Escolar Documentos

Profissional Documentos

Cultura Documentos

E5 - Geotextiles TDR - Rev00

Enviado por

Mohd Radzi MustaffaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

E5 - Geotextiles TDR - Rev00

Enviado por

Mohd Radzi MustaffaDireitos autorais:

Formatos disponíveis

SPECIFICATIONS SECTION E5 - GEOTEXTILE 5.

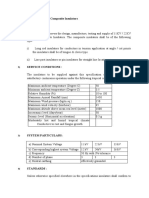

1 Properties of Geotextile There shall be two types of geotextile fabric to be used for the relevant different items of the Works which shall be summarised as follows : a) The following properties of geotextile shall be used in conjunction with the construction of the breakwaters, groyne and the relevant revetment as specified in the Drawings and as directed by the S.O. The geotextile fabric shall be of the woven type, Nicolon HD 625 or approved equivalent, and possess the following minimum properties :Physical Properties Yarn type Polymer Longlife (LL) UV-Protection (UV) Available loops (L) or side loops (S) Hydraulic Properties Permeability (100MM head) NEN 5167) Sieve analysis 0.90 (NEN 5168) Mechanical Properties Warp Breaking Load (DIN 53875) Extension Failure Weft Breaking Load Extension Failure E-modulus Angle Fabric Friction Cone drop (EMPA) CBR (DIN 54307A) Puncture Resistance Tear strength (ASTM) warp weft Shipping Information Weight (DIN 53845 Thickness (DIN 53855) Standard Width Standard Length Roll Diameter Roll Weight split filament PP LL UV (L)

20 L/m2/sec. 300

200 kN/m 15 % 40 kN/m 15 % 3100 kN/m 40 Degr. 6 mm 11kN 3500 N 700 N

625 gr/m2 1.8 mm 5.00 m 200 m 0.65 m 635 Kg

E/5.1

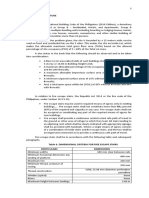

b) The following properties of geotextile shall be used in conjunction with the construction of revetments as specified in the Drawings and as directed by the S.O. The geotextile fabric shall be of the non-woven type, Polyfelt TS-800 or approved equivalent, and of polymer composition containing at least 85% by weight polypropylene or polyesters or polyamides. It shall have been stabilised against ultra-violet light and possess the following minimum properties :a. b. c. d. Fabric Weight : Tensile Strength : Effective Opening Size : Water Permeability under 10 cm constant head. 2 kN/m2 (vertical) not less than 400 g/m2 not less than 24 kN/m not greater than 0.08 mm not less than 120 litres/m2/s (under 10 cm water head)

5.2

Delivery and Storage The geotextile fabric shall be delivered in black polythene wrapper to protect it from the harmful effects of ultra violet rays prior to placement. It shall remain wrapped and stored in a cool and sheltered area until it is to be used.

5.3

Laying of Geotextile (1) Irregularities of the surface shall be levelled before the geotextile fabric is laid. The geotextile shall be laid loosely without stretching and shall conform to the surface such that distortion resulting from the superimposal of stones shall not excessively extend the fibres or tear the fabric. Where geotextile widths/lengths are greater than those supplied, jointing shall be effected by overlapping. When laid under water, a minimum overlap of 0.9m shall be provided in both directions. Above water level, the minimum overlap shall be 0.5m in both directions. Lapped areas and edges shall be weighted down with small amounts of aggregate/fill to keep them in place. After the geotextile has been placed in position and having been inspected by the S.O. or his representative, the various layers of the coastal structures or revetment shall be laid as soon as practicable. Any undue delay in covering the geotextile, which may render it to be deteriorated due to exposure to sunlight, may cause it to be rejected by the S.O. Any geotextile that is left exposed to direct sunlight for a period exceeding 2 weeks shall be rejected and removed from the Site.

(2)

(3)

(4)

E/5.2

Você também pode gostar

- Functional Polymer Coatings: Principles, Methods, and ApplicationsNo EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsNota: 1 de 5 estrelas1/5 (1)

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Ainda não há avaliações

- Cellular Confinement System Specification For Railroad USE DescriptionDocumento5 páginasCellular Confinement System Specification For Railroad USE DescriptionJimmy ThomasAinda não há avaliações

- Specification For Vertical Drains and Surcharge: 1.0 GeneralDocumento13 páginasSpecification For Vertical Drains and Surcharge: 1.0 GeneralrijalianAinda não há avaliações

- Stone ColumnDocumento8 páginasStone ColumnBilal Ahmed BarbhuiyaAinda não há avaliações

- Yachat Repair FacilityDocumento2 páginasYachat Repair FacilityOsama KheadryAinda não há avaliações

- Share 'Compliance 5-6-7 ADSS FiberDocumento6 páginasShare 'Compliance 5-6-7 ADSS FiberShashank SaxenaAinda não há avaliações

- 7sec.700 (Geosynthetics)Documento10 páginas7sec.700 (Geosynthetics)e_manpreetAinda não há avaliações

- Client: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEDocumento2 páginasClient: Jacobs: Waterproofing System For BASEMENT - HIGH WATER TABLEShakil AkhterAinda não há avaliações

- The Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesDocumento3 páginasThe Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesIr Ahmad AfiqAinda não há avaliações

- Design and Fabrication FRP PoolDocumento15 páginasDesign and Fabrication FRP Poolm4004Ainda não há avaliações

- DIVISION 2 - Asignment Technical SpecificationsDocumento4 páginasDIVISION 2 - Asignment Technical SpecificationsPatrisha SantosAinda não há avaliações

- DIVISION 2 - Asignment Technical SpecificationsDocumento4 páginasDIVISION 2 - Asignment Technical SpecificationsPatrisha SantosAinda não há avaliações

- Specifications For Geotextiles in India: by R. P. Indoria 19 November 2010Documento42 páginasSpecifications For Geotextiles in India: by R. P. Indoria 19 November 2010Sandeep MeruguAinda não há avaliações

- 8.2.2 Electrical and Mechanical Characteristics: Dhofar Power Company SAOGDocumento1 página8.2.2 Electrical and Mechanical Characteristics: Dhofar Power Company SAOG54045114Ainda não há avaliações

- AQUAPANEL Cement Board Indoor enDocumento2 páginasAQUAPANEL Cement Board Indoor enDumachita Cosmin AlexandruAinda não há avaliações

- Spec Geocell PDFDocumento9 páginasSpec Geocell PDFsankhaginAinda não há avaliações

- Cable Terminal Kit 2Documento11 páginasCable Terminal Kit 2luiszc2988Ainda não há avaliações

- Part - Vii: Power Cables 7.1 Scope of WorkDocumento21 páginasPart - Vii: Power Cables 7.1 Scope of WorkSri RamAinda não há avaliações

- Sika Geotextile 500gDocumento3 páginasSika Geotextile 500gKumarRamAinda não há avaliações

- TDS-US-Gabion, PoliMac-Jan19Documento2 páginasTDS-US-Gabion, PoliMac-Jan19johnnee98Ainda não há avaliações

- Leaflet SPM and SOPDocumento4 páginasLeaflet SPM and SOPAbdullah Al-ZahraniAinda não há avaliações

- SIKA Waterproofing - External and TankingDocumento10 páginasSIKA Waterproofing - External and TankingmarklesterAinda não há avaliações

- Gabion & Mattress Construction SpecificationDocumento8 páginasGabion & Mattress Construction SpecificationAkmarn Makmur100% (1)

- Alumino Silicate Fibre Mesh Product DataDocumento2 páginasAlumino Silicate Fibre Mesh Product DataKesavan DhuraiAinda não há avaliações

- Section 700Documento25 páginasSection 700Piyush SharmaAinda não há avaliações

- Specification GlassFiberDocumento6 páginasSpecification GlassFiberMukesh MaharjanAinda não há avaliações

- F#1203 SUNLITE Installation 5-06Documento16 páginasF#1203 SUNLITE Installation 5-06wolvewolverineAinda não há avaliações

- Thin Film Strain GaugesDocumento139 páginasThin Film Strain GaugesmhAinda não há avaliações

- Power Systems II Underground CablesDocumento20 páginasPower Systems II Underground CablesKinoti Mugiira NtundaAinda não há avaliações

- Dreno Tex PDFDocumento10 páginasDreno Tex PDFvranceanu.ovidiu-1Ainda não há avaliações

- Sdcs-02-13 Rev. 0 - Roof and Door Canopy Waterproofing SystemDocumento11 páginasSdcs-02-13 Rev. 0 - Roof and Door Canopy Waterproofing Systemkhani gAinda não há avaliações

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Documento5 páginasSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530Ainda não há avaliações

- 23.technical Spec For OFCDocumento16 páginas23.technical Spec For OFCAli RizviAinda não há avaliações

- FibranCatalog PDFDocumento16 páginasFibranCatalog PDFIonut JilAinda não há avaliações

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocumento13 páginasDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikAinda não há avaliações

- Reinforced EarthDocumento4 páginasReinforced EarthAnonymous g1LSaAAinda não há avaliações

- "Physics of Thin Films": Chapter1. IntroductionDocumento7 páginas"Physics of Thin Films": Chapter1. IntroductionEman NasirAinda não há avaliações

- Aijaz Et Al. - Mechanical Properties of Hydrogen Free DLC Thin Films Deposited by HiPIMS With Ne, 2018Documento11 páginasAijaz Et Al. - Mechanical Properties of Hydrogen Free DLC Thin Films Deposited by HiPIMS With Ne, 2018Lara M IharaAinda não há avaliações

- PreStressed Concrete Structures Unit 4 With ANS PDFDocumento7 páginasPreStressed Concrete Structures Unit 4 With ANS PDFNatarajan SaravananAinda não há avaliações

- Epoxy and ESD FlooringDocumento4 páginasEpoxy and ESD Flooringdox4printAinda não há avaliações

- Catalogue Solid Core PDFDocumento16 páginasCatalogue Solid Core PDFtholgasenelAinda não há avaliações

- Bitustick XLSDocumento2 páginasBitustick XLSAbed DaherAinda não há avaliações

- 1104 CC Civil Brochure UKDocumento4 páginas1104 CC Civil Brochure UKwillcrawfordAinda não há avaliações

- BoQ PowerGridDocumento3 páginasBoQ PowerGridParag KulkarniAinda não há avaliações

- QTN For Epoxy and ESD Flooring Dtd.28!2!2012Documento9 páginasQTN For Epoxy and ESD Flooring Dtd.28!2!2012dox4printAinda não há avaliações

- Canada - 2015 - Fiberglass Rods For Modern Composite InsulatorsDocumento6 páginasCanada - 2015 - Fiberglass Rods For Modern Composite InsulatorsgdssgdAinda não há avaliações

- Cable Terminal KitDocumento10 páginasCable Terminal KitJohn ThomasAinda não há avaliações

- Particular Spec For Geocell - Industrial Plots - East RailwayDocumento4 páginasParticular Spec For Geocell - Industrial Plots - East RailwayThameem SharaafAinda não há avaliações

- Datasheet 01 (April 07)Documento8 páginasDatasheet 01 (April 07)Emilian UrsuAinda não há avaliações

- GEOSYNTHETICDocumento5 páginasGEOSYNTHETICAnas IaAinda não há avaliações

- FIBER OPTIC CABLE - Technical SpecificationsDocumento2 páginasFIBER OPTIC CABLE - Technical SpecificationsMalik Shoaib khalidAinda não há avaliações

- Fiber Optic Cable SpecDocumento15 páginasFiber Optic Cable SpecChaitanya ShakyaAinda não há avaliações

- Coping and CappingDocumento15 páginasCoping and CappingWawaChumelAinda não há avaliações

- Insulated CablesDocumento10 páginasInsulated CablesethanAinda não há avaliações

- Flexamat Spec SheetDocumento5 páginasFlexamat Spec SheetJamesAinda não há avaliações

- 11 kV-22 kV-33 KV Composite InsulatorsDocumento15 páginas11 kV-22 kV-33 KV Composite InsulatorsSandip AhireAinda não há avaliações

- Defence Standard 02-801Documento2 páginasDefence Standard 02-801zubimehAinda não há avaliações

- Plate GirderDocumento74 páginasPlate Girderarif_rubin100% (1)

- Production: RovingDocumento3 páginasProduction: RovingUtkarsh KumarAinda não há avaliações

- NAAC 10.12.1888888 NewDocumento48 páginasNAAC 10.12.1888888 Newచిమ్ముల సందీప్ రెడ్డిAinda não há avaliações

- Comsigua HBIDocumento0 páginaComsigua HBIproxywarAinda não há avaliações

- Example of Presentation Planning Document 1uf6cq0Documento2 páginasExample of Presentation Planning Document 1uf6cq0Wilson MorenoAinda não há avaliações

- SkepticismDocumento5 páginasSkepticismstevenspillkumarAinda não há avaliações

- Hydrology: Dua'a Telfah PH.D, Civil Engineering Department Jadara UniversityDocumento104 páginasHydrology: Dua'a Telfah PH.D, Civil Engineering Department Jadara UniversityFaris AlmomaniAinda não há avaliações

- Interior Plains Unit PlanDocumento6 páginasInterior Plains Unit Planapi-256482747Ainda não há avaliações

- Gaara Hiden Series Light NovelDocumento127 páginasGaara Hiden Series Light NovelartfardadAinda não há avaliações

- Dossat PrinciplesOfRefrigerationDocumento554 páginasDossat PrinciplesOfRefrigerationHernan CobaAinda não há avaliações

- Sistema A-101 LVSDocumento4 páginasSistema A-101 LVSAdministrador AngloAinda não há avaliações

- Catalog ITEM - Pdf4a3667894b315Documento552 páginasCatalog ITEM - Pdf4a3667894b315Domokos LeventeAinda não há avaliações

- Tridium Europe DatasheetDocumento2 páginasTridium Europe DatasheetHoàngTrầnAinda não há avaliações

- C57.12.29 Pad-Mounted Equipment-Enclosure Integrity For Coastal EnvironmentsDocumento26 páginasC57.12.29 Pad-Mounted Equipment-Enclosure Integrity For Coastal EnvironmentsSureshKumarAinda não há avaliações

- Lesson 2 Principles of Cooperative ConversationDocumento9 páginasLesson 2 Principles of Cooperative Conversationdelilah o balladAinda não há avaliações

- AutoCAD 2006 Installing Network License Manager0Documento12 páginasAutoCAD 2006 Installing Network License Manager0gurugovindanAinda não há avaliações

- Disconnect Cause CodesDocumento2 páginasDisconnect Cause Codesdungnt84Ainda não há avaliações

- A Microscope For Christmas: Simple and Differential Stains: Definition and ExamplesDocumento4 páginasA Microscope For Christmas: Simple and Differential Stains: Definition and ExamplesGwendolyn CalatravaAinda não há avaliações

- 19 - 22187 - Pritchard RD (1969)Documento36 páginas19 - 22187 - Pritchard RD (1969)Isaias MoralesAinda não há avaliações

- GS Ep Tec 260 enDocumento61 páginasGS Ep Tec 260 enCesarAinda não há avaliações

- English Action Plan 2023-2024Documento5 páginasEnglish Action Plan 2023-2024Gina DaligdigAinda não há avaliações

- 01 AirCircuitBreakers LV10 102021 EN 202111301146249676Documento136 páginas01 AirCircuitBreakers LV10 102021 EN 202111301146249676bkAinda não há avaliações

- LV SWBDQualityInspectionGuideDocumento72 páginasLV SWBDQualityInspectionGuiderajap2737Ainda não há avaliações

- Case Analysis, Case 1Documento2 páginasCase Analysis, Case 1Aakarsha MaharjanAinda não há avaliações

- Sony DVD Player Power Circuit DiagramDocumento40 páginasSony DVD Player Power Circuit DiagramHariyadiAinda não há avaliações

- Missing Person ProjectDocumento9 páginasMissing Person ProjectLaiba WaheedAinda não há avaliações

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocumento7 páginasBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengAinda não há avaliações

- Getting Started in Steady StateDocumento24 páginasGetting Started in Steady StateamitAinda não há avaliações

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Documento2 páginasBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoAinda não há avaliações

- Vernacular in Andhra PradeshDocumento1 páginaVernacular in Andhra PradeshNandyala Rajarajeswari DeviAinda não há avaliações

- ACFrOgDVly789-6Z8jIbi7pBoLupubEgMyOp7PczEvUguHoW3uj oR2PKzDvuhRzzkIhacYjxXRrU6iA7sHt t6MhtpZFq0t uZL2pF5Ra NNZ kmcl5w7BCQeUegKhjRhNuou88XxLodzWwbsrDocumento14 páginasACFrOgDVly789-6Z8jIbi7pBoLupubEgMyOp7PczEvUguHoW3uj oR2PKzDvuhRzzkIhacYjxXRrU6iA7sHt t6MhtpZFq0t uZL2pF5Ra NNZ kmcl5w7BCQeUegKhjRhNuou88XxLodzWwbsrJohn Steven LlorcaAinda não há avaliações

- A Research Paper On DormitoriesDocumento5 páginasA Research Paper On DormitoriesNicholas Ivy EscaloAinda não há avaliações