Escolar Documentos

Profissional Documentos

Cultura Documentos

Working Capital Case Study

Enviado por

Rahul SinghDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Working Capital Case Study

Enviado por

Rahul SinghDireitos autorais:

Formatos disponíveis

CASE 27.

1:

RELIABLE TEXAMILL LIMITED17

components would assume greater importance. The company would need more working capital funds to support the expanding sales. Mr Shyam Lal knew that it may not be easy to get funds from banks. He was wondering how he could reduce the working capital funds requirement of his company without affecting the sales.

In the beginning of 2009, Mr Shyam Lal, Chairman and Managing Director of Reliable Texamill Limited (RTL)was concerned about the company's working capital management. As the company was expecting its net sales to increase from Rs 1,208.61 lakh in 2008 to Rs 2,185.94 lakh in 2009, the management of working capital

17. This case is an adapted version of the original case written by the author and published in Pandey, LM. and Bhat, Ramesh, Cases in Financial Management, Tata McGraw Hill, 2002.

670

FinancialManagement materials and stores at the current market prices from suppliers. Because of the frequent power cuts, the company built up adequate captive power generating capacity by installing one more set of 860 kVA diesel power generator. RTL is now planning to replace two sets of 250 kVAby the purchase of one imported SKODA set of 869 kVA at a cost of Rs 47.70. The new set is expected to be more economicalI from the point of view of diesel consumption and usage for longer period.

Background

RTL commenced commercial production in 2005. It manufactures synthetic blended yarn which is a raw material for other textile weaving mills and also for handloom and power looms. The company's mills are situated in an industrially less developed area in a northern state. The company has a licensed capacity of 80,000 spindles and existing installed capacity of 26,390 spindles (this includes 6, 210 spindles added during 2007-08). The average capacity utilization of the company was 81 per cent during 2006-07 and 85 per cent during 2007-08. It expects to use 87 per cent of the installed capacity during 2008-09. In the year 2005-06, the company could generate net sales ofRs 191.131akh, and incurred a net loss ofRs 57.11 lakh. The acute power shortage was the dominant reason, besides the initial teething troubles, for the poor beginning of the company. RTL has since been able to increase its sales to Rs 973.321akh in 2006-07, and to Rs 1,203.611akh in 2007-08 as against the estimated sales of Rs 1,767.55 lakh. It produced 1,315 tonnes of yarn in 2007-08 against 1,182 tonnes during the previous year. The management ofRTL has attributed the lower actual sales to the sluggish market conditions that prevailed during the second half of the year 2007-08, forcing the company to keep its production at a low level, and also to a certain extent due to the company manufacturing substantial quantity of yarn of lesser counts and blends of lower value to suit the market conditions. After incurring a loss in the first year (the company operated for seven months only), the company made a net profit ofRs 24.481akh in 2006-07. The company showed a net profit before depreciation ofRs 32.421akh in 2007-08. Power cuts, high input costs and increased administrative expenses on account of expansion resulted in poor profitability. RTL has not so far paid any tax and dividends. Its tax liability is expected to be nil for quite some time as it enjoys tax benefits being a new unit located in an industrially less' developed area. The actual and estimated balance sheets and the profit and loss account of the coinpany are given in Tables 27.1.1, 27.1.2 and 27.1.3.

COMPETITION AND SELLING ARRANGEMENTS

The company's end products cater to the needs of large and medium scale manufacturers of fabrics and also handlooms and power looms. The major buyers, accounting for 80 to 85 per cent of sales, include reputed firms. The remaining 15-20 per cent is sold to small dealers and traders. RTL faces a fair amount of competition from a number of companies. In spite of the stiff competition, the synthetic blended yarn manufactured by RTL is well received in the market and is supposed to enjoy a premium'over the yarn manufactured by other leading manufacturers in the country. Its four branches located in different parts of the country manage the selling operations of the company. The full-fledged sales depots, recently opened, are situated far away from the company's factory. As a result, a good part of the finished goods remains in transit at any point of time. About 65 per cent of the company's sales are being affected on credit terms ranging from 45 to 60 days depending on the market conditions. The company has been finding it difficult to realize its dues within the normal credit period allowed to customers. The management attributed this to its being new to the competitive textile market. Till 2007-08, the company had a practice of selling a part of its production through selling agents to small buyers. This practice has been discontinued, and now the company directly sells to these buyers. The company, however, allows a discount ranging between 2 to 21h per cent for sales on demand/cash basis.

PRODUCTION FACILITIES

The company's existing production facilities are considered adequate for operating the spinning mills at the enhanced installed capacity. The production process for obtaining the main product, viz .. the synthetic yarn, originates with the mixing up ofthe different fibres, i.e., acrylic, polyester and viscose, as per the blend proposedto be manufactured. The annual consumption of these fibres generally depends on the product mix manufactured during the particular year; the actual consumption during the years 2006-07 and 2007-08 being about 1,973 tonnes and 2,303 tonnes, valued respectively at Rs 713.11 lakh and Rs 902.30 lakh. The company generally does not encounter any significant difficulties in procuring its full requirements of raw

EXPANSION

Soon after starting commercial production in 2005, RTL planned to undertake an expansion programme for installation of another 20,000 additional spindles. Since the company incurred a loss in the very first year, the company attempted a modest expansion programme involving installation of additional 6,210 spindles only during 2007-08. The company felt that this increase in its installed capacity was absolutely necessary in order tobring about a better economy in its operations. The expansion programme was completed with a capital expenditure of about Rs 2761akh against the estimated cost ofRs 2531akh. The additional spindles would be put to commercial production from April 2009.

Principles of Working Capital Management

671

FUTURE PROSPECTS

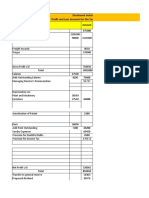

Theprices of the basic raw material, viz., viscose/polyester fibres,are lower in the international market than in India. Whilethe prices of viscose/polyester fibres have increased substantially during the last two years, i.e., 2006-07 and 2007-08,he prices of RTL's end products have, more or t less,remained at the same level. The company has not beenable to absorb in the selling prices, the increased costs of inputs. The power supply in the state, where the company is situated, is presently showing signs of improvement, and it is expected to be satisfactory in the comingmonths. With the consumer preference during the recent years having shifted to blended fabrics and the company's products being of good quality and well acceptedin the market, RTL can hope to fare well in the comingyears. Table27.1.1: Reliable Texamill Limited: Balance Sheet as on March 31 (Rs lakh)

~ <

RTL produced 1,182 tonnes and 1,315 tonnes of yam during the years 2006-07 and 2007-08 respectively. In 200809, it has planned production of 1,758 tonnes. RTL normally plans its production schedule on the basis ofthe market trend, i.e., as per the counts/blends of synthetic yarn acceptable in the market, so as to sell the end products with ease. RTL's production plan for 2008-09 has been devised keeping in view the changes in the market conditions and other factors. RTL has planned to manufacture more quantities of yarn in blends of higher value during the period 2008-09. Those blends are expected to be more acceptable in the market. Table 27.1.2: Reliable Texamill Limited Profit and Loss Account for the year ending March 31 . (Rs lakh) . s.'

R,!,.

~J .. ':--

t"~

'<

",,~.:,..:.-~!"{; .

.!,,"

~.

w-

..... ."~' ;

:--_

Net Sales Cost of goods sold Gross profit

973.32 1,208.61 775.98 921.96 197.34 97.26 81.68 18.40 6.08 24.48 0.00 24.48 286.65

2,185.94 1,850.33 335.61

v"

.:

LIABILITIES CurrentLiabilities Bank borrowings Trade creditors Term loans payable Misc. liabilities and provisions Termliabilities Term loans payable . Deferred credit Term deposits Others Total liabilities Net Worth Share capital

Reserves

625.95 366.74 200.94 10.56 47.71 531.22 479.68 29.95 10.27 11.32

805.78 490.02 239.16 5.89 70.71 801.14 641.88 24.06 20.54 114.66

866.16 622.91 70.79 98.74 73.72 802.37 613.73 17.21 56.77 114.66 1,668.53 288.74 199.44 24.26 65.04 1.957.27

Operating expenses: Selling and administration Interest Operating profit Other income (loss) Profit before tax Provision Profit after tax

123.30 137.83 25.52 6.90 32.42 0.00 32.42

127.74 140.6,8 67.19 -1.94 65.25 0.00 65.25

1,157.17 1,606.92 191.07 199.44 24.26 -32.63 223.49 199.44 24.26 -0.21

Table 27.1.3: Reliable Texamill Limited: Statement of Costs of Sales (Rs lakh)

P&Lsurplus (deficit) Total funds ASSETS CurrentAssets Cash and bank balance Receivables Inventory: Raw materials Stock-in process Finished goods Consumable spares Others Fixed Assets Gross Block Acc. Depreciation Net block Other non-current assets Intangible Assets Total assets

1,348.24 1.830.41 580.03 4.35 293.25 757.47 6.06 269.48

913.59 7.44 303.19 275.22 80.85 177.87 32.34 36.68 1,027.35 1,146.19 127.34 1,018.85 8.50 16.33 1,957.27

162.00 202.13 51.02 64.96 160.44 22.94 27.20 16.80 29.67 27.20 760.46 1,056.61 820.04 1,121.13 73.66 73.66 746.38 1.047.47 14.08 9.14 7.75 16.33 1,348.24 1,830.41

Raw material Power and fuel Direct labour Other manufacturing expenses Depreciation Total Add: Opening stock-in -progress Total Less: Closing stock-in -progress Cost of production Add: Opening finished goods Total Less: Closing finished goods Cost of Sales

685.94 36.67 40.00

933.67 55.37 57.14

1,649.36 64.68 79.41 36.52 53.68 1,883.65 64.96 1,948.61 80.85 1,867.76 160.44 2,028.20 177.87 1,850.30

12.87 27.21 41.57 817.05 1,073.39 51.02 24.92 841.97 1,124.41 51.02 64.96 790.95 1,059.45 7.97 22.95 798.92 1,082.40 22.94 775.98 160.44 921.96

3.4 per cent of the total cost of production.

The company has projected its energy costs at about The other

672

Financial Management

expenses have been estimated in line with the past experience. Also, the assets and liabilities of the company have been estimated in accordance with the past trends. RTL had depended quite substantially on trade credit for meeting its working capital needs. Trade credit forms about one-third ofthe current liabilities. The normal credit period allowed by the suppliers is 45 days; however, a discount of 2 per cent for payments made within 15. days of the purchase date is allowed. In the past, creditors did not object to RTL's stretching of payments to them. In view of the credit squeeze, they are likely to pressurize hard for early payment of dues.

Discussion Questions

evaluate RTL's performance and financing of its operations. 2. How has the company managed its working capital in the past? Illustrate with appropriate calculations. 3. What are RTL'splans to improve its working capital management? Show the calculation of operating cycle to justify your answer. 4. Do you accept the financial plan prepared by RTL? What modifications would you suggest in the plan and why?

1. Critically

Você também pode gostar

- Primary Database: Overview of Multivariate MethodsDocumento3 páginasPrimary Database: Overview of Multivariate MethodsAnja GuerfalaAinda não há avaliações

- Group 4 PittaRosso Case AIMDocumento5 páginasGroup 4 PittaRosso Case AIMPragya WasanAinda não há avaliações

- Reliable Textile LimitedDocumento9 páginasReliable Textile LimitedNikhil Reddy100% (1)

- Modern Pharma Is Considering The Manufacture of A New Drug, Floxin, For Which The FollowingDocumento7 páginasModern Pharma Is Considering The Manufacture of A New Drug, Floxin, For Which The FollowingbansalparthAinda não há avaliações

- FM - Assignment Batch 19 - 21 IMS IndoreDocumento3 páginasFM - Assignment Batch 19 - 21 IMS IndoreaskjdfaAinda não há avaliações

- Marginal Cost of CapitalDocumento13 páginasMarginal Cost of CapitalShubham RanaAinda não há avaliações

- Continuous Assignments: Ram Kumar KakaniDocumento10 páginasContinuous Assignments: Ram Kumar KakaniKabeer KarnaniAinda não há avaliações

- A Study On HR Policies of WalmartDocumento6 páginasA Study On HR Policies of WalmartSanjay shukla0% (1)

- Britannia Industries Ltd. (India) Ratio AnalysisDocumento35 páginasBritannia Industries Ltd. (India) Ratio AnalysisMansiShahAinda não há avaliações

- Decision Theory - I-18Documento4 páginasDecision Theory - I-18NIKHIL SINGHAinda não há avaliações

- Q1. What Are The Organizational and Operational Issues That Underlie The Problems Facing BPS?Documento5 páginasQ1. What Are The Organizational and Operational Issues That Underlie The Problems Facing BPS?Munsif JavedAinda não há avaliações

- Ratio Analysis of Coca-ColaDocumento26 páginasRatio Analysis of Coca-ColaWajid Ali71% (7)

- Corporate Finance Assignment Ultratech EIC AnalysisDocumento19 páginasCorporate Finance Assignment Ultratech EIC AnalysisAditya Bikram SinghAinda não há avaliações

- Financial Accounting: A Managerial PerspectiveDocumento22 páginasFinancial Accounting: A Managerial Perspectivegajalpeshin100% (3)

- Ch01-Discussion Questions and AnswersDocumento3 páginasCh01-Discussion Questions and Answerseeman kAinda não há avaliações

- Project Report On The Neogi Chemical CompanyDocumento7 páginasProject Report On The Neogi Chemical Companyabhisheknagpal27Ainda não há avaliações

- Cool AidDocumento11 páginasCool AidSuman SouravAinda não há avaliações

- Business Environment - Surf Excel - ShaheeraDocumento19 páginasBusiness Environment - Surf Excel - ShaheeraShaheera100% (1)

- 6 Additional Solved Problems 5Documento25 páginas6 Additional Solved Problems 5Deepak Solanki100% (1)

- Financial Management - Question Paper Review - 5 & 10 Marks (Problems)Documento2 páginasFinancial Management - Question Paper Review - 5 & 10 Marks (Problems)jeganrajrajAinda não há avaliações

- ABBDocumento1 páginaABBNischay RathiAinda não há avaliações

- Nishat Mills Ratio AnalysisDocumento6 páginasNishat Mills Ratio AnalysisBabar KhanAinda não há avaliações

- Cool-Aid Private LimitedDocumento8 páginasCool-Aid Private Limitedpankajbhatt1993Ainda não há avaliações

- Case 13-2 Amerbran CompanyDocumento37 páginasCase 13-2 Amerbran CompanyZati Ga'in100% (1)

- Buyback of Shares of HulDocumento7 páginasBuyback of Shares of HulBoota DeolAinda não há avaliações

- Cost Sheet CaseDocumento4 páginasCost Sheet CasetanishaAinda não há avaliações

- Amalgamation IIDocumento26 páginasAmalgamation IIMumtazAhmadAinda não há avaliações

- Capital Budgeting Illustrative NumericalsDocumento6 páginasCapital Budgeting Illustrative NumericalsPriyanka Dargad100% (1)

- Format of Project On Enterprise AnalysisDocumento13 páginasFormat of Project On Enterprise AnalysisHatim Ezzi100% (1)

- Kota Tutoring: Financing The ExpansionDocumento7 páginasKota Tutoring: Financing The ExpansionAmanAinda não há avaliações

- Week 1 Practice QuizDocumento7 páginasWeek 1 Practice QuizDonald112100% (1)

- Question No. 1 Is Compulsory. Attempt Any Four Questions From The Remaining Five Questions. Working Notes Should Form Part of The AnswerDocumento15 páginasQuestion No. 1 Is Compulsory. Attempt Any Four Questions From The Remaining Five Questions. Working Notes Should Form Part of The Answerritz meshAinda não há avaliações

- Neogi Chemical CoDocumento10 páginasNeogi Chemical Codpu_bansal83241Ainda não há avaliações

- Mini CaseDocumento15 páginasMini CaseSammir Malhotra0% (1)

- BKM CH 08 Answers W CFADocumento9 páginasBKM CH 08 Answers W CFAzyAinda não há avaliações

- Expenses Amount: Shashaank Industries Ltd. Profit and Loss Account For The Year Ended 31st March 2006Documento6 páginasExpenses Amount: Shashaank Industries Ltd. Profit and Loss Account For The Year Ended 31st March 2006Srijan SaxenaAinda não há avaliações

- Tata Motors ValuationDocumento38 páginasTata Motors ValuationAkshat JainAinda não há avaliações

- Case ReviewDocumento3 páginasCase Reviewfatima waqar100% (1)

- Assignment - Vishal EngineeringDocumento2 páginasAssignment - Vishal EngineeringAnish Pillai100% (1)

- Case US-64 ControversyDocumento4 páginasCase US-64 ControversyBiweshAinda não há avaliações

- NYPRO, Inc.: Case 4-3Documento19 páginasNYPRO, Inc.: Case 4-3QMiss100% (3)

- Corporate Governance Report of InfosysDocumento33 páginasCorporate Governance Report of InfosysAstha Shiv100% (2)

- Cost of CapitalDocumento26 páginasCost of CapitalRiti Nayyar100% (1)

- SOTP ValuationDocumento26 páginasSOTP ValuationRishabh KesharwaniAinda não há avaliações

- Capital Structure and Leverages-ProblemsDocumento7 páginasCapital Structure and Leverages-ProblemsUday GowdaAinda não há avaliações

- Ken Black QA 5th Chapter 3 SolutionDocumento47 páginasKen Black QA 5th Chapter 3 SolutionRushabh VoraAinda não há avaliações

- Demerger, Case Study of Larsen and ToubroDocumento12 páginasDemerger, Case Study of Larsen and ToubroRahmaniac Usha Krishna0% (1)

- The Raymond Limited: A Study: Director (Research) ICSI-CCGRT, Navi MumbaiDocumento14 páginasThe Raymond Limited: A Study: Director (Research) ICSI-CCGRT, Navi Mumbaioptra ceraAinda não há avaliações

- Advance Financial Management AssignmentDocumento4 páginasAdvance Financial Management AssignmentRishabh JainAinda não há avaliações

- Leverage Unit-4 Part - IIDocumento34 páginasLeverage Unit-4 Part - IIAstha ParmanandkaAinda não há avaliações

- FinancialManagement MB013 QuestionDocumento31 páginasFinancialManagement MB013 QuestionAiDLo50% (2)

- Renata Annual Report 2019 2020 PDFDocumento194 páginasRenata Annual Report 2019 2020 PDFTanayAinda não há avaliações

- Long-Term Financial Planning and Growth Chap4Documento39 páginasLong-Term Financial Planning and Growth Chap4spectrum_48Ainda não há avaliações

- Tata Motors:cost of CapitalDocumento10 páginasTata Motors:cost of CapitalAnkit GuptaAinda não há avaliações

- Managerial Economics Project ReportDocumento6 páginasManagerial Economics Project ReportchandanjeeAinda não há avaliações

- Working Capital Case Study PDFDocumento4 páginasWorking Capital Case Study PDFNishuAinda não há avaliações

- ProfitabilityDocumento9 páginasProfitabilityNaheed AdeelAinda não há avaliações

- ProfitabilityDocumento3 páginasProfitabilityNaheed AdeelAinda não há avaliações

- LGB Q4FY12Update 05may2012Documento4 páginasLGB Q4FY12Update 05may2012equityanalystinvestorAinda não há avaliações

- Supermax PDFDocumento7 páginasSupermax PDFperkisasAinda não há avaliações

- Voltamp Transformers Limited - ICMPLDocumento16 páginasVoltamp Transformers Limited - ICMPLvenugopallAinda não há avaliações

- Strategic Management Reading Material Feb 24Documento2 páginasStrategic Management Reading Material Feb 24voltes1Ainda não há avaliações

- Taxguru - In-Bank Audit-Issue of Reversal of Unrealised Interest On NPA AccountsDocumento5 páginasTaxguru - In-Bank Audit-Issue of Reversal of Unrealised Interest On NPA AccountsAjay BhattAinda não há avaliações

- Coffee Shop Business Plan TemplateDocumento12 páginasCoffee Shop Business Plan TemplateLanurias, Gabriel Dylan S.Ainda não há avaliações

- ESOP Best PracticesDocumento44 páginasESOP Best PracticesPrateek Goel100% (1)

- Assignment III - Descriptive QuestionsDocumento2 páginasAssignment III - Descriptive QuestionsAndroid AccountAinda não há avaliações

- Growth, Poverty, and Income Distribution PovertyDocumento6 páginasGrowth, Poverty, and Income Distribution PovertyMija DiroAinda não há avaliações

- Study and Analysis of Financial A ReportDocumento26 páginasStudy and Analysis of Financial A Reportpriyanka81287Ainda não há avaliações

- Pad115 Past QuestionDocumento11 páginasPad115 Past QuestionOlatunji MosesAinda não há avaliações

- Ekonomi Paint SectorDocumento4 páginasEkonomi Paint SectorDilansu KahramanAinda não há avaliações

- Value Added Tax PracticeDocumento7 páginasValue Added Tax PracticeSelene DimlaAinda não há avaliações

- New Microsoft Office Word DocumentDocumento18 páginasNew Microsoft Office Word DocumentSubhasish BhattacharjeeAinda não há avaliações

- Industry Average of Tobacco SectorDocumento55 páginasIndustry Average of Tobacco Sectorgohar006Ainda não há avaliações

- Form16-2018-19 Part ADocumento2 páginasForm16-2018-19 Part AMANJUNATH GOWDAAinda não há avaliações

- HMRC 6Documento86 páginasHMRC 6cucumucuAinda não há avaliações

- Reading 25 Non-Current (Long-Term) LiabilitiesDocumento31 páginasReading 25 Non-Current (Long-Term) LiabilitiesNeerajAinda não há avaliações

- 9 Most Common Hirevue QuestionsDocumento10 páginas9 Most Common Hirevue QuestionsShuyuan JiaAinda não há avaliações

- Qms PPT FinalDocumento13 páginasQms PPT FinalHaaMid RaSheedAinda não há avaliações

- Sunway Resort HotelDocumento3 páginasSunway Resort HotelBrianLeAinda não há avaliações

- G11 ABM Org and MGT Lesson 1 Handouts (Part 3)Documento4 páginasG11 ABM Org and MGT Lesson 1 Handouts (Part 3)Leo SuingAinda não há avaliações

- Cash Flow ProjectDocumento85 páginasCash Flow ProjectUsman MohammedAinda não há avaliações

- USAA - USAA Growth & Income Fund - USGRX - Summary Prospectus 12.01.2017Documento4 páginasUSAA - USAA Growth & Income Fund - USGRX - Summary Prospectus 12.01.2017anthonymaioranoAinda não há avaliações

- O&M Module PDF File-1Documento177 páginasO&M Module PDF File-1Strewbary BarquioAinda não há avaliações

- Business and Society Ethics Sustainability and Stakeholder Management 10Th Edition Carroll Solutions Manual Full Chapter PDFDocumento29 páginasBusiness and Society Ethics Sustainability and Stakeholder Management 10Th Edition Carroll Solutions Manual Full Chapter PDFjaniceglover2puc6100% (13)

- Tax Case StudyDocumento6 páginasTax Case StudyAditi GuptaAinda não há avaliações

- Activity Chapter 4: Ans. 2,320 SolutionDocumento2 páginasActivity Chapter 4: Ans. 2,320 SolutionRandelle James Fiesta0% (1)

- IFI Banking TranscriptDocumento21 páginasIFI Banking TranscriptAnonymous NeRBrZyAUbAinda não há avaliações

- NeocolonialismDocumento1 páginaNeocolonialismManny De MesaAinda não há avaliações

- Ismt LTD (2018-2019)Documento10 páginasIsmt LTD (2018-2019)Nimit BhimjiyaniAinda não há avaliações

- Case Study - 2Documento12 páginasCase Study - 2Khay GonzalesAinda não há avaliações