Escolar Documentos

Profissional Documentos

Cultura Documentos

Ribbed Slab

Enviado por

suhaimitmieDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ribbed Slab

Enviado por

suhaimitmieDireitos autorais:

Formatos disponíveis

Ribbed slabs

(One-way joists)

Introducing voids to the soffit of a slab reduces dead

weight and increases the efficiency of the concrete

section. A slightly deeper section is required but these

stiffer floors facilitate longer spans and provision of

holes. Economic in the range 8 to 12 m.

span

The saving of materials tends to be offset by some

complication in formwork. The advent of expanded

polystyrene moulds has made the choice of trough

profile infinite and largely superseded the use of

standard T moulds. Ribs should be at least 125 mm wide

to suit reinforcement detailing.

The chart and data assume line support (ie. beam or wall)

and bespoke moulds.

ADVANTAGES

DISADVANTAGES

Higher formwork costs than for other slab systems

Slightly greater floor thicknesses

Slower

Medium to long spans

Lightweight

Holes in topping easily accommodated

Large holes can be accommodated

Profile may be expressed architecturally, or used for

heat transfer in passive cooling

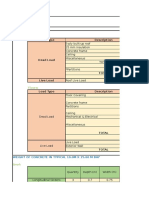

SPAN:DEPTH CHART

600

Single span

500

400

Multiple span

SLAB DEPTH, mm

300

250 mm practical minimum

200

100

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

KEY Characteristic imposed load (IL)

= 2.5 kN/m2

20

= 5.0 kN/m2

= 7.5 kN/m2

=10.0 kN/m2

14.0

SPAN, m

I N - S I T U

S L A B S

DESIGN ASSUMPTIONS

SUPPORTED BY

BEAMS. Refer to beam charts and data to estimate beam sizes and reinforcement.

DIMENSIONS

Square panels, minimum of three slab spans. Ribs 150 mm wide @ 750 mm cc. Topping 100 mm. Moulds of

bespoke depth. Rib/solid intersection at beam span/7 from centreline of internal support, and at span/9 from

end support.

REINFORCEMENT

Maximum bar sizes in ribs: 2T25B, 2T20T (in top of web) and R8 links. 25 mm allowed for A142 mesh (@

0.12%) in topping. 10% allowed for wastage and laps. fs may have been reduced.

LOADS

A superimposed dead load (SDL) of 1.50 kN/m2 (for finishes, services, etc.) is included. Ultimate loads assume

elastic reaction factors of 1.1 to internal beams and 0.5 to end beams. Self weight used accounts for 10

degree slope to ribs and solid ends as described above.

CONCRETE

C35, 24 kN/m3, 20 mm aggregate.

FIRE & DURABILITY

Fire resistance 1 hour; mild exposure.

SINGLE SPAN, m

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

THICKNESS, mm

IL = 2.5 kN/m2

IL = 5.0 kN/m2

IL = 7.5 kN/m2

IL = 10.0 kN/m2

250

272

294

314

288

320

346

372

334

372

406

438

382

428

472

564

434

492

594

514

588

610

772

722

n/a (72)

n/a (97)

n/a (126)

n/a (87)

n/a (116)

n/a (105)

n/a (146)

n/a (126)

ULTIMATE LOAD TO SUPPORTING BEAMS, INTERNAL (END),

IL = 2.5 kN/m2

n/a (35)

n/a (43)

n/a (52)

IL = 5.0 kN/m2

n/a (48)

n/a (58)

n/a (70)

n/a (61)

n/a (74)

n/a (88)

IL = 7.5 kN/m2

IL = 10.0 kN/m2

n/a (74)

n/a (89) n/a (106)

REINFORCEMENT, kg/m2 (kg/m3)

11 (42)

IL = 2.5 kN/m2

IL = 5.0 kN/m2

11 (42)

11 (39)

IL = 7.5 kN/m2

IL = 10.0 kN/m2

11 (36)

kN/m

n/a (61)

n/a (83)

n/a (104)

n/a (129)

12 (41)

11 (36)

12 (34)

12 (31)

11 (34)

11 (31)

12 (29)

12 (27)

11 (30)

12 (27)

12 (25)

12 (21)

14.0

Slab only, add mesh and beam reinforcement

12 (27)

12 (23)

12 (20)

12 (17)

12 (24)

12 (20)

12 (16)

12 (20)

MULTIPLE SPAN, m

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

THICKNESS, mm

IL = 2.5 kN/m2

IL = 5.0 kN/m2

IL = 7.5 kN/m2

IL = 10.0 kN/m2

250

250

258

250

266

282

298

278

302

318

342

312

336

364

392

342

376

414

476

392

440

484

588

452

510

592

730

520

590

732

598

688

ULTIMATE LOAD TO SUPPORTING BEAMS, INTERNAL (END), kN/m2

IL = 2.5 kN/m2

89 (40)

105 (48)

123 (56)

IL = 5.0 kN/m2

101 (46)

122 (55)

144 (65)

167 (76)

129 (59)

154 (70)

181 (82)

210 (96)

IL = 7.5 kN/m2

IL = 10.0 kN/m2

156 (71)

187 (85) 219 (100) 254 (115)

142 (65)

192 (87)

242 (110)

297 (135)

165 (75)

223 (101)

279 (127)

348 (158)

193 (88)

257 (117)

328 (149)

411 (187)

224 (102)

297 (135)

389 (177)

261 (119)

346 (157)

REINFORCEMENT, kg/m2 (kg/m3)

IL = 2.5 kN/m2

12 (53)

IL = 5.0 kN/m2

IL = 7.5 kN/m2

16 (64)

17 (64)

IL = 10.0 kN/m2

DESIGN NOTES

a = qk > 1.25 gk

IL = 2.5 kN/m2

IL = 5.0 kN/m2

e

abe

IL = 7.5 kN/m2

IL = 10.0 kN/m2

abe

11 (45)

16 (59)

17 (60)

17 (59)

12 (44)

16 (54)

18 (57)

18 (53)

b = qk > 5 kN/m2

abe

abe

abde

abde

16 (51)

18 (53)

18 (50)

18 (46)

c = 2T20B

e

abde

abde

Slab

17 (51)

18 (48)

18 (44)

18 (38)

only, add mesh and beam reinforcement

18 (46)

18 (40)

18 (35)

18 (31)

18 (41)

18 (36)

18 (31)

18 (27)

18 (38)

18 (31)

18 (25)

18 (31)

18 (25)

d = deflection critical

de

abe

abe

de

bde

abe

e = designed links in ribs

e

de

e

e

be

be

be

VARIATIONS TO DESIGN ASSUMPTIONS: differences in slab thickness for a characteristic imposed load (IL) of 5.0 kN/m2

Fire resistance

2 hours, 150 rib & 115 topping

+5 mm

4 hours, 150 rib & topping

see below

Exposure

Moderate

+15 mm

Severe, C40 concrete

see below

Standard moulds

T moulds

see below

NB: T moulds 125 mm ribs @ 600

cc

Thickness, mm

Span, m

6.0

7.0

8.0

9.0

10.0

11.0

12.0

4 hrs,150 rib & topping

258

300

338

386

442

534

600

Severe, C40 concrete

248

288

326

366

416

494

576

T2 mould, 175 deep

265

291

305

347

T3 mould, 250 deep

340

340

382

T4 mould, 325 deep

415

415

450

T5 mould, 400 deep

490

490

524

21

Você também pode gostar

- Waffle Slab EconomicsDocumento2 páginasWaffle Slab Economicsmumbler02Ainda não há avaliações

- Troughed Slabs: (Ribbed Slabs With Integral Beams and Level Soffits, Troughed Flat Slabs, One-Way Joist Floors)Documento2 páginasTroughed Slabs: (Ribbed Slabs With Integral Beams and Level Soffits, Troughed Flat Slabs, One-Way Joist Floors)renishkavukattAinda não há avaliações

- Raised access floors technical solutionsDocumento33 páginasRaised access floors technical solutionsGhenoiu PaulAinda não há avaliações

- Composite Slab DesignDocumento13 páginasComposite Slab Design_jesseca100% (2)

- Est SHTDocumento26 páginasEst SHTselvakumarAinda não há avaliações

- Cant SlabDocumento7 páginasCant Slabsantosh-a-biraj-3307Ainda não há avaliações

- Data Sheet C70 E 072011 02Documento3 páginasData Sheet C70 E 072011 02Stefano BarbieriAinda não há avaliações

- Multideck 60-V2: - Concrete Volume SavingsDocumento18 páginasMultideck 60-V2: - Concrete Volume Savingsdexterbox1Ainda não há avaliações

- N2XBYDocumento5 páginasN2XBYcyuenkAinda não há avaliações

- Unishield - Uniblend 5kvDocumento2 páginasUnishield - Uniblend 5kvfmillan5018Ainda não há avaliações

- Estimating Deadloads On Timber CanopiesDocumento1 páginaEstimating Deadloads On Timber CanopiesConrad HarrisonAinda não há avaliações

- Assan Panel Walls RockwoolDocumento5 páginasAssan Panel Walls RockwoolFlorin MatisAinda não há avaliações

- AQUAPANEL Cement Board Outdoor Datasheet 0817Documento3 páginasAQUAPANEL Cement Board Outdoor Datasheet 0817xander1982Ainda não há avaliações

- Continuous (One Way)Documento7 páginasContinuous (One Way)scribd1991Ainda não há avaliações

- Seismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameDocumento34 páginasSeismic Analysis of Structures - Concrete Ductile Moment Resisting Space FrameEmmanuel LazoAinda não há avaliações

- Brosur Glass WoolDocumento3 páginasBrosur Glass WoolHarry NovfriandiAinda não há avaliações

- ECS478 CHAPTER 3-Flat SlabDocumento40 páginasECS478 CHAPTER 3-Flat SlabAmron Abubakar0% (1)

- DataSheet SLS510 LC en 091201Documento4 páginasDataSheet SLS510 LC en 091201Nguyễn Văn SơnAinda não há avaliações

- Hollow Core DesignDocumento15 páginasHollow Core DesignMelinda Gordon100% (1)

- RCC94 Two-Way Slabs (Tables) GGGDocumento3 páginasRCC94 Two-Way Slabs (Tables) GGGThomas OluwafemiAinda não há avaliações

- Design of 75T Crane Girder for 10m SpanDocumento29 páginasDesign of 75T Crane Girder for 10m Spananbukgi100% (2)

- Beam design parameters and calculationsDocumento33 páginasBeam design parameters and calculationsAudarya Chaitanya DasAinda não há avaliações

- Structural Design of RCC Clear Water Reservoir (C. W. R.)Documento36 páginasStructural Design of RCC Clear Water Reservoir (C. W. R.)abhishek5810100% (1)

- Cu/PVC/SFWA/PVC cable specs (1.5-50 mm2, 0.6/1 kVDocumento4 páginasCu/PVC/SFWA/PVC cable specs (1.5-50 mm2, 0.6/1 kVRahul DevaAinda não há avaliações

- En 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Documento6 páginasEn 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Eduardo Martinez CaleroAinda não há avaliações

- Design of Rolling Stock Maintanance Shed - Roof Final ReviewDocumento29 páginasDesign of Rolling Stock Maintanance Shed - Roof Final ReviewKrishnan ChockalingamAinda não há avaliações

- EG7005 STEEL DESIGN-BATCH 21-22: Lijose Jacob 2235791Documento83 páginasEG7005 STEEL DESIGN-BATCH 21-22: Lijose Jacob 2235791lijosejacobAinda não há avaliações

- Roof and Wall LeafletDocumento6 páginasRoof and Wall LeafletcosineAinda não há avaliações

- Design of Staircase: Assoc. Prof. Ts. Dr. Izni Syahrizal Bin IbrahimDocumento73 páginasDesign of Staircase: Assoc. Prof. Ts. Dr. Izni Syahrizal Bin IbrahimRuben OoiAinda não há avaliações

- GROUP 14 PRODUCTION OF 21,000 MTPA OF ETHYLENE: COMPUTER SIMULATION, HEAT INTEGRATION, AND PROCESS EQUIPMENT SIZINGDocumento54 páginasGROUP 14 PRODUCTION OF 21,000 MTPA OF ETHYLENE: COMPUTER SIMULATION, HEAT INTEGRATION, AND PROCESS EQUIPMENT SIZINGAtika Mohd Yatim100% (1)

- Htri FileDocumento24 páginasHtri FileEalumalai MuthuAinda não há avaliações

- Magnetizing ForceDocumento20 páginasMagnetizing ForcebluesurviverAinda não há avaliações

- MVLV Wire and CableDocumento66 páginasMVLV Wire and CableMahmoud FawzyAinda não há avaliações

- 3c Cu Xlpe PVC 6.35 (11) KV Heavy Duty CwsDocumento2 páginas3c Cu Xlpe PVC 6.35 (11) KV Heavy Duty Cwsgari_monsantoAinda não há avaliações

- Floor Slab LIFTDocumento3 páginasFloor Slab LIFTV.m. RajanAinda não há avaliações

- Loading Computations, Slab, FootingsDocumento39 páginasLoading Computations, Slab, FootingsRommel Dave TejanoAinda não há avaliações

- Ancon - Stainless Steel SectionsDocumento10 páginasAncon - Stainless Steel SectionspiotrnowakAinda não há avaliações

- Energy Performance: Thermal Transmittance, Also Known As U-Value, Is The Rate of Transfer of Heat (In Watts)Documento10 páginasEnergy Performance: Thermal Transmittance, Also Known As U-Value, Is The Rate of Transfer of Heat (In Watts)Brahmam GuruAinda não há avaliações

- Abut DesignDocumento32 páginasAbut DesignSubir Kunda100% (2)

- Aluminium Power Cable Technical SpecificationDocumento5 páginasAluminium Power Cable Technical SpecificationAndri ProdjodiprodjoAinda não há avaliações

- Design CalculationDocumento4 páginasDesign CalculationEric PintoAinda não há avaliações

- High Quality CRA Solutions by Electroslag Process For Austenitic StainleDocumento14 páginasHigh Quality CRA Solutions by Electroslag Process For Austenitic StainleMubeenAinda não há avaliações

- Two-Way Spanning Slab DesignDocumento10 páginasTwo-Way Spanning Slab Designscribd1991Ainda não há avaliações

- 9Documento25 páginas9gazwang478Ainda não há avaliações

- Living Quarter LayoutDocumento69 páginasLiving Quarter LayoutPhornlert WanaAinda não há avaliações

- Example 4: Diesel Hammer Input: GRLWEAP Standard ExamplesDocumento3 páginasExample 4: Diesel Hammer Input: GRLWEAP Standard ExamplesbozarromegustaAinda não há avaliações

- Laser Technology: Applications in Adhesion and Related AreasNo EverandLaser Technology: Applications in Adhesion and Related AreasAinda não há avaliações

- Lecture Notes on Reinforced Concrete DesignNo EverandLecture Notes on Reinforced Concrete DesignAinda não há avaliações

- Reinforced Concrete Buildings: Behavior and DesignNo EverandReinforced Concrete Buildings: Behavior and DesignNota: 5 de 5 estrelas5/5 (1)

- Marine Electrical Practice: Marine Engineering SeriesNo EverandMarine Electrical Practice: Marine Engineering SeriesNota: 4 de 5 estrelas4/5 (8)

- Midpoint - Geometry - Math DictionaryDocumento2 páginasMidpoint - Geometry - Math DictionarysuhaimitmieAinda não há avaliações

- STORMWTRDocumento5 páginasSTORMWTRsuhaimitmieAinda não há avaliações

- Corrosivity at Various DistancesDocumento22 páginasCorrosivity at Various DistancessuhaimitmieAinda não há avaliações

- What Do The Disabled Students NeedDocumento22 páginasWhat Do The Disabled Students NeedsuhaimitmieAinda não há avaliações

- 9 WatershedModeling-TimeConcAndCNDocumento13 páginas9 WatershedModeling-TimeConcAndCNsuhaimitmieAinda não há avaliações

- Roofing Walling Installation 2013 Chapter 10Documento10 páginasRoofing Walling Installation 2013 Chapter 10suhaimitmieAinda não há avaliações

- Acanthosis Nigricans Terra Firma-Forme DermatosisDocumento6 páginasAcanthosis Nigricans Terra Firma-Forme DermatosissuhaimitmieAinda não há avaliações

- FR700 Series Owner's ManualDocumento60 páginasFR700 Series Owner's ManualmetasAinda não há avaliações

- BS 60811 Part 01 - 02Documento20 páginasBS 60811 Part 01 - 02danferreiro8318100% (1)

- Guided Wave and WeldingDocumento44 páginasGuided Wave and Weldingharoub_nas100% (1)

- Abcd. Proiect AdamDocumento14 páginasAbcd. Proiect AdamSfiriac LauraAinda não há avaliações

- Mellitah Plant: Western Libya Gas ProjectDocumento662 páginasMellitah Plant: Western Libya Gas ProjectAnas AhmedAinda não há avaliações

- 50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFDocumento19 páginas50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFChemkhiAinda não há avaliações

- Survey of Naval Surface Ship Propulsion and Auxiliary System DevelopmentsDocumento90 páginasSurvey of Naval Surface Ship Propulsion and Auxiliary System DevelopmentsAn NgocSonAinda não há avaliações

- SMT Vacuum PlusDocumento2 páginasSMT Vacuum PlusEerik-Hannes MatsinaAinda não há avaliações

- Motor Yanmar l48v6 Compactador Mvh-150d2Documento64 páginasMotor Yanmar l48v6 Compactador Mvh-150d2Mas Inyeccion ElectronicaAinda não há avaliações

- Production of Formaldehyde From MethanolDocumento7 páginasProduction of Formaldehyde From MethanolThrese AreolaAinda não há avaliações

- Renson Sliding PanelsDocumento20 páginasRenson Sliding Panelsjoao85Ainda não há avaliações

- Project 4 Acrylic AcidDocumento16 páginasProject 4 Acrylic AcidN193746100% (3)

- Cicol ET Screed: Constructive SolutionsDocumento2 páginasCicol ET Screed: Constructive SolutionstalatzahoorAinda não há avaliações

- Mass Flow MeterDocumento158 páginasMass Flow MeterMuhammad Furqan JavedAinda não há avaliações

- 166Documento72 páginas166nikolastevic100% (2)

- Post-tensioned Member End Zone DesignDocumento38 páginasPost-tensioned Member End Zone DesignJohn G Jose100% (1)

- Process for Producing Ammonium Nitrate from Ammonia OxidationDocumento20 páginasProcess for Producing Ammonium Nitrate from Ammonia OxidationGracia ManurungAinda não há avaliações

- Electrochemical Series of Photocatalysts and Common Organic CompoundsDocumento1 páginaElectrochemical Series of Photocatalysts and Common Organic CompoundsDevin FergusonAinda não há avaliações

- Acid Flooring SystemDocumento6 páginasAcid Flooring SystemtuonghaiAinda não há avaliações

- Trace Analytics ISO 8573 White PaperDocumento2 páginasTrace Analytics ISO 8573 White PaperDeepakAinda não há avaliações

- Organic Coated Steel: ArcelorDocumento37 páginasOrganic Coated Steel: ArcelordangmiuAinda não há avaliações

- Trajan 712 Owners ManualDocumento21 páginasTrajan 712 Owners ManualGIVAN93Ainda não há avaliações

- Laboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Documento17 páginasLaboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Engr Sakher100% (1)

- URAI ManualDocumento28 páginasURAI ManualSesFasabiSaavedraAinda não há avaliações

- 1 Welding Materials Control Procedure PDFDocumento3 páginas1 Welding Materials Control Procedure PDFMustafa MubderAinda não há avaliações

- Utilities Module 2Documento27 páginasUtilities Module 2Celinni DasigAinda não há avaliações

- Test FireDocumento11 páginasTest FireMario UyAinda não há avaliações

- Certification AbbreviationsDocumento3 páginasCertification AbbreviationsAmine DabbabiAinda não há avaliações

- Nur Syafiqah Binti Jaafar - 2019405402 - 6B - Individual AssignmentDocumento9 páginasNur Syafiqah Binti Jaafar - 2019405402 - 6B - Individual AssignmentNUR SYAFIQAH JAAFARAinda não há avaliações

- Cement Recruitment Details With Interview Questions: General 0 CommentsDocumento42 páginasCement Recruitment Details With Interview Questions: General 0 CommentsAsifRazaAinda não há avaliações