Escolar Documentos

Profissional Documentos

Cultura Documentos

Jung-Fu Lin Et Al - Amorphous Boron Gasket in Diamond Anvil Cell Research

Enviado por

DrebuioDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jung-Fu Lin Et Al - Amorphous Boron Gasket in Diamond Anvil Cell Research

Enviado por

DrebuioDireitos autorais:

Formatos disponíveis

REVIEW OF SCIENTIFIC INSTRUMENTS

VOLUME 74, NUMBER 11

NOVEMBER 2003

Amorphous boron gasket in diamond anvil cell research

Jung-Fu Lin,a) Jinfu Shu, Ho-kwang Mao, and Russell J. Hemley

Geophysical Laboratory, Carnegie Institution of Washington, Washington, DC 20015

Guoyin Shen

Consortium for Advanced Radiation Sources, The University of Chicago, Chicago, Illinois 60637

Received 21 July 2003; accepted 1 September 2003 Recent advances in high-pressure diamond anvil cell experiments include high-energy synchrotron x-ray techniques as well as new cell designs and gasketing procedures. The success of high-pressure experiments usually depends on a well-prepared sample, in which the gasket plays an important role. Various gasket materials such as diamond, beryllium, rhenium, and stainless steel have been used. Here we introduce amorphous boron as another gasket material in high-pressure diamond anvil cell experiments. We have applied the boron gasket for laser-heating x-ray diffraction, radial x-ray diffraction, nuclear resonant inelastic x-ray scattering, and inelastic x-ray scattering. The high shear strength of the amorphous boron maximizes the thickness of the sample chamber and increases the pressure homogeneity, improving the quality of high-pressure data. Use of amorphous boron avoids unwanted x-ray diffraction peaks and reduces the absorption of incident and x rays exiting the gasket material. The high quality of the diffraction patterns makes it possible to rene the cell parameters with powder x-ray diffraction data under high pressure and high temperature. The reactivity of boron prevents its use at high temperatures, however. When heated, boron may also react with the specimen to produce unwanted phases. The relatively porous boron starting material at ambient conditions also poses some challenges for sample preparation. 2003 American Institute of Physics. DOI: 10.1063/1.1621065

I. INTRODUCTION

Recent high-pressure studies using diamond anvil cells DACs provide rich insights into the physical and chemical properties of materials under extreme pressure and temperature conditions. The use of high-energy synchrotron x-ray sources, the development of new gaskets, and new designs of DACs are accelerating advances in this area of research.1,2 A low-Z material, beryllium, has been successfully used as a gasket material since it allows exible access of x rays entering and exiting the DAC axially and radially; such studies have led to discoveries of diverse phenomena under extreme conditions.35 Sample quality under extreme conditions plays an important role for the success of high-pressure experiments, in which the selection of gasket material is a key factor. Rhenium is commonly used as a gasket material because of its high strength, inertness, and ease of use. As a high Z metal, however, rhenium strongly absorbs the incident and exiting x rays and can contribute signicantly to diffracted x rays, preventing its use in many x-ray spectroscopic studies. Beryllium, a low Z element with low x-ray absorption, has served as a useful gasket in high-pressure x-ray spectroscopic studies in a DAC.35 The capability of measuring signals from soft x-ray energies exploits the enormous potential of studying x-ray spectroscopies in a DAC.15 However, since the shear strength of Be is relatively low, the thickness of the sample decreases signicantly with increasing pressure, posing a practical limitation in ultrahigh-pressure x-ray spectroscopic research. Moreover,

a

many laboratories restrict the use of Be gaskets because dust particles of Be inhaled in the drilling process can cause cancer. Diamond, the hardest material known, has also been used as a gasket material in DAC experiments to increase the thickness of the sample, thereby improving the data quality in high-pressure experiments.6,7 Although diamond, with atomic number six, has very low x-ray absorption at hard x-ray energies, its absorption for soft x rays below 10 keV is still very high. The strong diamond powder can produce pits on the diamond culets that degrade performance. A stiff yet light gasket material is therefore ideal for various high-pressure x-ray measurements. The gasket thickness depends only on the size of the diamond culet and the shear strength of the gasket materials, while the x-ray absorption mainly depends on the atomic number. Therefore, amorphous boron is a good candidate gasket material because of its high shear strength and low x-ray absorption. In fact, amorphous boron has been used as a sample chamber in large-volume high-pressure experiments because it is very transparent to x rays and has a low thermal conductivity.8,9 Here we discuss and summarize the use of amorphous boron as a gasket material in high-pressure DAC experiments. The application of the gasket in x-ray diffraction,10 in situ x-ray diffraction in a laser-heated DAC,11,12 radial x-ray diffraction,13 nuclear resonant inelastic x-ray scattering NRIXS , and inelastic x-ray scattering IXS is addressed in detail, and the possibility of using boron gaskets in other high-pressure experiments is also discussed.

II. GASKET AND SAMPLE PREPARATION

Author to whom correspondence should be addressed; electronic mail: j.lin@gl.ciw.edu 4732

Because amorphous boron by itself is too porous to easily use as a gasket material, amorphous boron Alfa Aesar;

2003 American Institute of Physics

0034-6748/2003/74(11)/4732/5/$20.00

Downloaded 04 Nov 2003 to 192.70.249.30. Redistribution subject to AIP license or copyright, see http://ojps.aip.org/rsio/rsicr.jsp

Rev. Sci. Instrum., Vol. 74, No. 11, November 2003

Boron gasket in DAC research

4733

FIG. 1. Photo of Al2 O3 and Pt samples 12:1 by weight at 136 GPa center bright part of the picture . Both transmitted and reected light sources were used. Beveled diamonds with an inner culet of 150 m and an outer culet of 300 m were used. Amorphous boron was used as an inner, insert gasket and rhenium metal was used as an outer gasket to conne the amorphous boron. The sample chamber was originally about 100 m in diameter, and its shape was still well preserved up to 136 GPa. Good x-ray diffraction patterns were collected without interference from diffraction peaks from the gasket material.

FIG. 2. Photo of a Fe0.85Si0.15 sample at approximately 55 GPa center bright part of the picture; approximately 40 m in diameter . Reected illumination was used. Flat diamonds with a culet of 250 m were used. Amorphous boron was used as a gasket insert about 100 m in diameter and a beryllium gasket was used as an outer, conning gasket. A small hole of 50 m was drilled into the inserted boron gasket and used as the sample chamber. This sample conguration has the advantage of the high shear strength of boron and the low x-ray absorption of Be. The sample was used for NRIXS experiments and radial x-ray diffraction experiments see Fig. 6 .

99% pure; part No. 11337 was mixed with epoxy Epoxy Technology; part No. 353ND . Different mixing ratios of boron and epoxy were tested in this study, and the mixture of 4:1 boron:epoxy by weight was found to give the most satisfactory results.1012 The two materials were well mixed with acetone in a mortar and then dried. The mixture was used as a gasket insert in the drilled hole of a metal gasket such as Re, Be, or stainless steel. The metal gasket was preindented to a specic thickness, depending on the size of the culet, and then a hole slightly smaller than the culet was drilled. The hole was lled with the boronepoxy mixture and compressed. Subsequently, another hole of 100 m was drilled and used as the sample chamber Figs. 1 and 2 . For laser-heating experiments, a sandwich sample conguration, consisting of dried NaCl or Al2 O3 as the thermal insulator and pressure medium on both sides of the sample, was used11,12 Fig. 3 . The boronepoxy mixture was also used to make a whole boron gasket, in which the powder mixture was compressed in a press to make a gasket at GSECARS, Advanced Photon Source.13 The size and shape of the gasket are similar to that of a Be gasket. After curing at 400 K for 1 h in a vacuum oven, the center part of the boron gasket was preindented to the desired thickness of approximately 30 m. A hole of 100 m was drilled and used as the sample chamber. The amorphous boron may transform to crystalline boron if the gasket is cured at higher temperature,14 resulting in background diffraction from the crystalline boron gasket.

III. APPLICATIONS AND DISCUSSION

creates a deeper sample chamber, giving stronger x-ray diffraction from a thicker sample and better laser-heating spots due to thicker thermal insulating layers. Moreover, use of the light and amorphous boron minimizes the x-ray absorption by the gasket material and avoids unwanted x-ray diffraction peaks from the gasket.1012 The amorphous boron gasket also provides better hydrostatic conditions in the sample chamber as revealed by the ruby uorescence peaks15 and radial x-ray diffraction measurements4,16 Fig. 4 , because of the higher shear strength of boron. As shown in Fig. 4, the ruby R 1 and R 2 uorescence peaks at approximately 55 GPa are well resolved from each other with the use of the boron gasket, whereas the two peaks would normally overlap each other without the use of a pressure medium at such a pressure i.e.,

The amorphous boron gasket has been applied to various high-pressure DAC experiments: in situ x-ray diffraction in the laser-heated DAC,1012 radial x-ray diffraction,13 NRIXS, and IXS. The amorphous boron provides higher strength and

FIG. 3. Schematic of the sandwiched sample conguration with amorphous boron as a gasket insert and metal Re as a conning gasket in a diamond anvil cell. Beveled diamonds with an inner culet of 150 m and an outer culet of 300 m were used as an example here. The rhenium was preindented to a thickness of 30 m and then a hole of 220 m diameter was drilled into it. An amorphous boron and epoxy mixture 4:1 by weight was then inserted and compressed into the hole. Another hole of 100 m was drilled and used as a sample chamber. Dried NaCl was used as the thermal insulator and pressure medium on both sides of the sample.

Downloaded 04 Nov 2003 to 192.70.249.30. Redistribution subject to AIP license or copyright, see http://ojps.aip.org/rsio/rsicr.jsp

4734

Rev. Sci. Instrum., Vol. 74, No. 11, November 2003

Lin et al.

FIG. 5. LeBail crystal structure renement, performed using the GSAS program, of the x-ray diffraction pattern of (Mg0.39Fe0.61)O collected in an in situ laser-heated DAC experiment at about 102 GPa and 1500 ( 150) K Ref. 12 . The space groups of (Mg0.39Fe0.61)O and NaCl are Fm3 m and Pm3 m, respectively. : Original x-ray diffraction pattern; vertical solid lines and dashed lines: diffraction peaks of (Mg0.39Fe0.61)O and NaCl, respectively; gray curve: background; horizontal solid curve diff : difference in calculated diffraction pattern and original x-ray diffraction pattern after background subtraction.

FIG. 4. Ruby uorescence peaks at approximately 55 GPa using amorphous boron as an insert gasket. Three ruby uorescence spectra numbered according to the wavelength of the R 1 peak are taken from three ruby chips within a region 50 m in diameter. The ruby R 1 and R 2 peaks are well resolved from each other. The standard deviation of the measured pressure of three small ruby chips is 1.3 GPa 1 . The ruby R 1 and R 2 peaks tend to overlap under nonhydrostatic conditions without any pressure medium at around 55 GPa; the use of a stiffer boron gasket reduces the nonhydrostatic conditions in the sample chamber.

gasket in a DAC have been used to study the elasticity and plasticity of materials.4,16 Nonhydrostatic stress is essential and is deliberately produced in the sample without the use of any pressure medium.4,16 The differential stress (t) is t

3 1,

a sample in a Re, Be, or stainless steel gasket only . Since the nonhydrostatic effect on the peak broadening has been minimized, x-ray diffraction peaks can be better resolved. The shape of the sample chamber with an boron gasket inserted is still well preserved even at 136 GPa after many laser-heating cycles Fig. 1 ; this lengthens the lifetime of the sample. Good x-ray diffraction patterns of magnesiowustites and Al2 O3 are obtained up to 102 GPa and 2550 K and 136 GPa and 2800 K, respectively, without any interference from diffraction peaks due to the gasket material and background noise Fig. 5 .12 The high quality of the diffraction patterns makes it possible to rene the cell parameters with powder x-ray diffraction data under high pressure and high temperature Fig. 5 .12 Amorphous boron with boron nitride BN seats has been used to study the structure of amorphous iron to 67 GPa.10 The use of an x-ray transparent BN seat with an amorphous boron gasket insert makes it possible to correct the x-ray absorption and to subtract the background in structural investigation of amorphous materials in a DAC.10 Although boron also has a high melting point and relatively high shear strength at high temperature, care must be taken in using the boron gasket in externally heated DAC experiments because of its high reactivity and possible crystallization at high temperature.14 Radial x-ray diffraction experiments with a Be or boron

where 3 and 1 are axial and radial stress, respectively. A polychromatic x-ray beam is commonly passed through the Be gasket radially, and energy-dispersive x-ray diffraction the angle bepatterns are collected at various steps of tween the diamond cell stress axis and the diffracting plane normal . The d spacing varies linearly with cos2 , d hkl d P hkl 1 1 3 cos2 Q hkl , 2

where the intercept d p (hkl) represents the d spacing under hydrostatic pressure and the slope Q(hkl) is the lattice strain under the uniaxial stress condition.4,16 Shifts in d spacing as a function of can be explained in terms of elastic deformation under stress, whereas the variations in intensities are due to the crystal alignment deduced during plastic deformation.16 The radial x-ray diffraction patterns of hexagonal-close-packed hcp Fe0.85Si0.15 were collected at approximately 59 GPa in a Be gasket and at 55 GPa in a boron gasket insert with a Be conning gasket Fig. 6 . The x-ray diffraction spectra of hcp Fe0.85Si0.15 in the Be gasket are similar to those of hcp Fe Fig. 6 a .4 At low , high intensities are observed for hcp 002 and low intensities for hcp 100 ; at high the opposite is true. The hcp-Fe0.85Si0.15 sample in a boron gasket displays a different intensity distribution Fig. 6 b ; the highest intensity is observed for hcp 10 and for hcp 100 at 60. Shifts in d 002 at the slope Q(hkl) in Eq. 2 in spacings as a function of the two samples are also different, indicating the difference in differential stress (t) conditions and plastic deformation

Downloaded 04 Nov 2003 to 192.70.249.30. Redistribution subject to AIP license or copyright, see http://ojps.aip.org/rsio/rsicr.jsp

Rev. Sci. Instrum., Vol. 74, No. 11, November 2003

Boron gasket in DAC research

4735

FIG. 6. Radial x-ray diffraction patterns of hcp Fe0.85Si0.15 as a function of the angle between the diamond cell stress axis and the diffracting plane normal . a hcp Fe0.85Si0.15 in a Be gasket. b hcp Fe0.85Si0.15 in an amorphous boron gasket insert and a Be outer conning gasket see Fig. 2 .

caused by the gasket materials.16 Therefore, use of amorphous boron complicates interpretation of the preferred orientation and rheology of the sample. In practice, it is not desirable to use a Be gasket for

radial x-ray diffraction with a monochromatic x-ray beam, because diffraction of the crystalline Be contributes signicantly to the signal at the detector. The amorphous boron gasket, on the other hand, allows incoming and diffracted x rays to pass through, that is, the whole diffraction ring can be collected using an area detector.13,17 We have successfully compressed Fe0.9Ni0.1 and Fe0.85Si0.15 alloys to approximately 60 GPa in a boron gasket. The technique has also been used to study the elasticity and rheology of MgO to 47 GPa.13 However, caution should be taken in interpretation of the data, because the essential condition, differential stress, in such experiments is different than that using a Be gasket. The Be gasket is commonly used in NRIXS in a DAC because of its relatively low x-ray absorption above 6 keV.1,18 The thickness of the sample decreases signicantly with increasing pressure due to the relatively low shear strength of the Be gasket. The relatively low shear strength of the Be gasket causes a reduction in sample thickness. NRIXS signals origin only from particular isotopes such as 57 Fe with 14.413 keV x rays, and the materials surrounding the sample do not contribute to the detected signals.18 We used the amorphous boron as a gasket insert in a Be gasket in a high-pressure NRIXS study of a Fe0.85Si0.15 alloy to 55 GPa Fig. 2 . Such sample conguration is found to be very useful because it takes advantage of the high shear strength of boron and the low x-ray absorption of Be. Hence, the thickness of the sample is increased with minimum x-ray absorption, and the nonhydrostatic conditions in the sample chamber are reduced Fig. 4 . This enables NRIXS experiments to reach higher pressures with shorter counting times and higher signal intensity, which were difcult to achieve previously with thin samples in Be gaskets. We have also used the boron gasket insert for highresolution IXS on hcp Fe at 75 GPa at BL35XU, SPring-8. Although using a boron gasket insert increases the sample thickness, the amorphous boron, unfortunately, contributes substantial background, and hinders observation of the longitudinal and transverse acoustic phonons of Fe.19 Such problems may be prevented with use of a crystalline boron gasket such as -boron,20 which should have distinct phonon peaks at high pressures. Boron gaskets should also be useful in IXS for measuring electronic excitations in the study of electronic structures.1 High-resolution x-ray emission spectroscopy has been used to study the magnetic moment of transition metal monoxides such as FeO and MgFe O in a DAC.5,21 The emission spectrum of high-spin Fe is characterized by a main peak K 1,3 with an energy of 7058 eV and a satellite peak K with an energy of 7045 eV. To reduce the loss of x rays due to absorption by diamond anvils, the incident and emitted x rays were passed through the Be gasket.5 Moreover, perforated anvils were used to reduce the large x-ray attenuation of the diamond anvils in the study of x-ray absorption ne structure XAFS .22,23 The increase of sample thickness allowed by using an insert boron gasket with a Be conning gasket would result in better signal intensity and shorter collection times in these experiments. In summary, the advantages of using amorphous boron gaskets are 1 a deeper sample chamber due to the high

Downloaded 04 Nov 2003 to 192.70.249.30. Redistribution subject to AIP license or copyright, see http://ojps.aip.org/rsio/rsicr.jsp

4736

Rev. Sci. Instrum., Vol. 74, No. 11, November 2003

4

Lin et al. H. K. Mao, J. Shu, G. Shen, R. J. Hemley, B. Li, and A. K. Singh, Nature London 396, 741 1998 . 5 J. Badro, V. V. Struzhkin, J. Shu, R. J. Hemley, H. K. Mao, C. C. Kao, J. P. Rueff, and G. Shen, Phys. Rev. Lett. 83, 4101 1999 . 6 R. Boehler, M. Ross, and D. B. Boercker, Phys. Rev. Lett. 78, 4589 1997 . 7 G. Zou, Y. Ma, H. K. Mao, R. J. Hemley, and S. A. Gramsch, Rev. Sci. Instrum. 72, 1298 2001 . 8 J. C. Jamieson and A. W. Lawson, J. Appl. Phys. 33, 776 1962 . 9 J. D. Barnett and H. T. Hall, Rev. Sci. Instrum. 35, 175 1964 . 10 G. Shen, V. B. Prakapenka, M. L. Rivers, and S. R. Sutton, Rev. Sci. Instrum. 74, 3021 2003 . 11 N. Sata, G. Shen, M. L. Rivers, S. R. Sutton, Eos. Trans. AGU 83 19 , Spring Meeting Suppl., Abstract M51B-03 2002 . 12 J. F. Lin, D. L. Heinz, H. K. Mao, R. J. Hemley, J. M. Devine, J. Li, and G. Shen, Proc. Natl. Acad. Sci. U.S.A. 100, 4405 2003 . 13 S. Merkel, H. R. Wenk, J. Shu, G. Shen, P. Gillet, H. K. Mao, and R. J. Hemley, J. Geophys. Res., Solid Earth Planets 107, 2271 2002 . 14 S. O. Shalamberidze, G. I. Kalandadze, D. E. Khulelidze, and B. D. Tsurtsumia, Solid State Phys. 154, 199 2000 . 15 H. K. Mao, J. Xu, and P. M. Bell, J. Geophys. Res., Solid Earth Planets 91, 4673 1986 . 16 H. R. Wenk, S. Matthies, R. J. Hemley, H. K. Mao, and J. Shu, Nature London 405, 1044 2000 . 17 H. K. Mao, J. Shu, Y. Fei, J. Hu, and R. J. Hemley, Phys. Earth Planet. Inter. 96, 135 1996 . 18 H. K. Mao et al., Science 292, 914 2001 . 19 G. Fiquet, J. Badro, F. Guyot, H. Requardt, and M. Krisch, Science 291, 468 2001 . 20 D. N. Sanz, P. Loubeyre, and M. Mezouar, Phys. Rev. Lett. 89, 245501 2002 . 21 J. Badro, G. Fiquet, F. Guyot, J. P. Rueff, V. V. Struzhkin, G. Vanko, and G. Monaco, Science 300, 789 2003 . 22 W. A. Bassett, A. J. Anderson, R. A. Mayanovic, and I. M. Chou, Chem. Geol. 167, 3 2000 . 23 A. Dadashev, M. P. Pasternak, G. Kh. Rozenberg, and R. D. Taylor, Rev. Sci. Instrum. 72, 2633 2001 .

strength of the gasket, thus giving stronger x-ray diffraction from a thicker sample; 2 better laser-heating properties due to thicker thermal insulating layers; 3 a reduction in x-ray diffraction peaks from the gasket material; 4 better hydrostatic conditions in the sample chamber; 5 minimum x-ray absorption from the gasket material. The reactivity of boron prevents its use at high temperatures, however. When heated, boron may also react with the specimen and produce unwanted phases. The relatively porous boron starting material at ambient conditions also poses some challenges for sample preparation.

ACKNOWLEDGMENTS

The authors thank beamlines X17C, NSLS, GSECARS, XOR, HPCAT of APS and BL35XU of SPring-8 for the use of the synchrotron beam time and the ruby uorescence system. APS is supported by U.S. Department of Energy, Basic Energy Sciences, Ofce of Science, under Contract No. W-31-109-ENG-38, and the State of Illinois under HECA. They are grateful to J. Liu, V. Struzhkin, J. Hu, N. Sata, J. Devine, W. Sturhahn, J. Zhao, A. Baron, and S. Hardy for their assistance in this study. This research was supported by DOE and NSF.

1

H. K. Mao, C. Kao, and R. J. Hemley, J. Phys.: Condens. Matter 13, 7847 2001 . 2 R. J. Hemley and H. K. Mao, in Proceedings of the International School of Physics Enrico Fermi Course CXLVII, edited by R. J. Hemley, G. L. Chiarotti, M. Bernasconi, and L. Ulivi Societa Italiana di Fisica, Amsterdam, 2002 , p. 3. 3 R. J. Hemley, H. K. Mao, G. Shen, J. Badro, P. Gillet, M. Hanand, and D. Hausermann, Science 276, 1242 1997 .

Downloaded 04 Nov 2003 to 192.70.249.30. Redistribution subject to AIP license or copyright, see http://ojps.aip.org/rsio/rsicr.jsp

Você também pode gostar

- Plasma Spheroidization of Ceramic Particles PDFDocumento5 páginasPlasma Spheroidization of Ceramic Particles PDFfishvalAinda não há avaliações

- JApplPhys 85 2595 PDFDocumento8 páginasJApplPhys 85 2595 PDFEidelsayedAinda não há avaliações

- JApplPhys 93 3837 PDFDocumento7 páginasJApplPhys 93 3837 PDFEidelsayedAinda não há avaliações

- Reaction Analysis of Initial Oxidation of Silicon by Uv-Light-Excited Ozone and The Application To Rapid and Uniform Sio2 Film GrowthDocumento8 páginasReaction Analysis of Initial Oxidation of Silicon by Uv-Light-Excited Ozone and The Application To Rapid and Uniform Sio2 Film GrowthAmitAinda não há avaliações

- Neutron Shielding MaterialsDocumento4 páginasNeutron Shielding Materialsthe_enthusiast100% (1)

- Band Gap Energy of Pure and Al-Doped Zno Thin Films: F.K. Shan, Y.S. YuDocumento4 páginasBand Gap Energy of Pure and Al-Doped Zno Thin Films: F.K. Shan, Y.S. YuSalim ChahidAinda não há avaliações

- Fluorination Mechanisms of Al 2 O 3 and Y 2 O 3 Surfaces Irradiated by High-Density C F 4 O 2 and S F 6 O 2 PlasmasDocumento6 páginasFluorination Mechanisms of Al 2 O 3 and Y 2 O 3 Surfaces Irradiated by High-Density C F 4 O 2 and S F 6 O 2 PlasmasbitasseomnamAinda não há avaliações

- Zhang 2004Documento5 páginasZhang 2004sivamadhaviyamAinda não há avaliações

- High-Density DLC Films Using Negative Ion SourceDocumento5 páginasHigh-Density DLC Films Using Negative Ion SourceEngels OchoaAinda não há avaliações

- Chemical Bath DepositionDocumento6 páginasChemical Bath DepositionJune AlapaAinda não há avaliações

- Report On Thin FilmsDocumento25 páginasReport On Thin FilmsAbhisikta MishraAinda não há avaliações

- Art:10 1007/BF00619084 PDFDocumento6 páginasArt:10 1007/BF00619084 PDFelectro242Ainda não há avaliações

- Annealing Effect On The Properties of Co-Evaporated Cu4SnS4 FilmsDocumento3 páginasAnnealing Effect On The Properties of Co-Evaporated Cu4SnS4 FilmsInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Pressure-Induced Amorphization of ZrTiCuNiBe Bulk Glass-Forming AlloyDocumento3 páginasPressure-Induced Amorphization of ZrTiCuNiBe Bulk Glass-Forming Alloycat nightAinda não há avaliações

- Critical Parameters To Obtain Yb Doped Lu O and Zno Transparent CeramicsDocumento6 páginasCritical Parameters To Obtain Yb Doped Lu O and Zno Transparent CeramicsSyiera MujibAinda não há avaliações

- Adsorption of Carbon Monoxide on CopperDocumento9 páginasAdsorption of Carbon Monoxide on CopperStefanus Rio RidwanAinda não há avaliações

- Near Infrared Luminescence Properties and Mechanism of High Bismuth-Doped SiO2-Al2O3-La2O3 GlassDocumento11 páginasNear Infrared Luminescence Properties and Mechanism of High Bismuth-Doped SiO2-Al2O3-La2O3 GlasszhenshichanAinda não há avaliações

- Corrosion of Stainless Steel in Chloride SolutionDocumento18 páginasCorrosion of Stainless Steel in Chloride SolutionAna Maria PerezAinda não há avaliações

- Article 10Documento9 páginasArticle 10Maroc EcoloadAinda não há avaliações

- RHenda MRS Proc RevDocumento6 páginasRHenda MRS Proc RevOmar AlshekhliAinda não há avaliações

- High Quality Crystalline Zno Buffer Layers On Sapphire (001) by Pulsed Laser Deposition For Iii-V NitridesDocumento3 páginasHigh Quality Crystalline Zno Buffer Layers On Sapphire (001) by Pulsed Laser Deposition For Iii-V NitridesEidelsayedAinda não há avaliações

- Jin Long 2013Documento7 páginasJin Long 2013diode kcAinda não há avaliações

- TSF, 16-Mec, Elect Prop RF MagSputt Dep Si-Rich SiN Thin FilmsDocumento6 páginasTSF, 16-Mec, Elect Prop RF MagSputt Dep Si-Rich SiN Thin Filmscarlos floresAinda não há avaliações

- PT Cal: Tellurite Glass: A New Candidate For Fiber Devices J.SDocumento17 páginasPT Cal: Tellurite Glass: A New Candidate For Fiber Devices J.ShimamahanAinda não há avaliações

- davidson1987Documento4 páginasdavidson1987shahin774Ainda não há avaliações

- 1 Artículo CorrosiónDocumento16 páginas1 Artículo CorrosiónFabiola CovarrubiasAinda não há avaliações

- BT_APLDocumento4 páginasBT_APLduong nguyenAinda não há avaliações

- Deep Drilling On A Silicon Plate With A Femtosecond Laser: Experiment and Model AnalysisDocumento9 páginasDeep Drilling On A Silicon Plate With A Femtosecond Laser: Experiment and Model AnalysisFranklin DurandAinda não há avaliações

- Investigation of Pitting Corrosion of Diamond-Like Carbon Films Using Synchrotron-Based SpectromicrosDocumento11 páginasInvestigation of Pitting Corrosion of Diamond-Like Carbon Films Using Synchrotron-Based SpectromicrosAnnie LauAinda não há avaliações

- Lei 2019Documento7 páginasLei 2019AYUSH SINGH IET Lucknow StudentAinda não há avaliações

- Structural changes in thin amorphous silicon filmsDocumento7 páginasStructural changes in thin amorphous silicon filmsmileivandaAinda não há avaliações

- Modeling and Experimental Studies of Diffusion Bonding of Inconel 600 To Pyrolytic GraphiteDocumento23 páginasModeling and Experimental Studies of Diffusion Bonding of Inconel 600 To Pyrolytic GraphiteTJPRC PublicationsAinda não há avaliações

- 1 s2.0 S0921452607003730 MainDocumento6 páginas1 s2.0 S0921452607003730 MainBhabaniAinda não há avaliações

- (2013) Photoluminescence and Thermoluminescence Studies of Tb3+ Doped ZnO NanorodsDocumento9 páginas(2013) Photoluminescence and Thermoluminescence Studies of Tb3+ Doped ZnO NanorodsJsjsjs SsjsjdjAinda não há avaliações

- Bhopal2016 - Influence of Annealing Temperature On Structural Properties of ITO PDFDocumento6 páginasBhopal2016 - Influence of Annealing Temperature On Structural Properties of ITO PDFmala sAinda não há avaliações

- Improved Conductivity and Mechanism of Carrier Transport in Zinc Oxide With Embedded Silver LayerDocumento8 páginasImproved Conductivity and Mechanism of Carrier Transport in Zinc Oxide With Embedded Silver LayerAbdul BasitAinda não há avaliações

- 1997 Goldby AIP 气体凝聚源用于团簇的制造和沉积Documento9 páginas1997 Goldby AIP 气体凝聚源用于团簇的制造和沉积1592162022Ainda não há avaliações

- 1-S2.0-S0264127523004161-Main PiezoDocumento12 páginas1-S2.0-S0264127523004161-Main Piezozmaxprom5Ainda não há avaliações

- Alumina and ATH1Documento4 páginasAlumina and ATH1Kathit VasavadaAinda não há avaliações

- Characteristics of Micro-Glass bead/PLA Porous Composite Prepared by ElectrospinningDocumento12 páginasCharacteristics of Micro-Glass bead/PLA Porous Composite Prepared by ElectrospinningNounaAinda não há avaliações

- Investigation on the diffusion of aluminium into SILAR grown SnS thin film using Al/SnS heterostructureDocumento10 páginasInvestigation on the diffusion of aluminium into SILAR grown SnS thin film using Al/SnS heterostructurePushan BanerjeeAinda não há avaliações

- Huang 2006Documento4 páginasHuang 2006LuisaCenchaAinda não há avaliações

- Final Report: Optical Properties of ZBLAN Microspheres Produced in MicrogravityDocumento13 páginasFinal Report: Optical Properties of ZBLAN Microspheres Produced in MicrogravityAmit KumarAinda não há avaliações

- Raman Spectroscopy Studies of Er3-Doped Zinc TelluDocumento6 páginasRaman Spectroscopy Studies of Er3-Doped Zinc TelluYosej ParthAinda não há avaliações

- 06 - 6236-IJOMS - PP 313-320Documento8 páginas06 - 6236-IJOMS - PP 313-320Kikelomo TeslimatAinda não há avaliações

- Rare MetalsDocumento4 páginasRare MetalsmohammadAinda não há avaliações

- Dror, Croitoru - 1990 - Ge-Sn-Se-Te For Infrared Optical Fibers (2) - AnnotatedDocumento9 páginasDror, Croitoru - 1990 - Ge-Sn-Se-Te For Infrared Optical Fibers (2) - AnnotatedJagan KbAinda não há avaliações

- Supercritical Carbon Dioxide Extraction PDFDocumento19 páginasSupercritical Carbon Dioxide Extraction PDF陳信辰Ainda não há avaliações

- Journal of Alloys and Compounds: Yongyong Wang, Wei Zhao, Gong Li, Riping LiuDocumento4 páginasJournal of Alloys and Compounds: Yongyong Wang, Wei Zhao, Gong Li, Riping Liu142520Ainda não há avaliações

- Dependence of The Electrical and Optical Properties On The Bias Voltage For Zno:Al Films Deposited by R.F. Magnetron SputteringDocumento5 páginasDependence of The Electrical and Optical Properties On The Bias Voltage For Zno:Al Films Deposited by R.F. Magnetron SputteringGeetha Sokkian RammanoharAinda não há avaliações

- 7Documento9 páginas7GopalaKrishnan MAinda não há avaliações

- Bo Jap 02Documento6 páginasBo Jap 02Vivek BelaAinda não há avaliações

- Procesamiento y Propiedades de Las Cerámicas BiFeO3 Dopadas Con YbDocumento3 páginasProcesamiento y Propiedades de Las Cerámicas BiFeO3 Dopadas Con Ybana eAinda não há avaliações

- Determination of Aluminum Diffusion Parameters in Silicon: Related ArticlesDocumento6 páginasDetermination of Aluminum Diffusion Parameters in Silicon: Related ArticlesAung ThuraAinda não há avaliações

- Structural Investigation and Gas BarrierDocumento7 páginasStructural Investigation and Gas BarrierVelásquez AndradeAinda não há avaliações

- Amorphous Boron Composite Gaskets For in SituDocumento12 páginasAmorphous Boron Composite Gaskets For in Situviscairsyad96Ainda não há avaliações

- PbO Al2O3 TeO2 GeO2 SiO2 CuODocumento9 páginasPbO Al2O3 TeO2 GeO2 SiO2 CuOhanumatharao kAinda não há avaliações

- 10 1016@j Jnoncrysol 2020 120533Documento6 páginas10 1016@j Jnoncrysol 2020 120533Adha StoreeAinda não há avaliações

- Properties of Amorphous Boron Nitride Thin Films: R. Zedlitz, M. Heintze M.B. SchubertDocumento4 páginasProperties of Amorphous Boron Nitride Thin Films: R. Zedlitz, M. Heintze M.B. Schubertuddeshya shuklaAinda não há avaliações

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Ainda não há avaliações

- Experiment Title: Experiment Number:: Received at ESRFDocumento2 páginasExperiment Title: Experiment Number:: Received at ESRFDrebuioAinda não há avaliações

- S. Ostanin Et Al - Ab Initio Study of The Phase Separation of Argon in Molten Iron at High PressuresDocumento3 páginasS. Ostanin Et Al - Ab Initio Study of The Phase Separation of Argon in Molten Iron at High PressuresDrebuioAinda não há avaliações

- Eva Chamorro-Perez Et Al - Low Argon Solubility in Silicate Melts at High PressureDocumento4 páginasEva Chamorro-Perez Et Al - Low Argon Solubility in Silicate Melts at High PressureDrebuioAinda não há avaliações

- Lkhamsuren Bayarjargal - Recent Developments of The Laser-Heating Facility in Frankfurt and at Petra-IIIDocumento23 páginasLkhamsuren Bayarjargal - Recent Developments of The Laser-Heating Facility in Frankfurt and at Petra-IIIDrebuioAinda não há avaliações

- Hisao Kobayashi Et Al - Phonon Density of States and Compression Behavior in Iron Sulfide Under PressureDocumento4 páginasHisao Kobayashi Et Al - Phonon Density of States and Compression Behavior in Iron Sulfide Under PressureDrebuioAinda não há avaliações

- Leonid Dubrovinsky and Natalia Dubrovinskaia - Novel Superhard MaterialsDocumento20 páginasLeonid Dubrovinsky and Natalia Dubrovinskaia - Novel Superhard MaterialsDrebuioAinda não há avaliações

- Emanuela Giuffre and Franz Saija - Melting Line of Krypton in Extreme Thermodynamic RegimesDocumento10 páginasEmanuela Giuffre and Franz Saija - Melting Line of Krypton in Extreme Thermodynamic RegimesDrebuioAinda não há avaliações

- Kenji Ohta Et Al - Phase Transitions in Pyrolite and MORB at Lowermost Mantle Conditions: Implications For A MORB-rich Pile Above The Core-Mantle BoundaryDocumento12 páginasKenji Ohta Et Al - Phase Transitions in Pyrolite and MORB at Lowermost Mantle Conditions: Implications For A MORB-rich Pile Above The Core-Mantle BoundaryDrebuioAinda não há avaliações

- S. Ono - Chemical Composition of The Earth's Lower MantleDocumento1 páginaS. Ono - Chemical Composition of The Earth's Lower MantleDrebuioAinda não há avaliações

- Wendy R. Panero, Laura Robin Benedetti and Raymond Jeanloz - Transport of Water Into The Lower Mantle: Role of StishoviteDocumento9 páginasWendy R. Panero, Laura Robin Benedetti and Raymond Jeanloz - Transport of Water Into The Lower Mantle: Role of StishoviteDrebuioAinda não há avaliações

- Shigeaki Ono and Takumi Kikegawa - High-Pressure Study of FeS, Between 20 and 120 GPa, Using Synchrotron X-Ray Powder DiffractionDocumento4 páginasShigeaki Ono and Takumi Kikegawa - High-Pressure Study of FeS, Between 20 and 120 GPa, Using Synchrotron X-Ray Powder DiffractionDrebuioAinda não há avaliações

- Zuzana Konopkova and Peter Lazor - Physics and Chemistry of Iron in The Earth's InteriorDocumento1 páginaZuzana Konopkova and Peter Lazor - Physics and Chemistry of Iron in The Earth's InteriorDrebuioAinda não há avaliações

- Zizheng Gong Et Al - High-Pressure Sound Velocity of Perovskite-Enstatite and The Possible Composition of The Earth's Lower MantleDocumento5 páginasZizheng Gong Et Al - High-Pressure Sound Velocity of Perovskite-Enstatite and The Possible Composition of The Earth's Lower MantleDrebuioAinda não há avaliações

- Phase Relationships and Equations of State For Fes at High Pressures and Temperatures and Implications For The Internal Structure of MarsDocumento11 páginasPhase Relationships and Equations of State For Fes at High Pressures and Temperatures and Implications For The Internal Structure of MarsDrebuioAinda não há avaliações

- Falko Langenhorst and Vladimir L. Solozhenko - ATEM-EELS Study of New Diamond-Like Phases in The B-C-N SystemDocumento6 páginasFalko Langenhorst and Vladimir L. Solozhenko - ATEM-EELS Study of New Diamond-Like Phases in The B-C-N SystemDrebuioAinda não há avaliações

- Sang-Heon Shim, Thomas S. Duffy and Guoyin Shen - The Stability and P-V-T Equation of State of CaSiO3 Perovskite in The Earth's Lower MantleDocumento14 páginasSang-Heon Shim, Thomas S. Duffy and Guoyin Shen - The Stability and P-V-T Equation of State of CaSiO3 Perovskite in The Earth's Lower MantleDrebuioAinda não há avaliações

- N.V. Chandra Shekar, P.CH - Sahu and K. Govinda Rajan - Laser Heated Diamond-Anvil Cell (LHDAC) in Materials Science ResearchDocumento8 páginasN.V. Chandra Shekar, P.CH - Sahu and K. Govinda Rajan - Laser Heated Diamond-Anvil Cell (LHDAC) in Materials Science ResearchDrebuioAinda não há avaliações

- Valerie J. Hillgren and R. Boehler - High Pressure Reactions Between Fe-Metal and Mantle SilicatesDocumento2 páginasValerie J. Hillgren and R. Boehler - High Pressure Reactions Between Fe-Metal and Mantle SilicatesDrebuioAinda não há avaliações

- Melting of Tantalum at High Pressure Determined by Angle Dispersive X-Ray Diffraction in A Double-Sided Laser-Heated Diamond-Anvil CellDocumento15 páginasMelting of Tantalum at High Pressure Determined by Angle Dispersive X-Ray Diffraction in A Double-Sided Laser-Heated Diamond-Anvil CellDrebuioAinda não há avaliações

- Akihito Tachiyama, Tadashi Kondo and Tatsuhiro Sakaiya - Chemical Differentiation in Fe-Bearing Minerals in Pressure-Temperature-GradientDocumento1 páginaAkihito Tachiyama, Tadashi Kondo and Tatsuhiro Sakaiya - Chemical Differentiation in Fe-Bearing Minerals in Pressure-Temperature-GradientDrebuioAinda não há avaliações

- L.S. Dubrovinsky Et Al - Study of Laser Heated Iron Using Third Generation Synchrotron X-Ray Radiation Facility With Imaging Plate at High PressuresDocumento7 páginasL.S. Dubrovinsky Et Al - Study of Laser Heated Iron Using Third Generation Synchrotron X-Ray Radiation Facility With Imaging Plate at High PressuresDrebuioAinda não há avaliações

- H.K. Mao, P.M. Bell and R.J. Hemley - Ultrahigh Pressures: Optical Observations and Raman Measurements of Hydrogen and Deuterium To 1.47 MbarDocumento4 páginasH.K. Mao, P.M. Bell and R.J. Hemley - Ultrahigh Pressures: Optical Observations and Raman Measurements of Hydrogen and Deuterium To 1.47 MbarDrebuioAinda não há avaliações

- R. Jeanloz and D.L. Heinz - Experiments at High Temperature and Pressure: Laser Heating Through The Diamond CellDocumento10 páginasR. Jeanloz and D.L. Heinz - Experiments at High Temperature and Pressure: Laser Heating Through The Diamond CellDrebuioAinda não há avaliações

- Anatoly B. Belonoshko and Leonid S. Dubrovinsky- A simulation study of induced failure and recrystallization of a perfect MgO crystal under non-hydrostatic compression: Application to melting in the diamond-anvil cellDocumento11 páginasAnatoly B. Belonoshko and Leonid S. Dubrovinsky- A simulation study of induced failure and recrystallization of a perfect MgO crystal under non-hydrostatic compression: Application to melting in the diamond-anvil cellDrebuioAinda não há avaliações

- M. Muñoz et al- Hyperspectral μ-XANES mapping in the diamond-anvil cell: analytical procedure applied to the decomposition of (Mg,Fe) -ringwoodite at the upper/lower mantle boundaryDocumento9 páginasM. Muñoz et al- Hyperspectral μ-XANES mapping in the diamond-anvil cell: analytical procedure applied to the decomposition of (Mg,Fe) -ringwoodite at the upper/lower mantle boundaryDrebuioAinda não há avaliações

- V. J. Hillgren and R. Boehler - Melting in The Earth's Lower MantleDocumento1 páginaV. J. Hillgren and R. Boehler - Melting in The Earth's Lower MantleDrebuioAinda não há avaliações

- Jung-Fu Lin Et Al - Synchrotron Mössbauer Spectroscopic Study of Ferropericlase at High Pressures and TemperaturesDocumento1 páginaJung-Fu Lin Et Al - Synchrotron Mössbauer Spectroscopic Study of Ferropericlase at High Pressures and TemperaturesDrebuioAinda não há avaliações

- Abby Kavner and Thomas S. Duffy - Pressure-Volume-Temperature Paths in The Laser-Heated Diamond Anvil CellDocumento8 páginasAbby Kavner and Thomas S. Duffy - Pressure-Volume-Temperature Paths in The Laser-Heated Diamond Anvil CellDrebuioAinda não há avaliações

- Peer Reviewed Title:: Lawrence Berkeley National LaboratoryDocumento31 páginasPeer Reviewed Title:: Lawrence Berkeley National LaboratoryDrebuioAinda não há avaliações

- Foerster Circograph 2014 enDocumento6 páginasFoerster Circograph 2014 enTiến NguyễnAinda não há avaliações

- DS2 ManualDocumento98 páginasDS2 ManualLuis CuasqueAinda não há avaliações

- Curtain WallDocumento3 páginasCurtain WalljitenderaAinda não há avaliações

- 8 4078a PDFDocumento5 páginas8 4078a PDFarasAinda não há avaliações

- Aqueous and Polar GPC/SEC Columns: Product GuideDocumento20 páginasAqueous and Polar GPC/SEC Columns: Product GuideCarl KeiferAinda não há avaliações

- Design of Square Footing F2Documento18 páginasDesign of Square Footing F2Mohammed Sumer100% (1)

- The Development of The Residential Steel Framing Industry in Australia - SC - v41 - n1 - J PDFDocumento16 páginasThe Development of The Residential Steel Framing Industry in Australia - SC - v41 - n1 - J PDFDenise2512100% (1)

- TG-500M CRANE SPECIFICATIONSDocumento16 páginasTG-500M CRANE SPECIFICATIONSnamduong368Ainda não há avaliações

- Esse 301 350 Se User ManualDocumento7 páginasEsse 301 350 Se User ManualrahimjondesignerAinda não há avaliações

- Metal Reinforcement - Term PaperDocumento35 páginasMetal Reinforcement - Term PaperDrei ServitoAinda não há avaliações

- Nissan Almera N15 1995-2000 Front SuspensionDocumento30 páginasNissan Almera N15 1995-2000 Front SuspensionŽilvinas-Jonas Lukas MateikisAinda não há avaliações

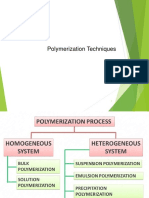

- Polymerisation Practice TEPEDocumento39 páginasPolymerisation Practice TEPEDr. Dure Najaf Iqbal100% (3)

- Production of Wire Via Friction Extrusion of Aluminum Alloy Machining ChipsDocumento7 páginasProduction of Wire Via Friction Extrusion of Aluminum Alloy Machining ChipsMartin DuarteAinda não há avaliações

- Pg032 - o Power LV (N) YyryDocumento1 páginaPg032 - o Power LV (N) YyryDolyAinda não há avaliações

- MNL46 ForewordDocumento16 páginasMNL46 ForewordvonipkoAinda não há avaliações

- Weld Flange To PipeDocumento1 páginaWeld Flange To PipeGraham MooreAinda não há avaliações

- Ajuste de Bomba VRZDocumento37 páginasAjuste de Bomba VRZJose David Huanca Taype100% (1)

- Mobil Delvac Hydraulic 10w Delvac Hydraulic 10w Delivers Excellent PerformanceDocumento2 páginasMobil Delvac Hydraulic 10w Delvac Hydraulic 10w Delivers Excellent PerformanceYordan YupanquiAinda não há avaliações

- Mmaw QDocumento9 páginasMmaw Qf_behdadAinda não há avaliações

- Strengthening Mechanisms PDFDocumento11 páginasStrengthening Mechanisms PDFSelva BabuAinda não há avaliações

- Benefit of Axial Design Waterjet Propulsion - Wartsila PDFDocumento20 páginasBenefit of Axial Design Waterjet Propulsion - Wartsila PDFPandega PutraAinda não há avaliações

- UploadedFile 130150889032970873Documento175 páginasUploadedFile 130150889032970873Sorescu Radu VasileAinda não há avaliações

- Materi5 Biaya Material HandlingDocumento44 páginasMateri5 Biaya Material HandlingIllyas JanuAinda não há avaliações

- Simulation Analysis of Spinning Forming of D6AC Ultrahigh-Strength Low-Alloy SteelDocumento8 páginasSimulation Analysis of Spinning Forming of D6AC Ultrahigh-Strength Low-Alloy SteelmikojmAinda não há avaliações

- Fabrication of Cu Znsns (CZTS) Nanoparticle Inks For Growth of Czts Films For Solar CellsDocumento10 páginasFabrication of Cu Znsns (CZTS) Nanoparticle Inks For Growth of Czts Films For Solar CellsSrinivas MathurAinda não há avaliações

- Gujarat based paver block, tiles and construction material suppliers contact detailsDocumento8 páginasGujarat based paver block, tiles and construction material suppliers contact detailsshahinmandaviyaAinda não há avaliações

- IM Protection Using PSCADDocumento8 páginasIM Protection Using PSCADRavishankar KankaleAinda não há avaliações

- Aalco Metals LTD Aluminium AlloyDocumento2 páginasAalco Metals LTD Aluminium Alloyanwarali1975Ainda não há avaliações

- External NCR MonitoringDocumento7 páginasExternal NCR MonitoringGhayas JawedAinda não há avaliações

- Polypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoDocumento11 páginasPolypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoPrashant SinghAinda não há avaliações