Escolar Documentos

Profissional Documentos

Cultura Documentos

Sample Execsum

Enviado por

John M. CavoteDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sample Execsum

Enviado por

John M. CavoteDireitos autorais:

Formatos disponíveis

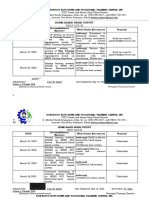

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Date of inspection: January 6, 2003 January 10, 2003 Technical specifications: The boiler system consists of an xxxxx Energy, Positive Pressure, Sub critical, B & W design unit. Introduction The inspection was conducted by United Dynamics Corporation (UDC) boiler inspection team consisting of Jon S. Cavote, John Linder, Dan Wyngarden, and Marvin Bronson. This inspection effort would not have been possible without the efforts of Lloyd Weber. UDC provided the inspection services, non destructive testing, and overall technical support. Inspection and planning methodology: Standard inspection and repair guidelines were utilized by the team. These guidelines were strictly complied with during this outage. All decisions were data driven backed up by substantial ultrasonic thickness examinations. In many cases data was reviewed from previous outages. The suggested repair criteria used on pressure parts during this outage was: 0-%-65% 66%-75% 76%-85% of design minimum wall was replaced. of design minimum wall was pad welded. of design minimum wall was shielded

All repairs were ranked at the time of inspection into two categories: Priority #1 Item that will in all probability cause a forced outage before the next scheduled outage, cause potential hazard to human life, or cause a financial loss to the operation of the unit.

1

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Priority #2 Item which poses a possible failure or performance issue. Priority #3 Item that under normal operations would not cause a forced outage although may decrease operations to a degree but of no significance. The item is typically planned for future work. Summary and Analysis of Inspections and Repairs: The process of inspection and repair interdiction is designed to statistically stack the deck in the plants favor when it comes to availability. This process is not fool proof although it has been proven over time to be a cost effective tool.

Conclusions and Recommendations: Rear Screen Tubes: The screen tube sections are noted for the front tube being a rear wall hanger tube 2.5 x .220 MWT SA210A1. All other screen tubes are composed of 2.0 x .220 MWT SA209T1A. All items indicated in the screen tube report are on the bottom level at the refractory wall. All other items are indicated in the crossover report. Only one tube has been noted for replacement, three tubes have been recommended for requiring pad welds, and several have been noted for requiring shield repairs. All shield work is due to soot blower erosion, and pad welds are a result of gouged tubing from a mechanical source. Ensure that all shields are installed on the trailing side of tubes and follow the pattern of the blower across the unit. Ensure that refractory wall is repacked to design form after all shield repairs are complete. ` 2

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Two attachment support lugs have been noted for requiring re-welding to the tube. Lugs being detached will allow for tube misalignment.

KEY POINTS: Complete all shielding work prior to refractory wall re-construction. Grant access to the remainder of elements at the right side of unit to complete inspection at lower level of tubes, element #81 - #114. Ensure that tubes are clean prior to shield installation.

Total of (4) Priority #1 items were identified. Total of (57) Priority #2 items were identified. Total of (1) Priority #3 items were identified. This makes (62) total observed deficiencies.

Rear Wall Hangers: The hangers have been noted for numerous shield repairs on the trailing edge of tubes. Some shields need replaced and others require realignment and straps. UT verification was noted in locations accessible, inspection report lists these results. Numerous shields are overheated and fatigued, proper cooling of shield is imperative

3

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

requiring clean tubes and a tight fit of shields to tube surface.

KEY POINTS: Ensure that tubes are clean and shields fit tight to tube surface prior to shield installation.

Total of () Priority #1 items were identified. Total of (2 records) Priority #2 items were identified. Total of (1 records) Priority #3 items were identified.

Secondary Superheat Inlet/Addendum 1: Only the lower level of the pendant was inspected due to lack of scaffolding access granted to upper levels. The spacer tube located on the front side of the inlet has been previously pad welded at the element intersections due to soot blower erosion. One 10 section of spacer tube has been recommended for replacement. The tier drop wrapper tubes located at the bottom of the pendants are being washed from blowing soot, and several are recommended for replacement and pad weld installation due to UT verification. Numerous lower pendant loops are noted for replacement and pad weld installations on the leading edge of tubes due to soot blower erosion. The addendum report indicates one pad weld required on the rear of pendant. ` 4

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

KEY POINTS: Check IK1&2 soot blowing frequency and sweep, ensure that blowers are not spraying in addition to what is required. Grant access to the upper levels of superheater for complete inspection.

Total of (17) Priority #1 items were identified. Total of () Priority #2 items were identified. Total of (1) Priority #3 items were identified. This makes (18) total observed deficiencies.

Reheat Inlet: The front of the inlet pendants has been noted for numerous shields requiring replacement due to overheat and fatigue, first and second tube in from the front. There is no scallop bar located on the lugs in front of pendant, however misalignment is not a problem. The problem area of the pendant is located on the trailing side in the IK 25/26 path. Soot blower erosion is the most common form of damage found on boiler pressure part components and can be easily overlooked if erosion is smooth across the entire surface of tube. The trailing reheat tubes have shielding on several elements however erosion is pushing off the bottoms of the existing shields causing wash on the outer radius bends of lower loops, others have no shielding at all. Numerous replacements, pad welds, and shields are recommended in this area.

5

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

The second tube in from the rear is showing significant signs of erosion however tubes are composed of .220 MWT. No repairs have been noted during this overhaul, however if soot blowing continues at the same rate, this will become a high priority area during future overhauls.

Shield work on the back of this pendant will include lower radius bends of tubes, as well as 3 straight sections. One bulged tube was found on the back side of this component and will need to be monitored during future overhauls.

KEY POINTS: Check blower frequency and pressure, do not run blower more than necessary. Grant access to elements #91 all the way to the right wall. It is imperative that the remainder of these elements be inspected and repairs are made accordingly. PSH work is in progress preventing further inspection at this time. Grant access to the upper elevation on the rear of pendant for inspection during a future overhaul. All front upper level repairs are indicated in the crossover report. Ensure that tubes are clean and shields fit tight to tube surface prior to shield installation.

6

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Total of (26) Priority #1 items were identified. Total of (4 Records) Priority #2 items were identified. Total of (3 Records) Priority #3 items were identified.

Reheat Outlet: Please note that all repair identified in the upper rear levels will be indicated in the crossover report. Two tubes have been noted for replacement on the back side of the pendant, and two tubes have been noted for requiring pad welds in the IK33 path. Numerous handcuff supports have been noted for re-welding the end weld due to cracking. Numerous shields have been recommended for installation as well, due to overheating of existing shields, Ensure that tubes are clean prior to new shield installation. Several support lugs have been found to be broken and elements misaligned. Ensure that pendants are re-aligned and new support lugs are installed. Broken lugs are found on the lower level as well as the upper level of pendants. The upper support/alignment lugs will require re-attachment because not only do they align the pendants, they provide structural support. The top portion of the pendants will sag forward causing the bottoms of pendants to kick back if upper support is lost. Elements 48 68 are showing moderate signs of overheating, no significant sign of exfoliation or creep is evident. It has been concluded that the tubes are suffering from long term overheat, not abnormal for a component of this vintage. ` 7

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

After discussions with plant personnel it has been concluded that tube surface temperature in the reheat crossover is running around 1,100 degrees F. This is an average tube surface temperature for this component, and would not expect that this would cause any short term overheat issues. It has also been noted that this component is run in excess of 1150+ degrees, this is the leading contributor to signs of long term overheat. Other factors can come into play to cause short term overheat in this component: 1. Plugging patterns (will increase gas velocity and temperature through open areas 2. ID blockage (if reheat has had a water filled static test, ensure that lower loops are cleared prior to unit returning to service. Tube surface temperature will reach excessive temperature before reheat loops clear enough to allow steam to circulate. This can cause excessive spaghetti like bowing as well as creep and exfoliation.) 3. Crushed tubes (flow restriction is the quickest way to overheat a tube in a short period of time.) 4. Sudden increases in steam temperature and surface temperature due to excessive slagging in the fire box (The more slagging and insulators on the water walls will increase the superheat and reheat temperatures due to less heat transfer in the fire box)

KEY POINTS: Grant access from elements 72 113 on the rear of pendant to complete inspection in the lower level.

8

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

To Reduce Superheat and Reheat temperatures (The removal of refractory that covers studded tubes in the fire box will decrease Superheat and Reheat temperature due to more heat transfer in the fire box. Too much heat transfer is also bad, not allowing superheats and reheats to reach necessary temperature. UDC recommends that if this process is to take action, that only 10% of the refractory is removed from the top of stud section. Ensure that exposed studs are removed from tubes to prevent heat absorption on tubes.)

Total of (5) Priority #1 items were identified. Total of (7 Records) Priority #2 items were identified. Total of (4 Records) Priority #3 items were identified.

Furnace Floor: The furnace floor has been noted for impact gouging requiring pad weld repairs. Refractory and other has been removed for restudding and inspection, pad welds are to be completed before re-studding and refractory are re-installed. The rear bends are planned for replacement ` 9

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

over the next several overhauls. No repair items have been noted for that location. Total of (12) Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of (1 Records) Priority #3 items were identified.

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Econ Gas outlet: The ductwork was noted for numerous casing cracks that will require seal welding, and the removal of ash and debris throughout the ducts. Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of (5 Records) Priority #3 items were identified.

Upper dead air space: Upper dead air space was noted for casing cracks requiring seal welding. Upper casing at the upper slope has been removed for reheat components replacements. Ensure that this casing is replaced after slope tubes are replaced.

Total of (1) Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of (2 Records) Priority #3 items were identified.

10

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Steam Drum: Steam drum was noted for requiring the removal of debris including excessive amounts of magnetite and remains of doors gaskets. The drum shell was found to be in good condition as found. No stress cracking in shell and corrosion was found at a minimum.

KEY POINTS: Removal of debris is imperative due to the affects it can have on the blocking lower inlet header orifices. Over time, debris that is run down the down comers will accumulate in the lower inlet headers and block orifices. If possible, UDC recommends that a lower inlet header inspection be performed by means of Bore Scope for debris accumulation.

Total of (1) Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of (7 Records) Priority #3 items were identified.

11

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Secondary Air duct: No action items have been found.

Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of ( Records) Priority #3 items were identified.

Air Heater Gas Outlet: No action items have been found.

Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of ( Records) Priority #3 items were identified.

Air Heater Gas Inlet: The right rear corner was noted for an expansion joint replacement. Expansion joint in the right front corner will need to be patched due to open holes. Remove ash from expansion joint flex points , to allow for proper expansion.

12

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Turning vane support struts are noted for repair as well.

Total of () Priority #1 items were identified. Total of (2 Records) Priority #2 items were identified. Total of (4 Records) Priority #3 items were identified.

Reheat Crossovers: The crossover section is the highest priority pressure part area of this overhaul. Numerous tubes have been noted for replacement, pad welding, and shielding. These repairs include the front side of the inlet, back side of the outlet, the crossovers themselves, and the rear screen tubes that intersect the crossovers. IK 23/24 is severely eroding reheat outlet tubes with a rough eroding surface. It appears that the steam is not completely superheated, saturated steam will erode sharp jagged edges and can cause tubes to reach quick failure. Numerous tubes have been previously pad welded and are now eroded through the pad weld and back into the tube. Screen tubes have been noted for shield, and pad weld repairs from blower wash and detached welds. 7 tube U straps at the upper level have been marked for replacement due to overheat and failure, install new strap 6 above or below previous strap to help prevent welding on the same heat effected zone. Numerous outlet tubes have been noted for existing horizontal weave pad welds, we need to plan to have these tubes replaced. During this overhaul, the thin tubes are a much higher priority to replace. ` 13

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

KEY POINTS: Prevent Saturated Steam: 1. Ensure that blower lance has weep holes located in the bottom of lance, and that lance is rested in its proper position. 2. Ensure that all steam piping is insulated properly to minimize condensation. 3. Ensure that all steam piping is at least at a 30 degree pitch to help drain access moisture.

Check soot blowing frequency (Only blow when necessary) If any of the replacement recommendations are not completed during this overhaul, ensure that they are completed during the next scheduled overhaul.

Total of (52) Priority #1 items were identified. Total of (14 Records) Priority #2 items were identified. Total of (8 Records) Priority #3 items were identified.

14

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Furnace Tube Sample: One tube in the fire box was pulled for metallurgical analysis per plant personnel request. Right sidewall tube #70, elevation 658.

Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of ( Records) Priority #3 items were identified.

PSH Bank 1, 2, 3: The primaries are noted for elements falling off of their saddle lugs at the front of the banks. The right half of the primaries are being replaced during this overhaul, and the left half of the primaries have been replaced last year. Debris has been noted for accumulation at the front of the bank from deteriorated refractory wall and slag. This will need to be cleaned out to prevent eddying channels for fly ash to erode, as well as allowing gas velocity to pass through component at an even pattern with no restrictions. A few scallop bar support have been noted for repair. Bank 3 was noted for repairing two support guides on the rear wall, and for the removal of loose debris.

15

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

UT verification surveys have been performed at the base of the riser tube sections to help project tube wastage rates during future overhaul. UT survey has also been performed on the dogleg sections between banks.

KEY POINTS: Review weld X-rays for a percentage (of plants request) of butt welds made on new PSH bank tubes (If greater than 10% of xrays reviewed fail, UDC recommends that a minimum of 50% of all welds be X-rayed and approved by contractor QC and an Alliant CWI.

Air Heater Gas Outlet: No action item have been found.

Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of ( Records) Priority #3 items were identified.

16

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

SSH Outlet: This component was noted for three pad welds on the front of the pendant on the spacer tube due to soot blower erosion. A 100% visual was not possible due to the excessive amount of slag build up on the tube surface.

KEY POINTS: Grant access to the upper levels of pendants for inspection.

Total of (1) Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of (2 Records) Priority #3 items were identified.

Furnace Grinds: The furnace was laid out with 6 bans for grinding to record accurate 3point UT verification. Discussions with plant personnel indicate that the unit may run with low oxygen if not negative in the fire box. No exact numbers or facts have been concluded as to stokemetric measures at and or below burner elevation. For a 100% water wall inspection, it is recommended to pressure wash or sand blast the water walls. Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of ( Records) Priority #3 items were identified. ` 17

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Penthouse: The penthouse was noted for numerous floor casing cracks, as well as holes in the side casings. Due to excessive cracking in the floor casing, there is approximately 8of ash build up on the floor. Ash build is a result of gases passing through the cracks and entering into the penthouse. Gases from the boiler below will elevate the penthouse temperatures which are not designed to exceed limits of structural steel integrity. SSH headers are noted for missing insulation; this will also elevate temperature and potentially affect carbon steel supports in the general vicinity of headers.

KEY POINTS: Excessive temperatures in the penthouse can contribute to structural degradation of support rods and other carbon steel structures. If interlocking tiles are used for isomembrane installation (Ensure that roof tube below are properly supported by means of support clips that should be connected to the collector bars running left to right at the front and rear of high crown seal boxes. Improperly supported roof tubes can sag at a greater rate due to additional tile weight.) If roof tubes are not supported properly (Install 8 fire blanketing in place of the interlocking tiles to reduce weight. Fire blanketing is effective however, is more of a short term fix than a permanent fix. Plan on additional repairs in less than 10 years if fire blanketing is used.)

Total of (0) Priority #1 items were identified. Total of (3 Records) Priority #2 items were identified. Total of (8 Records) Priority #3 items were identified. ` 18

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

xxxxxx unit #4 January 2003 Planned Outage Executive Summary

Economizer: The economizer banks were in good condition as found. Retractable blower lances have been noted for minor abrasion, no action is required. Total of () Priority #1 items were identified. Total of ( Records) Priority #2 items were identified. Total of (2 Records) Priority #3 items were identified. Items not inspected: DA Tank De-Superheat sprays Reheat De-superheat sprays Reheat Pendant (Upper level rear of inlet) Superheat Pendant (Upper levels) Fire Box (UT survey only) Cyclone Burners

19

United Dynamics Corporation 1345 Old Preston Hwy. N. Louisville, Ky 40229 voice 502.957.7525 fax: 502.957.5441 www.udc.net

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- 2010 Alliance Workshop: Figure 1 Chasm Miao Keng' in Chongqing Province of ChinaDocumento8 páginas2010 Alliance Workshop: Figure 1 Chasm Miao Keng' in Chongqing Province of ChinaJohn M. CavoteAinda não há avaliações

- Inspection Report: Area: Reheat Bank 2Documento10 páginasInspection Report: Area: Reheat Bank 2John M. CavoteAinda não há avaliações

- Penthouse January 2007 PDFDocumento1 páginaPenthouse January 2007 PDFJohn M. Cavote25% (4)

- Penthouse Nov 2006 Fourth QuarterDocumento2 páginasPenthouse Nov 2006 Fourth QuarterJohn M. CavoteAinda não há avaliações

- Presentation Draft ME 2010 AtlantaDocumento18 páginasPresentation Draft ME 2010 AtlantaJohn M. CavoteAinda não há avaliações

- Penthouse April 2007 EditDocumento2 páginasPenthouse April 2007 EditJohn M. CavoteAinda não há avaliações

- UDC Compilation 2011Documento8 páginasUDC Compilation 2011John M. CavoteAinda não há avaliações

- Epri 2008 PPDocumento29 páginasEpri 2008 PPJohn M. CavoteAinda não há avaliações

- NDE Capabilities 2011Documento2 páginasNDE Capabilities 2011John M. CavoteAinda não há avaliações

- DNFM ServicesDocumento1 páginaDNFM ServicesJohn M. CavoteAinda não há avaliações

- David N. French Metallurgists: 35 Years of Boiler Tube Failure Analysis ExperienceDocumento8 páginasDavid N. French Metallurgists: 35 Years of Boiler Tube Failure Analysis ExperienceJohn M. CavoteAinda não há avaliações

- Services With Descriptions 2008Documento2 páginasServices With Descriptions 2008John M. CavoteAinda não há avaliações

- Penthouse Winter 2000Documento2 páginasPenthouse Winter 2000John M. CavoteAinda não há avaliações

- Penthouse Winter 1995Documento2 páginasPenthouse Winter 1995John M. CavoteAinda não há avaliações

- Penthouse Winter 1998Documento2 páginasPenthouse Winter 1998John M. CavoteAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Electrodynamics Class NotesDocumento237 páginasElectrodynamics Class NotesSwashy Yadav80% (5)

- Proceedings CIB W062 2018 SymposiumDocumento354 páginasProceedings CIB W062 2018 SymposiumdplumbingAinda não há avaliações

- Distillation Column ModellingDocumento1 páginaDistillation Column ModellingChem.EnggAinda não há avaliações

- TM 9 4935 601 14 3&PDocumento137 páginasTM 9 4935 601 14 3&Pkhaerul jannahAinda não há avaliações

- Mag Drive PumpsDocumento5 páginasMag Drive PumpsakkineniAinda não há avaliações

- UOP Merox Chapter PDFDocumento12 páginasUOP Merox Chapter PDFrohl55Ainda não há avaliações

- Act 3 (PHY LAB)Documento4 páginasAct 3 (PHY LAB)Camille MagnoAinda não há avaliações

- Plumbing - HVAC August 2010Documento48 páginasPlumbing - HVAC August 2010aurelian177100% (1)

- Refrig - Samsung RF23J9011SR - v2 - User ManualDocumento108 páginasRefrig - Samsung RF23J9011SR - v2 - User ManualadamsusaAinda não há avaliações

- Aula Balancim DifusaoDocumento29 páginasAula Balancim DifusaoGabrielAntoniazziAinda não há avaliações

- Voltage DropDocumento18 páginasVoltage DropVaughn GaneloAinda não há avaliações

- AEH Company Profile-1Documento14 páginasAEH Company Profile-1Hrishikesh RaiAinda não há avaliações

- DNV Maritime Forecast 2050 2021-WebDocumento82 páginasDNV Maritime Forecast 2050 2021-WebДмитрий Ганжа100% (1)

- Mechanis Quizbee in Math and ScienceDocumento4 páginasMechanis Quizbee in Math and ScienceChristine De San Jose80% (5)

- Shell VOLUTA C 400: Neat Quenching OilDocumento2 páginasShell VOLUTA C 400: Neat Quenching OilalmasAinda não há avaliações

- 1 Home Base Work March 19-MRCH 31Documento3 páginas1 Home Base Work March 19-MRCH 31Celso AmotoAinda não há avaliações

- Shaffer Et Al. - 2003 - Foraging Effort in Relation To The Constraints ofDocumento9 páginasShaffer Et Al. - 2003 - Foraging Effort in Relation To The Constraints ofBenjamin MendezAinda não há avaliações

- Service Station Manual Vespa LX 125 - 150 4t Euro 3Documento241 páginasService Station Manual Vespa LX 125 - 150 4t Euro 3Adèle Standard100% (1)

- P&id LegendDocumento1 páginaP&id Legendkamal arabAinda não há avaliações

- Annexure-3 Calculation of Safe Bearing Pressure Based On N Value Settlement CriteriaDocumento4 páginasAnnexure-3 Calculation of Safe Bearing Pressure Based On N Value Settlement CriteriaAnkitaAinda não há avaliações

- CATERPILAR3516 1550-2200 BHPDocumento6 páginasCATERPILAR3516 1550-2200 BHPNadia AnandaAinda não há avaliações

- Parallel Operation of Three-Phase AlternatorsDocumento13 páginasParallel Operation of Three-Phase AlternatorsSTUDENTS OF DOE CUSATAinda não há avaliações

- 6.012 Microelectronic Devices and Circuits Spring 2005Documento10 páginas6.012 Microelectronic Devices and Circuits Spring 2005dan gAinda não há avaliações

- 5 Feeder Protection & Relay CoordinationDocumento51 páginas5 Feeder Protection & Relay CoordinationSatya VasuAinda não há avaliações

- STPxx-3SE-40-DS-en-11 Inversor SMADocumento4 páginasSTPxx-3SE-40-DS-en-11 Inversor SMAArnaldo Macchi MillanAinda não há avaliações

- TurbochargerDocumento8 páginasTurbochargersudheeshAinda não há avaliações

- TM9-2350-311-20-1 - M109a2 & M109a3Documento914 páginasTM9-2350-311-20-1 - M109a2 & M109a3Вадим ЗахарченкоAinda não há avaliações

- Geometric and Physical Optics: InterferenceDocumento35 páginasGeometric and Physical Optics: InterferenceHelenAinda não há avaliações

- ProMax 3 BrochureDocumento20 páginasProMax 3 BrochureNila Gama100% (2)

- 2002 Physics NQE QuestionsDocumento7 páginas2002 Physics NQE QuestionskarxriAinda não há avaliações