Escolar Documentos

Profissional Documentos

Cultura Documentos

Problem Statement

Enviado por

nickolasnaimDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Problem Statement

Enviado por

nickolasnaimDireitos autorais:

Formatos disponíveis

MAE 20 FALL 2011: COMPOSITE BEAM DESIGN PROBLEM

Due: Friday, December 9, 7:00pm (at the Final Exam)

NOTE: This design problem is related to the material of Chapter 16. Design Example 16.1 (in the book, page 651, 8th Edition) and Sample Problem 16.8 (on the course website) are helpful. This problem is worth 5% of the course. Therefore, the Final Exam will be 35% of the course. British system of units must be used throughout this design. A table in Excel format with the data, calculations, and final results must be attached to your solution. The page limit for this problem is 6 pages. Substantial points will be deducted if the solution is unclear, the report is messy, or the Excel results cannot be reproduced. Any questions regarding this problem must be directed to the TA.

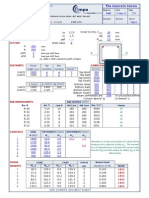

You are asked to produce an aligned and continuous fiber-reinforced epoxy composite beam with a length of 24 inches and a rectangular cross-section of 2 2 in2. The fibers must be oriented in the longitudinal direction (i.e., perpendicular to the cross-sectional area), and the maximum allowable fiber volume fraction is 0.70. The beam will be subject to a three-point flexural loading (Fig. 12.32), and must be able to withstand a load of 1,740 lbf with a deflection of less than 0.03 in. The distance between support points is to be 22 in. In a three-point-bending test, the point of maximum deflection occurs at the center, and the deflection is described by

FL3 y = 48EI where E is the modulus of elasticity, and I is the cross-sectional moment of inertia. For a rectangular cross section, the moment of inertia is given by bd 3 I = 12 where b is the width and d is the height of the cross section (Fig. 12.32).

(a): Among E-glass, carbon (PAN standard modulus), and Kevlar 49, choose a suitable fiber material and volume fraction of fibers that meet the requirements described above. Justify your answer with calculations and short answer explanations. Properties of the possible fiber materials are listed in Tables B.1, B.2 and B.4 in Appendix B. Material costs are listed in Appendix C. If a range of values is listed in these tables, use the average of the given values. (b): Calculate the longitudinal tensile strength, weight, and cost of the materials for your designed composite beam. Assume the following stress levels on the epoxy matrix at fiber failure: E-glass 10,000 psi; carbon (PAN standard modulus)4350 psi; and Kevlar 497250 psi. In addition, use a density of 0.045 lbm/in3 for the epoxy matrix. (c): Compare the values calculated in part (b) to those of a 4140 steel alloy (oil-quenched and tempered) beam of the same dimensions. Which is the more desirable material? Explain.

Você também pode gostar

- Advanced Numerical Methods with Matlab 2: Resolution of Nonlinear, Differential and Partial Differential EquationsNo EverandAdvanced Numerical Methods with Matlab 2: Resolution of Nonlinear, Differential and Partial Differential EquationsAinda não há avaliações

- BDA 31003 Finite Element Method TasksDocumento6 páginasBDA 31003 Finite Element Method TasksAmeerul AzmieAinda não há avaliações

- Biomechanics: Optimization, Uncertainties and ReliabilityNo EverandBiomechanics: Optimization, Uncertainties and ReliabilityAinda não há avaliações

- BDA 40303 Finite Element Method TasksDocumento6 páginasBDA 40303 Finite Element Method TasksNadia BalqisAinda não há avaliações

- CEE 4611 - Mid-Term Question (Online) - ModifiedDocumento2 páginasCEE 4611 - Mid-Term Question (Online) - ModifiedZames KhanAinda não há avaliações

- Analysis of Composite Beams With Web OpeningDocumento11 páginasAnalysis of Composite Beams With Web OpeningpraveenAinda não há avaliações

- Please Attach Your Answer Script in PDF Format in Google Classroom and Right OrientationDocumento3 páginasPlease Attach Your Answer Script in PDF Format in Google Classroom and Right Orientationdf fdsdAinda não há avaliações

- Preliminary Design and Analysis Sandwich FRP Bridge DeckDocumento6 páginasPreliminary Design and Analysis Sandwich FRP Bridge Decklecotier33Ainda não há avaliações

- CourseworkFEA CAD 2015Documento4 páginasCourseworkFEA CAD 2015Abdalla Mohamed AbdallaAinda não há avaliações

- Symmetric Bending of Laminated PlatesDocumento3 páginasSymmetric Bending of Laminated PlateskkkrajaAinda não há avaliações

- Guidelines For Fibre-Based Inelasticity Modelling of Reinforced Concrete MembersDocumento8 páginasGuidelines For Fibre-Based Inelasticity Modelling of Reinforced Concrete MembersRandolph BorgAinda não há avaliações

- Annen2IASS PDFDocumento8 páginasAnnen2IASS PDFErika Paz YanezAinda não há avaliações

- MSC NastranDocumento6 páginasMSC NastranJan ScarAinda não há avaliações

- Materials: Harmony Search Optimisation of Dispersed Laminated Composite PlatesDocumento12 páginasMaterials: Harmony Search Optimisation of Dispersed Laminated Composite PlatesKumar DivyanshAinda não há avaliações

- MECH9420 S2-2016 Assignment 3 v3Documento8 páginasMECH9420 S2-2016 Assignment 3 v3Mohammed MeeranAinda não há avaliações

- Implementation of A Multisurface Cap-Plasticity Model For Concrete and Its Application To The Simulation of Composite Joint TestsDocumento14 páginasImplementation of A Multisurface Cap-Plasticity Model For Concrete and Its Application To The Simulation of Composite Joint Testsklomps_jrAinda não há avaliações

- SUMMER 2010 Coventry University Faculty of Engineering and ComputingDocumento4 páginasSUMMER 2010 Coventry University Faculty of Engineering and ComputingVinay GowdaAinda não há avaliações

- Bamboo StructureDocumento5 páginasBamboo Structure52891Ainda não há avaliações

- Homework 1Documento4 páginasHomework 1yana33Ainda não há avaliações

- Faculty of Engineering and Technology: B.E. PRODUCTION (REV) ExaminationDocumento3 páginasFaculty of Engineering and Technology: B.E. PRODUCTION (REV) ExaminationpatilsspAinda não há avaliações

- 07a72106 AnalysisofcompositesstructureDocumento5 páginas07a72106 Analysisofcompositesstructureshiva_kumar_perumallaAinda não há avaliações

- Homework Assignments and Due Dates Assignment Problems Due DateDocumento3 páginasHomework Assignments and Due Dates Assignment Problems Due Dateksik10Ainda não há avaliações

- WWW - Manaresults.Co - In: Gpa G Gpa E E Gpa EDocumento1 páginaWWW - Manaresults.Co - In: Gpa G Gpa E E Gpa E2707SAKSHI TONDEAinda não há avaliações

- 8C 2 PensoDocumento11 páginas8C 2 PensoAmirhossein AnsariAinda não há avaliações

- 2.094 F E A S F: Inite Lement Nalysis of Olids and LuidsDocumento1 página2.094 F E A S F: Inite Lement Nalysis of Olids and Luidsletter_ashish4444Ainda não há avaliações

- Computer Aided Engineering With Ansys: The Final Project DescriptionDocumento8 páginasComputer Aided Engineering With Ansys: The Final Project DescriptionYeswanth Kumar TAinda não há avaliações

- Homework 1 - Materials SelectionDocumento1 páginaHomework 1 - Materials SelectionAdamAinda não há avaliações

- X86910 (ST5006)Documento2 páginasX86910 (ST5006)Kazi Tour DépenseAinda não há avaliações

- Finite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreDocumento8 páginasFinite Element Analysis of Compression of Thin, High Modulus, Cylindrical Shells With Low-Modulus CoreseventhhemanthAinda não há avaliações

- MEC 3111 - Finite Element AnalysisDocumento3 páginasMEC 3111 - Finite Element AnalysisRyan MahoneyAinda não há avaliações

- Equivalent Analysis of Honecomb PanelsDocumento5 páginasEquivalent Analysis of Honecomb Panelsprateekg92Ainda não há avaliações

- Tute Questions Set 2 2021 SID Thermal PoissonsDocumento5 páginasTute Questions Set 2 2021 SID Thermal PoissonsMichael NeeAinda não há avaliações

- MM312 Final Exam Paper - 2020Documento6 páginasMM312 Final Exam Paper - 2020Praveet ChandAinda não há avaliações

- 2018 Ordinary Exam UK 2Documento15 páginas2018 Ordinary Exam UK 2eman hussainAinda não há avaliações

- Hexahedral and Tetrahedral Element StudyDocumento6 páginasHexahedral and Tetrahedral Element Studylpararasasingam91Ainda não há avaliações

- Taggart AUC2008Documento15 páginasTaggart AUC2008klomps_jrAinda não há avaliações

- Legend: Pinned Support Fixed Support Vertical Support Point Load Uniformly Distributed LoadDocumento5 páginasLegend: Pinned Support Fixed Support Vertical Support Point Load Uniformly Distributed Loads1133387Ainda não há avaliações

- Material Identification of Viscoelastic Core Materials in Sandwich StructuresDocumento6 páginasMaterial Identification of Viscoelastic Core Materials in Sandwich StructuresHamed MemarianAinda não há avaliações

- Amos 2012Documento4 páginasAmos 2012prk74Ainda não há avaliações

- Finite Element MethodDocumento11 páginasFinite Element MethodRRAinda não há avaliações

- Composites: Part A: Juan Pablo Vitale, Gaston Francucci, Jian Xiong, Ariel StocchiDocumento9 páginasComposites: Part A: Juan Pablo Vitale, Gaston Francucci, Jian Xiong, Ariel Stocchiitsaashish12gmailcomAinda não há avaliações

- Mech 260-Final ExamDocumento3 páginasMech 260-Final ExamwerewaroAinda não há avaliações

- القبهDocumento10 páginasالقبهعبدالعزيز فخريAinda não há avaliações

- 4.7. Self-Study ProblemsDocumento9 páginas4.7. Self-Study Problemsfahmiamri93Ainda não há avaliações

- 3.9. Self-Study ProblemsDocumento9 páginas3.9. Self-Study Problemsfahmiamri93Ainda não há avaliações

- Application of BCN Test For Controlling Fiber Reinforced Shotcrete in Tunnelling Works in ChileDocumento9 páginasApplication of BCN Test For Controlling Fiber Reinforced Shotcrete in Tunnelling Works in ChileRB SinghAinda não há avaliações

- Composite Structures: Quantian Luo, Liyong TongDocumento11 páginasComposite Structures: Quantian Luo, Liyong TongSaid DjaballahAinda não há avaliações

- Final Exam, Manuf of CompositesDocumento2 páginasFinal Exam, Manuf of CompositesLaura RobayoAinda não há avaliações

- FEA of PipeDocumento11 páginasFEA of Pipedimos dimouAinda não há avaliações

- PHE-07 Assignments 2019 (English) PDFDocumento4 páginasPHE-07 Assignments 2019 (English) PDFHimanshu GargAinda não há avaliações

- 110me0335 6 PDFDocumento52 páginas110me0335 6 PDFAshwin KulkarniAinda não há avaliações

- CHW4Documento4 páginasCHW4bauemmvssAinda não há avaliações

- Asia Pacific College of Advanced Studies Instructions: General InstructionsDocumento2 páginasAsia Pacific College of Advanced Studies Instructions: General InstructionsJoshua John JulioAinda não há avaliações

- ASSIGNMENT 3 - EGR2208 - Question PDFDocumento2 páginasASSIGNMENT 3 - EGR2208 - Question PDFIhsan Samoh เพี่อนดีดีAinda não há avaliações

- Assignment 1-BS-ME07Documento2 páginasAssignment 1-BS-ME07Mateenullah MeoAinda não há avaliações

- A Fiber-Bundle Pull-Out Test For Surface-Modi Ed GlassDocumento15 páginasA Fiber-Bundle Pull-Out Test For Surface-Modi Ed GlassSathish NagarajanAinda não há avaliações

- Engineering Journal Optimal Design of Steel and Composite Vessels With Tube Branch JointDocumento12 páginasEngineering Journal Optimal Design of Steel and Composite Vessels With Tube Branch JointEngineering JournalAinda não há avaliações

- Mechanical Properties of Short-Fibre Layered CompositesDocumento13 páginasMechanical Properties of Short-Fibre Layered Compositesabilio_j_vieiraAinda não há avaliações

- Department of Civil Engineering CIVL2201 Structural MechanicsDocumento8 páginasDepartment of Civil Engineering CIVL2201 Structural Mechanicssky willaAinda não há avaliações

- Reg No.: - NameDocumento3 páginasReg No.: - NameSijuKalladaAinda não há avaliações

- Boundary Conditions in Fluid MechanicsDocumento6 páginasBoundary Conditions in Fluid MechanicsnickolasnaimAinda não há avaliações

- Notes PDFDocumento1 páginaNotes PDFnickolasnaimAinda não há avaliações

- 8.512 Theory of Solids Ii: Mit OpencoursewareDocumento5 páginas8.512 Theory of Solids Ii: Mit OpencoursewarenickolasnaimAinda não há avaliações

- A New Airmass Independent Formulation For The Linke Turbidity Coefficient - Ineichen - 2002Documento7 páginasA New Airmass Independent Formulation For The Linke Turbidity Coefficient - Ineichen - 2002nickolasnaim100% (1)

- AssignmentsDocumento2 páginasAssignmentsnickolasnaimAinda não há avaliações

- Microstrip AntennaDocumento56 páginasMicrostrip AntennaPrajakta MoreAinda não há avaliações

- Lab 12Documento4 páginasLab 12Samuel RodgersAinda não há avaliações

- Phan Mem FBDocumento919 páginasPhan Mem FBAnonymous DNb6yWERfBAinda não há avaliações

- Quantum Mechanical Explanation For Dark Energy, Cosmic Coincidence, Flatness, Age, and Size of The UniverseDocumento8 páginasQuantum Mechanical Explanation For Dark Energy, Cosmic Coincidence, Flatness, Age, and Size of The UniverseAsemSalehAinda não há avaliações

- Ib Physics HL Review Packet - ThermodynamicsDocumento19 páginasIb Physics HL Review Packet - ThermodynamicsGhenwa DimachkiAinda não há avaliações

- Unity Secondary School Physics Chapter 21: Electromagnetism AnswersDocumento5 páginasUnity Secondary School Physics Chapter 21: Electromagnetism AnswersFrancis Ho HoAinda não há avaliações

- Temperature Effects On Resistance PDFDocumento2 páginasTemperature Effects On Resistance PDFLaurence MichaelAinda não há avaliações

- Datasheet DXDocumento2 páginasDatasheet DXAsnawirarrr100% (2)

- Virtual Work and Power BalanceDocumento5 páginasVirtual Work and Power BalanceAlessio ScarabelliAinda não há avaliações

- University of Khartoum Faculty of Engineering Chemical Engineering DepartmentDocumento38 páginasUniversity of Khartoum Faculty of Engineering Chemical Engineering DepartmentAsila AhmedAinda não há avaliações

- Calculating Truss ForcesDocumento29 páginasCalculating Truss Forcesrecep1Ainda não há avaliações

- Effects of Moisture Content On The Foundry Properties of Yola Natural SandDocumento12 páginasEffects of Moisture Content On The Foundry Properties of Yola Natural SandatikAinda não há avaliações

- Rotation and Angular Momentum: RotationsDocumento20 páginasRotation and Angular Momentum: RotationsSayan RoyAinda não há avaliações

- 4 and 6 Pole MotorDocumento6 páginas4 and 6 Pole Motorarajamani78100% (1)

- Cebu Institute of Technology University: ECE 162 W1Documento8 páginasCebu Institute of Technology University: ECE 162 W1meshin yuAinda não há avaliações

- Static Force AnalysisDocumento19 páginasStatic Force Analysiskreddy260100% (1)

- 10 Years of Atom&NucleiDocumento4 páginas10 Years of Atom&NucleidipeshjoonAinda não há avaliações

- Solutions For SemiconductorsDocumento54 páginasSolutions For SemiconductorsOzan Yerli100% (2)

- SME 2002 Local Stresses in Belt Turnovers in Conveyor BeltDocumento18 páginasSME 2002 Local Stresses in Belt Turnovers in Conveyor BeltWashington Morais100% (1)

- VectorsDocumento9 páginasVectorsMohd Yousha AnsariAinda não há avaliações

- Universe Formation and Birth of StarDocumento3 páginasUniverse Formation and Birth of StarcollegeschoolfilesmjAinda não há avaliações

- Superlattices and Microstructures: SciencedirectDocumento9 páginasSuperlattices and Microstructures: SciencedirectIsmael AnconaAinda não há avaliações

- Detection Qualification and Types of Detectors in HPLC PDFDocumento17 páginasDetection Qualification and Types of Detectors in HPLC PDFconstantinAinda não há avaliações

- Mechanical Properties of Materials: Manufacturing Processes, 1311 DR Simin Nasseri Southern Polytechnic State UniversityDocumento44 páginasMechanical Properties of Materials: Manufacturing Processes, 1311 DR Simin Nasseri Southern Polytechnic State Universityspades24kAinda não há avaliações

- Wood in Fire AOFST - 1-380Documento6 páginasWood in Fire AOFST - 1-380Sun RuiAinda não há avaliações

- Loudon: Chapter 5, Section 4Documento3 páginasLoudon: Chapter 5, Section 4lcandyvAinda não há avaliações

- Pumping Tests: R R T Q S S H HDocumento6 páginasPumping Tests: R R T Q S S H HGonzalo Salazar PanequeAinda não há avaliações

- 6325 05 PDFDocumento33 páginas6325 05 PDFMatias Montenegro MancillaAinda não há avaliações

- TCC53 Column DesignDocumento18 páginasTCC53 Column DesignVasileios Manginas100% (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- Certified Solidworks Professional Advanced Weldments Exam PreparationNo EverandCertified Solidworks Professional Advanced Weldments Exam PreparationNota: 5 de 5 estrelas5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNo EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureNota: 4.5 de 5 estrelas4.5/5 (2)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!No EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Nota: 4 de 5 estrelas4/5 (3)

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®No EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Ainda não há avaliações

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNo EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchNota: 4 de 5 estrelas4/5 (10)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.No EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Nota: 4 de 5 estrelas4/5 (5)