páginasSeychelles Travel GuideAlex D.Ainda não há avaliações

- Science Month Celebration 2018Documento3 páginasScience Month Celebration 2018Ra MilAinda não há avaliações

- Spinning Mill ProcessDocumento10 páginasSpinning Mill ProcessAnees PainkalAinda não há avaliações

- Individual Performance Commitment and Review (Ipcr) : Name of Employee: Approved By: Date Date FiledDocumento12 páginasIndividual Performance Commitment and Review (Ipcr) : Name of Employee: Approved By: Date Date FiledTiffanny Diane Agbayani RuedasAinda não há avaliações

- Las Science 5 Melc 1 q2 Week1Documento10 páginasLas Science 5 Melc 1 q2 Week1Marjun BartoloAinda não há avaliações

- Outlining the Differences Between the Medical and Social Models of DisabilityDocumento8 páginasOutlining the Differences Between the Medical and Social Models of DisabilityJon CollageAinda não há avaliações

- C Ssrs Pediatric SLC 11.14.16Documento4 páginasC Ssrs Pediatric SLC 11.14.16Charity Asprer OsorioAinda não há avaliações

- Understanding the Mental Health Impact of DisastersDocumento11 páginasUnderstanding the Mental Health Impact of DisastersVan TotAinda não há avaliações

- Posterior AnatomyDocumento17 páginasPosterior AnatomyAziz RanaAinda não há avaliações

- Fundamentals of Ergonomics in Theory and Practice: John R. WilsonDocumento11 páginasFundamentals of Ergonomics in Theory and Practice: John R. WilsonAlexandra ElenaAinda não há avaliações

- Post Stroke DepressionDocumento15 páginasPost Stroke DepressionJosefina de la IglesiaAinda não há avaliações