Escolar Documentos

Profissional Documentos

Cultura Documentos

Uop HF Alkylation Technology: Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus Nowak

Enviado por

Bharavi K SDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Uop HF Alkylation Technology: Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus Nowak

Enviado por

Bharavi K SDireitos autorais:

Formatos disponíveis

Source: HANDBOOK OF PETROLEUM REFINING PROCESSES

CHAPTER 1.4

UOP HF ALKYLATION TECHNOLOGY

Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus Nowak

UOP Des Plaines, Ilinois

INTRODUCTION

The UOP* HF Alkylation process for motor fuel production catalytically combines light olefins, which are usually mixtures of propylene and butylenes, with isobutane to produce a branched-chain paraffinic fuel. The alkylation reaction takes place in the presence of hydrofluoric (HF) acid under conditions selected to maximize alkylate yield and quality. The alkylate product possesses excellent antiknock properties and high-octane because of its high content of highly branched paraffins. Alkylate is a clean-burning, low-sulfur, lowRVP gasoline blending component that does not contain olefinic or aromatic compounds. The HF Alkylation process was developed in the UOP laboratories during the late 1930s and early 1940s. The process was initially used for the production of high-octane aviation fuels from butylenes and isobutane. In the mid-1950s, the development and consumer acceptance of more-sophisticated high-performance automotive engines placed a burden on the petroleum refiner both to increase gasoline production and to improve motor fuel quality. The advent of catalytic reforming techniques, such as the UOP Platforming* process, provided an important tool for the production of high-quality gasolines available to refiners. However, the motor fuel produced in such operations is primarily aromaticbased and is characterized by high sensitivity (that is, the spread between research and motor octane numbers). Because automobile performance is more closely related to road octane rating (approximately the average of research and motor octanes), the production of gasoline components with low sensitivity was required. A natural consequence of these requirements was the expansion of alkylation operations. Refiners began to broaden the range of olefin feeds to both existing and new alkylation units to include propylene and occasionally amylenes as well as butylenes. By the early 1960s, the HF Alkylation process had virtually displaced motor fuel polymerization units for new installations, and refiners had begun to gradually phase out the operation of existing polymerization plants. The importance of the HF Alkylation process in the refining situation of the 2000s has been increased even further by the scheduled phase-out of MTBE and the increased

*Trademark and/or service mark of UOP.

1.33 Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.34

ALKYLATION AND POLYMERATION

emphasis on low-sulfur gasoline. The contribution of the alkylation process is critical in the production of quality motor fuels including many of the environmental gasoline blends. The process provides refiners with a tool of unmatched economy and efficiency, one that will assist refiners in maintaining or strengthening their position in the production and marketing of gasolines.

PROCESS CHEMISTRY

General In the HF Alkylation process, HF acid is the catalyst that promotes the isoparaffin-olefin reaction. In this process, only isoparaffins with tertiary carbon atoms, such as isobutane or isopentane, react with the olefins. In practice, only isobutane is used because isopentane has a high octane number and a vapor pressure that has historically allowed it to be blended directly into finished gasolines. However, where environmental regulations have reduced the allowable vapor pressure of gasoline, isopentane is being removed from gasoline, and refiner interest in alkylating this material with light olefins, particularly propylene, is growing. The actual reactions taking place in the alkylation reactor are many and are relatively complex. The equations in Fig. 1.4.1 illustrate the primary reaction products that may be expected for several pure olefins. In practice, the primary product from a single olefin constitutes only a percentage of the alkylate because of the variety of concurrent reactions that are possible in the alkylation environment. Compositions of pilot-plant products produced at conditions to maximize octane from pure-olefin feedstocks are shown in Table 1.4.1.

Reaction Mechanism Alkylation is one of the classic examples of a reaction or reactions proceeding via the carbenium ion mechanism. These reactions include an initiation step and a propagation step and may include an isomerization step. In addition, polymerization and cracking steps may be involved. However, these side reactions are generally undesirable. Examples of these reactions are given in Fig. 1.4.2. Initiation. The initiation step (Fig. 1.4.2a) generates the tertiary butyl cations that will subsequently carry on the alkylation reaction. Propagation. Propagation reactions (Fig. 1.4.2b) involve the tertiary butyl cation reacting with an olefin to form a larger carbenium ion, which then abstracts a hydride from an isobutane molecule. The hydride abstraction generates the isoparaffin plus a new tertiary butyl cation to carry on the reaction chain. Isomerization. Isomerization [Eq. (1.4.12), shown in Fig. 1.4.2c] is very important in producing good octane quality from a feed that is high in 1-butene. The isomerization of 1-butene is favored by thermodynamic equilibrium. Allowing 1-butene to isomerize to 2-butene reduces the production of dimethylhexanes (research octane number of 55 to 76) and increases the production of trimethylpentanes. Many recent HF Alkylation units, especially those processing only butylenes, have upstream olefin isomerization units that isomerize the 1-butene to 2-butene.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.35

CH3 CH3-C = CH2+CH3-CH-CH3 CH3 Isobutylene CH3 Isobutane

CH3 (1.4.1)

CH3-C-CH2-CH-CH3 CH3 (Isooctane) 2,2,4-Trimethylpentane

CH2 = CH-CH2-CH3 + CH3-CH-CH3 CH3 1-Butene Isobutane

CH3-CH-CH-CH2-CH2-CH3 CH3 CH3 2,3-Dimethylpentane

(1.4.2)

CH3 CH3-CH = CH-CH3 + CH3-CH-CH3 CH3 2-Butene Isobutane CH3- C-CH2-CH-CH3 CH3 CH3 (1.4.3)

2,2,4-Trimethylpentane CH3 CH3 CH3

or

CH3-CH-CH-CH-CH3 2,3,4-Trimethylpentane

CH3-CH = CH2 + CH3-CH-CH3 CH3 Propylene Isobutane

CH3-CH-CH-CH2-CH3 CH3CH3 2,3-Dimethylpentane

(1.4.4)

FIGURE 1.4.1 HF alkylation primary reactions for monoolefins.

Equation (1.4.13) is an example of the many possible steps involved in the isomerization of the larger carbenium ions. Other Reactions. The polymerization reaction [Eq. (1.4.14), shown in Fig. 1.4.2d] results in the production of heavier paraffins, which are undesirable because they reduce alkylate octane and increase alkylate endpoint. Minimization of this reaction is achieved by proper choice of reaction conditions. The larger polymer cations are susceptible to cracking or disproportionation reactions [Eq. (1.4.15)], which form fragments of various molecular weights. These fragments can then undergo further alkylation.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.36 TABLE 1.4.1 Feedstocks

ALKYLATION AND POLYMERATION

Compositions of Alkylate from Pure-Olefin Olefin

Component, wt % C5 isopentane C6s: Dimethylbutanes Methylpentanes C7s: 2,3-Dimethylpentane 2,4-Dimethylpentane Methylhexanes C8s: 2,2,4-Trimethylpentane 2,2,3-Trimethylpentane 2,3,4-Trimethylpentane 2,3,3-Trimethylpentane Dimethylhexanes C9 products

C3H6 1.0 0.3 29.5 14.3 36.3 7.5 4 3.2 3.7

iC4H8 0.5 0.8 0.2 2.0 66.2 12.8 7.1 3.4 5.3

C4H8-2 0.3 0.7 0.2 1.5 48.6 1.9 22.2 12.9 6.9 4.1

C4H8-1 1.0 0.8 0.3 1.2 38.5 0.9 19.1 9.7 22.1 5.7

F C-C = C + HF C C-C-C C

+ C-C-C C (1.4.5)

F C-C = C-C + HF C-C-C-C

+ C-C-C-C

iC4

+ C-C-C-C + C-C-C C (1.4.6)

F C = C-C-C + HF C-C-C-C

+ C-C-C-C

iC4

+ C-C-C-C + C-C-C C (1.4.7)

F C = C-C + HF C-C-C C-C-C + iC4

+ C-C-C + C-C-C C

(1.4.8)

FIGURE 1.4.2a HF alkylation reaction mechanisminitiation reactions.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.37

+ C=C-C-C + C-C-C = C

C-C-C-C-C-C C

iC4

+ Dimethylhexane + C-C-C (1.4.9) C

+ C-C = C-C + C-C-C C

C C C-C-C-C-C + C iC4

+ Trimethylpentane + C-C-C (1.4.10) C

+ C-C = C + C-C-C C

FIGURE 1.4.2b

C iC4

+ Trimethylpentane + C-C-C (1.4.11) C

C-C-C-C-C + C

HF alkylation reaction mechanismpropagation reactions.

C=C-C-C 1-Butene

C-C = C-C 2-Butene

(1.4.12)

(1.4.13) iC4 2, 2, 4 -Trimethylpentane

C-C-C-C-C + C

C-C-C-C-C + C

C-C-C-C-C + C

C+C C-C-C-C-C C

CCC C-C-C-C-C +

iC4

2, 3, 4 -Trimethylpentane

CCC C-C-C-C-C +

CC C-C-C-C-C + C iC4 2, 3, 3 -Trimethylpentane

FIGURE 1.4.2c HF alkylation reaction mechanismisomerization.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.38

ALKYLATION AND POLYMERATION

Polymerization C + + C-C = C-C C12+ C + etc.

16

(1.4.14)

C-C-C-C-C C C

Cracking-Disproportionation C12+ C5+ + C7+

(1.4.15)

Hydrogen Transfer C=C-C + C-C-C C C-C-C + C-C=C C

(1.4.16)

C-C=C + C-C-C C C

Trimethylpentane

(1.4.17)

Ov erall Reaction: C3H6 + 2i C 4H10

FIGURE 1.4.2d

(1.4.18) C3H8 + Trimethylpentane

HF alkylation reaction mechanismother.

Hydrogen Transfer. The hydrogen transfer reaction is most pronounced with propylene feed. The reaction also proceeds via the carbenium ion mechanism. In the first reaction [Eq. (1.4.16)], propylene reacts with isobutane to produce butylene and propane. The butylene is then alkylated with isobutane [Eq. (1.4.17)] to form trimethylpentane. The overall reaction is given in Eq. (1.4.18). From the viewpoint of octane, this reaction can be desirable because trimethylpentane has substantially higher octane than the dimethylpentane normally formed from propylene. However, two molecules of isobutane are required for each molecule of alkylate, and so this reaction may be undesirable from an economic viewpoint.

PROCESS DESCRIPTION

The alkylation of olefins with isobutane is complex because it is characterized by simple addition as well as by numerous side reactions. Primary reaction products are the isomer-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.39

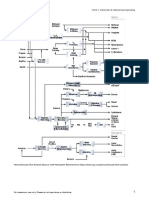

ic paraffins containing carbon atoms that are the sum of isobutane and the corresponding olefin. However, secondary reactions such as hydrogen transfer, polymerization, isomerization, and destructive alkylation also occur, resulting in the formation of secondary products both lighter and heavier than the primary products. The factors that promote the primary and secondary reaction mechanisms differ, as does the response of each to changes in operating conditions or design options. Not all secondary reactions are undesirable; for example, they make possible the formation of isooctane from propylene or amylenes. In an ideally designed and operated system, primary reactions should predominate, but not to the complete exclusion of secondary ones. For the HF Alkylation process, the optimum combinations of plant economy, product yield, and quality are achieved with the reaction system operating at cooling-water temperature and an excess of isoparaffin and with contaminant-free feedstocks and vigorous, intimate acidhydrocarbon contact. To minimize acid consumption and ensure good alkylate quality, the feeds to the alkylation unit should be dry and of low sulfur content. Normally, a simple desiccant-drying system is included in the unit design package. Feed treating in a UOP Merox* unit for mercaptan sulfur removal can be an economic adjunct to the alkylation unit for those applications in which the olefinic feed is derived from catalytic cracking or from other operations in which feedstocks of significant sulfur content are processed. Simplified flow schemes for a typical C4 HF Alkylation unit and a C3-C4 HF Alkylation unit are shown in Figs. 1.4.3 and 1.4.4. Treated and dried olefinic feed is charged along with recycle and makeup isobutane (when applicable) to the reactor section of the plant. The combined feed enters the shell of a reactorheat exchanger through several nozzles positioned to maintain an even temperature throughout the reactor. The heat of reaction is removed by heat exchange with a large volume of coolant flowing through the tubes having a low temperature rise. If cooling water is used, it is then available for further use elsewhere in the unit. The effluent from the reactor enters the settler, and the settled acid is returned to the reactor. The hydrocarbon phase, which contains dissolved HF acid, flows from the settler and is preheated and charged to the isostripper. Saturate field butane feed (when applicable) is also charged to the isostripper. Product alkylate is recovered from the bottom of the column. Any normal butane that may have entered the unit is withdrawn as a sidecut. Unreacted isobutane is also recovered as a sidecut and recycled to the reactor. The isostripper overhead consists mainly of isobutane, propane, and HF acid. A drag stream of overhead material is charged to the HF stripper to strip the acid. The overhead from the HF stripper is returned to the isostripper overhead system to recover acid and isobutane. A portion of the HF stripper bottoms is used as flushing material. A net bottom stream is withdrawn, defluorinated, and charged to the gas concentration section (C3-C4 splitter) to prevent a buildup of propane in the HF Alkylation unit. An internal depropanizer is required in an HF Alkylation unit processing C3-C4 olefins and may be required with C4 olefin feedstocks if the quantity of propane entering the unit is too high to be rejected economically as previously described. The isostripper overhead drag stream is charged to the internal depropanizer. Overhead from the internal depropanizer is directed to the HF stripper to strip HF acid from the high-purity propane. A portion of the internal depropanizer bottoms is used as flushing material, and the remainder is returned to the alkylation reactor. The HF stripper overhead vapors are returned to the internal depropanizer overhead system. High-purity propane is drawn off the bottom of the HF stripper, passes through a defluorination step, and is then sent to storage. A small slipstream of circulating HF acid is regenerated internally to maintain acid purity at the desired level. This technique significantly reduces overall chemical con-

*Trademark and/or service mark of UOP.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

1.40 Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 1.4.3 UOP C4 HF Alkylation process.

UOP HF ALKYLATION TECHNOLOGY

1.41 Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 1.4.4 UOP C3-C4 HF Alkylation process.

UOP HF ALKYLATION TECHNOLOGY 1.42

ALKYLATION AND POLYMERATION

sumption. An acid regenerator column is also provided for start-ups after turnarounds or in the event of a unit upset or feed contamination. When the propane or normal butane from the HF unit is to be used as liquefied petroleum gas (LPG), defluorination is recommended because of the possible breakdown of combined fluorides during combustion and the resultant potential corrosion of burners. Defluorination is also required when the butane is to be directed to an isomerization unit. After defluorination, the propane and butane products are treated with potassium hydroxide (KOH) to remove any free HF acid that might break through in the event of unit misoperation. The alkylation unit is built almost entirely of carbon steel although some Monel is used for most moving parts and in a few other limited locations. Auxiliary neutralizing and scrubbing equipment is included in the plant design to ensure that all materials leaving the unit during both normal and emergency operations are acid-free.

ENGINEERING DESIGN

The reactor and distillation systems that UOP uses have evolved through many years of pilot-plant evaluation, engineering development, and commercial operation. The overall plant design has progressed through a number of variations, resulting in the present concepts in alkylation technology.

Reactor Section In the design of the reactor, the following factors require particular attention:

Removal of heat of reaction Generation of acid surface: mixing and acid/hydrocarbon ratio Acid composition Introduction of olefin feed

The proper control of these factors enhances the quality and yield of the alkylate product. Selecting a particular reaction system configuration requires careful consideration of the refiners production objectives and economics. The UOP reaction system optimizes processing conditions by the introduction of olefin feed through special distributors to provide the desired contact with the continuous-acid phase. Undesirable reactions are minimized by the continuous removal of the heat of reaction in the reaction zone itself. The removal of heat in the reaction zone is advantageous because peak reaction temperatures are reduced and effective use is made of the available cooling-water supply.

Acid Regeneration Section The internal acid regeneration technique has virtually eliminated the need for an acid regenerator and, as a result, acid consumption has been greatly reduced. The acid regenerator has been retained in the UOP design only for start-ups or during periods when the feed has abnormally high levels of contaminants, such as sulfur and water. For most units, during normal operation, the acid regenerator is not in service. When the acid regenerator is in service, a drag stream off the acid circulation line at the settler is charged to the acid regenerator, which is refluxed on the top tray with isobutane.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.43

The source of heat to the bottom of the regenerator for a C3-C4 HF Alkylation unit is superheated isobutane from the depropanizer sidecut vapors. For a C4 HF Alkylation unit, the stripping medium to the acid regenerator is sidecut vapors from the HF stripper bottoms. The regenerated HF acid is combined with the overhead vapor from the isostripper and sent to the cooler.

Neutralization Section UOP has designed the neutralization section to minimize the amount of additional effluents such as offensive materials and undesirable by-products. Releasing acid-containing vapors to the regular relief-gas system is impractical because of corrosion and odor problems as well as other environmental and safety concerns. The system is composed of the relief-gas scrubber, KOH mix tank, circulating pumps, and a KOH regeneration tank. All acid vents and relief valves are piped to this relief section. Gases pass up through the scrubber and are contacted by a circulating KOH solution to neutralize the HF acid. After the neutralization of the acid, the gases can be safely released into the refinery flare system. The KOH is regenerated on a periodic basis in the KOH regeneration tank by using lime to form calcium fluoride (CaF2) and KOH. The CaF2 settles to the bottom of the tank and is directed to the neutralizing basin, where acidic water from acid sewers and small amounts of acid from the process drains are treated. Lime is used to convert any fluorides into calcium fluoride before any waste effluent is released into the refinery sewer system.

Distillation System The distillation and recovery sections of HF Alkylation units have also seen considerable evolution. The modern isostripper recovers relatively high-purity isobutane as a sidecut that is recycled to the reactor. This recycle is virtually acid-free, thereby minimizing undesirable side reactions with the olefin feed prior to entry into the reactor. A small rectification section on top of the modern isostripper provides for more efficient propane rejection. Although a single high-pressure tower can perform the combined functions of isostripper and depropanizer, UOPs current design incorporates two towers (isostripper and depropanizer) for the following reasons:

Each tower may be operated at its optimum pressure. Specifically, in the isostripper for this two-tower design, the relative volatilities between products increase, and the number of trays required for a given operation are reduced in addition to improving separation between cuts. This system has considerably greater flexibility. It is easily convertible to a butyleneonly operation because the depropanizer may be used as a feed splitter to separate C3s and C4s. The two-tower design permits the use of side feeds to the isostripper column, should it be necessary to charge makeup isobutane of low purity. This design also permits the production of lower-vapor-pressure alkylate and a high-purity sidecut nC4 for isomerizing or blending and the ability to make a clean split of side products. The two-tower design permits considerable expanded capacity at low incremental cost by the addition of feed preheat and side reboiling. Alkylate octane increases with decreasing reaction temperature. During cooler weather, the unit may be operated at lower isobutane/olefin ratios for a given product octane, because the ratio is fixed by the product requirement and not by the fractionation requirements. The commensurate reduction in utilities lowers operating costs.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.44

ALKYLATION AND POLYMERATION

Because of the low isostripper pressure in a two-tower system, this arrangement permits the use of steam for reboiling the isostripper column instead of a direct-fired heater, which is necessary in a single-tower system. In most cases, a stab-in reboiler system is suitable even for withdrawing a sidecut. Using a steam reboiler can be a considerable advantage when refinery utility balances so indicate, and it also represents considerable investment-cost savings. The two-tower system has proven its performance in a large number of operating units, and its flexibility has been proven through numerous revamps for increased capacity on existing units. The two-tower system also requires less overhead condenser surface, which lowers the investment required for heat exchange. Clean isobutane is available for flush, whereas only alkylate flush is available in the single-column operation. This clean-isobutane stream is also available to be taken to storage and is a time saver during start-ups and shutdowns. Although fewer pieces of equipment are required with the single tower, the large number of trays and the high-pressure design necessitate the use of more tons of material and result in a somewhat higher overall cost than does the two-tower system. The regenerator column contains no expensive overhead system, and the internal HF regeneration technique results in improved acid consumption. Because a high-temperature differential can be taken on most cooling water, coolingwater requirements for the two-tower system are only about two-thirds those of the single-tower system.

COMMERCIAL INFORMATION

Typical commercial yields and product properties for charging various olefin feedstocks to an HF Alkylation unit are shown in Tables 1.4.2 and 1.4.3. Table 1.4.4 contains the detailed breakdown of the investment and production costs for a pumped, settled acid-alkylation unit based on a typical C4 olefin feedstock.

ENVIRONMENTAL CONSIDERATIONS

The purpose of operating an HF Alkylation unit is to obtain a high-octane motor fuel blending component by reacting isobutane with olefins in the presence of HF acid. In the UOP HF Alkylation process, engineering and design standards have been developed and improved over many years to obtain a process that operates efficiently and economically. This continual process development constitutes the major reason for the excellent product qualities, low acid-catalyst consumption, and minimal extraneous by-products obtained by the UOP HF Alkylation process.

TABLE 1.4.2 Olefin feedstocks C3-C4 Mixed C4 HF Alkylation Yields Vol. alkylate produced/vol. olefin 1.78 1.77

Required vol. iC4/vol. olefin 1.28 1.15

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.45

TABLE 1.4.3 Property

HF Alkylation Product Properties Propylenebutylene feed 0.693 41 (105) 71 (160) 93 (200) 99 (210) 104 (219) 122 (250) 192 (378) 93.3 91.7 Butylene feed 0.697 41 (105) 76 (169) 100 (212) 104 (220) 107 (225) 125 (255) 196 (385) 95.5 93.5

research

Specific gravity Distillation temperature, C (F): IBP 10% 30% 50% 70% 90% EP Octanes: RONC MONC

Note: IBP initial boiling point; EP endpoint; RONC octane number, clear; MONC motor octane number, clear.

TABLE 1.4.4 Operating cost

Investment and Production Cost Summary* $/stream day $/MT alkylate $/bbl alkylate 0.176 0.734 0.627

Labor 1,587 0.016 Utilities 6,609 0.066 Chemical consumption, laboratory 5,639 0.056 allowance, maintenance, taxes, and insurance Total direct operating costs 13,835 0.138 Investment, estimated erected cost (EEC), first quarter 2002

*Basis: 348,120 MTA (9000 BPSD) C5 alkylate. Note: MT metric tons; MTA metric tons per annum; BPSD

1.537 $27,800,000

barrels per stream-day.

As in every process, certain minor process inefficiencies, times of misoperation, and periods of unit upsets occur. During these times, certain undesirable materials can be discharged from the unit. These materials can be pollutants if steps are not taken in the process effluent management and product-treating areas to render these by-product materials harmless. In a properly operated HF Alkylation unit, the amount of additional effluent, such as offensive materials or undesirable by-products is minimal, and with proper care, these small streams can be managed safely and adequately. The potentially offensive nature of the streams produced in this process as well as the inherent hazards of HF acid has resulted in the development of effluent management and safety procedures that are unique to the UOP HF Alkylation process. The following sections briefly describe these procedures and how these streams are safely handled to prevent environmental contamination. The refiner must evaluate and comply with any pertinent effluent management regulations. An overall view of the effluent management concept is depicted in Fig. 1.4.5. Effluent Neutralization In the Alkylation units effluent-treating systems, any neutralized HF acid must eventually leave the system as an alkali metal fluoride. Because of its extremely low solubility in

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.46

ALKYLATION AND POLYMERATION

FIGURE 1.4.5

UOP HF Alkylation process effluent management.

water, CaF2 is the desired end product. The effluent containing HF acid can be treated with a lime [CaO-Ca(OH)2] solution or slurry, or it can be neutralized indirectly in a KOH system to produce the desired CaF2 product. The KOH neutralization system currently used in a UOP-designed unit involves a two-stage process. As HF acid is neutralized by aqueous KOH, soluble potassium fluoride (KF) is produced, and the KOH is gradually depleted. Periodically, some of the KFcontaining neutralizing solution is withdrawn to the KOH regenerator. In this vessel, KF reacts with a lime slurry to produce insoluble CaF2 and thereby regenerates KF to KOH.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.47

The regenerated KOH is then returned to the system, and the solid CaF2 is routed to the neutralizing basin. Effluent Gases. The HF Alkylation unit uses two separate gas vent lines to maintain the separation of acidic gases from nonacidic gases until the acidic gases can be scrubbed free of acid. Acidic Hydrocarbon Gases. Acidic hydrocarbon gases originate from sections of the unit where HF acid is present. These gases may evolve during a unit upset, during a shutdown, or during a maintenance period in which these acidic gases are partially or totally removed from the process vessels or equipment. The gases from the acid vents and from the acid pressure relief valves are piped to a separate closed relief system for the neutralization of the acid contained in the gas. The acid-free gases are then routed from this acid-scrubbing section to the refinery nonacid flare system, where they are disposed of properly by burning. The acidic gases are scrubbed in the acid neutralization and caustic regeneration system, as shown Fig. 1.4.6. This system consists of the relief-gas scrubber, KOH mix tank, liquidknockout drum, neutralization drum, circulating pumps, and a KOH regeneration tank. Acidic gases, which were either vented or released, first flow to a liquid-knockout drum to remove any entrained liquid. The liquid from this drum is pumped to the neutralization drum. The acidic gases from the liquid-knockout drum then pass from the drum to the scrubbing section of the relief-gas scrubber, where countercurrent contact with a KOH solution removes the HF acid. After neutralization of the HF acid, the nonacidic gases are released into the refinery flare system. The KOH used for the acidic-gas neutralization is recirculated by the circulation pumps. The KOH solution is pumped to the top of the scrubber and flows downward to contact the rising acidic gas stream and then overflows a liquid-seal pan to the reservoir section of the scrubber. In addition, a slipstream of the circulating KOH contacts the acidic gas just prior to its entry to the scrubber. The circulating KOH removes HF through the following reaction: HF KOH KF H2O (1.4.19)

Maintaining the circulating caustic pH and the correct percentage of KOH and KF requires a system to regenerate the caustic. This regeneration of the KOH solution is performed on a batch basis in a vessel separate from the relief-gas scrubber. In this regeneration tank, lime and the spent KOH solution are thoroughly mixed. The regenerated caustic solution is pumped back to the scrubber. The CaF2 and any unreacted lime are permitted to settle out and are then directed to the neutralization pit. The regeneration of the spent KOH solution follows the Berthollet rule, by which the insolubility of CaF2 in water permits the complete regeneration of the potassium hydroxide according to the following equation: 2KF Ca (OH) 2 2KOH CaF2 (1.4.20)

Nonacidic Hydrocarbon Gases. Nonacidic gases originate from sections of the unit in which HF acid is not present. These nonacidic gases from process vents and relief valves are discharged into the refinery nonacid flare system, where they are disposed of by burning. The material that is vented or released to the flare is mainly hydrocarbon in nature. Possibly, small quantities of inert gases are also included. Obnoxious Fumes and Odors. The only area from which these potentially objectionable fumes could originate is the units neutralizing basins. To prevent the discharge of these odorous gases to the surroundings, the neutralizing basins are tightly covered and equipped with a gas scrubber to remove any offensive odors. The

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

1.48 Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

FIGURE 1.4.6 Acid neutralization and caustic regeneration section.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.49

gas scrubber uses either water or activated charcoal as the scrubbing agent. However, in the aforementioned neutralizing system, odors from the basin are essentially nonexistent because the main source of these odors (acid regenerator bottoms) is handled in separate closed vessels. Liquid Effluents. The HF Alkylation unit is equipped with two separate sewer systems to ensure the segregation of the nonacid from the possibly acid-containing water streams. Acidic Waters. Any potential HF containing water streams (rainwater runoff in the acid area and wash water), heavy hydrocarbons, and possibly spent neutralizing media are directed through the acid sewer system to the neutralizing basins for the neutralization of any acidic material. In the basins, lime is used to convert the incoming soluble fluorides to CaF2. The neutralizing basins consist of two separate chambers (Fig. 1.4.7). One chamber is filled while the other drains. In this parallel neutralizing basin design, one basin has the inlet line open and the outlet line closed. As only a few surface drains are directed to the neutralizing basins, inlet flow normally is small, or nonexistent, except when acid equipment is being drained. The operator regularly checks the pH and, if necessary, mixes the lime slurry in the bottom of the basin. After the first basin is full, the inlet line is closed, and the inlet to the second basin is opened; then lime is added to the second basin. The first basin is mixed and checked with pH paper after a period of agitation; if it is acidic, more lime is added from lime storage until the basin is again basic. After settling, the effluent from the first basin is drained. Nonacidic Waters. The nonacid sewers are directed to the refinery water disposal system or to the API separators.

FIGURE 1.4.7

Neutralizing basin.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.50

ALKYLATION AND POLYMERATION

Liquid Process Effluents (Hydrocarbon and Acid). Hydrocarbon and acid effluents originate from some minor undesirable process side reactions and from any feed contaminants that are introduced to the unit. Undesirable by-products formed in this manner are ultimately rejected from the Alkylation unit in the acid regeneration column as a bottoms stream. The regeneration-column bottoms stream consists mainly of two types of mixtures. One is an acid-water phase that is produced when water enters the unit with the feed streams. The other mixture is a small amount of polymeric material that is formed during certain undesirable process side reactions. Figure 1.4.8 represents the HF acid regeneration circuit. The first step in the disposal of these materials is to direct the regenerator bottoms to the polymer surge drum, where the two mixtures separate. The acid-water mixture forms an azeotrope, or constant boiling mixture (CBM), which is directed to the neutralizing drum (Fig. 1.4.8) for neutralization of the HF acid. The acid in this CBM ultimately ends up as insoluble CaF2 (as described previously). The polymer that remains in the polymer surge drum is then transferred to the tar neutralizer, where the HF acid is removed. The polymer has excellent fuel oil properties and can then be disposed of by burning as long as applicable regulations allow such. However, by the mid-1980s, technology and special operating techniques such as internal acid regeneration had virtually eliminated this liquideffluent stream for many units. Solid Effluents Neutralization Basin Solids. The neutralization basin solids consist largely of CaF2 and unreacted lime. As indicated previously, all HF-containing liquids that are directed to the neutralizing basins ultimately have any contained soluble fluorides converted to insoluble CaF2. The disposal of this solid material is done on a batch basis. A vacuum truck is normally used to remove the fluoride-lime sludge from the

FIGURE 1.4.8

HF acid regeneration circuit.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.51

pit. This sludge has traditionally been disposed of in a landfill after analysis to ensure appropriate properties are met. Another potential route for sludge disposal is to direct it to a steel manufacturing company, where the CaF2 can be used as a neutral flux to lower the slag melting temperature and to improve slag fluidity. The CaF2 may possibly be routed back to an HF acid manufacturer, as the basic step in the HF-manufacturing process is the reaction of sulfuric acid with fluorspar (CaF2) to produce hydrogen fluoride and calcium sulfate. Product-Treating Solids. The product-treating solids originate when LPG products are defluorinated over activated alumina. Over time, the alumina loses the ability to defluorinate the LPG product streams. At this time, the alumina is considered spent, and it is then replaced with fresh alumina. Spent alumina must be disposed of in accordance with applicable regulations or sent to the alumina vendor for recovery. Miscellaneous Solids. Porous material such as wiping cloths, wood, pipe coverings, and packings that are suspected of coming into contact with HF acid are placed in specially provided disposal cans for removal and are periodically burned. These solids may originate during normal unit operation or during a maintenance period. Wood staging and other use of wood in the area are kept to a minimum. Metal staging must be neutralized before being removed from the acid area.

MITIGATING HF RELEASESTHE CHEVRONTEXACO AND UOP ALKAD PROCESS

Growing environmental and public safety concerns since the mid-1980s have heightened awareness of hazards associated with many industrial chemicals, including HF acid. Refiners responded to these concerns with the installation of mitigation systems designed to minimize the consequences of accidental releases. ChevronTexaco and UOP developed the Alkad* technology1 to assist in reducing the potential hazards of HF acid and to work in conjunction with other mitigation technology.

HF Acid Concerns and Mitigation Although HF alkylation was clearly the market leader in motor fuel alkylation by the mid1980s, growing concerns about public safety and the environment caused HF producers and users to reassess how HF acid was handled and how to respond to accidental releases. In 1986, Amoco and the Lawrence Livermore National Laboratory conducted atmospheric HF release tests at the Department of Energy Liquefied Gaseous Fuels Facility in Nevada. These tests revealed that HF acid could form a cold, dense aerosol cloud that did not rapidly dissipate and remained denser than air. In 1988, another set of tests, the Hawk tests, was conducted to determine the effect of water sprays on an HF aerosol cloud. These tests indicated that a water/HF ratio of 40/1 by volume would reduce the airborne HF acid by about 90 percent.2 As a result of these investigations, many refiners have installed, or are planning to install, water spray systems in their HF alkylation units to respond to accidental releases. Other mitigation technology installed by refiners includes acid inventory reduction, HF detection systems, isolation valves, and rapid acid transfer systems. These mitigation sys-

*Trademark and/or service mark of UOP.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.52

ALKYLATION AND POLYMERATION

tems can be described as external, defensive response systems because they depend on an external reaction (for example, spraying water) to a detected leak. ChevronTexaco and UOP chose to develop a system that would respond prior to leak detection. Such a system could be described as an internal, passive response system because it is immediately effective, should a leak occur. In 1991, ChevronTexaco and UOP began to work together to develop an additive system to reduce the risk associated with the HF alkylation process. The objective was to develop an additive that would immediately suppress the HF aerosol in the event of a leak but would not otherwise interfere with the normal performance of the HF unit.

Aerosol Reduction ChevronTexaco screened a large number of additive materials for aerosol reduction capability in its R&D facilities in Port Arthur, Texas. The most promising materials that significantly reduced aerosol and maintained adequate alkylation activity were tested in a large-scale release chamber in Oklahoma.3 Release tests with additive demonstrated the potential reduction of airborne HF acid at various additive concentrations. This reduction was determined on the basis of the weight of material collected relative to the weight of material released. The aerosol reduction achieved is described in Fig. 1.4.9. As shown, reductions of airborne HF acid of up to 80 percent may be possible, depending on the additive concentration level at which a refiner is able to operate. Employing the Alkad technology in conjunction with water sprays may result in more than 95 percent reduction of the airborne HF acid.

Process Development ChevronTexaco and UOP conducted a trial with the most interesting additive material in the older of two alkylation units at the former Texaco refinery in El Dorado, Kansas, in 1992. During the trial, the alkylation unit operated well, with no changes as a result of the presence of additive in the acid. Following this successful trial, UOP designed facilities to recover the acid-additive complex from the acid regenerator bottoms stream and recycle this material to the reactor section.

FIGURE 1.4.9 Aerosol reduction results.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.53

The recovery process has been further optimized following the operations from 1994 through 1998. The addition of the recovery process to an HF alkylation unit or design generally requires a new column, separator, and associated equipment. The HF acid regenerator column is still used for the removal of water and light polymer from the process. A simplified flow scheme is shown in Fig. 1.4.10. A slipstream of circulating acid is sent to the additive stripper column. The additive stripper sends acid, water, and light acid-soluble oils overhead and on to the acid regenerator. Heavy acid-soluble oils and the concentrated HF-additive complex are sent to the additive stripper bottoms separator. From this separator the polymer is sent to neutralization, and the HF-additive complex is recycled to the reactor section. The acid regenerator removes water and light acid-soluble oils from the additive stripper overhead stream. The water is in the form of a constant boiling mixture of water and HF.

Commercial Experience After construction of the modular additive recovery section was completed, Texaco began operating the Alkad technology in September 1994. The immediate observation when the additive was introduced was an increase in product octane and a reduction in alkylate endpoint. Research octane was 1.5 or more numbers higher than the baseline operation (Fig. 1.4.11). A comparison of operations with and without additive is shown in Table 1.4.5, which breaks down two alkylate samples from equivalent operating conditions. An analysis of the alkylate components has shown that the increased octane is partially due to a significantly higher octane in the C9 material. Increased paraffin branching in the C7 and lighter fraction is also a contributor to the octane boost. As shown in Fig. 1.4.12, initial data indicated that the alkylate 90 percent distillation point had decreased 14 to 19C (25 to 35F) and the endpoint had dropped 17 to 22C (30 to 40F). As gasoline regulations change, this distillation improvement may allow refiners to blend in more material from other sources and still meet regulatory requirements in their areas and effectively increase gasoline pool volume. Texaco installed this additive-recovery system for approximately $7 million U.S.

HF to Reactor or Fractionaction Section

Additive Stripper Column Circulating Acid

Acid Regenerator Column

iC4

iC4 Light AcidSoluble Oils and CBM to Neutralization

Polymer to Neutralization HF-Additive to Reactor Section

FIGURE 1.4.10 UOP HF Additive Recovery Process.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY 1.54

ALKYLATION AND POLYMERATION

FIGURE 1.4.11 Alkylate octane.

TABLE 1.4.5

Alkylate Composition Comparison No additive With additive 92.2 3.58 19.06 44.35 16.28 89.5 2.5 77.1

Alkylate RONC (measured) Composition, LV %: C6 C7 C8 C9 Calculated C9 RONC Dimethylbutane/methylpentane Dimethylpentane/methylhexane

Note: LV % liquid volume percent.

90.8 2.84 14.15 45.24 17.49 81.6 1.7 51.0

FIGURE 1.4.12 Alkylate distillation.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

UOP HF ALKYLATION TECHNOLOGY

1.55

The Alkad process significantly reduces the hazards associated with an accidental release of HF acid and minimizes the refiners further investment in motor fuel alkylation mitigation technology.

REFERENCES

1. J. C. Sheckler and H. U. Hammershaimb, UOP Alkylation Technology into the 21st Century, presented at the 1995 UOP Refining Technology Conferences. 2. K. W. Schatz and R. P. Koopman, Effectiveness of Water Spray Mitigation Systems for Accidental Releases of Hydrogen Fluoride, summary report and volumes IX, NTIS, Springfield, Va., 1989. 3. K. R. Comey, III, L. K. Gilmer, G. P. Partridge, and D. W. Johnson, Aerosol Reduction from Episodic Releases of Anhydrous HF Acid by Modifying the Acid Catalyst with Liquid Onium Poly (Hydrogen Fluorides), AIChE 1993 Summer National Meeting, Aug. 16, 1993.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

UOP HF ALKYLATION TECHNOLOGY

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com) Copyright 2004 The McGraw-Hill Companies. All rights reserved. Any use is subject to the Terms of Use as given at the website.

Você também pode gostar

- Uop HF Alkylation Technology: Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus NowakDocumento24 páginasUop HF Alkylation Technology: Kurt A. Detrick, James F. Himes, Jill M. Meister, and Franz-Marcus NowakrujunliAinda não há avaliações

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsNo EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengAinda não há avaliações

- Alkylation, Isomerisation and PolymerisationDocumento9 páginasAlkylation, Isomerisation and Polymerisationapi-256504985Ainda não há avaliações

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerAinda não há avaliações

- New Catalytic Process For Production of Olefins: 1. Theme DescriptionDocumento13 páginasNew Catalytic Process For Production of Olefins: 1. Theme DescriptionSandra Mayta SilloAinda não há avaliações

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesAinda não há avaliações

- 6 - AlkylationDocumento90 páginas6 - AlkylationAn Lê TrườngAinda não há avaliações

- New Olefin Production Technologies in SINOPECDocumento10 páginasNew Olefin Production Technologies in SINOPECTrevor J. HutleyAinda não há avaliações

- Nanoporous Catalysts for Biomass ConversionNo EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoAinda não há avaliações

- 352,, - 6Xoixulf$Flg$On/Odwlrq &dvherrn: SimsciDocumento35 páginas352,, - 6Xoixulf$Flg$On/Odwlrq &dvherrn: Simscimfruge7Ainda não há avaliações

- Conocophillips Reduced Volatility Alkylation Process (Revap)Documento12 páginasConocophillips Reduced Volatility Alkylation Process (Revap)Bharavi K S100% (1)

- Alkylation Isomerization and Polymerization ProcessesDocumento13 páginasAlkylation Isomerization and Polymerization Processesnavya.cogni21Ainda não há avaliações

- 01pa JB 2 6 PDFDocumento9 páginas01pa JB 2 6 PDFMarcelo Varejão CasarinAinda não há avaliações

- Alkylation, Isomerisation and PolymerisationDocumento27 páginasAlkylation, Isomerisation and PolymerisationSudarshan GopalAinda não há avaliações

- Alkylation and Polymerization ProcessDocumento61 páginasAlkylation and Polymerization ProcessWan Afiff100% (2)

- Industrial Catalytic Processes-Phenol Production: Robert J. SchmidtDocumento15 páginasIndustrial Catalytic Processes-Phenol Production: Robert J. SchmidtUzair WahidAinda não há avaliações

- Alkylation Process, Feedstocks, Reactions, Products, Catalysts and Effect of Process Variables. Catalytic AlkylationDocumento17 páginasAlkylation Process, Feedstocks, Reactions, Products, Catalysts and Effect of Process Variables. Catalytic AlkylationyesuvaraprasadAinda não há avaliações

- Naphtha Cracking For Light Olefins ProductionDocumento5 páginasNaphtha Cracking For Light Olefins Productionbasura12345Ainda não há avaliações

- The Production of Cumene Using Zeolite Catalyst Aspen Model DocumentationDocumento16 páginasThe Production of Cumene Using Zeolite Catalyst Aspen Model Documentationديانا محمدAinda não há avaliações

- Uop Pacol Dehydrogenation Process: Peter R. PujadóDocumento10 páginasUop Pacol Dehydrogenation Process: Peter R. PujadóBharavi K S100% (1)

- 0910 8 AbsDocumento9 páginas0910 8 Absjlcheefei9258Ainda não há avaliações

- Industrial Applications of Olefin MetathesisDocumento7 páginasIndustrial Applications of Olefin Metathesisdogmanstar100% (1)

- NCL 2006 Pet. Chem.Documento58 páginasNCL 2006 Pet. Chem.madurchinnaAinda não há avaliações

- Alkylation: Tert-Butyl Ether) in Some US States Has FurtherDocumento12 páginasAlkylation: Tert-Butyl Ether) in Some US States Has FurtherrujunliAinda não há avaliações

- Metathesis: Refinery and Ethylene Plant ApplicationsDocumento6 páginasMetathesis: Refinery and Ethylene Plant ApplicationsArash AbbasiAinda não há avaliações

- ALKYLATIONDocumento6 páginasALKYLATIONtariq fareedAinda não há avaliações

- Pce-II Unit-I & II 1Documento84 páginasPce-II Unit-I & II 1Pavan SatishAinda não há avaliações

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocumento12 páginasPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshAinda não há avaliações

- Ethylene Midterms PetrochemDocumento8 páginasEthylene Midterms PetrochemEfraim AbuelAinda não há avaliações

- Unit 5 Alkylation ProcessDocumento7 páginasUnit 5 Alkylation Processammar saidAinda não há avaliações

- Lecture2 (Petrochemical)Documento12 páginasLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- New Oxidation Process For Production of Terephthalic Acid From P XyleneDocumento5 páginasNew Oxidation Process For Production of Terephthalic Acid From P XyleneJOSEPH HERBERT MABEL100% (1)

- Applications of The Olefin Metathesis Reaction To Industrial ProcessesDocumento15 páginasApplications of The Olefin Metathesis Reaction To Industrial ProcessesPetr Vaněk100% (1)

- Uop Alkylene™ Process For Motor Fuel Alkylation: Cara RoeselerDocumento8 páginasUop Alkylene™ Process For Motor Fuel Alkylation: Cara RoeselerBharavi K SAinda não há avaliações

- Uop Tatoray Process: Antoine Negiz and Thomas J. StoodtDocumento10 páginasUop Tatoray Process: Antoine Negiz and Thomas J. StoodtBharavi K SAinda não há avaliações

- PRP Unit - 6Documento4 páginasPRP Unit - 6Abdul GhafoorAinda não há avaliações

- Unit 13. Alkylation: Professional Course in English "Fundamentals of Petroleum Refining"Documento43 páginasUnit 13. Alkylation: Professional Course in English "Fundamentals of Petroleum Refining"Abdoul RahimAinda não há avaliações

- FILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesDocumento31 páginasFILE 20220921 173401 Homogeneously Catalyzed Industrial ProcessesPham ThaoAinda não há avaliações

- Phenol Evaluation - FinalDocumento23 páginasPhenol Evaluation - FinalCristian TorrezAinda não há avaliações

- Industrial Catalytic Processes Phenol PRDocumento15 páginasIndustrial Catalytic Processes Phenol PRJesús MorenoAinda não há avaliações

- Alkylation PDFDocumento7 páginasAlkylation PDFVasthadu Vasu Khanan DLAinda não há avaliações

- Uop Unionfining Technology: Peter KokayeffDocumento12 páginasUop Unionfining Technology: Peter KokayeffBharavi K SAinda não há avaliações

- Alkylation PDFDocumento7 páginasAlkylation PDFAnagha kvAinda não há avaliações

- Uop Butamer Process: Nelson A. CusherDocumento8 páginasUop Butamer Process: Nelson A. CusherBharavi K SAinda não há avaliações

- Processes Review of Propylene Production by Catalytic Cracking of C4-C8 OlefinsDocumento12 páginasProcesses Review of Propylene Production by Catalytic Cracking of C4-C8 OlefinsAndres Carmona OsorioAinda não há avaliações

- Production of Terephthalic Acid From Corn Stover LigninDocumento4 páginasProduction of Terephthalic Acid From Corn Stover LigninGRagaAinda não há avaliações

- Linear Alkylbenzene (Lab) Manufacture: Andrea BozzanoDocumento12 páginasLinear Alkylbenzene (Lab) Manufacture: Andrea BozzanoBharavi K SAinda não há avaliações

- Synthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDocumento18 páginasSynthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDevesh Pratap ChandAinda não há avaliações

- Alkylation Unit: Capacity Installed and Available Technologies CatalystsDocumento10 páginasAlkylation Unit: Capacity Installed and Available Technologies CatalystsMohammed AliraqiAinda não há avaliações

- Refining Process-AlkylationDocumento20 páginasRefining Process-AlkylationTusenkrishAinda não há avaliações

- Response-Content-Dispositionattachment FilenameDesign and Simulation of Cumene ManufactDocumento52 páginasResponse-Content-Dispositionattachment FilenameDesign and Simulation of Cumene ManufactAndrew100% (1)

- Plant DesignDocumento42 páginasPlant Designmuhammad ilyasAinda não há avaliações

- Assignment-1 Petroleum and Petrochemicals (UCH-850) : Submitted ToDocumento5 páginasAssignment-1 Petroleum and Petrochemicals (UCH-850) : Submitted Toarpit thukralAinda não há avaliações

- Petroleum Refining: Sulfuric Acid Alkylation in Petroleum Refining. Source: Occupational Safety & Health AdministrationDocumento2 páginasPetroleum Refining: Sulfuric Acid Alkylation in Petroleum Refining. Source: Occupational Safety & Health AdministrationliafitriifAinda não há avaliações

- Linear Alkylbenzene (Lab) Manufacture: Andrea BozzanoDocumento12 páginasLinear Alkylbenzene (Lab) Manufacture: Andrea BozzanojuanaAinda não há avaliações

- Penex Process PDFDocumento49 páginasPenex Process PDFAhmed Mohamed KhalilAinda não há avaliações

- Assignment 1Documento8 páginasAssignment 1Sulman KhalidAinda não há avaliações

- Unit-Iii Links For NPTEL LectureDocumento7 páginasUnit-Iii Links For NPTEL Lectureمحمد عليAinda não há avaliações

- Shell Middle Distillate Synthesis (SMDS) Process: F. J. M. SchrauwenDocumento16 páginasShell Middle Distillate Synthesis (SMDS) Process: F. J. M. SchrauwenBharavi K SAinda não há avaliações

- Hydrogen Processing: P A R T 1 4Documento68 páginasHydrogen Processing: P A R T 1 4Bharavi K SAinda não há avaliações

- Mathematical Methods Physics Partial Diiferential EquationsDocumento2 páginasMathematical Methods Physics Partial Diiferential EquationsBharavi K SAinda não há avaliações

- Uop Ethermax Process For Mtbe, Etbe, and Tame Production: Steve Krupa, Jill Meister, and Charles LuebkeDocumento4 páginasUop Ethermax Process For Mtbe, Etbe, and Tame Production: Steve Krupa, Jill Meister, and Charles LuebkeBharavi K S100% (1)

- The Syntroleum Process of Converting Natural Gas Into Ultraclean HydrocarbonsDocumento10 páginasThe Syntroleum Process of Converting Natural Gas Into Ultraclean HydrocarbonsBharavi K SAinda não há avaliações

- Gasoline Desulfurization: Douglas A. Nafis and Edward J. HoudeDocumento22 páginasGasoline Desulfurization: Douglas A. Nafis and Edward J. HoudeBharavi K SAinda não há avaliações

- FW Delayed-Coking Process: Howard M. Feintuch Kenneth M. NeginDocumento58 páginasFW Delayed-Coking Process: Howard M. Feintuch Kenneth M. NeginBharavi K S100% (2)

- Belco Edv Wet Scrubbing System: Best Available Control Technology (Bact) For Fccu Emission ControlDocumento16 páginasBelco Edv Wet Scrubbing System: Best Available Control Technology (Bact) For Fccu Emission ControlBharavi K S100% (1)

- Conocophillips S Zorb Diesel Process: Ed Sughrue and John S. ParsonsDocumento6 páginasConocophillips S Zorb Diesel Process: Ed Sughrue and John S. ParsonsBharavi K SAinda não há avaliações

- Oxypro Process: Steve Krupa, Larry Richardson, and Jill MeisterDocumento4 páginasOxypro Process: Steve Krupa, Larry Richardson, and Jill MeisterBharavi K SAinda não há avaliações

- Visbreaking and Coking: P A R T 12Documento32 páginasVisbreaking and Coking: P A R T 12Bharavi K SAinda não há avaliações

- Uop Merox Process: G. A. DziabisDocumento12 páginasUop Merox Process: G. A. DziabisBharavi K SAinda não há avaliações

- Uop Unisar Process For Saturation of Aromatics: H. W. GowdyDocumento8 páginasUop Unisar Process For Saturation of Aromatics: H. W. GowdyBharavi K SAinda não há avaliações

- Uop Par-Isom Process: Nelson A. CusherDocumento6 páginasUop Par-Isom Process: Nelson A. CusherBharavi K S100% (1)

- Uop Olex Process For Olefin Recovery: Stephen W. SohnDocumento4 páginasUop Olex Process For Olefin Recovery: Stephen W. SohnBharavi K SAinda não há avaliações

- Sulfur Compound Extraction and Sweetening: P A R T 11Documento14 páginasSulfur Compound Extraction and Sweetening: P A R T 11Bharavi K SAinda não há avaliações

- Uop Molex Process For Production of Normal Paraffins: Stephen W. SohnDocumento4 páginasUop Molex Process For Production of Normal Paraffins: Stephen W. SohnBharavi K SAinda não há avaliações

- Uop Sorbex Family of Technologies: James A. JohnsonDocumento8 páginasUop Sorbex Family of Technologies: James A. JohnsonBharavi K SAinda não há avaliações

- Uop/Fw Usa Solvent Deasphalting Process: Daniel B. GillisDocumento26 páginasUop/Fw Usa Solvent Deasphalting Process: Daniel B. GillisBharavi K SAinda não há avaliações

- The Rose Process: Tayseer Abdel-Halim and Raymond FloydDocumento14 páginasThe Rose Process: Tayseer Abdel-Halim and Raymond FloydBharavi K SAinda não há avaliações

- Uop Tip and Once-Through Zeolitic Isomerization Processes: Nelson A. CusherDocumento12 páginasUop Tip and Once-Through Zeolitic Isomerization Processes: Nelson A. CusherBharavi K SAinda não há avaliações

- Uop Butamer Process: Nelson A. CusherDocumento8 páginasUop Butamer Process: Nelson A. CusherBharavi K SAinda não há avaliações

- Isomerization: P A R T 9Documento6 páginasIsomerization: P A R T 9Bharavi K SAinda não há avaliações

- Uop Unicracking Process For Hydrocracking: Donald AckelsonDocumento12 páginasUop Unicracking Process For Hydrocracking: Donald AckelsonBharavi K SAinda não há avaliações

- Chevron Lummus Global Ebullated Bed Bottom-Of-The-Barrel Hydroconversion (Lc-Fining) ProcessDocumento18 páginasChevron Lummus Global Ebullated Bed Bottom-Of-The-Barrel Hydroconversion (Lc-Fining) ProcessBharavi K SAinda não há avaliações

- Uop RCD Unionfining Process: Daniel B. GillisDocumento10 páginasUop RCD Unionfining Process: Daniel B. GillisBharavi K SAinda não há avaliações

- Uop Catalytic Dewaxing Process: Hemant GalaDocumento6 páginasUop Catalytic Dewaxing Process: Hemant GalaBharavi K SAinda não há avaliações

- Hydrocracking: P A R T 7Documento22 páginasHydrocracking: P A R T 7Bharavi K SAinda não há avaliações

- Hydrotreating: P A R T 8Documento24 páginasHydrotreating: P A R T 8Bharavi K SAinda não há avaliações

- Uop Unionfining Technology: Peter KokayeffDocumento12 páginasUop Unionfining Technology: Peter KokayeffBharavi K SAinda não há avaliações

- EF4e Beg Quicktest 05Documento3 páginasEF4e Beg Quicktest 05terrenoruralcamboriuAinda não há avaliações

- Tri-Partite Agreement AssociationDocumento9 páginasTri-Partite Agreement AssociationThiyagarjanAinda não há avaliações

- Mobrey CLT PDFDocumento18 páginasMobrey CLT PDFAnonymous Oydnu9Ainda não há avaliações

- LECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentDocumento32 páginasLECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentmusabAinda não há avaliações

- Datasheet MEC MPS200 v1 2018Documento4 páginasDatasheet MEC MPS200 v1 2018Cepi Sindang KamulanAinda não há avaliações

- Legg Calve Perthes Disease: SynonymsDocumento35 páginasLegg Calve Perthes Disease: SynonymsAsad ChaudharyAinda não há avaliações

- Chapter Six Account Group General Fixed Assets Account Group (Gfaag)Documento5 páginasChapter Six Account Group General Fixed Assets Account Group (Gfaag)meseleAinda não há avaliações

- Packed Bed Reactor Slides (B)Documento32 páginasPacked Bed Reactor Slides (B)Meireza Ajeng PratiwiAinda não há avaliações

- Geography - Development (Rural - Urban Settlement)Documento32 páginasGeography - Development (Rural - Urban Settlement)jasmine le rouxAinda não há avaliações

- Payroll Solution in Single SheetDocumento818 páginasPayroll Solution in Single SheetTarique KhanAinda não há avaliações

- Blood DonationDocumento19 páginasBlood DonationsuruthiAinda não há avaliações

- Series RL: Standards General DataDocumento4 páginasSeries RL: Standards General DataBalamurugan SankaravelAinda não há avaliações

- Wilo Water PumpDocumento16 páginasWilo Water PumpThit SarAinda não há avaliações

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocumento10 páginasVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorAinda não há avaliações

- Ecological Imbalance in IndiaDocumento4 páginasEcological Imbalance in IndiaabhywaAinda não há avaliações

- Form 28 Attendence RegisterDocumento1 páginaForm 28 Attendence RegisterSanjeet SinghAinda não há avaliações

- Article 1, The Role of Science and TechnologyDocumento3 páginasArticle 1, The Role of Science and TechnologyNSBMRAinda não há avaliações

- Jurnal SOL MeningiomaDocumento6 páginasJurnal SOL MeningiomaConnie SianiparAinda não há avaliações

- Onuaguluchi1996 1Documento10 páginasOnuaguluchi1996 1IkaSugihartatikAinda não há avaliações

- Nodular Goiter Concept MapDocumento5 páginasNodular Goiter Concept MapAllene PaderangaAinda não há avaliações

- Case StudyDocumento7 páginasCase StudyLeighvan PapasinAinda não há avaliações

- Disorders of The Reproductive SystemDocumento10 páginasDisorders of The Reproductive SystemRose Kathreen Quintans AuxteroAinda não há avaliações

- Abfraction, Abrasion, Biocorrosion, and The Enigma of Noncarious Cervical Lesions: A 20-Year PerspectivejerdDocumento14 páginasAbfraction, Abrasion, Biocorrosion, and The Enigma of Noncarious Cervical Lesions: A 20-Year PerspectivejerdLucianoAinda não há avaliações

- L A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDocumento21 páginasL A R G e - S C A L e M e T H A M P H e T A M I N e M A N U F A C T U R eDaria Schka100% (1)

- 21A Solenoid Valves Series DatasheetDocumento40 páginas21A Solenoid Valves Series Datasheetportusan2000Ainda não há avaliações

- Active Contracts by Contract Number Excluded 0Documento186 páginasActive Contracts by Contract Number Excluded 0JAGUAR GAMINGAinda não há avaliações

- EM2U60CLP 115-127 V 60 HZ 1Documento4 páginasEM2U60CLP 115-127 V 60 HZ 1armagedrumAinda não há avaliações

- Facts About Concussion and Brain Injury: Where To Get HelpDocumento20 páginasFacts About Concussion and Brain Injury: Where To Get HelpJess GracaAinda não há avaliações

- (Engine International Air Pollution Prevention) : EIAPP CertificateDocumento2 páginas(Engine International Air Pollution Prevention) : EIAPP CertificateTan DatAinda não há avaliações

- Borelog CP.101Documento1 páginaBorelog CP.101radixkusumaAinda não há avaliações

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsAinda não há avaliações

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingNo EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAinda não há avaliações

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideNo EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideNota: 2 de 5 estrelas2/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNo EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesNota: 4 de 5 estrelas4/5 (2)

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesNo EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesNota: 5 de 5 estrelas5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Casing and Liners for Drilling and Completion: Design and ApplicationNo EverandCasing and Liners for Drilling and Completion: Design and ApplicationNota: 5 de 5 estrelas5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsAinda não há avaliações

- Abrasive Water Jet Perforation and Multi-Stage FracturingNo EverandAbrasive Water Jet Perforation and Multi-Stage FracturingAinda não há avaliações

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsNo EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsNota: 4.5 de 5 estrelas4.5/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNo Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonAinda não há avaliações

- Acquisition and Processing of Marine Seismic DataNo EverandAcquisition and Processing of Marine Seismic DataNota: 4 de 5 estrelas4/5 (4)

- The Petroleum Engineering Handbook: Sustainable OperationsNo EverandThe Petroleum Engineering Handbook: Sustainable OperationsNota: 3.5 de 5 estrelas3.5/5 (5)