Escolar Documentos

Profissional Documentos

Cultura Documentos

Ism Sorular Genel

Enviado por

Çetin SManagementDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ism Sorular Genel

Enviado por

Çetin SManagementDireitos autorais:

Formatos disponíveis

What makes a ship safe? Safety has to be ship sponsored, not something we push from shore.

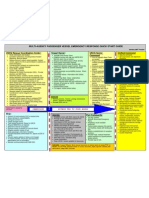

. A safety culture, brought about by all staff working together to achieve safety. Diligence, and good officers who give a lead to the crew. Its about duty of care, for oneself, for ones fellows, for the environment. If everyone lives safely, you have safety in numbers. How do you communicate safety messages? Face to face, or by questioning and challenging physical evidence. Through example, discussion and guidance. Training, educating, re-educating and providing the resources necessary. Leading by action and openly acknowledging areas for personal improvement. Remotely, by email. On board by ASA conversations. Personally, leading by example. What is your role in safety? Supportive. Leadership and setting an example. To lead from the front and set an example. Ensure my own actions are safe.Then help others. To make sure safety equipment arrives on board asap. We are all leaders in safety. How do you guard against complacency? Never give up. Always have safety on the agenda. Always show zero tolerance for any unsafe acts or conditions. By taking no chances at all. Compromise with safety and you compromise with your life. Regular drills. Practice makes perfect. Safety is our shield against accidents, dont let cracks develop in it. Question everyday activities, query pre-defined norms. A safety slogan: Look safe, be safe. Engage your brain before your hands. Assumption is the mother of all accidents. Accidents dont happen they are caused! Involvement drives excellence in safety. What one thing could be done to improve safety? Training, training and more training. Improve worker education in the shipyards. Slow down, safety is about time. Take your time and stay safe. Listen to lessons learned by others. Make it a habit to identify, report and fix potential failure. 1.1 How well understood is the object of the ISM Code? 5.0 Verify the addresses and contact numbers of the companys head office and regional office. 7.0 Determine that staff knows location of definitions in FSM (fleet safety manual).

7.0 Core understanding of definitions of "observation" and "non-conformity". 8.1 Check availability of publications in departmental libraries. 1.0 Is the commissioners safety policy posted prominently? 1.4 What is the posted version date? 1.0 Is staff familiar with the safety policy? 2.0 Is the drug and alcohol Policy posted prominently? 2.0 What is the posted version date? 2.3.2 Does staff know the rule on impairment? 2.3.5 Does staff know the five hour rule? 2.3.6 Does staff know their obligation in turning over a watch? Does supervisory staff know the over-all organizational structure for the FSM? Does staff know the ship specific organizational structure for the FSM? Do supervisors have a reasonable understanding of the position responsibilities of the Director of Operations? Does staff have a reasonable understanding of the position responsibilities of the Commanding Officer? Does staff have a reasonable understanding of the position responsibilities of their Department Head? Does the Marine Superintendent have copies of job descriptions? Are copies of job descriptions held aboard? Has staff received a copy of their own job description? Does the job description held by the staff member agree with the job description for the position that is held ashore by the Marine Superintendent? 4.0 Who Is the NDPA? (Shore Managers and RDPAs) 4.0 Who is the RDPA? (All personnel) 2.0 & 3.0 Evidence of ships being advised of temporary replacement of the DPA? Does this tally with shore records of absence of the DPA? 4.0 Verify contact numbers of the RDPA

Verify DPA's are familiar with their responsibilities. 1.1 Verify Commanding Officer is aware of own responsibility. 1.2 Number of items reported to the DPA since the last audit. Compare against register of non-conformances. 1.3.2 Evidence of systematic reviews of safety and pollution prevention activities. 1.3.4 Have activities been undertaken to motivate crew? 1.3.9 What is last date shown for review of on-board plans and procedures? Has review been conducted regularly? 2.2 Evidence that Commanding Officer is conversant with the FSM. 2.4 Verify that orders and instructions are posted, dated, and signed. 2.5 Obtain records of on-board safety meetings and drills. Are they regular? 2.6 Has systematic review been conducted so that all procedures have been reviewed within a two-year period? 2.6 Has crew been involved in the review of the system? 2.6 Records of RDPA being notified of reviews conducted? 2.6 RDPA records follow up or tracking to ensure reviews being completed. 3.1 Seek evidence that Commanding Officer fully understands and is prepared to exercise authority as may be required by circumstances or conditions. 3.3.1 Sight copies of Commanding Officers Standing Orders. 3.4.1 Are Night Orders used regularly? 4.0 Review logbook entries for drills, exercises, and inspections. 4.0 Review minutes of Safety Management Meetings - check to ensure all items have been actioned or corrective action plan is in place to deal with outstanding items. 4.0 Review file of non-conformance reports. 4.0 Review record of review of manual procedures. Are reviews conducted regularly? 4.0 Is Fleet Safety Manual up-to-date? Confirm manual number (or numbers if more than one held) against DPA register.

1.1 Review personnel records of Commanding Officers for certificates, CPE, and medical. 2.1.1 Seek evidence that methods employed to ensure officers are qualified for positions held. 2.2.1 Seek evidence that methods employed to ensure crewmembers are qualified for positions held. 2.3.1 Verify competency profiles have been established for each ship and that they are posted. 4.1 Obtain records of training conducted. 5.2 What is the designated language of work aboard the ship? 5.3 By observation, are there individuals aboard who do not appear familiar with the use of the language designated for use aboard the ship? 2.2 Are there signed competency profiles for all ships in the region on file? 2.2 Are the certification requirements in the competency profiles in accordance with the companys and the crewing regulations? 2.3 Seek evidence that the Marine Superintendent ensures that persons assigned to ships have met the competency and certification standards? 2.3 Take representational sample of Marine Superintendents crewing records and compare against competency profiles. 2.3 Does the Marine Superintendent conduct reference checks and does the Marine Superintendent authenticate certification documents? 2.4 How many occasions since the previous audit has the marine superintendent informed the Operations Center that the competency profile is not sufficient to meet planned operations? 2.5 Review requests for Exemption, are they signed by the marine superintendent and counter signed by the DPA? 2.6 Seek evidence that the Commanding Officer reviews certificates and records when personnel sign-on. 2.7 Have the competency profiles been developed by the Commanding Officer in consultation with the Director of Operations? 2.8 Are heads of departments continually monitoring and assessing subordinates? Sight records. 3.1 Does the Marine Superintendent maintain a register of seafarer certificates?

3.1 Is there evidence that the Register is sighted quarterly? 3.1 Is there evidence of follow-up when certificates are expiring or have expired? 3.3 Are competency profiles established and posted for all positions under all operating regimes aboard the vessel? 3.4 Is there at least one entry level position shown in the competency profiles for each department? 3.5 Has minimum manning been established in line with the SAR competency profile for the vessel? 3.6.1 Is there evidence that qualifications are compared against certification and competency requirements before assigning the seafarer to the vessel? 3.6.2 Is there evidence that newly appointed seafarers are familiarized before assuming duties aboard? 3.6.2 Is there evidence that newly appointed seafarers are supervised before assuming unsupervised duties aboard? 3.7.2 Do filed copies of exemption requests provide evidence that the situationgiving rise to the request was sudden and unforeseen? 3.7.4 Are exemption approvals given and signed by the appropriate authority? 3.7.4 Is there any evidence that the ship sailed in advance of an exemption authority being received? 3.7.5 Is there any evidence that the ship has sailed with more than one exemption being used in a department? 3.7.6 Where exemptions have been granted, did the exemptee have a certificate not more than one level below the level of certificate required for the voyage? 3.7.6 In the case of Commanding Officer exemptions, where such exemptions have been granted, did the exemptee hold a Masters qualification not more than one level below the certificate require? 3.7.7 What evidence exists to support the fact that the Marine Superintendent conducted a search for a suitably certified and qualified individual before requesting an exemption? 3.7.8 How was the practical ability of the examples assessed? 3.7.9 Were exemptions granted only for the minimum period required? 3.7.9 Is there any evidence that an exemption was relinquished immediately upon the availability of a qualified person?

3.7.10 Were exemption requests filled out completely? 3.7.11 Have exemption requests been properly reported through the system to the Safety Management System Review? 3.8.1 Do all persons aboard possess appropriate medical certification? 3.8.2 Are special medical evaluations completed following Iong absences for Illness or Injury? 3.8.3 Is there evidence of a scheduling system to ensure medical evaluations are completed on a timely basis? 3.8.4 Are there records of any person being removed from ships as a result of an "unfit' medical evaluation? Annex A Sight posted competency profile for completeness, signatures, and dates. 2.1 Has the Commanding Officer given directions on the content and scope of the familiarization materials? 3.1 Is time is allowed on board the ship for new personnel to become familiar with their duties? Does this vary by position and are time limits appropriate? 3.2.1 Is there evidence that all first time joiners have received familiarization training? 3.2.2 Is there a process in place which ensures that previous service is checked to ensure that all joining personnel with more than six months elapsed since lost service aboard are re-familiarized? 3.3.1 Is there a familiarization checklist used and does ft meet the minimum requirements of the FSM? 3.3.2 Do all new Personnel complete supervised on-the-job training during their first week aboard? 3.3.3 Is there evidence that new personnel are not standing watches or performing duties unsupervised? 3.3.5 Site familiarization-training records and compare against Ship's Book. 3.4.1 Have processes and procedures ashore that are essential to ensure the effectiveness of the safety management system been Identified? 3.4.2 Site familiarization checklists used ashore. 3.4.3 site shore site familiarization training records.

3.1 Is there evidence that supernumerary personnel have been familiarized prior to sailing? 3.3 Are there Copies of the declaration of Health for all supernumerary personnel that have been carried aboard? 3.4 Have non-employees of the Department completed the passenger waiver and Release Form? 3.5 Have Supernumerary personnel signed the Ship's Book on joining and departing? 3.6 Is there evidence that personnel who have refused to sign the Ship's Book or complete the declaration of health having been refused carriage? 2.2 Has identified training been provided in a timely fashion? 2.3 Are individual training records maintained and are they complete? 2.4 Are training plans available? 3.1.1 Are training requirements identified and are they reviewed biennially? 3.1.2 Are annual training plans in place for each employee? 3.1.3 Are unique unit-specific training requirements identified and is there a training plan in place for these elements? 3.2.1 Have shore managers satisfied training to IMO Course 6.03? 3.2.2 Have crewing officers satisfied training to IMO Course 5.04? 3.3.1.1 Have employees been provided with training necessary to the safe performance of their positions? 3.3.1.2 Are there records of training having been completed satisfactorily before employees are tasked with completing duties unsupervised? 3.4.1 Are training records maintained detailing employees work and training history? 2.1 Do the Commanding Officers Standing Orders contain specific Instructions related to access to the bridge? 3.3 Are Office-of-the-Watch familiar with their authority to suspend visits to the bridge where necessary? 3.5 Are restricted entry signs posted at entrances to the bridge? 2.2 Are the watchkeeping arrangements on the bridge adequate for the conditions and operations?

3.1 Are the International Regulations for Preventing Collisions at Sea available on the bridge and is there evidence that the OOW's observe the Regulations? 3.2 Are watches conducted-in accordance with the Watchkeeping Standards? 3.2 Has the Commanding Officer issued specific practices and procedures for the conduct of a watch and are these instructions known and followed? 3.3 Are changes of watch logged? 3.3 Is the time when the commanding officer assumes control of navigation logged? 3.4 Have all watchkeepers attended a Bridge Resource Management Course? 3.5 Is the rest period called for in the watchkeeping Standards observed? 3.1 Are voyages pre planned? 3.2 Is the voyage plan communicated before the voyage commences? 3.2 Is there anecdotal evidence that suggestions for improvements to the voyage plan are solicited or welcome? 3.3 Is it clear to all watchkeepers when the vessel is to be operated in pilotage mode? 3.4 Are modified plans used for operational phases? 3.5.1 Are appropriate folios or charts carried for the intended voyages? 3.5.2 Are charts corrections up-to-date with the latest Notice to Mariners? 4.0 Are voyage plans on file and do they appear to have been prepared completely? 3.1 Has the Commanding Officer issued clear instructions to be followed in case of restricted visibility? 3.3 Does the ship use a checklist in restricted visibility and is the use of the checklist logged? 3.1.1.1 Is the commanding officer informed when the ship enters confined waters? 3.1.1.1 Is the engine room informed when the ship enters confined waters? 3.3.1.1 Is there evidence that the ship employs closer attention to the position of the ship when in confined waters? 3.3.1.3 Is there evidence that more than one method of fixing is used?

2.1 Has the commanding officer issued any amplifying orders regarding the use of lookout are these orders understood and followed? 2.3 Do lookouts report for duty in advance of the required time to allow-for adjustments to conditions? 3.1 Are lookouts employed as required by the Canadian Watchkeeping Standards? 3.2.1 Does the OOW ensure that each lookout is fit for duty? 3.2.2 Are the names and times of the watch logged for each lookout? 3.2.3.1 Is there anecdotal evidence that lookouts are employed solely for that purpose? 3.2.3.2 Does the OOW brief the lookout on the duties of the position? 3.2.3.3 Are the means of communication between the OOW and lookout known and tested? 3.2.3.4 Does the OOW ensure that lookouts are relieved regularly to ensure fitness and efficiency? 3.3.1 Is there anecdotal evidence that lookouts understand the duties of their position? 3.3.3 Do Lookouts report when they are relieved and by whom? 3.1 Are deck officers familiar with the contents of Ice Navigation in Canadian Waters? 3.2 Is there evidence that closer attention is paid to navigation of the ship when in ice covered waters and that navigation instruments are tested and checked? 3.3 Has the ship prepared checklists for conducting operations in ice covered waters? 3.1.1 Does the ship use an anchoring plan when coming to an anchorage? 3.1.1 Is this plan communicated to the Bridge Team? 3.1.2.2 Has the Engineroom been notified of intentions and requirements for auxiliary machinery? 3.1.2.3 Has maneuvering machinery been tested and logged? 3.1.4 Does the ship observe the practice of walking out the chain in deep anchorage? 3.2.1 Are confined spare entry Procedures in Place for entering the chain locker?

3.2.2 Do personnel entering the chain locker wear the appropriate protective equipment? 3.2.5 When removing personnel from the chain locker is anchor hoisting stopped? 2.3 If required, does the ship have checklists for transiting canals? 2.3 If the ship does not carry a checklist, and if a canal has been transited since the previous audit, is there a plan on file? 3.1 Are canals Regulations and Sailing Directions carried as may be appropriate? 3.2.1 Are primary and secondary communication established with line handling location before transit? 3.2.4 Is the Engineroom informed to verify standby and required equipment is tested and ready? 3.2.5 Are winches tested prior to transit and is this it logged? 2.2 Does the crew understand who is the commanding officers delegate for the supervision of cargo operations? 3.1 Are the requirements of the tackle Regulations observed in cargo handling? 3.2 Is the cargo handling crew wearing the appropriate personal protective equipment? 3.3.1 Can it be confirmed that the commanding officers delegate inspects slings, hooks, shackles, and other devices prior to operation? 3.3.2 Do the crane operators and the signalmen both understand and use appropriate hand signals? 3.3.3 Does the commanding officers delegate inspect cargo to be loaded? 3.3.4 Are the cargo plans used when necessary? 3.3.5 Are cargo plans used when requires by the Transportation of Dangerous Goods Regulations? 3.4.1 Is the lift area free from debris and are tag lines adequately manned? 3.4.2 Is the access to the working area controlled? 3.4.3 Are cargo weights known so that SWLs are observed? 4.0 Are SWLs clearly marked on all lifting machinery and appliances?

1.1.1 Martins Marine Engineering Page rocks! http://members.home.net/dieselduck 3.1 Are the fall protection standards of the Marine Occupational Safety and Health Regulations readily available? 3.1 Are fall protection systems inspected prior to use? 3.2 Is there evidence that Personnel routinely report deficiencies found with fall protection equipment? 3.3 Do fall-protection systems used aboard meet the minimum standards? 3.4 Is fall-protection systems quarantine after fall arrest until inspected and passed by a qualified person? 3.5 Are lockout systems used systematically and appropriately and is the use of lockouts logged? 3.6 Have appropriate checklists been created for work aloft or work over the side? 3.7 Are equipment records maintained In accordance with the procedure? 3.1.1 Has the Chief Engineer issued written instructions to subordinates for routine engineering tasks aboard the vessel? 3.1.1 Are the Chief Engineers Standing Orders signed and dated? 3.1.1 Is there evidence that engineers have seen the Chief Engineers Standing Orders? 3.2.1 Are engineering watches conducted in accordance with the Canadian Watchkeeping Standard and the Chief Engineers Standing Orders? 3.2.2 Are watch changes recorded in the Chief Engineers logbook? 3.3.1.1 Are pre-watch inspections made? 3.3.1.4 Is there evidence that a system is in place to ensure that the relieving engineer is made aware of ongoing work being performed in the engine room? 3.3.1.7 Is there evidence that the engineer OOW determines that engine room personnel are capable of performing their duties? 3.4.1 Is a copy of the Canadian watchkeeping Standard accessible to Engine room personnel? 3.4.2 Have ship-specific instructions been written in sufficient quantity and detail to adequately cover the systems listed in this procedure?

3.5.1.1 Are pre hand-over rounds completed by the departing engineer? 3.5.1.2 Does the departing engineer record machinery that has been isolated, bypassed, or undergoing maintenance? 3.5.1.3 Are log book entries completed and signed before the departing engineer is relieved? 3.5.1.4 Is there evidence that the departing engineer OOW determines that the relieving engineer is capable of carrying out his or her duties? 3.5.1.5 Is there evidence that abnormalities or deficiencies are discussed and/or rectified before the watch is handed over? 2.1 Is there evidence that the Commanding Officer knows if ballast water discharge restrictions are applicable to the ships zone of operations and that these regulations are observed? 2.2 Has the Marine Superintendent compiled a list of ballast water discharge restrictions that apply to the geographic zone of operations? 3.1 Are the voluntary Guidelines applied when transiting fresh water? 3.3 Are ballast operations planned to account for hull stresses, stability, sea conditions, and possible crossovers from the fuel system? 3.4 Are ballast operations logged? 3.5 Has the ship been issued with directions issued by local authorities respecting ballast water discharge? 4.0 Site the Oily Water Separator Records. 2.1 Is there evidence that ships personnel are familiar with the Ship Oil Pollution Emergency Plan (SOPEP)? 2.3 Are work scheduled established for bunkering operations? 2.4 Is there evidence that the Chief Officer is aware of local harbor regulations pertaining to bunkering operations? 3.1 Has the ship developed specific checklists for transfer of oil and bunkering operations? 3.1 Have the checklists addressed legislative requirements for bunkering and transferring? 3.2.1 Is the SOPEP available on the Bridge? 3.2.7 Does the ship have Insulating flanges or non-conductive hoses?

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Animalia: Graeme BaseDocumento40 páginasAnimalia: Graeme BaseMonica Tesa86% (7)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Cat C32 ACERT Spec Sheet - CommercialDocumento12 páginasCat C32 ACERT Spec Sheet - Commercialzzsq3550% (2)

- Columbus' ShipsDocumento160 páginasColumbus' ShipsRed Rex 2015100% (2)

- Christopher Columbus Explorer of The New WorldDocumento46 páginasChristopher Columbus Explorer of The New Worldyuye0913100% (5)

- Future ContinuousDocumento3 páginasFuture ContinuousHanh NguyenAinda não há avaliações

- Guillemot Kayaks Plans Catalog 2011Documento16 páginasGuillemot Kayaks Plans Catalog 2011Guillemot Kayaks50% (4)

- BarbariansDocumento81 páginasBarbariansKhull Spax100% (1)

- Boat International 2014-02.bakDocumento228 páginasBoat International 2014-02.baksrdjan013Ainda não há avaliações

- Chan Keep v. Chan - GiocoDocumento3 páginasChan Keep v. Chan - GiocoMico Maagma CarpioAinda não há avaliações

- Ship Anchor ImagesDocumento66 páginasShip Anchor ImageshutsonianpAinda não há avaliações

- Guide Me June-July Issue 2012Documento51 páginasGuide Me June-July Issue 2012VisitMaltaAinda não há avaliações

- Duties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingDocumento12 páginasDuties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingMohan Krishnan100% (1)

- Ism Conteingency PlanningDocumento12 páginasIsm Conteingency PlanningÇetin SManagement100% (1)

- Emergency Situations CrisisDocumento17 páginasEmergency Situations CrisisÇetin SManagementAinda não há avaliações

- Expeditions Five 55' Catamaran Ferry Between Maui & LanaiDocumento1 páginaExpeditions Five 55' Catamaran Ferry Between Maui & LanaiEman AgiusAinda não há avaliações

- You and the Sea - TTS Marine Engineering SolutionsDocumento12 páginasYou and the Sea - TTS Marine Engineering SolutionsSyaiful AnamAinda não há avaliações

- Emsa Work Programme 2012Documento105 páginasEmsa Work Programme 2012Çetin SManagementAinda não há avaliações

- 1ism GuidesDocumento1 página1ism GuidesÇetin SManagementAinda não há avaliações

- Emergency Planning IsmDocumento1 páginaEmergency Planning IsmÇetin SManagementAinda não há avaliações

- Ism NotesDocumento1 páginaIsm NotesÇetin SManagementAinda não há avaliações

- DPA An ISM Requiremnet or A CommitmentDocumento6 páginasDPA An ISM Requiremnet or A CommitmentÇetin SManagementAinda não há avaliações

- West Bengal Tourism PolicyDocumento6 páginasWest Bengal Tourism Policyapi-3711789100% (3)

- Coral Reef Packages - LakshadweepDocumento31 páginasCoral Reef Packages - Lakshadweeparijit_ghosh_18Ainda não há avaliações

- United States Patent (19) : Hood Et Al.Documento5 páginasUnited States Patent (19) : Hood Et Al.8787Ainda não há avaliações

- ISLAND SAILING CLUB COWES 2012 ROUND THE ISLAND RACE RESULTSDocumento64 páginasISLAND SAILING CLUB COWES 2012 ROUND THE ISLAND RACE RESULTSmatthias_25Ainda não há avaliações

- Disneyland Attraction GuidebookDocumento21 páginasDisneyland Attraction GuidebookJilliene IsaacsAinda não há avaliações

- CHE - Sunreef 114 BrochureDocumento15 páginasCHE - Sunreef 114 BrochureSunreefCharterAinda não há avaliações

- Mercyhurst Magazine - Winter 1992-93Documento24 páginasMercyhurst Magazine - Winter 1992-93hurstalumniAinda não há avaliações

- Parasailing - An Introduction to the Recreational SportDocumento14 páginasParasailing - An Introduction to the Recreational SportNadyaCazacAinda não há avaliações

- Literacy Narrative Enc 1101Documento6 páginasLiteracy Narrative Enc 1101api-242332162Ainda não há avaliações

- AGC Printing Patchogue History Part 2 LayoutDocumento115 páginasAGC Printing Patchogue History Part 2 Layoutlnichols6754Ainda não há avaliações

- Original Essay - Memorable Journey To A Past LifeDocumento9 páginasOriginal Essay - Memorable Journey To A Past LifeissaerudAinda não há avaliações

- Posidonia 2018 Newsletter Issue 05Documento5 páginasPosidonia 2018 Newsletter Issue 05Axilleas TheocharisAinda não há avaliações

- FISA Racing RulesDocumento61 páginasFISA Racing Ruleshn7410Ainda não há avaliações

- Cruise Weekly For Thu 30 Oct 2014 - New CLIA Accreditation Tier, Quantum Delivered, DOT, CruiseManagers and Much MoreDocumento2 páginasCruise Weekly For Thu 30 Oct 2014 - New CLIA Accreditation Tier, Quantum Delivered, DOT, CruiseManagers and Much MorecruiseweeklyAinda não há avaliações

- Round Bilge Hull With Full Length ChineDocumento4 páginasRound Bilge Hull With Full Length ChinewalacrAinda não há avaliações

- A Rigging Guide For A Boat So Easy To Rig, It Barely Needs OneDocumento15 páginasA Rigging Guide For A Boat So Easy To Rig, It Barely Needs Oneagustinrubio7946100% (1)