Escolar Documentos

Profissional Documentos

Cultura Documentos

Norway FPSO Survey Report

Enviado por

Ding LiuDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Norway FPSO Survey Report

Enviado por

Ding LiuDireitos autorais:

Formatos disponíveis

10 YEAR OPERABILITY SURVEY OF NORWEGIAN FPSOs

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 2 __________________________________________________________________________

Preface

This report is sponsored by OLF's FPSO network. The primary objective of the network is to gather and transfer lessons learned on Norwegian FPSOs, so that future projects can benefit from the experience gained from earlier projects. In the period from 1986 to 1999, six FPSOs started operation in the Norwegian sector of the North Sea ( Petrojarl1, Varg, Norne, Balder, Jotun and sgard). In 2002, a survey was initiated by OLF to assess and record the key project lessons learned on 5 of these projects and this data became the basis for a web accessible database, which has received wide usage throughout the industry. However, most of the lessons learned relate to the project and early start-up phases. The purpose of this survey is to assess the Operating lessons learned over the last 10 years and the extent to which decisions made in the design phase have influenced the overall success of the project. The conclusions, though not comprehensive, can be useful input to the development of future FPSO designs and projects, particularly when used in conjunction with the existing FPSO lessons database. In due course, the lessons recorded here will also be added to the OLF FPSO database. This report has been prepared with the assistance of members of the OLF FPSO Network who have both participated in the interviews and reviewed the information recorded here. It is intended in the report that specific FPSOs are not identified and so for this reason, Supplier and Company names have also been omitted . The report is the property of the Norwegian Oil Industry Association (OLF). The Norwegian Oil Industry Association (OLF) Vassbotnen 1, Sandnes P.O. Box 8065 4068 Stavanger, Norway Tel.: + 47 51 84 65 00 Fax: + 47 51 84 65 01 Web site: www.olf.no E-mail: firmapost@olf.no

Report Prepared by: Approved for issue by:

David Llewelyn. FPSO and ST Workgroup Facilitator, OLF Per Otto Selnes. Manager Operations, OLF

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 3 __________________________________________________________________________

Table

of

Contents

1.

Introduction....................................................................................................................... 4

1.1

1.2

1.3

1.4

1.5

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

Background ..............................................................................................................................................4

Survey

Objective ....................................................................................................................................4

Definitions ................................................................................................................................................5

References ................................................................................................................................................6

Interview

process..................................................................................................................................6

Production

performance ....................................................................................................................7

People

and

safety...................................................................................................................................8

Marine ........................................................................................................................................................9

Turret

Swivel

and

Risers................................................................................................................. 11

Utilities.................................................................................................................................................... 12

Topsides ................................................................................................................................................. 12

Offloading

Operations ...................................................................................................................... 13

Integrity

and

Compliance................................................................................................................ 14

Factors

influencing

Operating

Costs .......................................................................................... 15

2. Discussion of results....................................................................................................... 7

2.10 Wish List and Surprises ................................................................................................................... 16 2.11 Conclusions ........................................................................................................................................... 17 2.12 Follow-up Work .................................................................................................................................. 17 3.0 3.1 3.2 APPENDIX ................................................................................................................... 17 Detailed results ................................................................................................................................... 18 Results ranking chart (2 FPSOs omitted)................................................................................. 19

3.3 POB Average chart.............................................................................................................................. 20

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 4 __________________________________________________________________________

1.

1.1

Introduction

Background

The OLF FPSO Network was set up in 2001 under the combined sponsorship of the OLF Operations Committee and the PSA to ensure lessons learned in FPSO projects were transferred to new projects. To deliver this objective, the Network has initiated a number of surveys to gather lessons learned on the Norwegian FPSO projects. These included a survey of 5 FPSOs (Balder, Jotun, Norne, sgard and Varg) in 2002, and Shuttle Tanker - FPSO interface survey 2003, inclusion of Alvheim project data 2008 and a follow-up review of the Shuttle tanker survey in 2009. See references below. On completion of each survey, summary lessons were entered into the OLF FPSO Lessons Learned database which is accessible on http://fpso.olf.no/lesson/ . In all over 270 lessons have been recorded. However only 16% of the lessons reported relate to experience in the operating phase and the majority of these report offloading issues. Given that the 6 FPSOs are now over 10 years old, it should be expected that new problems, relating for example to high water cuts, corrosion and fatigue will begin emerging. The OLF FPSO Network therefore initiated a proposal to undertake a 10 year Operability survey into 6 FPSOs - Petrojarl1, Varg, Norne, Balder, Jotun and sgard. It was agreed that the report would not identify individual FPSOs or suppliers, therefore in subsequent tables and reports the FPSOs are identified by number only. The conclusions were presented to the FPSO network on 9.11.2010 and comments adopted. The report was completed in Jan 2011.

1.2

Survey Objective

The main objective of the survey is to assess the performance of the Norwegian FPSO fleet over the last 10 years and to record both operational concerns and capture best practices. The intention is that the results will be used to influence new designs, promote experience sharing and ultimately to assist in the further development of best practice solutions. The data recorded in this report will be included under appropriate project phase headings in the FPSO Lessons Learned database. For example, where an issue could have been resolved by an improved design or construction practice it will be entered in the Design or Construction sections of the database, where it relates to Operational practices it will be entered in the Operations section.

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 5 __________________________________________________________________________

Typical issues of interest are:

The problem of corrosion and how this has been managed Cost effectiveness of Norsok standards regarding material selection Meeting Integrity requirements Mechanical handling Process systems and power generation Marine systems -turret, hull and accommodation Modifications and upgrades Factors that dominate Opex

The survey also asked FPSO Operators what design features do they wish had been different and why. And finally Operators were asked to list surprises that they had not expected when the project was initiated.

1.3

Definitions

Acknowledgement of Compliance Barrels of Oil per day Central Control Room Control room Operators Floating Producing Storage and Offloading Vessel Floating Storage Units Heating Ventilation and Air Conditioning Low pressure/ High Pressure Offshore Installation Manager Plan for Development and Operation Personnel on Board Petroleum Safety Authority (PTil - Norwegian) Quality Control Remote Operating vehicles (underwater) Standby Vessel Shuttle Tanker Wellhead platform

AoC Bopd CCR CRO FPSO FSU HVAC LP / HP OIM PDO PO PSA QC ROV SBV ST WHP

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 6 __________________________________________________________________________

1.4

References

The following documents are relevant to the survey and may be referred to in the discussion section below: Ref 1. A summary Report on FPSO Lessons Learned, gathered from 5 Norwegian FPSOs May 2002 Published by OLF Ref 2. A summary Report on FPSO Shuttle tanker interface. Lessons Learned, gathered from 4 shuttle tanker operators and 2 Norwegian FPSO/FSUs operators. April 2004 Published by OLF.

Ref 3. A Report on the FPSO Shuttle tanker interface.

A follow-up review of Lessons reported in 2003 with two major North Sea Shuttle Tanker Operators. October 2008 Published by OLF

1.5

Interview process

Interviews were arranged, half a day per FPSO with an interview team of three, consisting of one oil company participant, one DNV participant and a recorder from OLF. Representing the FPSO were typically the Operations manager, a maintenance superintendent and often an OIM. A typical agenda was as follows: Why are we doing this and what is in this for you? Overview of FPSO operations last 10 years - key issues including HSE and production planed vs actual Open discussion on the following topics Marine, turret and hull Utilities and power generation Mechanical handling successes and failures Process systems Offloading Managing corrosion Modifications and upgrades Other issues inc. Opex drivers What design features do you wish had been different and why? Review of summary chart

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 7 __________________________________________________________________________

2.

Discussion of results

Performance assessment and value delivery

An FPSO is utilised to produce, store and offload hydrocarbons, safely, with minimal environmental damage, at a cost which meets economic criteria set for the project. If these primary requirements are achieved the project will deliver the value anticipated by the investors. The assessment here will consider the extent to which the performance expectations originally set out for the project have been achieved. It is worthy of note here that in the project phase, four of the five FPSOs built in the 90s significantly over-ran project budgets and schedules - Ref 1 (ie greater that 30% over expenditure and more that 6 months behind schedule). However the operators claimed that the final quality was higher than the original specification and design improvements were implemented. This report will also address this issue. The results of the survey are presented under a number of Topic headings. Details of individual responses on each topic, by FPSO are shown in Table 3.1. Further in Table 3.2 an assessment has been made to rank each topic against original performance expectations (eg to fully meet hydrocarbon production, no HSE incidents etc) and where appropriate, delivery of additional value. A simple ranking system has been used as a visual aid for each topic in the summary, with rankings ranging from Excellent Performance (beyond designer expectations) to Significant Operational concern ( causing cost overruns, HSE risks or production losses). Factors which influence Opex are discussed in Section 2.9 and while many are determined by factors outside the operators control, some can be influenced by design and operation. Finally a short operators wish list is shown in Section 2.10 indicating the design improvements the Operators would prefer to have had in their respective FPSOs. A list of the surprises that Operators did not expect 10 years ago is also included. 2.1

Production

performance

2.1.1 Production performance on all FPSOs had been excellent and hydrocarbons have been delivered at or above design rates. Peak production of at or above 200k Bopd have been achieved on 2 FPSOs with 2 others achieving peaks at or above 100k Bopd. Over the last 10 years, net oil production has declined to around 25% of the above figures, though overall productions volumes (including water) are still comparable to earlier figures. Production regularity has been high and after early teething problems, has reached between 92 and 97% across the fleet, with the biggest operational concern being gas compressor reliability. Well volumetric performance is generally 2-3% higher on the two FPSOs connected directly to a wellhead platform.

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 8 __________________________________________________________________________

2.1.2 All reservoirs have delivered to or better than plan, and 5 of 6 FPSOs are likely to stay on site for 5-10 years beyond original PDO, primarily due to field extensions, further discoveries and tiebacks.

2.2

People and safety

2.2.1 HSE performance Overall the personnel safety record on the FPSO fleet has been good with accident frequencies below industry norms and only a small number of minor LTIs reported. There is ongoing concern with dropped objects as a result of several near misses. On the Environmental side, two significant oil spills were reported, one a deck leak and the other when the hose to the WHP failed. There have been a number of offloading incidents, see below. There have also been several minor gas leaks particularly in relation to the reciprocating compressors and this trend is likely to increase as the equipment gets older and more fatigue and corrosion problems emerge. 2.2.2 Working environment and crew morale The FPSO work environment and accommodation quality is generally considered good, partly as a result of Norwegian requirements. Staff turnover on all FPSOs is exceptionally low. On 2 FPSOs some concerns are expressed about the HVAC noise and vibration from reciprocating compressors/ diesel engines. There also is an ongoing issue on all FPSOs regarding the occasional need to share cabins which is not normally accepted by unions in the Norwegian sector. Early mechanical handling problems have largely been solved now. One FPSO has the CCR, meeting rooms and offices at the process deck level. The Operator considers this has significant advantages for workflow management and Operator/CCR communication, over the bridge located CCR design. The escape tunnel is considered beneficial for crew access to the topsides. There are very few reports of problems with sea sickness. Crew turnover is generally very low. 2.2.3 Crewing There are 3 different approaches to crewing on Norwegian FPSOs. On 2 FPSOs core crewing levels have been reduced from around 40 initially to 30 by consolidating Marine Departments into the Maintenance Dept, leaving the Production Dept. to operate all aspects of the FPSO. These 2 FPSOs run with only 4 on during night shifts (1 marine CRO, 1 Process CRO and 2 deck operators). 2 other FPSOs run crews of 35-37, also without a marine Dept. however they too have fully trained Marine CROs. On the remaining 2 FPSOs, the core crew is 42 in 3 departments. with around 10 support staff on average. In the 4 FPSOs with smaller crews, there is frequently a substantial contractor support team, adding approximately 10-30 crew undertaking vessel maintenance and/or modifications. On one FPSO maintenance services are also

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 9 __________________________________________________________________________

provided to the Wellhead platform which increases the FPSO POBs by 7-10. The figures referred to here are averages. See chart Fig 3.3 2.2.4 Accommodation As reported in the 2002 Survey ref 1, on 5 of 6 FPSOs the accommodation is considered too small. On several FPSOs, some additional cabins have been added or split where this is possible. These 5 FPSOs are almost always close to full (Fig 3.3). In some cases there are more beds available, but are unused because of the Norwegian union agreement for a single sleeper per cabin. This therefore requires some support staff to work nights to make best use of the cabins. The lack of beds causes problems with maintenance and repairs and subsequent production efficiency, and in one case, makes providing staff for the WHP much more challenging. The only FPSO not suffering POB problems also benefits from low levels of equipment breakdown and required maintenance. 2.2.5 Stand-by Vessel FPSOs are often remote from other facilities, and only one of the six has been able to share their SBV vessel and its associated costs with other fields. All Operators are using their standby boat for useful purposes including ROV inspections, temporary storage, oil spill response, equipment transfer between wellhead platform and FPSO, and where it has the capability, emergency towing support for offloading and in some cases it provides firefighting capability.

2.3

Marine

2.3.1Thusters Thrusters have generally been reliable and 3 FPSOs have had no failures. One had had 2 failures and uses a strategy of change-out on failure. the other 2 FPSOs change all thrusters on a rotation basis. Change-out requires 2 boats, ROVs and at least 2-3 days in good weather. However this can be more difficult and time consuming in winter where a failure could create heading control problems. In two cases, newly installed thrusters have failed early as a result of poor factory QC or poor installation. Condition monitoring of thrusters is proving very important for lifetime management and failure prediction. In design, lifting aids should be installed on the FPSO ( small davit crane and pad eyes on the hull) to assist in thruster change-out. One FPSO has an internal system for thruster change-out, but it has not yet been used, 2.3.2 Moorings and anchoring system Mooring chain wear has been greater than expected particularly in areas close to the fairlead. In certain cases, inadequate fairlead design has resulted in movement and out of plane bending with damage and wear being caused to the chains links. Several top chains have been changed and in one case, manufacturing problems and QC failures led to an early chain link failure on the new replacement chain. Wear

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 10 __________________________________________________________________________

problems have been largely solved by moving the chain in the fairleads over time and changing top sections where the turrets have mooring winches (5 of 6 can do this). Inspection of the fairlead area and chain tensions and links has also proven difficult. Some problems have also been experienced with sea bed bacterial corrosion specially in areas covered with oil based mud cuttings. In general FPSO mooring systems have required much more supervision, replacement and inspection that was anticipated. 2.3.3 Hull and tanks In general hull structures have performed as well or better than expected. A number of minor cracks have been successfully repaired in service on 3 FPSOs, and in two cases this was a result of poor QC in the yard. One FPSO required 30tons of additional steel and also required the successful use of an external habitat to permit internal welding on the hull. The oldest of the FPSOs is now experiencing side shell fatigue and some stiffener cracking as would be expected, and will soon need significant steel replacement in dry dock. One FPSO required extensive repairs to internal tank coatings which had cracked, causing serious pitting from bacterial action. There is general concern about external hull painting and anode replacement as diver access is limited. Most FPSOs now rely on impressed current for external corrosion protection. Marine growth build up in summer is usually removed by wave action in winter. Concern is noted with the difficulty of gas freeing tanks for manned entry. 2.3.4 Green water There were a number of green water incidents in the early years offshore on 3 FPSOs, where equipment was damaged. These issues have been resolved by a combination of protection walls, equipment relocation to provide a clear tank deck where possible, and/or operating in winter (on these 3 FPSOs) at higher drafts. 2.3.5 Cranes Cranes were noted as a major concern in the 2002 report for most FPSOs -Ref 1. Based on platform designs, their booms were too heavy, too wind effected and under powered for a moving vessel. They also had insufficient response times for supply vessel offloading. It also became clear that they were unsuited for maintenance activity due to movement of the heavy block. These problems are largely resolved after significant modifications were undertaken both to improve responsiveness and to upgrade back-up systems in the event of failure. Later experience has indicated that knuckle boom cranes or cranes with light weight lattice booms are preferable. See also section on mechanical handling. 2.3.6 Cargo and ballast system Marine growth has been a problem on some FPSOs with up to 70% of the inlet flow area blocked and batch hypochlorite treatments have caused massive overloading of material . Poor quality steel on the COW pipework on 2 FPSOs have necessitated changeout of the pipework after 10 years. After experiencing gas trips, all FPSO have fitted venting pipework from tanks vents.

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 11 __________________________________________________________________________

2.3.7 Fabric maintenance One FPSO had extensive work in the first 2 years to repair a failed paint system. Generally operators report that though some issues are now developing, if painting work is kept up to date and not sacrificed for other work, the issue is manageable.

2.4

Turret Swivel and Risers

2.4.1 Turrets Three different turret bearing systems have been used on the 6 FPSOs. Rail and wheel(3), sliding pads (2) and bogies and track(1). Only the latter is free rotating, however all the others require control room intervention to change heading which on average is required at least 3 times a day. Rail and wheel suffered early problems with rail and wheel surface cracking and require occasional replacement of rail sections and bearings, Hydraulic supported sliding pad systems are sensitive to the hydraulic system design and capacity several modifications were required to enlarge the hydraulic system, and ongoing maintenance levels are relatively high. The bogey track system has been the most reliable and any concerns with additional wear on the swivel (due to small movements of the turret) have not been a significant problem. 2.4.2 Fluid Transfer System and Swivels At the time these FPSOs were built, swivel technology was relatively untried. As a result three of the FPSO were equipped with drag chains (flexible hoses and cables). These have proven successful but require high levels of maintenance (pad and hose replacement) and supervision (heading control) and in some cases cause production restrictions due bend radius. The inability to rotate through 360 degrees places demands on the crew to manage heading and anticipate weather conditions. One FPSO has since start-up installed a swivel and the other two have installed gas swivels. The 3 FPSOs with full swivels have had good performance with some minor incidents (power swivel failures, water injection swivel leaks). One FPSO has replaced its swivel to upgrade its functionality ( 5 week shutdown) and another is considering a similar option. In general swivels have fully met design expectations. 2.4.3 Risers Generally production and injection risers have performed well except one significant incident with a riser failure to the WHP. A small number of failures have also occurred with the riser stiffener joint below the turret loosening off, but all have been repaired. The non-availability of riser slots can be a constraint when considering new field tiebacks.

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 12 __________________________________________________________________________

2.5

Utilities

2.5.1 Fire Water System and Deluge Generally Fire water systems have been trouble free one FPSO suffers suction problems due to turbulence at the sea chests specially at reduced draft. Corrosion in firewater and deluge systems has been reduced by use of exotic materials and/or flushing with potable water after testing. FPSOs with steel pipework are frequently suffering blocked nozzles due to corrosion. One operator would like to investigate alternatives to full deluge testing as this contributes to corrosion of topsides pipework and damages electrical equipment.. 2.5.2 Power generation Power generation is a critical function on FPSOs. Three FPSOs use dual fuel Gas turbines (GT) and three use dual fuel reciprocating generators. The two with LM 2500 GTs are most satisfied as this is a well proven technology offshore and maintenance levels are moderate. More difficulties were experienced with the larger LM6000s due to early pipework failures (casing minor fires), support failures and variable loading from thrusters which can add a cyclic 15MW. Since installation, both LM 6000s have required change-out, and these are very difficult to lift and move. Design for this must be included in the mechanical handling plan.. Failures were also experienced in the heating medium system due to vibration and corrosion. The use of the alternative duel fuel diesel or gas powered reciprocating generators provides reliability and flexibility, though there are several drawbacks: They require more maintenance - can be 3-4 extra crew on board (there are multiple moving and maintainable components), They require more supervision - in two cases a separate control room has to be manned continuously There is more noise and vibration from reciprocating engines which has to be considered in hull design They require an engine room ( or two for full redundancy ) which consumes tank space and requires gas to be fed to an enclosed area HP fuel gas compressors are required for gas feed which themselves create additional maintenance. However these engines are generally reliable, flexible and have an excellent track record in the marine industry. The future availability of LP gas intake engines will also reduce the risks and failures associated with HP fuel gas compression.

2.6

Topsides

2.6.1 Topsides Pipework Four FPSOs are experiencing severe problems with Corrosion under insulation. The humid environment combined with sea spray causes corrosion under thermal insulation on separators, supports, valves and piping. . Despite manufacturers claims, the seals and overlaps frequently fail. The problem once detected, requires removal

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 13 __________________________________________________________________________

of all insulation, sand blasting and replacement of pipework or for minor damage, repair with Belzona filling compound. Installing of doubler plates under supports is also required. It is also advisable to minimise insulation . Insulation specifications should be challenged at the design stage and if insulation is required for personal protection, open mesh screens should be used. On some FPSOs upto 10 staff are deployed repairing pipework. The root causes are failures of insulation, metallurgy and overly complex pipework layouts. Where exotic materials (Ti, Cr steels etc) are used as recommended by Norsok, these have helped. 2.6.2. Oil and water separation All FPSOs are generally experiencing good oil/water separation performance, even during high separator movement in severe weather. In at least one case, separator internals had to be changed due to liquid sloshing damage. Low levels of oil in water discharge are being achieved by all FPSOs. Where steel has been used (for example on produced water discharge lines) this pipework is now corroding badly and some of these lines are large and inaccessible. Some scaling issues are also evident and restricting water flow in discharge lines. 2.6.3 Gas compression Three FPSOs use reciprocating gas compressors and on 2 these, the compression system has been a major concern, impacting production and requiring extensive maintenance. The problems arise due to poor structural support on the topsides, component failure due to vibration, poor QA or material selection, liquid carry over causing valve or piston failure and corrosion and valve actuator failures. In addition, insufficient spare capacity has been installed, so all failures become production critical. On the 3rd FPSO there is no back-up system for the gas compressor so the 5% downtime directly impacts production. On the other 3 FPSOs centrifugal compressors have performed better. However on one FPSO, initial problems were experienced as a result of scrubber under-sizing, resulting in liquid carry over and repeated dry seal failures. Before this problem was solved the compressor bundles were changed over 25 times. 2.6.4 Flare system The flare tower is too short on 2 FPSOs and as a result, heat shielding is required. For example, the MOB boat has been damaged on one FPSO as a result of radiant heat. The location of the flare tower on the stern of the vessel also creates a risk. At certain draft combinations of FPSO and ST, the flare tower could be damaged in a collision. One FPSO has a ground flare which while reliable requires ongoing maintenance and does not produce a very clean burn.

2.7

Offloading

Operations

2.7.1 Effectiveness

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 14 __________________________________________________________________________

Over the 10 year period FPSO offloading has been very successful with high regularity and no spills, with offloading taking place routinely in 4-5m significant wave heights. This reflects the good performance of the DP2 Shuttle tankers, the FPSO and both sets of crews. Details of FPSO offloading operations were reviewed in OLF report Ref 2. There have however been several near misses due to ST drive offs linked to position errors and one contact incident occurred which could have escalated seriously as the flare tower was close to the contact point. To minimize collision damage, a rounded stern is recommended for future FPSOs in place of the current square sterns on each of the 6 FPSOs. ST operators prefer hose reels over the hose shutes used by two FPSOs as they are easier to deploy however the shute does allow better access for hose inspection. One operator improves the working relationship between the FPSO and ST teams by holding an annual meeting between representatives of the two crews. In general the ST Operators want to see increased standardization of work methods, equipment and procedures between the different FPSOs. See OLF Report ref 3. 2.7.2 Package Sizes FPSO storage volumes of the 6 FPSOs range from 190k -900k bbls. To avoid production cutbacks, offloading should take place well before the tanks are full, so usable capacities are less than stated. Further reductions apply to FPSOs operating at winter drafts due to Green water or lifeboat limitations. With oil production ranging from 5k bopd to 150k bopd, offloading frequency has varied from once a month to twice a week. Typical N. Sea ST cargo sizes are 850,000bbls and ideally the FPSO should be able to fill the ST at one loading, however only one FPSO can do this. As a result most FPSOs have to offload twice to deliver a full cargo adding offloading costs which in the case of one FPSO involves 4-5 days of ST standby after each primary offloading.

2.8

Integrity and Compliance

2.8.1 Maintenance Strategy With the improved functionality of Maintenance management systems, increasing use is being made of intelligent risk or criticality based assessments. This enables maintenance to be managed at realistic levels without taking undue HSE or production risks. Planned shutdowns are generally avoided but implemented on an opportunistic basis. One FPSO however, implements an annual shutdown due to the inability to complete such work while production is online. There is a general concern with all the FPSOs regarding life extension, because the field end date is usually uncertain. This means that decisions are being taken on a short term basis, whereas a clear end date could make investments in upgrades or dry docking much easier to justify. 2.8.2 Mechanical handling Three FPSOs were designed with cranes as the primary and almost only means of mechanical handling. This has not been ideal as cranes have limited access, are

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 15 __________________________________________________________________________

difficult to operate due to blind spots and are poor for maintenance tasks due to movement of the block. Mechanical handling was considered early in the other designs, and flat open runways, linked to landing areas and workshops all with forklift access have proven successful. However there are still many inaccessible areas; on the main deck, below decks, near the hose reel and around the helideck where handling aids were generally inadequate. There has been an extensive program to add mechanical handling aids on all FPSOs including hydraulic manipulators, trolley beams and lifts. The situation is now significantly improved, it is however an area where better early design work in the future is essential. 2.8.9 Industry Standards and Classification All six FPSOs were built to class, however only three have stayed in Class. Operators have found it appropriate to design each vessel to class, which both simplifies construction, tow and approvals particularly for ships systems. Topsides of 3 of the vessels were built to Norsok standards where the others were built to Class or ANSI Standards. Major Operators use integrity management systems either to supplement or as an alternative to Class. Contractors prefer the use of Class for integrity assurance for the entire vessel and have a preference for the AOC approval route with the PSA. The three vessels with class have ERS (Emergency Response Service) for hull / stability emergencies, whereby a Classification society team is provided within 2hrs, to support them.

2.9

Factors influencing Operating Costs

In the survey, FPSO operators were asked to review special factors that influenced Operating costs. Clearly in early years with high production rates these are less important but as production drops, Opex become more critical so by the end of field life, the cost of operation approaches the value of the production. The major drivers for Opex are personnel, logistics, maintenance, offloading and Fuel. Comments on these can be summarized as follows; Personnel: This is driven by offshore crew and onshore staff levels. While some FPSOs have low core crew numbers they also have higher maintenance crews. Five FPSOs have average POBs between 55 and 75 but only one has POBs as low as 40. Regarding onshore support, this ranges from around 15 dedicated staff to 40. Logistics: This is driven by location remoteness and the level of service required. 2 FPSOs are relatively far North, which adds costs. Significant savings can however arise from sharing of supply boats, helicopters and standby boats, however four of the FPSOs have little opportunities for such savings. Support costs are also increased by POB restrictions if contractors have to make repeated short visits to get work completed. Maintenance: High equipment reliability helps keep Opex down, however major overhauls of equipment such as main engines, gas turbine power generators and compressors all add costs. Unexpected failures of equipment such as thrusters, mooring lines, pipework (corrosion under insulation), swivels can all add significant Opex. Fabric

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 16 __________________________________________________________________________

and hull maintenance and repair is also an ongoing expense that tends to increase as vessels age. Offloading. Crude storage capacity significantly impacts offloading costs per barrel because as time taken to hook up a Shuttle Tanker, offload the cargo and transit is similar for large and smaller volumes. Of the six FPSOs, only one (900k) can fill an ST with a single offloading. Other FPSOs are progressively smaller (800k, 580k, 420k, 380k, 190k) Also due to operating restrictions the full storage volume cannot be fully utilized. Fuel. All FPSOs prefer to utilise produced gas for fuel. However for a number of reasons fuel gas compressor failure, engine overhauls, insufficient produced gas, Gas oil or diesel is required this can have a significant impact on Opex.

2.10 Wish List and Surprises

The operators were asked, that given 10 years experience, which aspects of their design they would most like to change. The responses are listed below and alongside each topic is the number of FPSOs requesting that change. The balance of the FPSOs of course, already had that aspect resolved in their own designs. More beds and single rooms Improved mooring system Simpler thruster replacement method More suitable cranes Mechanical handling improvements Low maintenance turret bearings No pipe corrosion under insulation Larger Storage volumes Low maintenance power generators Higher Flare tower Centrifugal gas compressors Swivel to replace drag chain (5) (5) (5) (4) (4) (4) (3) (3) (3) (3) (2) (2)

Finally the operators were asked for a short list of the surprises (both good and bad) that they had not anticipated 10 years ago. These included: Mooring chain failures Corrosion under Insulation Challenges of operating drag chain turrets Poor reliability of reciprocating compressors Success of swivels Excellent performance of crude separators on a moving vessel Effectiveness of Shuttle Tanker offloading operations Requirement to extend FPSO life with no dry dock for 10 years or more.

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 17 __________________________________________________________________________

2.11

Conclusions

FPSO Operations in Norway over the last 10 years have been very successful. Production targets have been met or exceeded, costs have been controllable and most important, very few injuries or spills have occurred. This result confirms the claims from the Operators in 2002, that investments made in quality and operability in the project phase (that resulted in cost over-runs) have in fact been justified. There have however been a number of challenges gas compression has been less reliable than expected particularly with reciprocating compressors, first generation drag chain turrets have been more difficult to manage than expected and corrosion under insulation has become a significant problem on a number of FPSOs. Further, these and other problems are being resolved on vessels where accommodation capacity is very limited. But there have also been a number of successes, crude offloading to shuttle tankers has demonstrated high regularity, crude separation and produced water treatment has met required specification, even the most severe weather conditions and as an indication of morale, staff turnover is very low. Equally important, FPSO crews and their contractors have successfully maintained and improved their vessels offshore, such that Operators now propose to retain 4 of the 6 vessels on location for10 years or more beyond initial development plans. Many challenges remain, particularly as the vessels get older and need more attention, but methods of work and experience developed by the Operators over last 10 years should give the industry cautious optimism for the future.

2.12 Follow-up Work

It is not intended to list proposals for future work here, however as at least 4 of these 6 FPSOs will be spending a further 10 years offshore, each still has a number of challenges to handle, as indicated by the wish list and surprises above. It is proposed that Operators continue to share experiences with the resolution or mitigation of these challenges, the OLF FPSO network can assist with this, and that Classification societies and Regulators also actively provide assistance and understanding, whenever appropriate.

3.0 APPENDIX

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 18 __________________________________________________________________________

3.1

Detailed results

Se detailed results at http://www.olf.no/no/Publikasjoner/Konjunkturrapport/FPSOoperability-survey-/

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 19 __________________________________________________________________________

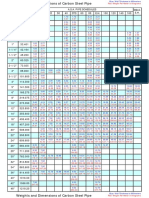

3.2

Results ranking chart (2 FPSOs omitted)

Key:

OLF 10 Year Operability Survey of Norwegian FPSOs Date: 18.2 2011 Revision no: Approved Date revised:15.3.2011 Page: 20 __________________________________________________________________________

3.3 POB Average chart

90 80 70 60 50 40 30 20 10 0 FPSO 1 FPSO 2 FPSO 3 FPSO 4 FPSO 5 FPSO 6 Max POB Core Crew Typical POB

Você também pode gostar

- Floatover SummaryDocumento12 páginasFloatover SummaryDing Liu100% (1)

- Offshore Field Development PlanDocumento44 páginasOffshore Field Development PlannagalakshmiAinda não há avaliações

- Design of Floating Offshore Platform: January 2021Documento29 páginasDesign of Floating Offshore Platform: January 2021vucokt100% (2)

- Civ-su-1.10-A Design and Installation of Living QuartersDocumento86 páginasCiv-su-1.10-A Design and Installation of Living QuartersBolarinwa100% (1)

- FPSOInterface Engineering 09Documento43 páginasFPSOInterface Engineering 09Ronnie Paul100% (1)

- Guidelines For Floating Offshore Facilities For LNG/LPG Production, Storage and OffloadingDocumento80 páginasGuidelines For Floating Offshore Facilities For LNG/LPG Production, Storage and Offloadingkaspersky2009100% (2)

- Literature Review - Bilge Keel Damping - MJ Van Kampen 08-05-2015Documento86 páginasLiterature Review - Bilge Keel Damping - MJ Van Kampen 08-05-2015Ding LiuAinda não há avaliações

- Development Plans For Oil and Gas ReservoirsDocumento11 páginasDevelopment Plans For Oil and Gas ReservoirsFranklyn FrankAinda não há avaliações

- Ships Lay Up and Reactivation Normal Procedures For Ships Lay UpDocumento23 páginasShips Lay Up and Reactivation Normal Procedures For Ships Lay UpRiteshAinda não há avaliações

- Fpso Asset Integrity Part 2Documento17 páginasFpso Asset Integrity Part 2Ella AgbettorAinda não há avaliações

- Lloyd's Register Marine Fire Safety Pocket ChecklistsDocumento18 páginasLloyd's Register Marine Fire Safety Pocket Checklistsamin_corporationAinda não há avaliações

- EN8000 Aqwa Tutorial: Aqwa-Line Aqwa-Fer Aqwa-Librium Aqwa-Drift Aqwa-NautDocumento13 páginasEN8000 Aqwa Tutorial: Aqwa-Line Aqwa-Fer Aqwa-Librium Aqwa-Drift Aqwa-NautDani GarciaAinda não há avaliações

- Marine DesignDocumento123 páginasMarine DesignDEEPAK100% (2)

- 2nd ISODC05 Tamuteam2 West AfricaDocumento137 páginas2nd ISODC05 Tamuteam2 West AfricawhusadaAinda não há avaliações

- 2002 Rio Fpso 1stDocumento269 páginas2002 Rio Fpso 1stAlex Rodriguez100% (1)

- Fpso Hull Integrity: MurdjitoDocumento38 páginasFpso Hull Integrity: MurdjitoNoor Virliantarto100% (1)

- Steel Catenary RisersDocumento29 páginasSteel Catenary RisersZadeh NormanAinda não há avaliações

- Fpso IseDocumento166 páginasFpso IseDing LiuAinda não há avaliações

- HTTP Fpso - Olf.no 21625Documento27 páginasHTTP Fpso - Olf.no 21625thlim19078656Ainda não há avaliações

- OrcaFlex Demonstration IIT MadrasDocumento11 páginasOrcaFlex Demonstration IIT MadrasvigambetkarAinda não há avaliações

- Containers in Non-Cellular ShipsDocumento7 páginasContainers in Non-Cellular ShipschildofheavenAinda não há avaliações

- Docking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.Documento3 páginasDocking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.capone55Ainda não há avaliações

- 13 Types of VesselsDocumento41 páginas13 Types of VesselsCornelia Theodora67% (3)

- A Summary Report On FPSO Lessons Learned by OLF - May 2002 PDFDocumento27 páginasA Summary Report On FPSO Lessons Learned by OLF - May 2002 PDFAgung Doank Yess100% (1)

- TUDelft Clay Suction PDFDocumento8 páginasTUDelft Clay Suction PDFDing LiuAinda não há avaliações

- Ships Repair ConversionDocumento13 páginasShips Repair ConversionGouthamVenkatesh100% (1)

- STS OperationsDocumento2 páginasSTS OperationshibadaAinda não há avaliações

- Statoil Specific GuidelinesDocumento17 páginasStatoil Specific GuidelinessridharAinda não há avaliações

- (2013.05.21) Loads On Offshore Structures Webinar: This Webinar Was Originally Presented On May 21st, 2013Documento8 páginas(2013.05.21) Loads On Offshore Structures Webinar: This Webinar Was Originally Presented On May 21st, 2013Nabigh NabiylAinda não há avaliações

- Simple Stability MosesDocumento11 páginasSimple Stability Mosesikhwanul_muslimAinda não há avaliações

- FPSO ToolkitDocumento28 páginasFPSO ToolkitNathachai LeewathanakijAinda não há avaliações

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocumento1 páginaMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiAinda não há avaliações

- Benefits and Limits of FPSO Standardisation For DistributionDocumento36 páginasBenefits and Limits of FPSO Standardisation For DistributionRobert WatersAinda não há avaliações

- Shipping ResearchDocumento14 páginasShipping ResearchbharathkrishnaimuAinda não há avaliações

- FPSO-FSO State of The ArtDocumento12 páginasFPSO-FSO State of The Artjsouza16Ainda não há avaliações

- Ice PassportDocumento49 páginasIce PassportAbdel Nasser Al-sheikh YousefAinda não há avaliações

- 2596.1.03 - OfFSHORE - 02 - Selection of Trading Tankers For FPSO Conversion ProjectsDocumento15 páginas2596.1.03 - OfFSHORE - 02 - Selection of Trading Tankers For FPSO Conversion Projectsbooraj007100% (1)

- SCO Rustaveli LLC - JunJul22Documento6 páginasSCO Rustaveli LLC - JunJul22ANDI TAUFIK ARIEFAinda não há avaliações

- Mooring Chain Guide E-Feb14Documento47 páginasMooring Chain Guide E-Feb14EduardoAinda não há avaliações

- Introduction To Subsea Pipe LinesDocumento39 páginasIntroduction To Subsea Pipe Linesharshul16100% (1)

- Decommissioning in The North Sea Demand Vs Capacity Low ResDocumento100 páginasDecommissioning in The North Sea Demand Vs Capacity Low ReslpczyfansAinda não há avaliações

- DNV RP f202 2010-10Documento46 páginasDNV RP f202 2010-10b_afrinaldiAinda não há avaliações

- 1.single Point MooringsDocumento2 páginas1.single Point MooringsAman SinghalAinda não há avaliações

- NTNU Thesis-Mooring DesignDocumento105 páginasNTNU Thesis-Mooring DesignDing LiuAinda não há avaliações

- Gryphon FPSO and Incident FactsheetDocumento3 páginasGryphon FPSO and Incident Factsheetyalçın_dalgıçAinda não há avaliações

- ABS SPM Rules Jan22Documento100 páginasABS SPM Rules Jan22Mahesh Babu AddalaAinda não há avaliações

- FUNCTION 3 Anang FINISHDocumento58 páginasFUNCTION 3 Anang FINISHAdiiAinda não há avaliações

- Structural Design of A Semi-Submersible Platform With Water-Entrapment Plates Based On A Time-Domain Hydrodynamic Algorithm Coupled With Finite-ElementsDocumento8 páginasStructural Design of A Semi-Submersible Platform With Water-Entrapment Plates Based On A Time-Domain Hydrodynamic Algorithm Coupled With Finite-Elementssaeed-21Ainda não há avaliações

- Shell Trinidad 100 YearsDocumento104 páginasShell Trinidad 100 YearsPato GutigAinda não há avaliações

- Advanced Welding Techniques in Ship ManufacturingDocumento15 páginasAdvanced Welding Techniques in Ship Manufacturingmadhan_kumar2000Ainda não há avaliações

- Arctic Marine Operations Report PDFDocumento463 páginasArctic Marine Operations Report PDFfergerson100% (1)

- Marine Environment Awareness CourseDocumento61 páginasMarine Environment Awareness CourseAndre NapalaAinda não há avaliações

- Sts Transfer Operations Plan: XYZ Marine IncDocumento57 páginasSts Transfer Operations Plan: XYZ Marine IncJitendra NayakAinda não há avaliações

- Hawser Operating ManualDocumento14 páginasHawser Operating ManualFaisal AwanAinda não há avaliações

- Offshore JacketDocumento13 páginasOffshore Jacketsatishchemeng100% (1)

- Afiche Offshore MooringDocumento1 páginaAfiche Offshore MooringSharon FreemanAinda não há avaliações

- Afiche Offshore MooringDocumento1 páginaAfiche Offshore MooringSharon FreemanAinda não há avaliações

- Failure Modes, Reliability & Integrity Offloating Storage Unit (FPSO, FSU) Turret & Swivel Systems PDFDocumento133 páginasFailure Modes, Reliability & Integrity Offloating Storage Unit (FPSO, FSU) Turret & Swivel Systems PDFmimi_chan_17Ainda não há avaliações

- Mooring Risk Focus and Risk AssessmentDocumento8 páginasMooring Risk Focus and Risk AssessmentKartik BalaAinda não há avaliações

- Ship and Boat Building and Repair-5Documento5 páginasShip and Boat Building and Repair-5navalmamunAinda não há avaliações

- SPMDocumento24 páginasSPMMS75% (4)

- Overview of STX Shipyard Facilities - Rev.1Documento25 páginasOverview of STX Shipyard Facilities - Rev.1emba2015Ainda não há avaliações

- Offshore Marginal Field - 23.05.2014 (Ver2)Documento38 páginasOffshore Marginal Field - 23.05.2014 (Ver2)moechamad_aditiaAinda não há avaliações

- Condition Assessmnt Scheme For Ship Hull MaintenanceDocumento22 páginasCondition Assessmnt Scheme For Ship Hull MaintenanceAnilKumar100% (1)

- Bull Company Profile PDFDocumento60 páginasBull Company Profile PDFputra bhagasAinda não há avaliações

- Bonaparte Australia FLNGDocumento12 páginasBonaparte Australia FLNGLawrence LauAinda não há avaliações

- Kolkata MMD Oral QuestionsDocumento53 páginasKolkata MMD Oral QuestionsSumit Sinha100% (1)

- Cold and Heavy Weather FileDocumento43 páginasCold and Heavy Weather Filebylen100% (3)

- UK CAA Cap 437Documento91 páginasUK CAA Cap 437jaikay3198Ainda não há avaliações

- 1 03 Ottobre 2015 Model Course On Advanced Training For Chemical Tanker Cargo Operations Secretariat PDFDocumento149 páginas1 03 Ottobre 2015 Model Course On Advanced Training For Chemical Tanker Cargo Operations Secretariat PDFbharatheeeyuduAinda não há avaliações

- FPSODocumento156 páginasFPSOmusaveerAinda não há avaliações

- Petrobras Cascade Chinook PDFDocumento92 páginasPetrobras Cascade Chinook PDFinstsureshAinda não há avaliações

- 337TO 003 World's Largest FLNG PreludeDocumento9 páginas337TO 003 World's Largest FLNG PreludeRamAinda não há avaliações

- Marine & Offshore Safety ProductsDocumento40 páginasMarine & Offshore Safety ProductsJose Manuel Jose ManuelAinda não há avaliações

- IAMWS PresentationDocumento23 páginasIAMWS PresentationBooraj DuraisamyAinda não há avaliações

- Statoil Minimum Criteria For TankersDocumento2 páginasStatoil Minimum Criteria For TankersAnonymous 7z6OzoAinda não há avaliações

- Dry Dock TermsDocumento15 páginasDry Dock TermswaleedyehiaAinda não há avaliações

- SBM Offshore Annual Report 2014Documento263 páginasSBM Offshore Annual Report 2014Jashveer SeetahulAinda não há avaliações

- Decks: Deck ConstructionDocumento7 páginasDecks: Deck ConstructionBrian FreemanAinda não há avaliações

- Pneumatic Fenders-Floating Fenders, Yokohama Fenders, Ship Fenders - Evergreen-Maritime Marine Fendering Systems™Documento2 páginasPneumatic Fenders-Floating Fenders, Yokohama Fenders, Ship Fenders - Evergreen-Maritime Marine Fendering Systems™enrimauryAinda não há avaliações

- Enhanced Qualitative Method For Long Life Anti Fouling Painting - PPT 2Documento31 páginasEnhanced Qualitative Method For Long Life Anti Fouling Painting - PPT 2Oladokun SulaimanAinda não há avaliações

- Proceedings of The 20th International Ship and Offshore Structures Congress Volume 2Documento542 páginasProceedings of The 20th International Ship and Offshore Structures Congress Volume 2Shivam SinghAinda não há avaliações

- Schiehallion Loyal Decommissioning Phase1 ESIA PDFDocumento83 páginasSchiehallion Loyal Decommissioning Phase1 ESIA PDFBehrang BaghernejadAinda não há avaliações

- Cargo Oil Heating Requirements For An FSO Vessel Conversion PDFDocumento11 páginasCargo Oil Heating Requirements For An FSO Vessel Conversion PDFPierluigiBusettoAinda não há avaliações

- Inspection Chart MonobuoyDocumento2 páginasInspection Chart MonobuoyJavier VillasmilAinda não há avaliações

- Mudmat Role in Offshore Drilling Operations: August 2015Documento4 páginasMudmat Role in Offshore Drilling Operations: August 2015Dr R Panneer SelvamAinda não há avaliações

- Monthly Production ReportDocumento3 páginasMonthly Production Reportprasad_satyamAinda não há avaliações

- 0 - OLF Recommended Guidelines For The Assessment and Documentation of Service Life Extension of Facilities, Rev 1, 040612Documento35 páginas0 - OLF Recommended Guidelines For The Assessment and Documentation of Service Life Extension of Facilities, Rev 1, 040612Eyoma EtimAinda não há avaliações

- Financial Stratement Cosco ShippingDocumento16 páginasFinancial Stratement Cosco ShippingDing LiuAinda não há avaliações

- 电影票房英文翻译Documento5 páginas电影票房英文翻译Ding LiuAinda não há avaliações

- American Bureau of Shipping: CustomerDocumento10 páginasAmerican Bureau of Shipping: CustomerDing LiuAinda não há avaliações

- Floatover BrochureDocumento9 páginasFloatover BrochureDing Liu100% (1)

- Bangal Basin MetoceanDocumento142 páginasBangal Basin MetoceanDing LiuAinda não há avaliações

- PMA1Documento10 páginasPMA1Ding LiuAinda não há avaliações

- Aqwa Line PDFDocumento136 páginasAqwa Line PDFDing LiuAinda não há avaliações

- T/o SH PS, NAVY D &T T) @J'RDocumento198 páginasT/o SH PS, NAVY D &T T) @J'RDing LiuAinda não há avaliações

- 004Documento28 páginas004Ding LiuAinda não há avaliações

- 005Documento50 páginas005Ding LiuAinda não há avaliações

- Library .' ,': fY?TRBDocumento122 páginasLibrary .' ,': fY?TRBDing LiuAinda não há avaliações

- Ship TermsDocumento8 páginasShip TermsDing LiuAinda não há avaliações

- Eldridge Oaks DirectionsDocumento1 páginaEldridge Oaks DirectionsDing LiuAinda não há avaliações

- Global Oil & Gas Equipment & Services: November 2014Documento38 páginasGlobal Oil & Gas Equipment & Services: November 2014Ding LiuAinda não há avaliações

- SBM Fso Mis SharjahDocumento2 páginasSBM Fso Mis Sharjahapi-3836040100% (2)

- Requirements For Thickness Measurements Applicable To Inland Navigation VesselsDocumento58 páginasRequirements For Thickness Measurements Applicable To Inland Navigation VesselsAamir ShahzadAinda não há avaliações

- DOTR vs. Philippine Petroleum Sea TransportDocumento26 páginasDOTR vs. Philippine Petroleum Sea TransportAlthea Angela GarciaAinda não há avaliações

- Methods For Preliminary Determination of Escort Tugs, RINA, February 1993Documento29 páginasMethods For Preliminary Determination of Escort Tugs, RINA, February 1993Matheus FerriAinda não há avaliações

- Offshore Oil and Gas Risk Context StatementDocumento27 páginasOffshore Oil and Gas Risk Context StatementJaeman ParkAinda não há avaliações

- Azara Application FormDocumento6 páginasAzara Application FormKristijan PolicAinda não há avaliações

- GSK 9 Set QuesDocumento19 páginasGSK 9 Set QuesLaboni Hossain 1721473Ainda não há avaliações

- CSR-Background Document On Loads - SloshingDocumento2 páginasCSR-Background Document On Loads - SloshingJym GensonAinda não há avaliações

- IsraelDocumento7 páginasIsraelRobert Ionut DinuAinda não há avaliações

- MR Product TankerDocumento6 páginasMR Product TankerPeter BaloghAinda não há avaliações

- Researches of Sustainable Development On Waterway Transportation in ChinaDocumento8 páginasResearches of Sustainable Development On Waterway Transportation in ChinaLinggaAinda não há avaliações

- Interorient Application FormDocumento4 páginasInterorient Application FormPeter AlexAinda não há avaliações

- Compass Maritime Weekly Market ReportDocumento6 páginasCompass Maritime Weekly Market ReportJoel SegoviaAinda não há avaliações

- OISD 225 TT Decantation Procedure - Check ListDocumento5 páginasOISD 225 TT Decantation Procedure - Check Listtaranakgec100% (1)

- Digital Ship - 02 - October 2004Documento23 páginasDigital Ship - 02 - October 2004DanielSombeAinda não há avaliações