Escolar Documentos

Profissional Documentos

Cultura Documentos

Avantages Des Membranes Polymem Anglais

Enviado por

nlucky_ram9058Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Avantages Des Membranes Polymem Anglais

Enviado por

nlucky_ram9058Direitos autorais:

Formatos disponíveis

Ingnierie

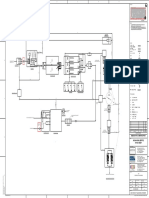

Aqua Technique Ingnierie uses polysulfone membranes developped by Polymem company

What to know about Ultra Filtration membranes

Story Under development since 1985 in order to face the new European Norms and more precisely to face the turbidity limits, a team of searchers was appointed at Toulouse to develop a membrane which could, simultaneously, be produced per tons of products, last at least one tenth of years, work at low water pressure, be hydrophilic to prevent from chemical washing. This ultra-filtration technology was first developed with the cellulose poly-acetate product, a development which cost more than 30 million from 1985 to 1990. The first ultra-filtration reference was the Amoncourt plant in 1988, where the first replacement of the modules happened only in 2004 (but the working conditions are quite good). Anyway, nowadays, we can confirm the very high interest of the water treatment companies in this elegant technology which, being not polluting, is perfectly adapted in the new trends of long term sustainable developments. The potential UF market is appearing to be huge as most of the calls for bids for drinking water treatment plants in France are now requesting Ultra-Filtration technology, at least as an option. This ultra-filtration technology is still being improving through the use of the polysulfone membranes, instead of cellulose poly-acetate. As a matter of fact polysulfone is very resistant to bacteriae and is consequently not biodegradable, thus requesting no particular care. Advantages of Ultra-filtration membranes versus sand filtration UF membranes were first applied to solve the problem raised by water tables located in karstic areas, water turbidity of which is generally good but which can vary suddenly a lot during storm showers due to direct accesses of the underground to the surface. It appears that this is the only one technology which allows to face sudden turbidity variations without any interferences with the crystal water quality obtained as a treated water, and also without any change in the chlorine and/or chemicals consumption. This is not the case when using conventional treatment like flocculation on sand filtration. The turbidity of the ultra-filtered water which can be guaranteed is, at least, several tens times better (< 0,1 NTU) than the one of the sand filtered water (< 5 NTU). This means that the amount of suspended matter, which is chlorine consuming, is much better than the one obtained in the sand filtered water. This involves to expect at least twice as less chlorine consumption in ultra-filtered water than it is necessary in sand filtered waters1. Likewise, ultra-filtration is used to treat surface waters or well waters which might be contaminated by all sorts of bacteriae coming from breeding areas. In addition, ultra-filtration appears to be the only one technology which can get rid of Giarda or Cryptosporidium cysts, responsible of gastro-intestinal diseases.

Refer to the attached comparative evaluation resulting from the pilot tests carried out at Pailles in July 2006

Ingnierie

The pores of the membranes are so small (< 0,01) than they can stop not only bacteriae, but also viruses. Therefore the use of this technology as a disinfecting treatment, prevents from any apparition of THM or chloramines giving rise to risks of bad taste, as it may often happen when using chlorination after conventional treatment like any sand filtration. Ultra-filtration units are manufactured under modular systems. This means that they are very easy to be enlarged by simple addition of modules in case of extension. On the other end, the backwashing effluents (which results in a corresponding loss of treated water) are less (5% to 8%) than the ones of the sand filters (approximately 10%). In addition, they do not contain any floculant which would be necessary to add to properly achieve a sand filtration of turbid raw waters and so they are not harmful for the environment. . Lastly, the maintenance staff required to look after such ultra-filtration units is reduced to a minimum. Advantages of the Polymem polysulfone membranes versus cellulose poly-acetate membranes Being neither really sensitive to the running conditions nor sensitive to the quality of the raw water since they are not bio-degradable, poly-sulfone membranes are now used, more and more and with a lot of success, for small drinking water plants in rural areas where a simple watch over is enough. A long term stand-by of the poly-sulfone membranes without chlorine is even not harmful (which, on the contrary, is not allowed when using cellulose poly-acetate membranes). The chemical cleanings of the membranes, which must be carried out only twice a year, need the use of Chlorine (under the hypochlorite or gas form) and caustic soda available everywhere (which, on the contrary, is not the case of cellulose poly-acetate membranes which need proprietary imported washing powder) Chemical cleanings effluents can easily be thrown away in the environment since they can be easily neutralised. On the contrary, this is not so in the case when using the poly-acetate membranes where cleanings are long to rinse and effluents are even foaming. In addition, Polymem has always been developing membranes constituted by hollow fibres having an external skin (which involves an external to internal flow), while cellulose polyacetate hollow fibres have internal skin. Such a characteristic confers to the Polymem modules a much better behaviour in turbid waters since the fibres cannot be clogged. Backwashings and cleanings are also easy, very efficient and less water consuming. Lastly, Polymem modules are very simple to install since they have only one inlet and one outlet, resulting from the energy saving dead end ultra-filtration process (versus the tangential process first developed with cellulose poly-acetate). Precautions to be taken when using filtration technology Since ultra-filtration plays its role at the limit between dissolved and particular matters, additional treatment might be necessary to remove Iron or manganese in excess (like aeration by pulverisation of raw water in the air through special nozzles), or to remove colour or pesticides (by means of active coal), as it is always the case in any filtration process. In addition, ultra-filtration process keeps unchanged the good drinking quality of minerals since it is not a desalination process.

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Group 4 Ceng 415Documento14 páginasGroup 4 Ceng 415Jeremiah SeleAinda não há avaliações

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocumento7 páginas20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Water Purifying DevicesDocumento42 páginasWater Purifying Devicestapan12345Ainda não há avaliações

- Water Quality at Residential and Industrial AreaDocumento11 páginasWater Quality at Residential and Industrial AreaMohamad AizanAinda não há avaliações

- Development Costs: Clackamas CountyDocumento6 páginasDevelopment Costs: Clackamas Countypriyanshi SharmaAinda não há avaliações

- Buku Saku Proteksi Kebakaran 2022Documento25 páginasBuku Saku Proteksi Kebakaran 2022rajaAinda não há avaliações

- Adama Town Water Supply ProjectDocumento145 páginasAdama Town Water Supply ProjectZed Phil IndAinda não há avaliações

- Gujarat Technological UniversityDocumento2 páginasGujarat Technological Universityfeyayel990Ainda não há avaliações

- Communal Septic Tanks As Appropriate Technology To Achieve Surabaya Open Defecation Free (Odf)Documento6 páginasCommunal Septic Tanks As Appropriate Technology To Achieve Surabaya Open Defecation Free (Odf)Nurina FitrianiAinda não há avaliações

- Water ConservationDocumento18 páginasWater ConservationKhiZra ShahZad100% (2)

- Waste Water Treatment PlantsDocumento5 páginasWaste Water Treatment Plantssharath100% (1)

- Case Study Pallavaram MunicipalityDocumento4 páginasCase Study Pallavaram MunicipalityAgnishaThyagraajanAinda não há avaliações

- KSP RBT P1 Rac CD RPT Civ 0004Documento34 páginasKSP RBT P1 Rac CD RPT Civ 0004alaa sadikAinda não há avaliações

- Anamaduwa Integrated Water Supply Project (Aiwsp) : Precondition Survey ReportDocumento6 páginasAnamaduwa Integrated Water Supply Project (Aiwsp) : Precondition Survey Reportlakshitha WithanageAinda não há avaliações

- Building Services 1 (BAP 213) : Assignment 1Documento8 páginasBuilding Services 1 (BAP 213) : Assignment 1puja Dhamija100% (1)

- Rainwater Harvesting: Sagar Malsane, Asst. Prof., NICMARDocumento33 páginasRainwater Harvesting: Sagar Malsane, Asst. Prof., NICMARJithesh DharmadasAinda não há avaliações

- 3.isolation Hospital (IIYW) PDFDocumento2 páginas3.isolation Hospital (IIYW) PDFSandeepan ChowdhuryAinda não há avaliações

- Challenges in The Tapi BasinDocumento43 páginasChallenges in The Tapi Basinbigrjs100% (1)

- Greater Yangon Water Supply Improvement Project (Phase II) Final Report Feb 2017Documento198 páginasGreater Yangon Water Supply Improvement Project (Phase II) Final Report Feb 2017lwin_oo2435Ainda não há avaliações

- Unit 4 Rain PDFDocumento34 páginasUnit 4 Rain PDFNaGamani KanDanAinda não há avaliações

- Process Control AssDocumento24 páginasProcess Control AssGkou DojkuAinda não há avaliações

- BestPractices in Water ManagementDocumento78 páginasBestPractices in Water Managementverrapa100% (1)

- Cloud Based Smart Water MeterDocumento3 páginasCloud Based Smart Water Meteryisakabera123Ainda não há avaliações

- On-Site Sewage Treatment HandoutDocumento14 páginasOn-Site Sewage Treatment HandoutJhyneJazarenoAtutuboAinda não há avaliações

- Syabas Workflow ChartDocumento2 páginasSyabas Workflow Chartchung_kee_3100% (7)

- ST1 ZZZ DWG CW 080001Documento1 páginaST1 ZZZ DWG CW 080001Ashraf ElmagdoubAinda não há avaliações

- Chlorination of WaterDocumento16 páginasChlorination of WaterGeethanjali SadasivamAinda não há avaliações

- Handbook On Plumbing Installation For BuildingDocumento107 páginasHandbook On Plumbing Installation For BuildingKhristine CloribelAinda não há avaliações

- Jal Jeevan Mission - Har Ghar Jal: Summary of The ReportDocumento4 páginasJal Jeevan Mission - Har Ghar Jal: Summary of The ReportAKHIL H KRISHNANAinda não há avaliações

- 2-AWWA Manual Od Water Audit and Leak DetectionDocumento55 páginas2-AWWA Manual Od Water Audit and Leak Detectionmuhammad.civilAinda não há avaliações