Escolar Documentos

Profissional Documentos

Cultura Documentos

Building Commissioning Guideline

Enviado por

sekemekeDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Building Commissioning Guideline

Enviado por

sekemekeDireitos autorais:

Formatos disponíveis

Commissioning Program Guideline

University of Manitoba Physical Plant Page 1 of 14

COMMISSIONING PROGRAM GUIDELINE

UNIVERSITY OF MANITOBA Physical Plant

June 8, 2009

Commissioning Program Guideline

University of Manitoba Physical Plant Page 2 of 14

University of Manitoba Physical Plant Building Commissioning

The philosophy behind commissioning efforts at Physical Plant is that thoughtful design, professional installation and in depth analysis will enhance the quality of final construction product while promoting an overall reduction in the ongoing operating costs. This guideline is intended to provide an understanding of the building commissioning process and define responsibilities of all commissioning participants at the University of Manitoba. The fundamental goals of the commissioning process are to: Enhance communication by identifying and discussing operational goals, documenting decisions and applying the accumulated knowledge of the participants throughout the project. Provide documented verification that the performance of the facility and its systems meet the University of Manitoba requirements. Validate and report that the completed project meets the design intent and that all contractual obligations of the construction forces have been achieved. Provide the ability to repeat the process at regular intervals in order to maintain cost effective operations.

To achieve these goals, the commissioning process begins at the earliest stages of planning, assisting in systems selection, continuing through the design phase with timely reviews of progress, closely monitoring construction to ensure ongoing quality and concludes with guiding the building systems from static completion to dynamic operation. Benefits of Commissioning The activities of the students, faculty and staff at the University of Manitoba require functional facilities that contain components, equipment and systems that operate as an integrated whole to provide a comfortable and functional environment that will fully support the educational experience. A deficiency in any one system can result in less than optimal performance in other systems. Identifying, documenting, communicating and correcting deficiencies at an early stage can result in a variety of benefits including: Reducing construction expenses and potential delays. Fewer warranty claims and call backs. Operational energy savings. Consistently reliable systems operations. Enhanced building productivity Extended service life of components. Reduction of future maintenance activity and costs.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 3 of 14

Commissioning Program

This Commissioning Program provides the details for the implementation of the commissioning process as related to the project. The objectives of the Commissioning Program Guideline are to: Outline and describe the commissioning process specific. Identify the members of the Commissioning Team. Describe the roles and responsibilities of each member of the Commissioning Program Team

This plan does not include the details of the required testing procedures; rather, it outlines the scope of responsibilities for development and application of the testing. Testing procedures and assignment of responsibilities shall be clearly presented in the project specifications.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 4 of 14

Commissioning Program Outline

Design Phase Review of design development submittals. Commissioning specifications are created and incorporated into tender documents. Review of construction tender documents. Construction Phase Commissioning scope meeting held. Contractor submits Commissioning Plan. Shop Drawing submittals are reviewed in parallel by consultants and review team members. Commissioning meetings are scheduled with consultants and/or contractors as required. Commissioning Equipment Forms submitted and reviewed. Commissioning Installation Forms submitted and reviewed. Project Operation & Maintenance manuals and as-built drawings submitted and reviewed. Functional Performance Testing. Commissioning Performance Forms submitted and reviewed. Integrated Systems Review Acceptance Phase Project turnover meeting - Construction Management to Facilities Management. Training and orientation of University of Manitoba personnel is scheduled and conducted. Systems are formally accepted and warranty period begins. Finalized Commissioning Plan documents turned over to owner. Consultant / Contractor performance reviews completed. Occupancy Phase (Post-Acceptance) Off-season functional testing is scheduled and performed. Preventative maintenance work orders added to PMC System. 21st month of 24 month warranty period site review held with Physical Plant Trades Managers to coordinate any remaining warranty work. Re-commissioning schedule.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 5 of 14

Systems to be Commissioned

The following is a list of systems that the University of Manitoba considers important for commissioning. The project specific list of equipment to be commissioned will be included in the construction specifications. Major equipment associated with each system is identified. Commissioning of each system includes all major equipment, unless noted otherwise. General Building Systems 1. Drainage, Grading and Compaction 2. Concrete Quality 3. Concrete Floor Flatness 4. Finish Carpentry and Millwork 5. Building Envelope and Roofing 6. Fire Stopping Systems 7. Door Hardware 8. Card Access System 9. Window Fabrication / Weather Tightness 10. Curtain Wall Systems 11. Architectural Specialties 12. Elevators Mechanical Systems 1. Site Services / Underground Utilities 2. Insulation Systems 3. Chemical Treatment 4. Plumbing 5. Fire Protection 6. HVAC 7. Sound / Vibration Isolation 8. Building Management Controls Systems 9. Testing and Balancing Electrical System 1. Power Distribution Systems 2. Motor Control Centers 3. High Voltage Switchgear 4. Grounding 5. Lighting Control Systems 6. Emergency Lighting 7. Card Access 8. Emergency Generators 9. Voice Data 10. Fire Alarm Systems 11. CCTV Specialty Systems 1. Swimming Pools 2. Underground Services 3. Sewage Plants

Commissioning Program Guideline

University of Manitoba Physical Plant Page 6 of 14

Roles and Responsibilities

U of M Project Designer / Facilitator Notifies Commissioning Advocate and Review Team members when submittals are available for review. Tracks the review comments so that the reviewers are informed as to the status of their comments. U of M Commissioning Advocate Develops the commissioning specification with Consultants. Assists the Contractor as requested in developing the project specific commissioning documents. Reviews project submissions. Make periodic site visits and submits review comments to Project Coordinator. Periodically witnesses functional testing. Attends construction site meetings as required. Witnesses Integrated Systems Review Activities. Reviews project close out documents. Verify project commissioning is complete and satisfactory. Review Team Members Review design submissions and provide commentary to Project Designer / Facilitator. Assist Consultant and Contractor by providing technical input as required. Perform periodic construction inspections and submit deficiencies through Project Coordinator. Review Commissioning Forms where U of M technical input is required. U of M Project Coordinator The Project Coordinator provides the Commissioning Advocate with all project documentation. Receive all Commissioning Forms and distribute for review or completion. Ensure all Commissioning Forms have been signed off by responsible parties. Receive individual deficiency lists. Distribution of Consultants Master Deficiency list. Sign off completed Commissioning Forms and return to Contractor. Coordinates Owner training and spare material turnover. Physical Plant Trades Perform periodic construction reviews and forward deficiencies in writing to Project Coordinator. Provide technical support as required. Attend and participate in commissioning sessions. Attend and participate in training sessions. Creates preventative maintenance work orders for inclusion in PMC system.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 7 of 14

Consultants (Architect & Engineers) Provide written responses to design document review comments. Provide input as required to assist in Commissioning Process. Chair Commissioning Meetings, record and distribute minutes of meetings, maintain Commissioning Issues log as part of Commissioning Meeting Minutes. Review Equipment, Installation and Performance Commissioning forms and sign off when satisfactorily completed by the Contractor. Review Contractor submitted Commissioning Plan. Perform periodic construction reviews and document deficiencies. Maintain Master Deficiency List. Verify that equipment is supplied and installed per specifications and manufacturers recommendations prior to startup. Witness functional testing and sign off Commissioning Forms. Prepare Integrated Systems Review Documentation and verify Integrated Systems Testing. Participate in and record results of Integrated Systems Review testing. Perform coordinated substantial performance and life safety inspections. Contractors Prepare Commissioning Plan. Modify the sample commissioning forms provided in the specification to make them project specific. Provide all coordination required to schedule and complete all commissioning activities. Provide instruction and training of Physical Plant Personnel on all systems.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 8 of 14

Commissioning Program Activities Defined

Design Development Review The design development review is performed by the Review Team Members and then documented in writing and submitted to the Project Designer / Facilitator, who forwards the information to the Primary Consultant. The Primary Consultant distributes the comments to the design team members for action. The design team responds to the Primary Consultant, who provides a written response to the Project Designer / Facilitator for each review comment. Commissioning Objectives Developed The design development will define the performance objectives for the projects operation, efficiency and functionality. These factors will determine the level of focus of commissioning program. All systems will be functionally tested to ensure operational performance. Commissioning Specification Development The commissioning specifications have been developed by the U of M Building Commissioning Advocate. The design team shall modify those specifications to be project specific for inclusion in the construction bid documents. The specifications provide detail regarding scope of work, responsibilities of the parties, description of commissioning activities, templates for forms and a list of deliverables. The specification shall be detailed so that those bidding on the project can clearly understand the requirements of the commissioning process. General Review of Drawings and Specifications Drawings and specifications are reviewed as the design progresses. The Project Designer / Facilitator notifies the Review Team Members at each stage of design development. Project reviews are intended to: Ensure that the University of Manitoba standards are included in the construction documents. Ensure the commissioning requirements are incorporated into the design documents. Review for concerns regarding maintainability. Check to ensure devices are present for proper balancing of systems. Determine the training requirement expectations for the project. Define PMC system information requirements

Commissioning Program Guideline

University of Manitoba Physical Plant Page 9 of 14

Construction Phase Commissioning Activities

Commissioning Scope Meeting The purpose of this meeting shall be to familiarize the involved parties with their commissioning roles and responsibilities. The commissioning scope meeting shall be scheduled and chaired by the Primary Consultant within 60 days of award of contract. Representatives from all involved trades and Consultants shall be present, as well as the U of M Project Coordinator and Building Commissioning Advocate. At this meeting the Contractor shall present a preliminary Commissioning Plan and schedule. Commissioning Plan The Contractor shall submit a formal Commissioning Plan for review within 90 days of award of contract. The Commissioning Plan shall include but is not limited to: General Project Information Overview and Scope of Project Commissioning Commissioning Process including Team Responsibilities Communication Protocols Commissioning Schedule Sample Documentation Testing and Inspection Plans Functional Test Procedures Completed Integrated Systems Review Documentation Construction Checklists Commissioning Issues Log The Commissioning Advocate, Project Coordinator and Consultant will review and return the plan with comments or concerns to the Contractor. Commissioning Site Meetings The Primary Consultant shall coordinate Commissioning Site Meetings at regular intervals. The Primary Consultant is responsible to record and distribute minutes of this meeting. These meeting will serve to discuss and coordinate any commissioning issues which will be recorded by the Primary Consultant in the Commissioning Meeting Minutes. Commissioning Equipment Forms Commissioning Equipment Forms, samples of which have been provided in the Project Specification, shall be modified to be project specific and submitted for review once the equipment has arrived on site. The forms shall be complete in every way prior to review. As with all Project Documentation the forms shall be submitted through the Project Coordinator for distribution. The Consultant shall review the completed forms to ensure compliance with contract documents. Reviewed Equipment Forms shall be returned to the Contractor for inclusion in the Commissioning Plan.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 10 of 14

Commissioning Installation Forms Commissioning Installation Forms, samples of which have been provided in the Project Specification, shall be modified to be project specific and submitted for review once the equipment has been installed. The forms shall be complete in every way prior to review. As with all Project Documentation the forms shall be submitted through the Project Coordinator for distribution. The Consultant shall verify the information submitted is correct and that installation conforms to manufacturers recommendations as well as contract documents. The Commissioning Advocate will check the installation of equipment and the accompanying forms. Operation & Maintenance Manuals and As-Built Drawing Review The Contractor shall submit for review completed O & M Manuals and As-Built Drawings for review 21 days prior to scheduled Functional Testing and Verification. Reviewed O & M Manuals shall be returned to the Contractor prior to Functional Testing for revisions and updates. As-Built Drawings shall be reviewed by the Consultant for accuracy and returned to the Contractor as Accepted or for Revisions prior to Functional Testing. Finalized documents shall be re-submitted by the Contractor at the completion of the Commissioning process. Functional Performance Testing Functional Performance Testing is the operational testing of individual components to ensure that the equipment and systems are connected, operational and deficiency free so that the Integrated Systems Review may proceed without unnecessary delays. The Contractor shall prepare Pre-Functional Checklists for each piece of equipment or system prior to initial operation (e.g., oil levels, fan belt tension, labels affixed, gauges in place, sensor calibration, etc.) The completed checklists shall be submitted with the completed Commissioning Performance Form as part of the completed Commissioning Plan. The Contractor shall notify the Project Coordinator 14 days prior to starting Functional Performance Testing. The Consultant and Building Commissioning Advocate will review Functional Performance Testing. Commissioning Performance Forms Commissioning Performance Forms shall be completed with data recorded during the Functional Performance Testing and submitted for review. The forms shall be complete in every way prior to review. As with all Project Documentation the forms shall be submitted through the Project Coordinator for distribution. The forms shall be reviewed by the Consultant and Commissioning Advocate and returned to the Contractor for inclusion in the finalized Commissioning Plan.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 11 of 14

Integrated Systems Review Integrated Systems Review is the dynamic testing of systems (rather than individual components) at full operation. Systems are tested under various modes, such low loads, high loads, component failures, varying occupancy cycles, varying outside air temperatures, fire alarm, and power failure. The systems are run through all of the control systems sequences of operation and components are verified to be responding as per design. The Consultant Team develops the Integrated Systems Review procedures for each system in a sequential written form and provides this information to the Project Coordinator and Contractor 60 days after award of contract. The Consultant team records the information and results from the Integrated Systems Testing and provides a copy to the U of M and the Contractor for inclusion in the Commissioning Plan. The Contractor is responsible to schedule Integrated Systems Testing and coordinate the activities of all required trades and vendors to ensure this testing can be successfully accomplished. The Contractor shall provide 14 days notice to the Consultant and Owner prior to this testing. U of M Trades Managers, their delegates and the Building Commissioning Advocate may be present during this process and provide technical input where required on behalf of the U of M. Not all Integrated Systems Testing will be completed during the construction phase of a project. Some of this work will carry on post-occupancy due to varying seasonal and occupancy loads. This will be done with as little disruption to the occupants as possible by coordinating these efforts through the Project Coordinator in a timely fashion. It is the Contractors responsibility to schedule this work.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 12 of 14

Acceptance Phase

Turnover Meeting The purpose of this meeting is to officially transfer the responsibility of maintaining the facilities from the Contractors to the University of Manitoba. Attendees will be the U of M Project Coordinator, U of M Commissioning Advocate, Director Physical Plant, Assistant Director Physical Plant, Physical Plant Trades Managers, Primary Consultant, SubConsultants, General Contractor, Mechanical Contractor and Electrical Contractor. The Project Coordinator will schedule and lead the meeting. The following is a basic agenda for the turnover meeting. Turnover O & M Manuals and As-built drawing status. Turn over spare parts and special tools. Keys / Access. Warranty start / finish dates. Training status and scheduling of additional sessions. Commissioning status - seasonal functional performance testing schedule. Master Deficiency List / Commissioning Issues Review. Training & Orientation Training and Orientation requirements are described in the project specification but are also included in this section because of the importance of complete and professional training to the overall success of any project. Training shall be scheduled a minimum of 14 days in advance through the Project Coordinator. The Contractor is responsible to complete training in accordance with all specification sections. The Commissioning Advocate may attend these sessions to monitor overall content and quality. Systems Acceptance Formal systems acceptance will only be granted when all contractual obligations and the described commissioning activities are successfully completed. At this time the warranty period shall begin. The Contractor shall apply in writing for formal Systems Acceptance. This application shall be accompanied by a checklist indicating the status of all project deliverables and commissioning activities. Finalized Commissioning Manual The Contractor shall turn over three copies of the completed Commissioning Plan to the Project Coordinator. Distribution as follows, 1 copy to U of M Commissioning Advocate, 1 copy to Assistant Director Physical Plant for circulation to Physical Plant Trades for review and return to record drawing filing, and 1 copy to archives.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 13 of 14

Consultant / Contractor Performance Review The Project coordinator shall circulate appropriate review forms to the following for completion and return: U of M Project Designer / Facilitator U of M Building Commissioning Advocate U of M Trades Managers Director / Assistant Director Physical Plant Manager, Engineering Services Completed review scores will be summarized by the Project Coordinator and forwarded with recommendations to the Director of Physical Plant.

Commissioning Program Guideline

University of Manitoba Physical Plant Page 14 of 14

Occupancy Phase (Post Acceptance)

Off Season Integrated Systems Review Integrated Systems Testing not completed during the construction phase of a project will take place during the Occupancy Phase. HVAC systems will require functional testing during the two peak seasons, cooling and heating, to complete the commissioning process. This will be done with as little disruption to the occupants as possible by coordinating these efforts through the Project Coordinator. The responsibilities for the process, performance and attendance of involved parties shall remain with the Contractor. Any deficiencies discovered as a result of this testing will be the responsibility of the contractor to address immediately. Completed documentation shall be submitted to the Project Coordinator for review by the Consultant and Commissioning Advocate. Accepted documentation shall be included in the finalized Commissioning Plan. Twenty One (21) Month Final Walk-Thru and System Review At twenty-one months into the twenty-four month warrantee period, the Project Coordinator will schedule a meeting with the Assistant Director Physical Plant, Physical Plant Trades Managers and a representative of the occupancy group to discuss any operational issues and review the performance of each system. Any warranty related issues shall be forwarded by the Project Coordinator to the Contractor for completion prior to the end of the warranty period. Preventative Maintenance Physical Plant Trades Managers are responsible to review the installation and prepare preventative maintenance work orders in the PMC system. Re-commissioning The Commissioning Advocate shall prepare the Re-Commissioning Manual complete with blank functional test forms and procedures. Physical Plant will use this information for Re-commissioning the project every five years.

Você também pode gostar

- Archi CADDocumento2 páginasArchi CADTheresa CostalesAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- HP Web2Documento4 páginasHP Web2ShefalimodiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Grid StructuresDocumento15 páginasGrid StructuresShraddha BahiratAinda não há avaliações

- Silabus ArcGIS Server TutorialsDocumento2 páginasSilabus ArcGIS Server Tutorialswilly filkosima100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- GROHE Sanitary SystemsDocumento135 páginasGROHE Sanitary SystemsKadiri OlanrewajuAinda não há avaliações

- Final Synopsis (Thesis)Documento8 páginasFinal Synopsis (Thesis)masood khanAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- File:///C:/Users/Asus Vivobook/Downloads/Article - For - Tas - Bit - Arsi PDFDocumento6 páginasFile:///C:/Users/Asus Vivobook/Downloads/Article - For - Tas - Bit - Arsi PDFMuhammad LitilolyAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Azen Axial Fan Catalogue1Documento14 páginasAzen Axial Fan Catalogue1Isaac GuijarroAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- AWS Services OverviewDocumento5 páginasAWS Services OverviewSrikanth Pentakota100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- 1-Introduction To Soil Mechanics (Introduction)Documento57 páginas1-Introduction To Soil Mechanics (Introduction)Farhat Iqbal Malik100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Blender Keyboard Shortcuts - Page 1: Basic Navigation CommonDocumento3 páginasBlender Keyboard Shortcuts - Page 1: Basic Navigation CommonMariana PascacioAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- AsdaDocumento29 páginasAsdacbacer891Ainda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- CAN Protocol: Desd at Sunbeam InfotechDocumento3 páginasCAN Protocol: Desd at Sunbeam InfotechKomal ChouguleAinda não há avaliações

- Beautiful Data - Halpern, ODocumento353 páginasBeautiful Data - Halpern, Odvallejoa100% (1)

- Controlled WordDocumento47 páginasControlled WordMakhloufi Hocine100% (1)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- FM200Documento23 páginasFM200Ahmed SherifAinda não há avaliações

- Focus 40 Keystroke Commands FINALDocumento30 páginasFocus 40 Keystroke Commands FINALn1kskeAinda não há avaliações

- Dokras Wada Part IIIDocumento17 páginasDokras Wada Part IIIUday DokrasAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Java4s Com HibernateDocumento5 páginasJava4s Com HibernatevijayAinda não há avaliações

- Six Laning Irc SP 87 2013Documento3 páginasSix Laning Irc SP 87 2013Suyog GoreAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Resume Tamer Elshayal October 2012Documento2 páginasResume Tamer Elshayal October 2012Tamer ElshayalAinda não há avaliações

- Example 1 - Two-Way SlabDocumento2 páginasExample 1 - Two-Way SlabLemuel TeopeAinda não há avaliações

- Comparison of Rooftop Rainwater Harvesting Systens in Tropical Countries Life Cycle Energy Approach - PDF (Dragged)Documento7 páginasComparison of Rooftop Rainwater Harvesting Systens in Tropical Countries Life Cycle Energy Approach - PDF (Dragged)Timur Ahadi SantosoAinda não há avaliações

- Design A Cantilever Retaining Wall To Retain An Earth Embankment of 4 - 1Documento12 páginasDesign A Cantilever Retaining Wall To Retain An Earth Embankment of 4 - 1yudhishkarthickAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Theta Newsletter Spring 2010Documento6 páginasTheta Newsletter Spring 2010mar335Ainda não há avaliações

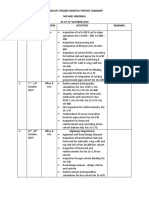

- Graduate Trainee Monthly Report SummaryDocumento2 páginasGraduate Trainee Monthly Report Summarymichael100% (1)

- Dcam FM Manual 11-7-6Documento49 páginasDcam FM Manual 11-7-6lcruz117Ainda não há avaliações

- Introduction To Atmospheric ChemistryDocumento400 páginasIntroduction To Atmospheric ChemistryShruthi Akkal100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Order Management Technical TOI READYDocumento25 páginasOrder Management Technical TOI READYGyan SharmaAinda não há avaliações

- GFF - Flat Roof PDFDocumento19 páginasGFF - Flat Roof PDFSêlva AvlêsAinda não há avaliações