Escolar Documentos

Profissional Documentos

Cultura Documentos

Welding Visual Check Procedure

Enviado por

endri2000Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Welding Visual Check Procedure

Enviado por

endri2000Direitos autorais:

Formatos disponíveis

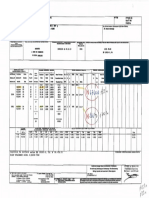

Owner: KPIC

Costumer: Namvaran

Stack-4201

namvaran Consulting Engineers

Managers

Location: Kermanshah- Iran

Document No.: SEC-PJ045-ST-IFP-0010

K.P.I.C.

SEC-Project No.: PJ045

WELDING VISUAL INSPECTION PROCEDURE

Purchaser review and comment shall not be assumed to indicate either responsibility or liability f or accuracy and completenes of this document or to alter any contractual terms and conditions. Item Numbers: S-4201 Purchasers Disposition No Comments Comments as Noted Rejected

Date

Name

Initial

SDRL Code A 60

Purchase Order No. I-41D1-B213-01

Document No.

Rev. 02

SEC-PJ045-ST-IFP-0010

02 01 Rev.

02.08.2004 20.06.2004 Issue Date

COMMENT AS NOTED ISSUED FOR COMMENT

DESCRIPTION

M.Z H.H

PRD. BY

M.Z M.Z

CHKD. BY

M.S.KH M.S.KH

APPR. BY

DISCIPLINE

Quality Assurance System Welding Visual Inspesction Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 2 of 5

Contents: 1- PURPOSE 2- SCOPE 3- RESPONSIBILITY 4- REFERANCE STANDARD 5- DESCRIPTION 6- ACCEPTANCE STANDARD 7- TEST REPORT 8- DOCUMENTION

Quality Assurance System Welding Visual Inspesction Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 3 of 5

WELDING VISUAL INSPECTION PROCEDURE

1) PURPOSE This procedure describes the inspection method for visual inspection of welded joints. 2) SCOPE The following procedure covers the general requirement for welding visual inspection of steel structure parts and header boxes relevant to air cooled heat exchangers.

3) RESPONSIBILITY All welded joints shall be inspect and reported by qualified welding inspector under supervision of quality control manager.

4) REFERENCE STANDARD i) ii) iii) Project specification ASME VIII & ASME V API 661

5) DESCRIPTION 5.1- All joint preparation shall be control by welding inspector before commencement of any welding activity. 5.2- The bevel preparation shall be according to welding details and project drawing or specification, and also the weld seams to be cleaned and free of oil, dust and other contamination before performance of welding activity. 5.3- Butt weld shall be aligned and retained in position during welding. Misalignment will be within the tolerances as per ASME VIII. Div.1 UW-31 5.4- Component may be assembled by bars, clamps, tack welds or other suitable methods. Tack welding of base metal outside area interested by welding shall be avoided whenever possible. Material used for tack welding shall be compatible with base metal.

Quality Assurance System Welding Visual Inspesction Procedure 6) ACCEPTANCE STANDARD

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 4 of 5

6.1- Surface of welded joints shall be sufficiently uniform, free from coarses, ripples, sharp corners, interpass valleys and shall be suitable for performance of required NDE. The following acceptance criteria apply: ASME sec. VIII Div 1- ASME V and project specification. 6.2-. Cracks, lack of fusion, lack of penetration: Not acceptable 6.3- Undercuts: Max. depth 0.8 mm or 10% of base metal thickness (whichever is less) without however reducing thickness below minimum design thickness. 6.4- Reinforcement: The indication of ASME sec. VIII Div. 1- UW-35 shall be applied. For other defects like porosity, slags, etc. refer to relevant clauses in the applicable code. 7) TEST REPORT All joints shall be inspected visually by manufacturer welding inspector and relevant report shall submit to client authorized inspector for approval.(Attachment 1). 8) DOCUMENTATION Original certificates shall remain in quality control department. One copy to be submitted to client inspector.

Quality Assurance System Welding Visual Inspesction Procedure

Project No. PJ.045

Rev. 02

Date: 02.08.2004 Sheet 5 of 5

SR. NO.

HEADER NO.

JOINT NO.

W. STAMP

RESULT

REMARK

NOTE:

Você também pode gostar

- PEB Specification and Standards With DetailsDocumento15 páginasPEB Specification and Standards With DetailsMujjo SahbAinda não há avaliações

- Structural Steel Inspection ReportDocumento2 páginasStructural Steel Inspection ReportAnnaAinda não há avaliações

- Procedure For Installation of Steel Stair StructureDocumento6 páginasProcedure For Installation of Steel Stair StructureImamah AliAinda não há avaliações

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocumento5 páginasQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Method Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Documento9 páginasMethod Statement No: 04 Fabrication and Installation of Steel Structure SUPPORT (SPS-B065-099) FOR 52-K0624Azel Bumagat94% (18)

- Design Manual For Structural Stainless Steel - 3rdDocumento119 páginasDesign Manual For Structural Stainless Steel - 3rdJianhua WuAinda não há avaliações

- Gedik Kaynak - Gedik WeldingDocumento4 páginasGedik Kaynak - Gedik Weldinga4140110Ainda não há avaliações

- ASME VIII-1 pressure vessel design code and operating conditionsDocumento1 páginaASME VIII-1 pressure vessel design code and operating conditionsNomi KhanAinda não há avaliações

- Analysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareDocumento6 páginasAnalysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareSRINIVAS DAinda não há avaliações

- How To Prevent Control Welding DistortionDocumento2 páginasHow To Prevent Control Welding DistortionNilesh DalviAinda não há avaliações

- 1 Beam Fails Ub305x165x54Documento4 páginas1 Beam Fails Ub305x165x54Elencheliyan PandeeyanAinda não há avaliações

- Structure Method StatementDocumento8 páginasStructure Method StatementIrfanadi PratomoAinda não há avaliações

- DIN 934 NutsDocumento1 páginaDIN 934 NutsleroniusAinda não há avaliações

- Client PresentationDocumento29 páginasClient Presentationapi-254207666Ainda não há avaliações

- Ufgs 33 56 10Documento38 páginasUfgs 33 56 10mohamed fathiAinda não há avaliações

- Bolting NewDocumento6 páginasBolting Newsam_roy124Ainda não há avaliações

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Documento4 páginasIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanAinda não há avaliações

- Apl Apollo PDFDocumento16 páginasApl Apollo PDFAditya ShilkarAinda não há avaliações

- Best Welding Practices (Pernis) : Doel / ScopeDocumento91 páginasBest Welding Practices (Pernis) : Doel / Scopechompink6900100% (1)

- Eureka Air Curtains CatalogueDocumento3 páginasEureka Air Curtains CatalogueSumit BhandariAinda não há avaliações

- Welding Symbol enDocumento27 páginasWelding Symbol enAliaa El-BannaAinda não há avaliações

- S275JRDocumento1 páginaS275JRpsaayoAinda não há avaliações

- Purlins Load Tables 1Documento72 páginasPurlins Load Tables 1Mohit NatuAinda não há avaliações

- SteelDocumento22 páginasSteels63et79jgeesdgAinda não há avaliações

- Stainless Steel Tube Stock DataDocumento18 páginasStainless Steel Tube Stock DataFU SHING STAINLESS STEEL CO.Ainda não há avaliações

- STR No. CORE-STR-01 For Fabricated & Galvanized Steel Structures For Ohe & Tss Effective From-21.05.2021Documento79 páginasSTR No. CORE-STR-01 For Fabricated & Galvanized Steel Structures For Ohe & Tss Effective From-21.05.2021Sharad SinghAinda não há avaliações

- Astm 1.05Documento3 páginasAstm 1.05asprclms durgapurAinda não há avaliações

- Perdele Economic B 2VVDocumento4 páginasPerdele Economic B 2VVakitainupufAinda não há avaliações

- A Tig Welding MainsDocumento37 páginasA Tig Welding Mainshiya mistryAinda não há avaliações

- Notes Api650Documento6 páginasNotes Api650MasoodMiyanAinda não há avaliações

- Weld SymbolsDocumento14 páginasWeld SymbolsSureshraaviAinda não há avaliações

- Visual Inspection - AWS & BS PDFDocumento22 páginasVisual Inspection - AWS & BS PDFSelvakpm06Ainda não há avaliações

- List of en Standards: SR No Code/Standard DescriptionDocumento4 páginasList of en Standards: SR No Code/Standard DescriptionAnilAinda não há avaliações

- UB5 Steel Beam Analysis & Design (BS5950Documento4 páginasUB5 Steel Beam Analysis & Design (BS5950yambalaoingjrAinda não há avaliações

- Fusion Welidng Acceptance CriteriaDocumento25 páginasFusion Welidng Acceptance CriteriakarthickenigooAinda não há avaliações

- How To Weld "T-1" Constructional Alloy Steels: ForewordDocumento12 páginasHow To Weld "T-1" Constructional Alloy Steels: ForewordjoseritoAinda não há avaliações

- Weld Cleaning MethodsDocumento7 páginasWeld Cleaning MethodsTrần Thùy LinhAinda não há avaliações

- Everything You Need to Know About WeldingDocumento49 páginasEverything You Need to Know About WeldingproxywarAinda não há avaliações

- S BeamDocumento1 páginaS Beammanu_giteAinda não há avaliações

- BS en 1090 - A Legal Requirement For The Structural Steel Industry (CE Marking)Documento3 páginasBS en 1090 - A Legal Requirement For The Structural Steel Industry (CE Marking)alanlongfieldAinda não há avaliações

- SHS WeldingDocumento42 páginasSHS Weldingrusf123Ainda não há avaliações

- Material Certificate Plate 16mmDocumento1 páginaMaterial Certificate Plate 16mmAdeoyeAinda não há avaliações

- Welding PlanDocumento1 páginaWelding Planapi-298346841Ainda não há avaliações

- Sequence of Works For Mezzanine FloorDocumento8 páginasSequence of Works For Mezzanine FloorMyureshwaranAinda não há avaliações

- Difference between SS316 and SS316L Stainless Steel GradesDocumento1 páginaDifference between SS316 and SS316L Stainless Steel GradesSableen SinghAinda não há avaliações

- British Universal Columns and Beams Weight ChartDocumento6 páginasBritish Universal Columns and Beams Weight ChartSameer SawantAinda não há avaliações

- A Review On Various Welding TechniquesDocumento7 páginasA Review On Various Welding TechniquesIJMER100% (1)

- Crane Rail Erection Presentation for SMS2 PlantDocumento21 páginasCrane Rail Erection Presentation for SMS2 PlantsourajpatelAinda não há avaliações

- Global TolerancesDocumento24 páginasGlobal TolerancesSimbu Arasan100% (1)

- Scale of Professional ChargesDocumento26 páginasScale of Professional Chargesfazal1988Ainda não há avaliações

- ASME Codes for Welding StandardsDocumento5 páginasASME Codes for Welding StandardsIzzadAfif1990Ainda não há avaliações

- Milling OperationDocumento22 páginasMilling Operationnuraini ab rahimAinda não há avaliações

- Indian Standard For Steel Erection ToleranceDocumento5 páginasIndian Standard For Steel Erection ToleranceMartine BareauAinda não há avaliações

- Calculation For IPE200Documento10 páginasCalculation For IPE200HaymanAHMEDAinda não há avaliações

- Blasting &painting Pocedures MTD SOP 15 01Documento1 páginaBlasting &painting Pocedures MTD SOP 15 01vinothAinda não há avaliações

- Heat TreatmentDocumento14 páginasHeat TreatmentAkhilesh KumarAinda não há avaliações

- Structural Steel Spec. and ConstructionDocumento12 páginasStructural Steel Spec. and ConstructionAshwani DograAinda não há avaliações

- Specification for ShacklesDocumento13 páginasSpecification for ShacklesRajendran NairAinda não há avaliações

- Annexure-5-Technical Specification For Structural Steel WorksDocumento20 páginasAnnexure-5-Technical Specification For Structural Steel WorksGarapati Bala KrishnaAinda não há avaliações

- Ect ProDocumento18 páginasEct ProAnonymous gFcnQ4go100% (2)

- Alliance Global Group Inc AGI: Last Close Fair Value Market CapDocumento4 páginasAlliance Global Group Inc AGI: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- Color Test PageDocumento1 páginaColor Test Pageskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- GloDocumento4 páginasGloskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- East West Banking Corp EW: Last Close Fair Value Market CapDocumento4 páginasEast West Banking Corp EW: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- East West Banking Corp EW: Last Close Fair Value Market CapDocumento4 páginasEast West Banking Corp EW: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- GMA Network Inc GMA7: Last Close Fair Value Market CapDocumento4 páginasGMA Network Inc GMA7: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- Filinvest Land Inc FLI: Last Close Fair Value Market CapDocumento4 páginasFilinvest Land Inc FLI: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- Vista Land & Lifescapes Inc VLL: Last Close Fair Value Market CapDocumento4 páginasVista Land & Lifescapes Inc VLL: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- SCCDocumento4 páginasSCCskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- Vista Land & Lifescapes Inc VLL: Last Close Fair Value Market CapDocumento4 páginasVista Land & Lifescapes Inc VLL: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- PLDT Inc Tel: Last Close Fair Value Market CapDocumento4 páginasPLDT Inc Tel: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações

- BXPHARMADocumento4 páginasBXPHARMASayeedAinda não há avaliações

- Vista Land & Lifescapes Inc VLL: Last Close Fair Value Market CapDocumento4 páginasVista Land & Lifescapes Inc VLL: Last Close Fair Value Market Capskynyrd75Ainda não há avaliações