Escolar Documentos

Profissional Documentos

Cultura Documentos

AWT Gelling Properties High Methyl Ester

Enviado por

onceanforallDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AWT Gelling Properties High Methyl Ester

Enviado por

onceanforallDireitos autorais:

Formatos disponíveis

T ECHNICAL A PPLICATION I NFORMATION

Gelling Properties of High Methylester Classic Apple Pectins and Classic Citrus Pectins: Comparison in Dependence from Degree of Esterification and Setting Time

G ELLING P ROPERTIES OF High Methylester Classic Pectins

In the production of jams, jellies, fruit spreads and confectionery, both high methylester Classic Apple Pectins and high methylester Classic Citrus Pectins are used successfully for a long time. To reach optimal products the manufacturer has very certain demands on the particular pectin as regards quality. These demands are very different depending on product type and country and refer to the properties during processing, to the texture of the final products, to the syneresis behaviour, and especially to the setting temperature / setting time. With that, fruit spreads produced with pectins The manufacturers ask for most different textures which - depending on the desired product - can be very firm and brittle or firm and smooth up to smooth and easy to spread. with a higher degree of esterification gel faster and exhibit a more elastic texture than fruit spreads produced with pectins with a lower degree of esterification. For the use in jams, jellies and fruit spreads Herbstreith & Fox produces high methylester Classic Apple Pectins and Classic Citrus Pectins which develop very typical gelling properties due to their degree of esterification and the raw material used. spread may not start until a lower temperature is reached, as otherwise pre-gelation and thus an irreversible loss of gelling strength occur.

Furtheron, depending on the product and the fixed filling temperature, very certain demands are made on the setting temperature of the fruit spreads and with that on the gelling properties of the pectin used:

Compared with Classic Apple Pectins, Classic Citrus Pectins with comparable degree of esterification form gels with higher setting temperatures and an elastic-brittle texture whereas gels with Classic Apple Pectin gel more slowly and result in elastic-viscous textures

Fruit spreads containing fruit pieces should gel as quick as possible in order to prevent the possible rising of the fruits (floating) after filling into the packagings. If, due to technological reasons, the product is filled at relatively low temperatures, the gelation of the fruit

which are easy to spread.

The knowledge of these gelling properties, both in dependence from degree of esterification and from the raw material used, allows the selection of a pectin, which meets the requested demands optimally.

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

M ETHODS

FOR

D ETERMINATION of the Gelling Properties

In this method a gel consisting of pectin, sugar, acid and water (65% SS, pH-value 2.2), produced under defined conditions, is assessed 24

Methods for Determination of the Gelling Properties of High Methylester Pectins

As the degree of esterification solely is not meaningful enough to describe the behaviour of high methylester pectins in fruit spreads sufficiently, the gelling properties of high methylester pectins such as gelling strength, breaking strength and texture as well as setting time are determined in this application.

hours after production due to the rigidity under its own weight (Cox and Higby, 1944).

Both the simple handling and the good reproducibility are the main advantages of this method whereas the less practice-oriented recipe parameters such as the low pH-value and the absence of buffer salts as well as the

The determination of gelling strength according to the USA-Sag method, the determination of the breaking strength and the texture properties of a practice-oriented model gel (e.g. apple juice jelly) using the Herbstreith Pektinometer as well as the determination of setting time according to Joseph and Bayer are suitable methods for this purpose.

relatively long standing time of 24 hours are considered to be rather disadvantageous.

As the gel is not becoming destroyed during the Ridgelimeter measurement, the measuring results do not correlate with the inner firmness (breaking strength) of the gel which can be determined by using the Herbstreith Pektinometer when disrupting the gel.

The systematic composing of the information obtained from the results of these methods is decisive for an application-oriented assessment.

a) Determination of gelling strength according to USA-Sag method (Ridgelimeter method) The determination of gelling strength according to the Ridgelimeter method is traditionally accepted. This method describes the standardisation of pectins to a defined gelling strength stated in USA-Sag, which serves internationally also today still as commercial basis (IFT, 1959).

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

b) Determination of breaking strength and texture properties with the Herbstreith Pektinometer For determining the breaking strength and the texture with the Herbstreith Pektinometer a nearly optional gel is put on strain up to the destruction of the gel network. The force necessary for this effect is measured in dependence from time.

The simple handling, good reproducibility and above all the great flexibility regarding the recipe are the advantages of this method. With that gels can be assessed which are exactly adjusted to the particular application.

But, fruit spreads containing fruit components can only be assessed reproducibly if the fruits are finely ground or at least relatively small and distributed homogeneously. From the ratio of the maximum force and the integral of the resulting force-time-curve the so-called texture constant K is determined. This For determination of the breaking strength and the texture with the Herbstreith Pektinometer the gel preparation is filled into a standardised measuring beaker with shear insert. After a defined time this shear insert is pulled out of the gel and the force necessary herefore is measured. From the resulting force-time-diagram the following information is obtained: With the Herbstreith Pektinometer Mark IV the terms breaking strength and texture constant K can be determined. Different types of pectin gels can be distinguished: Elastic-viscous gels for example require a smaller The maximum value is the force which is necessary for disrupting the gel and which is called breaking strength. This breaking strength resp. inner firmness correlates very well with the firmness which is perceived during the first swallowing or first spooning up for sensory assessment. force to be disrupted resp. broken and therefore their breaking strength is relatively low. As elastic-viscous gels have an inner cohesion, a low but steady power input is necessary to pull the shear insert out of the gel. Therefrom a relatively large integral area in the force-timecurve results. value gives information on the ability to spread gels and on the behaviour of a gel preparation during chewing and swallowing in the mouth.

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

From the ratio of breaking strength, i.e. the maximum force, and integral of the force-timecurve a relatively low value for the texture constant K is obtained. Sensorily the gels are assessed very easy to spread and homogeneously firm with high mouthfeel.

gel is determined by a special oscillating measurement mode (W = G : G).

Pectin gels are visco-elastic substances, which means they are predominantly elastic. However, they additionally possess more or less high viscous shares which have a very significant influence on texture.

Elastic gels show high breaking strength values, thus they require a high power input for breaking. Elastic gels break into single fragments when ruptured. Therefore after breaking only a small power input is necessary to pull the shear insert out of the gel which results in a comparatively small area in the force-timecurve. The calculated texture constant K is then higher than for viscous, easy to spread gels. The texture, that means appearance and structure of the gel surface, the sensorily felt firmness when spooning and spreading, and the haptic impression (mouthfeel) of fruit spreads are determined by the ratio Sensorily elastic-brittle gels are often assessed less easy to spread and slightly rough with less mouthfeel. of elastic and viscous properties. The higher the elastic shares in a gel, the c) Determination of texture properties with the oscillating rheometer The above mentioned texture constant K which is used together with the Herbstreith Pektinometer Mark IV for determining the texture properties of pectin gels correlates very well with the so-called dynamic Weienberg number W (Windhab, 1990) which can be determined by using the oscillating rheometer. The determination of the dynamic Weienberg number W is a comparatively extensive rheometric method in which the ratio between elastic (G) and viscous shares (G) of a pectin Gels with a small dynamic Weienberg number (W = 5 - 10) are elastic-viscous, easy to spread and smooth, and show a glossy surface with low tendency to syneresis. The texture of gels with a high dynamic Weienberg number (W = 15 - 20) is elasticbrittle, the gels show a structured, rough surface and often a slightly higher tendency to syneresis. higher is the dynamic Weienberg number W.

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

d) Determination of setting time Besides the desired texture also the setting time is a very important term for the manufacturers of fruit preparations. The higher the setting temperature, the faster the product starts to gel and the higher the filling temperature in the production process has to be fixed. If the setting temperature of the product is higher than the fixed filling temperature, pre-gelation will occur, that means the products already starts gelling before the filling process. The mechanical treatment during the filling process irreversibly destroys the gel network already formed resulting in a partial loss of the final gel strength in the product.

The determination of setting time according to Joseph and Bayer (Joseph, G.H., Bayer, W.F., 1949) has proved to be simple and easy to carry out without any technical input.

In this method a gel preparation is produced according to the Ridgelimeter method. The setting process is observed under defined cooling conditions. The time at which gelation starts is measured and defined as setting time.

Due to the less practice-oriented recipe parameters (no buffer salts, pH-value approx. 2.2) the measured values correlate only to some extend with practical experiences.

On the other hand, products, which contain whole fruits or fruit pieces, require a comparatively high setting temperature as these products are intended to gel quickly after the filling process in order to prevent the contained fruits or fruit pieces from floating and with that from separating from the gel. This becomes very clear when observable reactions with ions, mostly bivalent cations such as calcium ions, are already expected due to the low degree of esterification or due to the raw material (as for Citrus Pectins by a blockwise distribution of carboxyl groups).

Comment: Herbstreith & Fox alternatively also offers special Classic Apple Pectins for this application which form an perceivable viscosity resp. yield point already in hot condition. This effect delays the floating of the fruits until gelation starts.

On the basis of setting time the high methylester pectins are usually divided into the following groups:

rapid set (rs) medium rapid set (mrs) slow set (ss)

Setting time resp. setting temperature are influenced on the one side by recipe parameters such as soluble solids content, pH-value of the product, buffer salts and pectin dosage, on the other side by the degree of esterification, the raw material for pectin production and production technology of pectin.

extra slow set (xss)

As up to now there is no official method for the determination of setting time resp. setting temperature of pectin gels, this classification is arbitrary and may highly fluctuate from producer to producer.

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

G ELLING P ROPERTIES OF High Methylester Classic Pectins

Gelling Properties of High Methylester Classic Pectins in Dependence from Degree of Esterification With decreasing amount of methylester groups, that means with declining degree of esterification, also the gel texture changes. Rigid bonds between the pectin chains arising The gelling properties (breaking strength, texture and setting time) of high methylester pectins are decisively influenced by the degree of esterification of the pectin. This results from the fact that the amount of hydrophobic methylester groups in the pectin molecule decreases with declining degree of esterification while the amount of free carboxyl groups increases. Hydrogen bonds develop time-delayed during gel formation at the free, undissociated carboxyl groups which are present more numerously with declining degree of esterification. With that gelation starts not until lower temAccording to the well-known gelling mechanisms of high methylester pectins the formation of a network during gelation is influenced from both methylester groups and carboxyl groups of the pectin molecule. peratures are reached. Hydrogen bonds are comparatively mobile bonds. The more cross linkages are present due to such mobile bonds, that means the lower the degree of esterification of the high methylester pectin is, the smoother and easier to spread is the gel texDuring the gelling process methylester groups are due to their hydrophoby responsible for the accumulation of the pectin molecules in a way, that the methylester groups have only little contact surface to the water. With that, relatively rigid and immovable bonds occur spontaneously already at high temperatures. A further explanation for the differences between gels with Classic Apple Pectin and Classic Citrus Pectin deals with the frequency of the neutral sugar side chains resp. with the length of the homogalacturonan segments which are considered to be responsible for the This means for very high methylester pectins which exhibit a large amount of methylester groups that during the production process of a gel preparation in heated condition there are already sufficient cross linkages present for gel formation and gelation will already start at high temperatures. The distribution of the free carboxyl groups over the pectin molecule has an additional influence on the gelation. stability of the linkage resp. for formation of the elastic shares in the gel (G = storage modulus). ture. from aggregation of the hydrophobic methylester groups, lead to elastic-brittle gel textures and to a decrease of breaking strength with declining degree of esterification.

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

Regarding Classic Apple Pectins the carboxyl groups are distributed statistically over the molecule, whereas the free carboxyl groups at Classic Citrus Pectins are blockwise present due to some enzyme activity in the raw material. Thus a certain ion sensitivity is achieved by the Classic Citrus Pectins which leads to higher setting temperatures and more elastic gels.

If this degree of esterification is exceeded, the setting temperature of the gel preparation will be that high, that pre-gelation will occur under the given conditions. The gel network, which is already formed in the heat at high setting temperatures, is partially destroyed during the filling process. With that the values for breaking strength decrease again.

The texture of the concerned apple juice jellies a) Classic Apple Pectins The higher the degree of esterification of the used Classic Apple Pectin, the faster gel preparations produced with this pectin will gel. changes from elastic-viscous and easy to spread (dynamic Weienberg number W approx. 4 - 8) at lower degrees of esterification to elasticbrittle (dynamic Weienberg number W approx. 12 - 16) at higher degrees of esterificaThis means for the production of fruit spreads, that the setting temperature also increases with increasing degree of esterification of the used pectin or, in other words, that the time until gelation starts under constant cooling conditions, is shortened. If pre-gelation occurs, the values of the texture constant K and the dynamic Weienberg number W will become smaller again as the gel is partially destroyed due to the pre-gelation, which results in a decrease of the elastic The breaking strength of a practice-oriented gel (apple juice jelly, 62% SS, pH 3.0, 0.5% Classic Apple Pectin, standardised to 150 USASag) increases with increasing degree of esterification of the Classic Apple Pectin up to reaching a defined degree of esterification. Sensorily the Apple Pectin gels appear smooth and glossy, they are easy to spread. The gels have a high mouthfeel (body) and a very good flavour release due to the smooth texture. shares. tion.

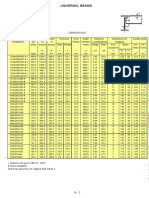

Texture constant K, Dynamic Weienberg number W

Breaking Strength [HPU], Setting time [s]

Setting time

Breaking strehgth

Texture constant K

Dynamic Weienberg number W

Fig. 1: Setting time (method Joseph & Bayer) and breaking strength, texture constant K, dynamic Weienberg number W of an apple juice jelly (0.5% pectin, standardised to 150 USA-Sag, 62% SS, pH 3.0) in dependence from degree of esterification of the Classic Apple Pectin used.

Degree of esterification [%]

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

b) Classic Citrus Pectins Basically Classic Citrus Pectins behave in dependence from degree of esterification similar as Classic Apple Pectins whereas the measured absolute values differ from each other.

the breaking strength also with increasing degree of esterification, whereas the texture of gels made with Classic Citrus Pectins change from elastic-viscous (dynamic Weienberg number W approx. 4 - 8) at low degrees of esterification up to elastic and very brittle

With increasing degree of esterification the setting time of Classic Citrus Pectins decreases and the setting temperature increases. At comparable degree of esterification Citrus Pectin gels gel faster than Apple Pectin gels. Due to the blockwise distribution of the carboxyl groups at Citrus Pectins and with that the connected ion sensitivity, it is possible that this raw material conditioned difference becomes even more evident in practice.

(dynamic Weienberg number W approx. 13 17) at very high degrees of esterification.

At a standardized gelling strength of 150 USASag the breaking strength of an apple juice jelly increases in correlation with the sensorily perceptible firmness with increasing degree of esterification up to reaching a defined degree of esterification. When pre-gelation starts, the viscous shares of the gel rise strongly whereby the values for the texture constant K and

At higher degrees of esterification pre-gelation may occur due to the high setting temperatures, which results in a loss of gel strength.

the dynamic Weienberg number W decrease.

Sensorily the gels made with Citrus Pectins appear structured and slightly dull, they are

The texture constant K and the dynamic Weienberg number W increase according to

less easy to spread. The gels are brittle and feel more rough with less body when tasting.

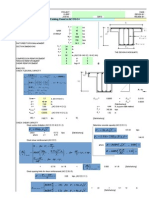

Texture constant K, Dynamic Weienberg number W

Breaking Strength [HPE], Setting time [s]

Setting time

Breaking strehgth

Texture constant K

Dynamic Weienberg number W

Degree of esterification [%] Fig. 2: Setting time (method Joseph and Bayer) and breaking strength, texture constant K, dynamic Weienberg number W of an apple juice jelly (0.5% pectin, standardised to 150 USA-Sag, 62% SS, pH 3.0) in dependence from degree of esterification of the Classic Citrus Pectin used.

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

When comparing Classic Apple Pectin and Classic Citrus Pectin in dependence from the degree of esterification the following differences become obvious:

Due to this texture the fruity flavour is especially optimal released in Apple Pectin gels. In contrast to that, Citrus Pectin gels are assessed less easy to spread and brittle with less mouth-feel.

At comparable degree of esterification the texture of Citrus Pectin gels is slightly more elastic and brittle than the texture of Apple Pectin gels. Thus the Classic Citrus Pectins have a higher texture constant K and a hig her dynamic Weienberg number W than Classic Apple Pectins. At comparable degree of esterification Classic Citrus Pectins reach a higher breaking strength in gel preparations than Classic Apple Pectins. At comparable degree of esterification Apple Pectin gels are sensorily assessed as very easy to spread and smooth with high mouth feel (body) and therefore comparably firm as Citrus Pectin gels.

At comparable degree of esterification gel preparations with Classic Citrus Pectins gel faster, that means at higher temperatures than gel preparations with Classic Apple Pectin. The reason is that Apple Pectins show a lower sensitivity towards ions than Citrus Pectins due to the statistic distribution of the carboxyl groups.

10

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

Gelling Properties of High Methylester Classic Apple Pectins and Classic Citrus Pectins in Dependence from Setting Time

For reaching for example a comparable setting time of approx. 500 s, the degree of esterification of the Citrus Pectin with approx. 56% has to be slightly lower than the degree of esteri-

The parameter setting temperature resp. setting time is of great importance for the production process. The manufacturers of fruit spreads are therefore especially interested in the gelling properties of Classic Apple Pectins and Classic Citrus Pectins in dependence from setting time resp. setting temperature.

fication of the Apple Pectin with 62%.

The raw material conditioned difference in ion sensitivity of the pectin which is caused in the distribution of the carboxyl groups, is responsible for the very slow gelation of Apple Pectins at relatively low degree of esterification (DE approx. 56%).

In order to obtain comparable setting times in the same recipe, Classic Citrus Pectins must have a lower degree of esterification than Classic Apple Pectins as the gelation process of Classic Citrus Pectins is faster than for Classic Apple Pectins due to the blockwise distribution of carboxyl groups at comparable degree of esterification. Classic Apple Pectins show a statistical distribution of carboxyl groups over the pectin molecule (fig. 3). Particularly in the slowly setting range Classic Apple Pectins reach higher breaking strength values than Classic Citrus Pectins at comparable setting time (fig. 4). With decreasing setting time, that means with increasing setting temperature of the gel preparation, the breaking strength of the Classic Apple Pectins and Classic Citrus Pectins increases.

Setting time [s]

Apple pectin Citrus pectin

11

Degree of esterification [%] Fig. 3: Setting time of Classic Apple Pectin and Classic Citrus Pectin in dependence from degree of esterification (method Joseph and Bayer).

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

Setting time [s]

Apple pectin Citrus pectin

Degree of esterification [%]

Fig. 4: Breaking strength of an apple juice jelly (0.5% pectin, standardised to 150 USA-Sag, 62% SS, pH 3.0) of Classic Apple Pectin and Classic Citrus Pectin in dependence from setting time (method Joseph and Bayer). For example, at a setting time of approx. 440 s the apple juice jellies with Classic Apple Pectin and a breaking strength of approx. 895 HPE are much firmer than with Classic Citrus Pectin (breaking strength approx. 310 HPE). At higher setting temperatures, that means at shorter setting times, the Apple Pectin gels also gel firmer than the Citrus Pectins, however then the differences are no more very big. The degree of esterification which is required to reach a faster gelation of the Citrus Pectins, At the same time the texture of the Apple Pectin gels is firm and very smooth, whereas the Citrus Pectin gel is assessed being too weak. The reason is the low degree of esterification of the Classic Citrus Pectin, which is necessary to reach the desired setting time. results in a higher elasticity of the gel and with that in a higher breaking strength. These Citrus Pectin gels form their typical elastic-brittle texture not until then, which can be seen at the high values of the texture constant K and the dynamic Weienberg number W (fig. 5).

Texture constant K, Dynamic Weienberg number W

Texture constant K apple pectin Texture constant K citrus pectin Dynamic Weienberg number W apple pectin Dynamic Weienberg number W citrus pectin

12

Setting time [s]

Fig. 5: Texture of an apple juice jelly (0.5% pectin, standardised to 150 USA-Sag, 62% SS, pH 3.0) of Classic Apple Pectin and Classic Citrus Pectin in dependence from setting time (method Jospeh and Bayer).

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

The comparison of Classic Apple Pectins and Classic Citrus Pectins in dependence from the setting time shows the following differences:

The texture of gel preparations, which are produced with Classic Apple Pectin or Classic Citrus Pectin becomes more elastic with decreasing setting time. Classic Citrus Pectins

To reach a comparable setting time in a specified constant recipe, Classic Apple Pectins with a slightly higher degree of esterification than Classic Citrus Pectins can be chosen. In gel preparations with constant recipe parameters particularly slow set Classic Apple Pectins reach higher breaking strength values than Classic Citrus Pectins with comparable setting time. a) Extra slow set pectins

form their typical elastic-brittle texture not until their gelation is adequately firm.

The following tables give a summary on the properties of Classic Apple Pectins and Classic Citrus Pectins in dependence from setting time for three particular setting ranges (extra slow set, slow set and medium rapid set):

Classic apple pectin Setting time [s] Degree of esterification [%] USA-Sag Breaking strength apple juice jelly [HPU] Texture constant K Dynamic Weienberg number W b) Slow set pectins Classic apple pectin Setting time [s] Degree of esterification [%] USA-Sag Breaking strength apple juice jelly [HPU] Texture constant K Dynamic Weienberg number W 440 64.0 150 895 10.2 12.6 520 61.9 150 570 8.3 8.3

Classic citrus pectin 505 56.3 150 195 5.5 2.2

Classic citrus pectin 440 59.6 150 310 6.5 4.5

c) Medium rapid set pectins Classic apple pectin Setting time [s] Degree of esterification [%] USA-Sag Breaking strength apple juice jelly [HPU] Texture constant K Dynamic Weienberg number W 375 66.9 150 1085 11.1 15.7 Classic citrus pectin 370 64.2 150 905 11.0 13.5

13

Literature: Windhab, Dr. E. (1990): Lebensmitteltechnik 7-8/90 404-414 Joseph, G.H., Bayer, W.F. (1949): Food Technol.3, 18-22

TECHNICAL APPLICATION LABORATORY HERBSTREITH & FOX CORPORATE GROUP 21/1O/2005

H ERBSTREITH & F OX Corporate Group Turnstrae 37 75305 Neuenbrg/Wrtt. Germany Phone: +49 7082 7913-0 Fax: +49 7082 20281 info@herbstreith-fox.de www.herbstreith-fox.de

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Organic Field-Effect Transistors PDFDocumento17 páginasOrganic Field-Effect Transistors PDFAjayaKumarKavalaAinda não há avaliações

- Weld Joint Mismatch KoçakDocumento17 páginasWeld Joint Mismatch KoçakAlberto HibinoAinda não há avaliações

- PHYS1001 Test 1 2017 SEM-1Documento14 páginasPHYS1001 Test 1 2017 SEM-1Angad MangatAinda não há avaliações

- Atomic Force MicrosDocumento6 páginasAtomic Force MicrosAli RazaAinda não há avaliações

- Green Behaviour Reinforced 1985 PDFDocumento91 páginasGreen Behaviour Reinforced 1985 PDFtevredeAinda não há avaliações

- NSTS-08307 (Criteria For Preloaded Bolts)Documento38 páginasNSTS-08307 (Criteria For Preloaded Bolts)ffontanaAinda não há avaliações

- BS Section PDFDocumento96 páginasBS Section PDFUpendra WalinjkarAinda não há avaliações

- Chenming Hu Ch1 SlidesDocumento31 páginasChenming Hu Ch1 SlidesdewddudeAinda não há avaliações

- Concrete Beam Design, For New or Existing, Based On ACI 318-14Documento6 páginasConcrete Beam Design, For New or Existing, Based On ACI 318-14teren_vnzareAinda não há avaliações

- General Data: Bending StessesDocumento8 páginasGeneral Data: Bending Stessesprajakt_pieAinda não há avaliações

- ECE8863-Lecture2-Introduction Nanotechnology Nanoscience Part2Documento36 páginasECE8863-Lecture2-Introduction Nanotechnology Nanoscience Part2Soufiane KarrakchouAinda não há avaliações

- ENCE 455 Design of Steel StructuresDocumento6 páginasENCE 455 Design of Steel StructuresTooraj RoozkhoshAinda não há avaliações

- Evaluation of White Metal Adhesion (Conventional Casting and Thermal Wire Arc Spraying) by Ultrasonic Non-Destructive MethodDocumento4 páginasEvaluation of White Metal Adhesion (Conventional Casting and Thermal Wire Arc Spraying) by Ultrasonic Non-Destructive MethodHamid MojiryAinda não há avaliações

- Design of Power-Transmitting Shafts: Reference Publication 1123Documento30 páginasDesign of Power-Transmitting Shafts: Reference Publication 1123Rodrigo MachadoAinda não há avaliações

- SM Triaxial Compression Test 1983 PDFDocumento6 páginasSM Triaxial Compression Test 1983 PDFNicolás SilvaAinda não há avaliações

- 3D Optical and Device Simulation of Surface Plasmonic Effects On Organic Solar Cells Using Silver Nano PrismsDocumento5 páginas3D Optical and Device Simulation of Surface Plasmonic Effects On Organic Solar Cells Using Silver Nano PrismsSakshiKoulAinda não há avaliações

- PrestressingDocumento26 páginasPrestressingNupur BhadraAinda não há avaliações

- Ce6603 Scad MSMDocumento141 páginasCe6603 Scad MSMSasmita SahooAinda não há avaliações

- ME 1022 Materials TechnologyDocumento77 páginasME 1022 Materials TechnologyShubham PadwalAinda não há avaliações

- Stability Charts For Rock Slopes Based On The Hoek-Brown Failure CriterionDocumento12 páginasStability Charts For Rock Slopes Based On The Hoek-Brown Failure CriterionHas TomoAinda não há avaliações

- Final Exam ES 126Documento4 páginasFinal Exam ES 126Michael Mendez OfficialAinda não há avaliações

- Structural Analysis of Concrete Spherical Shells: MEKJAVIC, I (Vana)Documento2 páginasStructural Analysis of Concrete Spherical Shells: MEKJAVIC, I (Vana)Iver LopezAinda não há avaliações

- 3.30 Within A Cubic Unit Cell, Sketch The Following DirectionsDocumento13 páginas3.30 Within A Cubic Unit Cell, Sketch The Following DirectionsTrong LanAinda não há avaliações

- J. Aci PDFDocumento54 páginasJ. Aci PDFJunior Garcia100% (1)

- Fermi Surfaces and MetalsDocumento36 páginasFermi Surfaces and MetalslulukAinda não há avaliações

- Program Shkences Konsrtuksioneve1 Ark (Igjate) PER FIN ANGLISHTDocumento3 páginasProgram Shkences Konsrtuksioneve1 Ark (Igjate) PER FIN ANGLISHTGentiRamajAinda não há avaliações

- 20 MN CR 5Documento4 páginas20 MN CR 5Pulkit GururaniAinda não há avaliações

- Fenwick ThesisDocumento358 páginasFenwick ThesisMaurício Prado MartinsAinda não há avaliações

- 7th Sem Prestressed Concrete StructuresDocumento9 páginas7th Sem Prestressed Concrete StructuresSubhikshaAinda não há avaliações

- Elemen Struktur Baja-III. COMPRESSION STRUCTUREDocumento27 páginasElemen Struktur Baja-III. COMPRESSION STRUCTUREirfananda hutomoAinda não há avaliações