Escolar Documentos

Profissional Documentos

Cultura Documentos

Two-phase loop thermosyphon hydrodynamics

Enviado por

Vlad MartianDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Two-phase loop thermosyphon hydrodynamics

Enviado por

Vlad MartianDireitos autorais:

Formatos disponíveis

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

1

HYDRODYNAMICS OF TWO-PHASE LOOP THERMOSYPHON

Wei Qu

*

Institute of Engineering Thermophysics, Chninese Academy of Sciences, Beijing, 100190, China

ABSTRACT

Two-phase loop thermosyphons are important devices for large heat transport to a longer distance. The hydrodynamics of such device is closely

related with the evaporator and condenser details. The evaporator is modeled by an integral balance of bubble flow, considering the relative velocity

difference between the vapor and liquid. The condenser is calculated by liquid film condensation of vapor-liquid concurrent flow, corresponding to

the two shear forces of viscous flow and momentum transfer. For the evaporator of one two-phase loop thermosyphon, the vapor bubble and liquid

flow velocities, the axial density of the vapor-liquid mixture are formulated and analyzed. For the whole loop, the equivalent liquid position of

operating evaporator, the driving liquid position difference between that in the liquid line and that of the evaporator equivalent, the liquid position

difference in the liquid line before and after operating, are calculated and analyzed. The evaporator model and results can be referenced to the

optimal design.

Keywords: Two-phase loop thermosyphon, hydrodynamics, the vapor bubble and liquid flow velocities, the axial density of the vapor-liquid mixture,

liquid position

*

Corresponding author. Email: weiqu@iet.cn

1. INTRODUCTION

The conventional heat pipe or non-loop thermosyphon each is self-

contained, the adiabatic sections are not commonly designed long.

They are suitable for short distance between the heat source and the

heat sink, and the number of them is closely related with the power of

heat transfer (Roesler, 1991; He, 1992).

Conveniently for some situations, two-phase loop thermosyphon

has become highly efficient heat transfer element for a variety of

applications (Huang, 1988, Chen, 1988). This type of arrangement

completely decouples the evaporator and the condenser parts of the

above-mentioned heat pipe or thermosyphon. Two major advantages

are obtained compared to the classical heat pipe or thermosyphon, one

is that the large distances between evaporator and condenser are easily

Fig. 1 Basic construction of a two-phase loop thermosyphon

manageable, the other is that the mechanism opposite to the counter

flow of conventional heat pipe or thermosyphon (Liu, 1988), the vapor

and liquid flow co-currently.

Two-phase loop thermosyphons have been strongly propagated in

the past few decades due to the high efficiency, reliability and cost-

effectiveness. Devices of this type consist of separated assemblies of

evaporator and condenser, which are connected by one or more

common vapor and liquid lines, respectively. A schematic of a two-

phase loop thermosyphon is given in Figure 1.

In the previous researches to the two-phase loop thermosyphon, the

evaporator heat transfer and flow were mostly calculated by empirical

formulae, the best filling rate was experimented to the real application.

Such as (Chen, 1986), for the evaporator assembly of a loop

thermosyphon, the heat transfer coefficient is given as

0.66 0.06

7.915

e e v

h q p = (1)

Where the heat flux and the vapor pressure should be within a scope

respectively as, 0.503 3.5

e

q < < W/cm

2

; 0.045 1.63

v

p < < Mpa. The

accuracy of these methods is not good and if the structure and

transferred power are varied, then the previous results are nearly

useless.

It is commonly believed that the driving force of the condensation

liquid return is the liquid position difference between that in the liquid

return line and that of the evaporator. However, the liquid position of

the evaporator is not obvious, since that the state of the evaporator is

the mixture of vapor bubbles and the liquid.

When a thermosyphon works normally, many bubbles appear in the

evaporator, this causes the rise of liquid pool surface. The increment of

boiling liquid pool height is recommended as 30% of the original

height. However, for a two-phase loop thermosyphon, this height

Frontiers in Heat Pipes

Available at www.ThermalFluidsCentral.org

Pressure gauge

Hot

fluid

Cold

fluid

Liquid

line

Vapor

line

Drainage valve

Gas valve

Evaporator

assembly

Condenser

assembly

Fin

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

2

p

v

o

p

l

R

F

r

F

f

u

F

r

increment is obviously not suitable due to the smaller diameter of

evaporator tubes.

This work focuses on the two-phase loop thermosyphon. Firstly, the

governing equations are given to describe the whole loop. Then, the

evaporator is modeled to describe the flow and heat transfer of liquid

and bubbles, the axial density of mixture is formulated. After that, the

flow and heat transfer of the condenser, the vapor and liquid lines are

considered theoretically together with the evaporator, and several liquid

positions are calculated and discussed. Finally the results of liquid

position difference is summarized and concluded.

2. THEORETICAL ANALYSES

The theoretical analysis is the following. The governing equations are

established. The evaporator is modeled in every detail and particular,

considering the relative speed between vapor and liquid. While for the

condenser, the viscous friction force and momentum transfer force

between vapor core and liquid film are considered.

2.1 Governing Equations

For a two-phase loop thermosyphon, the momentum of the evaporator,

of the condenser, of the vapor and liquid lines has nearly the same type.

The flow and heat transfer of the whole loop thermosyphon can be

described by the continuum equation, the momentum equation and the

heat transfer equation respectively as

m uA = (2)

sin

w

w dp m du

g

ds A A ds

(3)

fg

Q mh =

(4)

Along the thermosyphon loop, for equation (3), there is

sin 0

w

w m du

dp ds ds g ds

A A ds

= =

} } } }

(5)

For the vapor and liquid lines, during the vapor and liquid flowing,

no phase change occurs, so the governing equations (2) and (3) apply.

Euqation (4) are only applied for the evaporator and the condenser.

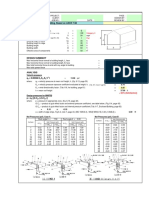

Fig. 2 Evaporator modelling of Fig. 3 The forces function to

a two-phase loop thermosyphon the flowing bubble

2.2 Evaporator Modelling

The heat transfer in the evaporator belongs to the boiling in restricted

space. The vapor-liquid mixture surface will be higher for more vapor

bubbles. For the evaporator, the more vapor bubbles are, the less total

working fluid are needed. The vapor upflow speed is much bigger than

that of the liquid supply.

Considering the bubbles in the evaporator, as shown in Figure 2,

the height of the vapor-liquid mixture is H, the bubbles in the micro

control volume dh take time t to get to the surface. During time t, the

total vapor volume is produced in dh section as

in

v

fg v

q d

dV t dh

h

=

( 6)

Where, t is the function of h. In order to find the function relation

t=t(h), the bubble is assumed as globe, the radius is R, as illustrated in

Figure 3.

For the vertical direction, the bubbles are controlled by the up-

floating force and the liquid resistance, as shown in Figure 3. The

upflow velocity is u. Then the vapor bubble momentum is written as

( )

3 3 3

4 4 1 4

3 3 2 3

v l v l

d d

R u R g R u

dt dt

| | | |

=

| |

\ . \ .

(7)

Equation (7) is simplified as

( )

( )

3 3

2

2

l v

l v

d

R u R g

dt

=

+

(8)

It is assumed that the radius of each dh does not change with time,

and then there is

( ) 2

2

l v

l v

du

g

dt

=

+

(9)

Integrate equation (9) once, the velocity of vapor bubble at h is

obtained as

( )

1

2

2

l v

l v

u gt C

= +

+

(10)

At initial time, t=0, the velocity of vapor bubble, u=0, then, C

1

=0.

( ) 2

2

l v

l v

u gt

=

+

(11)

Integrate equation (11) once more, the relation of h to t is gotten

2

2

2

l v

l v

h gt C

= +

+

(12)

When t=0, u=0, h=0, there is, C

2

=0.

2

1

2

h Wt =

, ( ) 2

2

l v

l v

W g

=

+

(13)

Then the relation of time t with height h is

2h

t

W

=

(14)

Substitute equation (14) into equation (6), then integrate it

3

2

0

2 2 2

3

H

in in

v

fg v fg v

d q d q

V hdh H

h W W h

= =

}

(15)

For the evaporator, the geometrical relations are as

2

1

4

l in

V d H =

(16)

2

4

t in

V d H =

(17)

t v l

V V V = +

(18)

Substitute equations (16)~(18) into equation (15), there is

3

2

1

8 2

0

3

fg v in

q

H H H

W h d

+ =

(19)

H

h

dh

Liquid

Vapor

Bubble

H

e

a

t

Q

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

3

Equation (19) expresses the equivalent position H

1

of vapor-liquid

mixture in the evaporator. The mean velocity of vapor bubble at

position h is also obtained as

( )

0

1 2

2 2

3

H h

u Whdh W H h

H h

= =

}

(20)

The flow cross-section of vapor in the evaporator can be written as

( ) 3

2 2

in

void

fg v fg v

q D H h d q H h

A

h u h W

= =

(21)

The mean liquid flow velocity is balanced by

( )

2

4

in e fg void v

l

l in void

d l q h uA

u

d A

(22)

So, at position h, the density of vapor-liquid mixture in the

evaporator is

( )

( )

( ) 2 3

void l void v

h l l v

in fg v

A A A H h q

A d h W

+

= =

(23)

The dynamic viscosity of the vapor-liquid mixture in the evaporator

can be calculated by the Cicchitti equation

(1 )

m v l

x x = +

(24)

Then the equivalent Reynolds number can be gotten to calculate the

flow resistance.

2.3 Condenser Calculation

For a two-phase loop thermosyphon, the condensation heat transfer has

many differences compared with those of classical Nusselt theory. The

vapor flowing, the shear stress of the vapor-liquid interface should not

be neglected.

Based on the Nusselt theory, the frictional shear stress and that of

the momentum transfer due to the velocity difference between the

vapor and liquid are added to the analysis of condensation and flow in

the two-phase loop thermosyphon.

Fig. 4 Liquid film and vapor downward flows in the condenser.

As illustrated in Figure 4, the momentum equation of liquid film

flow is given as

( )

2

2

0

l

l v l

u dp

g

dx y

| |

+ + =

|

\ .

(25)

The energy equation becomes the following

2

2

0

l

T

y

(26)

The boundary conditions are as follows

At y=0, u

l

=0; T

l

=T

w

(27)

At y=,

l v

l y

u

y

; T

l

=T

v

(28)

Ignore the pressure gradient along the y direction, integrate

equation (25), together consider equation (28)

( ) ( ) 0

l

l v v l

du dp

g y

dx dy

| |

(

+ =

|

(

\ .

(29)

Integrate equation (29), together consider boundary condition (27)

( )

2

0

2

l v v l l

dp y

g y y u

dx

| |

(

+ =

|

(

\ .

(30)

So the liquid film velocity is expressed as

( )

2

1

2

v

l l v

l l

y dp y

u g y

dx

| |

(

= +

|

(

\ .

(31)

Substitute y= into equation (31)

( )

2

1

2

v

l l v

l l

dp

u g

dx

(

= +

(

(32)

Where

v

is the shear stress between the flowing vapor and liquid

due to two reasons. One is that of friction,

f

, the other is from the

momentum transfer owing to the condensation,

m

.

v f m

= +

(33)

( )

2 1

,

2

f f v l v l

C u u u u

= >

(34)

( )

2 1

,

2

f f v l v l

C u u u u

= <

(35)

Where, the friction coefficient C

f

depends on the vapor Reynolds

number

Re

v v l v

v

v

u u d

=

(36)

16 Re

f v

C =

Re 2000

v

<

(37)

0.33

Re 1525

f v

C =

2000 Re 4000

v

< <

(38)

0.25

0.079Re

f v

C

=

4000 Re 30000

v

< <

(39)

0.2

0.046Re

f v

C

=

6

30000 Re 10

v

< <

(40)

( ) ,

c

m v l v l

fg

q

u u u u

h

= >

(41)

( ) ,

c

m v l v l

l

fg

q

u u u u

h

= <

(42)

At the condenser entrance, the vapor velocity is maximum

max

4

c c

fg v v

l q

u

h d

=

(43)

For the mass flow rate of liquid film, there is

0

2

2

in

l l l

d

m y u dy

| |

=

|

\ .

}

(44)

in c

l

fg

d xq

m

h

=

(45)

Consider equations (30), (44) and (45), there is

Liquid film

Vapor

l

c

x

dx

u

v

u

l

H

e

a

t

Q

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

4

( ) ( )

4 3

2

4

25 6 3

4 2

v

l v l v

v l c

fg

dp d dp

g g

dx dx

d dxq

h

( (

+

`

( (

)

+ =

(46)

Based on equation (45), there is

2

2

4 4

4

l c

v

in v v fg

in v

m m xq m

u

d d h

d

= =

(47)

The vapor flow diameter is given as

2

v in

d d =

(48)

2.4 Vapor Line, Circular Liquid Film Line and Liquid

Line Calculations

For the vapor line, the upward vapor flow is single phase, the mean

vapor flow velocity is constant at each cross-section. Equation (3)

becomes

4

sin

w

v

dp

g

ds D

=

(49)

In equation (49),

w

is the viscous force between the vapor and the

tube wall.

2

2

f

w v v

C

u =

(50)

In equation (50) C

f

is calculated by equations (36)~(40).

The pressure loss includes local effect, that is calculated by the

common fluid formula.

2

1

2

local v v

p u =

(51)

Where, is the local flow resistance coefficient.

The liquid line consists of the liquid film part and the single phase

liquid part. Considering these two parts and the boundary, as illustrated

in Figure 5, the working liquid position should be balanced by the

operating conditions.

For the liquid film flow in the liquid line, the core vapor does not

flow, the momentum equation becomes simple type as

v

dp

g

ds

=

(52)

For the single phase liquid flow line, the inertial term is zero due to

the constant liquid velocity.

sin

w

l

P dp

g

ds A

=

(53)

For the whole two-phase loop thermosyphon, the liquid amount of

working fluid is selected just exactly the best filling. Then there is no

excess working fluid to entrain the influential liquid, increase the flow

resistance and worsen the heat transfer and flow.

3. RESULTS AND DISCUSSION

The calculation procedures are as follows. (1) Modeling of the

evaporator. The heating tube is divided by n differential parts. The

frictional coefficient of each evaporator cross-section is different,

however, it is constant in each part. The vapor bubble velocity is

calculated. Then the frictional pressure drop, the inertial pressure drop,

the gravitational drop can be obtained. Further, the total liquid amount

needed in the evaporator and the equivalent operating height H

1

are

determined. (2) Calculating of the condenser. Holding together

equations (31)~(41), (46), (47) and (3), the frictional, inertial and

gravitational pressure drops, and the total pressure drop are obtained.

The total working fluid in condenser can be gotten by integrating the

liquid film flow and the core vapor flow. (3) Calculating of the vapor

line, liquid line and the local resistance. The liquid line consists of the

liquid film flow line and the single liquid flow line. The latter is shown

in Figure 5, the equivalent length is L. The length H

2

is first assumed,

the original value can be a little increase of the previous obtained H

1

.

By increasing the height step many times, the circulation results are

obtained and compared. The criteria to stop the calculation can be as,

L L"

H

2

L'

H

1

H

t

H

H

0

E

v

a

p

o

r

a

t

o

r

C

o

n

d

e

n

s

e

r

V

a

p

o

r

l

i

n

e

L

i

q

u

i

d

l

i

n

e

Filling

liquid

position

Working

liquid

position

Equivalent

working liquid

position

C

o

n

d

e

n

s

e

r

V

a

p

o

r

f

l

o

w

L

i

q

u

i

d

f

i

l

m

f

l

o

w

L

i

q

u

i

d

f

l

o

w

H

e

a

t

Q

H

e

a

t

Q

Fig. 5 Liquid positions before and after startup of a two-phase loop thermosyphon

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

5

the total flow resistance of the whole loop thermosyphon will be

approaching zero very much by the last step increased. Then the several

height positions, the related parameters could be analyzed.

3.1 Vapor-liquid Mixture of Evaporator

For evaporator, if the basic geometrical parameters are given, then the

density of vapor-liquid mixture along the heating tube can be obtained

by equation (23).

The length of the heating tube is 412mm, the inner diameter is

26mm and 20mm. Water is taken as the working fluid. The two-phase

loop thermosyphon works at saturation temperature 100 . The

thermosypnon is filled at the best filling rate, there is no excess liquid

to increase the flow resistance. Three heat flux are selected as 21.5,

28.6 and 35.8 kW/m

2

.

-0.05 0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45

300

400

500

600

700

800

900

1000

Water

T

v

=100

o

C

H =412 mm

d

in

= 26 mm

q =21.5

q =28.6

q

=35.8 kW/m

2

,

k

g

/

m

3

x, m

Fig. 6 Density of vapor-liquid mixture in evaporator as a function of

heating tube height

Figure 6 shows the density distribution along the height. At the

evaporator entrance, the liquid density is the initial. Along the upward

direction, the vapor bubbles are increased more and more. So the

density will decrease gradually. And for the higher heat flux, the

density is smaller at the same cross-section. Such results mean that the

higher heat flux corresponds to the less working fluid in the evaporator.

These results could be used by the selection of the diameter and the

length of the evaporator assembly. Another result is that at the exit of

the evaporator, the density of the vapor-liquid mixture is not that of the

vapor. It depends on the balance of the vapor bubble flow rate, that is,

the phase change heat transfer. In order to guarantee that no dry-out

point occurs, the heat flux should be less one boundary limit to the

evaporator..

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45

0.0

0.5

1.0

1.5

2.0

2.5

3.0

Water

T =100

o

C

H =412 mm

d

in

= 26 mm

u

,

m

/

s

x, m

Fig. 7 Velocity of vapor in evaporator versus heating tube height

Figure 7 demonstrates the mean vapor bubble velocity at different

axial position in the evaporator. The curve is like one parabolic shape.

At the initial point, x=0, the velocity is zero. At the exit, x=412mm, the

mean bubble velocity u=2.68m/s. And for different heat flux, the

velocity curve is the same. Equation (20) also tells that the velocity is

only related with axial position and the physical properties.

For the liquid flow in the evaporator, by equation (22), the velocity

at different heat flux and different axial position is illustrated in Figure

8. Compared the results with those of Figure 7, the liquid velocity is

three order quantity less than that of the vapor. So, the liquid flow

velocity can nearly be neglected, no matter from the point of liquid

flow resistance, or from the point of the comparison with that of the

vapor. At the exit of the evaporator, the liquid velocity is zero. And for

the lower heat flux, the liquid velocity is smaller. However, the axial

maximum liquid velocity will move forward a little, that is the vapor-

liquid equilibrium.

0.0 0.1 0.2 0.3 0.4

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Water

T

v

=100

o

C

H =412 mm

d

in

= 26 mm

q=21.5

q=28.6

q=35.8 kW/m

2

u

l ,

m

m

/

s

x, m

Fig. 8 Velocity of liquid in evaporator versus heating tube height

3.2 Three Liquid Positions and Two Heights

As shown in Figure 5, actually there are three liquid positions. Before

the operating of the two-phase loop thermosyphon, there is a filling

liquid position. The other two liquid positions should be calculated.

One of them is the equivalent working liquid position in the operating

evaporator. The other one, the working liquid position in the liquid line,

is the boundary, dividing the liquid film flow and the single phase

liquid flow.

Corresponding to the above three positions, there are two heights.

The first height, H, the level difference between the working liquid

position of the liquid line and the equivalent working liquid position of

the operating evaporator. This is believed to be the driving force of the

whole loop thermosyphon. It is mentioned most commonly in some

papers (Chen et al., 1986). And the second height, H

t

, is the position

difference between the initial filling position and the operating position

in the liquid line. This height can be measured by experiment, so it is of

significance.

For the equivalent working liquid position in the evaporator, as

illustrated in Figure 9, the equivalent heights H

1

are orders of 200 mm

for the calculated heat flux range. H

1

will decrease with heat flux,

nearly is a linear relation. That is, the higher heat flux need less

working fluid in the evaporator. And the inner diameter of the heating

tube also exerts influences on the height. If the diameter is replaced

from 26 mm to 20 mm, then the equivalent height will be increased

about 0.05m.

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

6

20 22 24 26 28 30 32 34 36

0.10

0.12

0.14

0.16

0.18

0.20

0.22

0.24

0.26

0.28

Water

T

v

=100

o

C

H =412 mm

d

in

=26

d

in

=20 mm

H

1

,

m

q, kW/m

2

Fig. 9 Equivalent working liquid height of vapor-liquid mixture in

evaporator

As shown in Figure 10, the level difference between the working

liquid position of the liquid line and the equivalent working liquid

position of the operating evaporator, H versus heat flux is presented.

All the calculated H are less than 10mm, this reflects the smaller flow

resistance. So, the two-phase loop thermosyphon can transfer larger

power. For a certain working temperature, H will increase with heat

flux, this reflects the increment of the driving force. If the heat flux is

higher, then the driving force will be affected by the working

temperature a lot. The higher is the temperature, the bigger driving

force. The higher temperature corresponds to the higher pressure. The

higher pressure means the vapor is less expanded, there is less flow

resistance. So, the driving force H can be smaller.

0 10 20 30 40 50 60 70

-2

0

2

4

6

8

10

,

m

m

q , kW/m

2

Water

H =412 mm

d

in

= 26 mm

T

v

=100

T

v

=130

T

v

=150

o

C

Fig. 10 The level difference H, as a function of heat flux

The position difference H

t

, versus heat flux is demonstrated in

Figure 11. The position difference between the initial filling position

and the operating position in the liquid line will increase then decrease

with heat flux. The loci are nearly parabolic. The maximum of H

t

will

increase with temperature and will occur at the higher heat flux.

Further, for one heat flux, the higher temperature corresponds to the

bigger liquid level decrease, H

t

, is bigger. These results are due to the

actions of total flow resistance, physical properties.

10 20 30 40 50 60 70

10

20

30

40

50

60

70

80

90

t

,

m

m

q, kW/m

2

Water

H = 412 mm

d

in

= 26 mm

T

v

=150

T

v

=130

T

v

=100

o

C

Fig. 11 The position difference, between the initial filling position and

the operating position in the liquid line, H

t

, versus heat flux

4. CONCLUSIONS

The two-phase loop thermosyphon is analyzed theoretically. The

evaporator is modeled to describe the flow and heat transfer of liquid

and bubbles. The flow and heat transfer of the condenser, the vapor and

liquid lines are considered theoretically together with the evaporator.

By calculation, some important results are obtained as the following.

(1) For the operating evaporator, the density of the vapor-liquid

mixture at the exit is not that of the vapor. The vapor velocity curve of

different heat flux is the same, the maximum bubble velocity is

2.68m/s. And the liquid velocity is three orders quantity less than that

of the vapor, the liquid flow velocity can nearly be neglected.

(2) The obtained equivalent heights H

1

are orders of 200 mm or

so for the calculated heat flux range. In order to guarantee that no dry-

out point occurs, the heat flux should be less one boundary limit to the

evaporator.

(3) The level difference H, between the working liquid position

of the liquid line and the equivalent working liquid position of the

operating evaporator, stands for the driving force of the whole loop. All

the calculated H are less than 10mm, this reflects the smaller flow

resistance. The two-phase loop thermosyphon can transfer larger power

due to the smaller driving force needed. And the condenser need not be

placed much higher than the evaporator.

(4) The total height drop H

t

, of the liquid line before and after

the loop operating, are orders of several tens of millimeters for the

calculated heat flux range.

ACKNOWLEDGEMENTS

The author thanks Prof. Jifu Liu from Harbin Institute of Technology

for his suggestions and project support about this work.

NOMENCLATURE

A area of cross-section (m

2

)

C coefficient of flow resistance(/)

d diameter(m or mm)

h

fg

latent heat of phase change (J/kg)

H height (m or mm)

l length(m)

m mass flux(kg/s)

p pressure(Pa)

Frontiers in Heat Pipes (FHP), 1, 023004 (2010)

DOI: 10.5098/fhp.v1.2.3004

Global Digital Central

ISSN: 2155-658X

7

P perimeter(m)

q heat flux (W/m

2

, or kW/m

2

)

R bubble radius(m)

Re Reynolds number(/)

s,x coordinate (m)

t time (s)

T temperature ()

u velocity (m/s)

V volume(m

3

)

W parameter defined by equation (13)

Greek Symbols

liquid film thickness (m)

density (kg/m

3

)

coefficient of local flow resistance

shear stress(N/m

2

)

Subscripts

c condenser

e evaporator

f flow, friction

in inner

m momentum

t total

liquid film surface

v vapor

l liquid

REFERENCES

Chen K. S., 1988, Steady-state Analysis of Two Phase Natural

Circulation Loop, International Journal of Heat and Mass Transfer,

31(5), 931-940.

doi:10.1016/0017-9310(88)90082-8

Chen Y., Gao M. and Xin M., 1986, "Experiments of Heat Transfer

Performance of Separate Type Thermosyphon," Proceedings of

International Heat Pipe Symposium, Osaka, Japan.

He J., Ma T. and Zhang Z, 1992, Heat Transfer Characteristics in the

Evaporator Section of a Two-phase Closed Thermosyphon, Advances

in Heat Pipe Science and Technology, Proceedings of the 8th

International Heat Pipe Conference, International Academic

Publishers, 335-340.

Huang B. J., 1988, Heat Transfer Behavior of a Rectangular

Thermosyphon Loop, Journal of Heat Transfer, 110, 437-493

doi:10.1115/1.3250512

Liu X., 1988, Effect of the Filling Ratio of Working Fluids on the

Characteristics of the Two-phase Closed Thermosypnon, Advances in

Phase Change Heat Transfer, Proceedings of International Symposium

on Phase Change Heat Transfer, Chongqing, Sichuang China, 551-556.

Roesler S., 1991, Performance and Performance Limitations of Closed

Two-phase Thermosyphons, Proceedings of the International

Symposium on Heat Pipe Research and Application, Shanghai China,

Japan Association for Heat Pipes, 50-68.

Você também pode gostar

- Shell and Tube Heat ExchangerDocumento36 páginasShell and Tube Heat ExchangerSiti Nurshahira67% (3)

- Qpedia Oct14 Heat Transfer Calculations of ThermosyphonDocumento5 páginasQpedia Oct14 Heat Transfer Calculations of ThermosyphonHMMSPAinda não há avaliações

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Documento2 páginasWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldAinda não há avaliações

- Modelling of tube and fin coils for evaporators and condensersDocumento6 páginasModelling of tube and fin coils for evaporators and condensersAntarip PoddarAinda não há avaliações

- Cable Sizing PDFDocumento8 páginasCable Sizing PDFkumarAinda não há avaliações

- PARTIAL CONDENSER DESIGN CHEMICAL ENGINEERINGDocumento26 páginasPARTIAL CONDENSER DESIGN CHEMICAL ENGINEERINGsegunju50% (2)

- Ground Fault Protection and Coordination in Industrial and Commercial Power SystemsDocumento46 páginasGround Fault Protection and Coordination in Industrial and Commercial Power Systemsgerrzen64100% (1)

- Non Linear Analysis of RC Column PDFDocumento61 páginasNon Linear Analysis of RC Column PDFLabinotMMorinaAinda não há avaliações

- What Are Stiffness Modifiers in EtabsDocumento35 páginasWhat Are Stiffness Modifiers in EtabsHiren Desai50% (2)

- Complette Course On RefrigerationDocumento746 páginasComplette Course On RefrigerationVlad MartianAinda não há avaliações

- The Relevance of YS/UTS RatioDocumento21 páginasThe Relevance of YS/UTS RatiocarrespmAinda não há avaliações

- Faraday Lenz LawDocumento5 páginasFaraday Lenz LawSk BalanAinda não há avaliações

- Ground Water Flow and Well MechanicsDocumento47 páginasGround Water Flow and Well MechanicsZainab JereckoAinda não há avaliações

- Finned Tube Heat ExchangerDocumento15 páginasFinned Tube Heat ExchangerAna Quintana0% (1)

- Model For Calculating Steam Ejector PerformanceDocumento15 páginasModel For Calculating Steam Ejector PerformanceMuhammad KhurramAinda não há avaliações

- Steam Hammer - TheoryDocumento6 páginasSteam Hammer - TheoryktsnlAinda não há avaliações

- Heat and Mass Transfer Calculation of The Intercooler With SprayiDocumento6 páginasHeat and Mass Transfer Calculation of The Intercooler With SprayiBertalan Gyuszi Kristóf0% (1)

- COOLING OF GAS BY WATER SPRAYDocumento8 páginasCOOLING OF GAS BY WATER SPRAYpnshrfbAinda não há avaliações

- Simulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsDocumento14 páginasSimulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsSaidFerdjallahAinda não há avaliações

- Drift Flux Model For Vapor-Liquid Two-Phase Flow Through Short Tube OrificesDocumento4 páginasDrift Flux Model For Vapor-Liquid Two-Phase Flow Through Short Tube OrificesstoicadoruAinda não há avaliações

- CFD Analysis of Shell-and-Tube Heat Exchanger DesignDocumento15 páginasCFD Analysis of Shell-and-Tube Heat Exchanger DesignHari SimhaAinda não há avaliações

- Modeling of Geothermal Water Cooling SystemDocumento7 páginasModeling of Geothermal Water Cooling Systemsum1else4Ainda não há avaliações

- CFD Analysis of Mixing and Residence Time Distribution in Cool Flame VaporizersDocumento7 páginasCFD Analysis of Mixing and Residence Time Distribution in Cool Flame VaporizersKahwai WongAinda não há avaliações

- Air Entrainment - 02Documento16 páginasAir Entrainment - 02ThejaswiniAinda não há avaliações

- Two-Phase Condensation Heat Transfer ModelsDocumento14 páginasTwo-Phase Condensation Heat Transfer Modelsaldaadrina100% (1)

- Energies 12 03266Documento14 páginasEnergies 12 03266BillyAinda não há avaliações

- Thermo CEPDocumento9 páginasThermo CEPm.sheraz malikAinda não há avaliações

- Alternative design approach for spiral plate heat exchangersDocumento6 páginasAlternative design approach for spiral plate heat exchangers1940LaSalleAinda não há avaliações

- A Simplified Model For Real Gas Expansion Between Two Reservoirs Connected by A Thin TubeDocumento14 páginasA Simplified Model For Real Gas Expansion Between Two Reservoirs Connected by A Thin TubeSatyanarayan SahooAinda não há avaliações

- Droplet Evaporation With Reference To The Effectiveness of Water Mist CoolingDocumento9 páginasDroplet Evaporation With Reference To The Effectiveness of Water Mist CoolingWhidas PrihantoroAinda não há avaliações

- FueldnerDocumento6 páginasFueldnerali105Ainda não há avaliações

- Thermal Resistance of Steam Condensation in Horizontal Tube BundlesDocumento8 páginasThermal Resistance of Steam Condensation in Horizontal Tube BundlesRavinder SinghAinda não há avaliações

- Transient Simulation of Vapor LiqDocumento5 páginasTransient Simulation of Vapor LiqsantoshkumarvenuAinda não há avaliações

- Study of Two-Dimensional Heat and Mass Transfer During PDFDocumento11 páginasStudy of Two-Dimensional Heat and Mass Transfer During PDFali105Ainda não há avaliações

- Czasopismo Techniczne Volume 3 (2017) 16Documento14 páginasCzasopismo Techniczne Volume 3 (2017) 16nidhul07Ainda não há avaliações

- A.zerrouki Et El The Natural Circulation Solar Water Heater ModelDocumento11 páginasA.zerrouki Et El The Natural Circulation Solar Water Heater ModelJuan-Pierre HerbothAinda não há avaliações

- Theoretical and Numerical Analysis of Heat Transfer in Pipeline SystemDocumento9 páginasTheoretical and Numerical Analysis of Heat Transfer in Pipeline SystemSigit MaulanaAinda não há avaliações

- Condensers and EvaporatorsDocumento28 páginasCondensers and EvaporatorsJerico LlovidoAinda não há avaliações

- Fluid Damper: Created in COMSOL Multiphysics 5.3aDocumento20 páginasFluid Damper: Created in COMSOL Multiphysics 5.3aVirat DesaiAinda não há avaliações

- An Engineering Model of Coils and Heat Exchangers For HVAC System Simulation and OptimizationDocumento6 páginasAn Engineering Model of Coils and Heat Exchangers For HVAC System Simulation and Optimizationsilentsoldier781344Ainda não há avaliações

- Romanov 2011Documento13 páginasRomanov 2011jalestAinda não há avaliações

- Heat Transfer Tutorial For Heat ExchangersDocumento0 páginaHeat Transfer Tutorial For Heat ExchangersvicopipAinda não há avaliações

- Heat Transfer Processes in Detergent IndustryDocumento17 páginasHeat Transfer Processes in Detergent Industryعبدالمحسن علي EAinda não há avaliações

- ContentDocumento13 páginasContentSaidAinda não há avaliações

- A Simplified Procedure For Calculating C PDFDocumento11 páginasA Simplified Procedure For Calculating C PDFsumayaAinda não há avaliações

- International Journal of Thermal Sciences: F.J. AriasDocumento4 páginasInternational Journal of Thermal Sciences: F.J. AriasPrashant IngaleAinda não há avaliações

- Modelling of Heat and Mass Transfer Involving Vapour Condensation in The Presence of Non-Condensable GasesDocumento4 páginasModelling of Heat and Mass Transfer Involving Vapour Condensation in The Presence of Non-Condensable GasesSOCRATESAinda não há avaliações

- Nonlinear Observer Design For Two-Phase Flow Heat Exchangers of Air Conditioning SystemsDocumento6 páginasNonlinear Observer Design For Two-Phase Flow Heat Exchangers of Air Conditioning SystemsRajwinder SinghAinda não há avaliações

- Vertical ConderDocumento9 páginasVertical Condermanoj kumarAinda não há avaliações

- Design of SRU Thermal Reactor and Waste Heat Boiler Considering Recombination ReactionsDocumento8 páginasDesign of SRU Thermal Reactor and Waste Heat Boiler Considering Recombination ReactionsNandha KumarAinda não há avaliações

- Maxwell'S Demon in The Ranque-Hilsch Vortex Tube: 10.1103/physrevlett.109.054503Documento4 páginasMaxwell'S Demon in The Ranque-Hilsch Vortex Tube: 10.1103/physrevlett.109.054503rahulrampal1988Ainda não há avaliações

- Empirical Relations For Pipe and Tube FlowDocumento11 páginasEmpirical Relations For Pipe and Tube FlowChemical EngineeringAinda não há avaliações

- Optimum Height of Cooling TowerDocumento15 páginasOptimum Height of Cooling TowerwaqashabibAinda não há avaliações

- Cálculo Radiación ValvulasDocumento5 páginasCálculo Radiación ValvulasmarcmanichAinda não há avaliações

- Cylinder Flow Heat TransferDocumento18 páginasCylinder Flow Heat Transfermalek mustafaAinda não há avaliações

- DPHX Report G5Documento13 páginasDPHX Report G5Engr. AbdullahAinda não há avaliações

- International Journal of Thermal Sciences: Jonathan Dallaire, Louis Gosselin, Alexandre K. Da SilvaDocumento9 páginasInternational Journal of Thermal Sciences: Jonathan Dallaire, Louis Gosselin, Alexandre K. Da SilvaDelian KurniawanAinda não há avaliações

- Shell and Tube Heat ExchangerDocumento12 páginasShell and Tube Heat ExchangerZi ChingAinda não há avaliações

- Laporan He Stem To Water: Teknik Kimia Program Studi Petro Dan Oleo Kimia Politeknik Negeri Samarinda Tahun Akademik 2018Documento15 páginasLaporan He Stem To Water: Teknik Kimia Program Studi Petro Dan Oleo Kimia Politeknik Negeri Samarinda Tahun Akademik 2018Getrudis PhipinTri JanuartiAinda não há avaliações

- Design and Analysis of Heat Exchanger Evaporator TDocumento7 páginasDesign and Analysis of Heat Exchanger Evaporator TIslamic world 360Ainda não há avaliações

- Heat Exchanger PDFDocumento7 páginasHeat Exchanger PDFlikith333Ainda não há avaliações

- Analysis of liquid–vapor pulsating flow in a U-shaped miniature tubeDocumento8 páginasAnalysis of liquid–vapor pulsating flow in a U-shaped miniature tubeFidel FernandesAinda não há avaliações

- ExchangersDocumento13 páginasExchangersPeter ArmaosAinda não há avaliações

- ERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerDocumento18 páginasERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerNorzaifee NizamudinAinda não há avaliações

- Estudo Sobre A Escolha Do FluidoDocumento7 páginasEstudo Sobre A Escolha Do FluidoEgemael ViesserAinda não há avaliações

- 31 Evaporative Winter and All Year Air Conditioning SystemsDocumento18 páginas31 Evaporative Winter and All Year Air Conditioning SystemsPRASAD326100% (1)

- Corrosion Behavior of Cermet Coatings in Sulfuric AcidDocumento6 páginasCorrosion Behavior of Cermet Coatings in Sulfuric AcidVlad MartianAinda não há avaliações

- Analysis, Measurements - 1999 - Annotated Bibliography - UnknownDocumento19 páginasAnalysis, Measurements - 1999 - Annotated Bibliography - UnknownVlad MartianAinda não há avaliações

- R&AC Lecture 36Documento25 páginasR&AC Lecture 36jadasaripAinda não há avaliações

- PsychrometryDocumento17 páginasPsychrometryChirag GoyalAinda não há avaliações

- Intro To Pumping SystemsDocumento0 páginaIntro To Pumping SystemssatstarAinda não há avaliações

- Easy Tuning of Pid ControllerDocumento9 páginasEasy Tuning of Pid ControllerVlad MartianAinda não há avaliações

- Transient Heat Transfer 1d Simulations For Electrical Vehicle Battery Using Openmodelica Software PackageDocumento14 páginasTransient Heat Transfer 1d Simulations For Electrical Vehicle Battery Using Openmodelica Software PackageVlad MartianAinda não há avaliações

- 2009 Djebedjian Mans Eng JDocumento21 páginas2009 Djebedjian Mans Eng JanghelexAinda não há avaliações

- 1.3 Kinematic Transport Theorem: ZZZ ZZZ ZZDocumento4 páginas1.3 Kinematic Transport Theorem: ZZZ ZZZ ZZrcgt500Ainda não há avaliações

- Tatara, Lupia - Assessing Heat Exchanger Performance Data Using Temperature Measurement Uncertainty - 2011Documento12 páginasTatara, Lupia - Assessing Heat Exchanger Performance Data Using Temperature Measurement Uncertainty - 2011Vlad MartianAinda não há avaliações

- Practical Applications of Taguchi Method For Optimization of Processing Parameters For Plastic Injection Moulding: A Retrospective ReviewDocumento12 páginasPractical Applications of Taguchi Method For Optimization of Processing Parameters For Plastic Injection Moulding: A Retrospective ReviewVlad MartianAinda não há avaliações

- Patankar NHTFF 1980Documento205 páginasPatankar NHTFF 1980cuerbassAinda não há avaliações

- Melting and SolidificationDocumento0 páginaMelting and SolidificationVlad MartianAinda não há avaliações

- ParaView Tutorial: Visualizing DataDocumento129 páginasParaView Tutorial: Visualizing DataVlad MartianAinda não há avaliações

- Modelarea A A BateriilorDocumento67 páginasModelarea A A BateriilorVlad MartianAinda não há avaliações

- Mechanics and Free Fall - FIDPDocumento4 páginasMechanics and Free Fall - FIDPAustin Capal Dela Cruz100% (1)

- WKST - 1.4 Converting Graphs - ChallengeDocumento8 páginasWKST - 1.4 Converting Graphs - Challengefaltu accountAinda não há avaliações

- Pemfc Modeling Mvkf25Documento37 páginasPemfc Modeling Mvkf25Xiaoqiang zhangAinda não há avaliações

- To Determine Angle of Minimum Deviation For A Given Prism by Plotting A Graph Between Angle of Incidence and Angle of Deviation PDFDocumento6 páginasTo Determine Angle of Minimum Deviation For A Given Prism by Plotting A Graph Between Angle of Incidence and Angle of Deviation PDFriyanmedhi04Ainda não há avaliações

- Surface Area of A Semi-Cylinder WorksheetDocumento1 páginaSurface Area of A Semi-Cylinder WorksheetvirtualmathsAinda não há avaliações

- Shaft Critical SpeedDocumento8 páginasShaft Critical SpeedkannanjuAinda não há avaliações

- Fourier's Law Heat Transfer ExperimentDocumento7 páginasFourier's Law Heat Transfer ExperimentAman SinhaAinda não há avaliações

- Applications Using The Partial Differential Equation ToolboxDocumento11 páginasApplications Using The Partial Differential Equation ToolboxIgor WosniakAinda não há avaliações

- Motion of Charged Particles in Electric Fields W BlanksDocumento4 páginasMotion of Charged Particles in Electric Fields W BlanksAshir50% (2)

- Apllied Electric Circuit Objective Question and AnswerDocumento42 páginasApllied Electric Circuit Objective Question and AnswerGanesan KandasamyAinda não há avaliações

- 2 Alternating CurrentsDocumento20 páginas2 Alternating CurrentsJaseela NaufalAinda não há avaliações

- Design of 6.6 KV, 100 A Saturated DC Reactor Type Superconducting Fault Current LimiterDocumento4 páginasDesign of 6.6 KV, 100 A Saturated DC Reactor Type Superconducting Fault Current LimiterwaleedkhanpelAinda não há avaliações

- Reduction To Functions of Positive Acute AnglesDocumento8 páginasReduction To Functions of Positive Acute Anglesx seyiAinda não há avaliações

- Applied MathematicsDocumento119 páginasApplied MathematicsIAMMARKSAinda não há avaliações

- Solution Recording and Playback Vortex SheddingDocumento27 páginasSolution Recording and Playback Vortex SheddingerenAinda não há avaliações

- Forces and Gravity QuestionsDocumento4 páginasForces and Gravity QuestionsJan DefrAinda não há avaliações

- 13C NMR Spectroscopy of Coumarin DerivativesDocumento18 páginas13C NMR Spectroscopy of Coumarin DerivativesGeorge MoshiashviliAinda não há avaliações

- Design and Fabrication of Hand Water Pump Operated by A PendulumDocumento6 páginasDesign and Fabrication of Hand Water Pump Operated by A PendulumAyyanrajAinda não há avaliações

- Sae Technical Paper Series: Tankut Acarman and Umit OzgunerDocumento9 páginasSae Technical Paper Series: Tankut Acarman and Umit OzgunerLeonel Bejar VelardeAinda não há avaliações

- Change of Order of IntegrationDocumento4 páginasChange of Order of IntegrationShubham Teju100% (2)

- EE207 Problem Set 1Documento2 páginasEE207 Problem Set 1Rishabh AgarwalAinda não há avaliações

- CH 04Documento17 páginasCH 04Vishal PanwarAinda não há avaliações