Escolar Documentos

Profissional Documentos

Cultura Documentos

Salsbury: Torque Converters

Enviado por

vt133primDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Salsbury: Torque Converters

Enviado por

vt133primDireitos autorais:

Formatos disponíveis

PRICE $1.

00

SALSBURY

TORQUE CONVERTERS

ED I T ION

By Publication) Sale , o r Distribution of this

manual , Salsbury Corpo ration in no way wai ve s

o r othe rwise nullifie s any of the t e rms and c on-

ditions of it's wa r ranty.

SECOND

1010 EAST 62 nd STREET. LOS ANGELES, CA LIFORNIA 90001 PHONE ( 2131 232 6181

FORM NO 510 - 4- 42 PRIN TED I N US A

I-A-I U it is necessary to o perate an engine

without a load fo r t e sti ng a nd the bel t is removed,

the d rive pulley must also be removed.

I-A-Z Before testing a dri ve asse mbly , always

r epla c e the shi elding ins talled by the vehi cle

manufa cturer . In the event that a s catter shi e l d

is not a vailable, fabricate o ne from s t e el or a

ma t e rial of similar tensile s t r e ngth and duct-

ility . The scatt e r s hield mu s t be de signed t o

enclose both pulle ys and contain any parts that

may b reak away.

I -A-3 Inspe c t the d rive and dri ven pulleys month-

ly if used f requently. Clean and s e rvice befo re

each season.

FIGURE l -A-l

I-A-4 Ge ar pullers must not be u s ed on either

fixed or m ovable fac e or r a m p plate . Use Sals-

bury puller s t o remove . See pri ce s e c ti on of

the Master Servi ce Manual fo r the list of pull -

e r s , a ppli cation and p rice.

I -A-5 F ollowing p r o ce dur e s a r e recommended

for the re m oval of dri ve and dri ven pulley hu bs

that a r e sei ze d to the shalt.

3

I- A-6 Pulleys can be disauembled on the shaft

if they do not slide off with r ea s onable a moun t

of p ressure with pullers.

Afte r di s a s s embly, use heat o r tap s ha r pl y but

lightly with a light hamme r. Ap ply pressure

with the puller (figure I -A- Ij while heating o r

tapping. A heat gun is the recommended source

of heat. U open n ame is used, kee p away f rom

fuel line s , fuel tanks, ca r bur e t o r s , and plastic

hoods . Before u sing heat, r emove a ny solvent

that may have been used wi th c om pressed ai r

and d ry thoroughly.

I-A-7 Some eady Model 500 and 700 Series

drive pulleys di d not have threade d hub s . Aft e r

r e moving r a m p pl a t e, pla c e two 703046 s pace rs

between s pi de r a nd ena p ri ng . Thi s will equal

the t hi ckne e s of the r amp pla t e a nd preve nt move -

me n t of the spider when a gear puller is used.

Care must be taken when pos i tioning the ge a r

pulle r to prevent moving or damaging the s pider .

I-A-8 Driven pulleys that have a snap r i ng on

the hub can be pulled with a gear puller (figure

I -A-Z). Pla ce a clos e fitting tubula r colla r on

the hub, replace the snap ring and position the

gear puller. Enla rge the i ns ide diameter of a

drive pulley spider with e me ry cloth and s lide

on hub as a seat f o r the gear pulle r .

FIGURE I -A-Z

HO\/\/ IT \/\/ORKS

Two types of driven pulley systems availab le :

SPEED SENSITIVE TORQUE SENSITIVE

DRIVEN PULL EY DRIVER PULLEY

OlU V(A PULLET DRIVEN PULLEY

1- B-1 At l ow speeds the normal posi -

tion of the drive r pulle y maintains the

V - bel t a t a s malle r diamete r whi ch

with the c o r re s pondi ng l arger diamete r

on the d r i ven pulley. create5 a "low

gear" r a tio.

I - B-Z A s the speed inc rease s . the

c ent rifugally actuated roller wei ghts

( A ) follow the contour of t h e bo wl -

shap ed r a mp pl a te, forcin g t he d r iver

she a ves t ogether . Th i s action through

the belt compresses t he driven pulle y

spring (B), thus achi eving a " high gear"

r a t i o .

4

I-B- 3 In the t orque s e nsiti ve desi gn

(a s in the speed s ensiti ve design the

norm al position of the d ri ver pulley at

l ow engine speeds mai ntains t he V-belt

in a small diame te r . Normal r-otatt ou-

a l fo rce on ca m actuator (C) keeps the

d r i ve n pulle y in " l ow ge a r" r atio.

l -B-4 As the dri ve r pulley i s es sen-

tially the same in both type units . high-

er e ngine s peeds c a u s e the roller

wei ghts to clos e the d ri ver pulley

s heav e s c r eat i ng a "hi gb gear" r a tio

(n ote position of cam a c tuator) .

I - B- 5 If a n inc rease d l oad occurs (such

a s climbi n g a hill ) a f t e r t h e vehide i s

up to spe ed the c am a ctuator on the

d r i ve n pull e y take s ov e r and automatic-

a lly "down s hi ft s" without los s of engine

speed. Then engine rem a ins at peak

p owe r r a nge f o r all but the most severe

l oa d s, at which time it will shift int.o

p e a k t orque r a nge.

-

TORQUE REQUIREMENTS

RAMP PLATE

RETAINER BOLTS

8- 10 i t l b .

Model 500

700 Series

Torque Value for

Torque Pin Nut

Mode1 1l 90. 1195

T orque

ao v zs n n

RI VE PULLEY

RETAINER

(not Sal s bury Part )

Model Torque

3 30 25 i t l b .

500 25 i t lb.

700 ser ie 5 25 it l b s

780 35 i t l b .

9 10 70 it l b .

11 90 80 it l b .

Hold Dri ve Pull e y with

Strap Wrench

Us e S. A . E. Grade 5

o r be tte r. 3 marks

\

Secure wi th

Cotte r Key

RAMP PLATE

RETAINER NUTS

Mo de l Torque

780 125+1 5 ft lb.

910 150+15 it l b.

1ol0 Di:l. 110 NU T

THltCA D OfOIl.

Pll LLR IlOLT

6

Nut Mus t Be

Loc ked Bend

as Shown

Torque

5-7 it lb.

5- 7 it l bs

57 it lb.

57 it lb.

57 it lb.

57 it l b .

Bolt Mu st Be

Loc ke d Bend

Plate as Shown

Model

330

5 00

700 series

78 0

9 10

11 90

___HEX BOLT

VISUAL IDENTIFICATION GUIDE

DRIVE PULLEYS

F IXE D FACE

NO y.... u:

rACE UNIlEa

........ P1.ATlI:

~ ~

LUl L'f _cu: ---..

300

400

MOVA BLE rAe :

UNOI. ""up PLAT:

500

110 SPLINE !alV

MODE1. no. 7 l ~ . 190. 195

View C

View B

Il l " I.IP

I

MODEl. 710

700 Se r i e s

See Vi e w s A. B. C

""'

VISUAL IDENTIFICATION GUIDE

DRIVE PULLEYS

I

Vi e w A

Ill" uP

- '

700 - 705

FWT GIIOOVE

NOT USED

780 Spider Drive 780 Spli ne Drive

8

VISUAL IDENTIFICATION GUIDE

DRIVE PULLEYS

880

9 10

'.1"

IUV,':.- ' - - - - , ~ : : : : : : = " ,

o. ~ _

NUTS '"'

\\

\\

J/

J/

11 9 0{11 9 5

9

MODEL NUMBERS MARKED

IN AREAS INDICATED

A. Ramp Pl a t e Retainer

B. Lock Pla te

C. Labe l on Ramp Plate

D. Ink Stamped Number

E. F i xe d Fa c e at Cente r Hub

BRAKE

DR UM

NARROW

FLANGE

TYPICAL

SPE E D

SENSI TIVE

I

-

RAMP S

BOL TE D ON

SP RING COVE R

TYP ICAL

TORQ\: E

---- SENSI TI VE

WIDE

FLANGE

/

MOVABLE

FACE

VISUAL IDENTIFICATION GUIDE

DRIVEN PULLEYS

TYPICAL SPEE D OR TORQUE SE NSITIVE

DRIVE N P ULLE Y FLANGES

10

'P FLANGE

<,

SERVICING MODE. 330,

780, 910 DRIVE P ULLEYS

Z-A-I Use puller s screwed into inte rnal hub

t hrea ds to umove pulle y s f rom shafu. (figure

Z- A- I ). See Pric e List Section, Maste r Service

Manual for li s t of pulle rs, application and price.

See also, Chapter I , r e comm e nde d methods for

pulle y r emoval .

Do not use gear pulle r s on either face or r a m p

plate, this will cause damage.

Model 780 r amp plat e retainer nut 15 threaded

fo r a puller bolt. Prot e ct c rankshaft threads.

(fi gure Z-A- Z)

Z- A- Z Clean a nd e xa mine prior to disassembly.

No te mounting of ram p plate in r elatio n to bub.

U numbe rs I and Z a re stamped on ramp plate,

note thei r posi tion in r elatio n to tbe bub and r ol-

l e r arm. Replace ra m p plate in same position.

(fi gure Z-A- Z)

Z-A-3 Re move Model 330 ramp pla.te by knock-

i ng out r e tainer with 10Dg drift pin inserted f rom

fixed fa ce e nd . To r eplac e, position ramp plat e

on s pline and r e tainer with hammer to seat.

TYPICAL.

DRIVE: PU1.1.Y

INSTAl..1Jo TION

FIGURE Z-A- I

NOO>:L 710 NUT

FOil

PUI..I..U IlOLT

....M P PUlT

FOIl LOC/I.tOf; r<UNBI;U

a.: p....ce LIlN PCl5!tlON

FIGURE Z- A-Z

Flatten lock plate (fi gure Z-AZ) <LDd unscrew

r a mp plate retainer nut of MOdels 780 and 910.

Hol d with st rap o r dou ble pronged tool

i nse r ted i nt o vents i n r amp plate. Nut has right

hand thre a d and must be ext remely tight. See

T o r que Specifications. Chapte r!. (figure Z-A- Z)

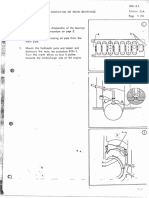

Z-A-4 Removal of the r amp plate exposes r oller

a rms, s p rings . pins, bushi ng. . (fi gure Z-A-3)

Cl e a n thoroughl y a nd se rvice a s r e quire d . Ex-

amine r olle r a rms, s p ri ngs, pins for wear a t

be aring points, r epla ce if worn. Replace parts

in s e ts a s i ndicated in parts list. Do not mix

. new and used pa rts , u s e sets c om ple tel y.

11

RETRACTOR

ROLLER ARM

FIGURE Z-A-3

s pl ine

Su -

torque all bo l ts and

See Tor que Chart,

l - A- I O Du ri ng assembly

secu re with l o c k plates .

Chapte r 1.

2- A- 9 Idler bearing i s installed with ins i de

c hamf e r t owa r d fi xed fa ce. Idler bearing i s a

fre e turning, close fit o n the hub. Replace if

e xcessi vel y worn. Do not use lubrication. Clea n

idle r bearing with d ry cloth, do not use solvent.

After releas ing springs f rom roller arms, slide

movable face shar ply against r e tra c t or to re-

move fr om hub. (figure 2-A-4)

l -A-13 See Torque Chart for cor rect torqu e

f or bolt r etaining dri ve pulley t o c r a nks haf t . Use

a good g r a de bolt, at lea st S. A. E. Grade 5 o r

better . T his is i ndica ted b y three ma r k s on the

he a d of the bolt.

2 -A- 12 1 drive pulley is i nstalled on a tapere d

shaft, clean s haft i n side tape r of pulley before

assembl y. Ta pe r s mus t be anembled dry .

l -A-8 Examine belt surfa c e of pulley fac e s , r e -

pl a c e if worn, g roove d, pitted, sco r ed o r other

damage . Check fo r wea r by pl a cing strai ght

e dge across s u rface . Re place par t if wear is

i ndicated. (!igure 2-A-5) .

2-A-5 Not e positon o f r etr a ctor prior to roe-

moving. Ramps of r etr a ctor align wi th

a rms. (fi gure 2- A -3) When r epl a cing. .iLl.low

adaquate s pline length fol' e ngagement of n.mp

plate with hub. (figure 2-A-6)

2-A-ll Use tool number 703152 or 70 315 3 f or

e ngagi ng the springs with r oller arms.

Z-A-? Clearance is ma intained between

liners and i dl e r bearing b y keyed washer.

vice a s required. (figur e 2- A- 5 )

2- A- 6 Exami ne movabl e f a ce a t spline line r s ,

r e plac e eithe r o r both part s t o r e duc e clea r -

ance i f excessive . (fi gure Z- A-4)

12

SPLIN E

LIN ER

USE STRAIGHT EDGE

TO CHECK WEA R

REPLACE IF GROOVED,

PITT E D, SCORED

-

FIXED FACE

HUB

FIGURE Z-A-5

\

SPUNES

FIGURE Z-A-4

MOVAB LE

FACE

FIGURE 2-A-b

IDLER BE.... RING

Wn H CHAMFER

I

HUB

kETRACTOJl

AUCN WtTH

Jl.Ow.&Jl 'AllM$

LONG CNO Df"

SPR ING

5EATl:D ON

" au-D / AItM

SERVICING MODEL 500 AND 700 SERIES

Il US Tll RADED

. OR PU1.1.ER

Z-Bl Ul e puller 70Z807 if hub is threaded. Do

not wee gear puller on any part of drive pulley to

remove from crankehaIt. See Chapte r 1. General.

for i n s t ructi one for removal of pulleys seized to

s haft .

Z-B-Z Clean and esamtee prior to disassembly.

Note method of aeeembly and position of ramp

plate prior to di saasembly.

TH lS .sNA P R1. '1G

IN Jl:CqND GROO VE

FIGURE 2-B-l

NOTE: Hub hal two g rooves for insta.lla.tion of

s nap r ing. (fi gu r e a Z-B-l. Z-B-Z) Check posi -

tion prior to disasaembly. Use same g roove to

r e build. Some models have a spacer between

snap ring and ramp plate. See visual identifica-

tion chart for illustration.

Z-B-3 Removal of r a mp plat e exposes r olle r arms.

springs. pins. buehings. (fi gure 2- B-3) Clean

thoroughly and se rvice as r e qui r e d. Replace all

worn parts . Use complete service kits fo r springs

or roller a rms. Do not combine new and used

parts of the eame kind. Any indication of wear

r e qui r e s r e pl a cement .

s.NAP RING

GROOVES

EXAMI.'I E ROl.J..R

..~

AT au.1NC

.sURFACE.

REPL.AC IF

' ~ N . / . , . ~

MOVABL E FACE

SPIDER P J.ESS

rrr , a OolOVE WITH

GEAR PUt..I..R

ItPUCE IF

1tlol0 VE D

Spide r's position on hub is r elated to pos iti on of

snap ri ng.

U the s pide r ia removed i t must be r epla c e d with

a new part. Re m ove o nly if necessa ry to r epl a ce

either movable o r fixed ra ce ,

FIGURE Z-B-Z

The

heat

Replace if

noted. (fig-

13

Z-B-5 Examine the movable face.

bushingsarewornor other carnage if

ure 2-B-3)

Z-B-4 The I pi der 18 an i nterfe rence kit on the

hu b a nd it must be ti ght . Any indi cation of move -

me nt r e quire s r epla ce m ent.

Remove apider with gear pulle r . o r heat.

r e c omme nde d method of beating is with a

gun.

2. Remove nut and wa she r , place p roper cup

wa sher cen te r ed over hub and r e t i gh t en unt il i n-

s i de o( cu p washe r bottoms o n hub. (fi gure 2-B-

6) Se e Dr i ve Pulley I dent ifi cati ons , Chapter 1.

(or co r r e c t cu p washe r . Remove washer, DQt.

a nd cup washe r .

5 . Movable fa c e mus t slide f reely o n hu b. Cor-

r e ct binding b y lightly tap ping s pide r on top of leg

that binds i n movable {ace bushing.

3. Install r a m p plate, cup washer , washer a.n&!

nu t . Ti gh t en until cup washe r bottomed and re-

move . (fi gu r e 2-B-6)

2-B- 7 Du ring assembly s pide r must be

Iy posi tione d on the hub. Use a lar ge boll o r _

inch l ength of thr e a de d s t ock, 5/ 8 inch diametex.

t wo nu ts a nd two washe rs . Use the cup _.:be-T

t o po si ti on th e s pi de r . (fi gur e s 2-5- 4, 2 - &-'5.

2-B- 6) Heat spide r t o 180 - 250 degrees, pre

on ho t , and dry.

4. Pos i tion r a m p pla t e , s nap ring, cu p washer.

and nul. (fi gure 2-5- 6 ) T i ght e n u ntil snap ri l:l&

l o cks into g r oove . Model 780 r equi r e s spacer

betwe en ramp plate and s nap r ing. Remove all

i tems: nu t s , washer s , cup washe rs, and ramp

pl a t e .

2-B- 6 Check the belt su rfa c e of both fa.c.es 'IndL

a stra i gh t ed g e . Replac e if worn, g.r CllO'ft:_ Ill!e"

pined.

1. Position spider into movable face for di a -

ment and pl a ce o n hub. In s e r t t h rea ded stoc;k..

wa shers and nuts . (figu re 2-5-41 Ti ght e n auu

u ntil spide r fl ush with t op of hub. ,

netfTOO ..., T

C.. T.... . ...stlas

-" / "'" 10r

,

FIGURE 2- B-4

U:U ' C.UE

.aWEEI<

T WO " AmOS

FIGURE 2- 5 -5

FIGUR E 2- B- 6

'......, ..... J.. cu, .......u

2- B- 8 Engage spr i ngs with r oller a rm t ool

703152 o r 70315 3. P o si tio n r a mp pl a t e , snap

r ing, locking pl ate and secure wi th bolts . To r qu e

a s requ i red. Wa she r s are plac e d between ramp

pl ate and l ock plate. Bend taps of l oc k plat e to

s ecure bolts.

2- B- 9 I! d ri ve pulley i s i ns t alled on a tapered

shaft, cl ean s haft and i nside tape r o f pulley be-

{o r e a.sembl y . Ta pe r s must be d ry.

See torque chart fo r cor rect torque for bolt r e -

taining d r ive pulley to c rankshaft.

Use a good g r a de bolt, a t l e a st S. A. E . Gra de "

o r bette r . Thi s is i ndicated by thr ee marks OD

the hea d of th e bolt .

14

SER VICINO P ROCE DURE

1190 AND 1195 DRIV E P ULLE Y

Z-C-I Us e puller number 70Z9Z6 t o r e m ove f rom

c r a nks hait .

Clean a nd examine the dri ve pulle y for external

damage .

Z-C- Z These instructio n s appl y to all models of

the 1190 and 1195 drive pulle y s. Model variations

a re identified by r i ve t o r castellated nuts on the

ramp plate. (fi gur e Z-C- I)

Ur<DI:.

cooc or WOOD IIl.D(: KS

llA MP PLAT I: '------------.... TO ....151: F lX!: D

F...ce

Z-C- 3 Ramp pl ate s are pressed on the s pli ne d

hub. Do not r e mo ve the three c a s t ellat e d nuts.

Us e three o r four e venl y s paced Z X 4 wood bl ocks

t o s uppor t the outer e dge of the r a mp plate rai s -

i ng the fixed face a pproximately l I Z i nc h oil the

bed of an a rbor pre5s. Sc rew i n the r emo val

tool, 70Z9Z6 and a pply p ressu re t o separat e the

r a mp pla t e f rom th e hub. (figu re Z- C-I)

Examine the r a m p plate. Re plac e the r amp plate

if riveted torque pi n s a r e l oos e . Tor que pins r e-

tained wi th nut a r e replac eable in s ets .

Z-C-4 Alignment eof repla c e ment torque pins is

i mportant. Start in r a m p finger t i ght. Place

movabl e face a nd r a mp plate o n hub with t o rque

pins i n guide bushings in movable face, t i ghten

nutl and lock with co tte r key if u s ed. Torque

nut s t o ZO - Z5 foot pounds. With spring s disc on-

ne cted from r oller a rms movable fa c e shoul d s lide

f reel y on hub.

Z- C- 5 Support the c ent e r of the hub when pres-

sing o n the r a m p plate. Do not support on the

outer e dge of the fixed face . Use cup wa sher

703135 t o press r amp plate o n hub to c o r rect

po s ition. (figure Z-C-Z)

Cup washe r 703135 must be used when s e cur i ng

drive pulley to crankshaft of driving shaft . Cup

washe r s e cur es the ramp plate to the hub. (fig-

u re Z-C-Z )

15

FIGURE Z- C- I

- -

F IGU RE Z-C-Z

2-C- 6 Re move r o lle r a rms , spr ings, p i n ~ ax..

bu s hi ng s f rom mo va ble face . Clea n and e x a . ~

Re place if wea r is f ou nd on spr i ngs, pin s , nt!:!%" :,

a rms, fi gur e 2- C -3 . Re place in s e t s a ll indic:a:a'C

o n pa rt s li st. Use set of pa r t s compete a. ee-.

cei ved, do no t combine new a nd us ed pa r t s , To r-

que r e tai ner bolts, be nd up l ock pla t e to s e cure

bol t .

FIGURE Z-C- 3

2 -C-7 Exami ne t he fi xed and mova bl e {a ce s {or

wear on the belt surface . Re place if worn, scored,

and pi tte d . (f i gure 2-C-4) P l a ce a straight e dge

ac ross t he drive surface of t he pulle y f aces to

c he c k fo r e xc e s sive g r oo vi ng .

2-C-8 P os i t i on mova bl e face to pre vent binding

wi t h snap ri ng. Cent er s nap ri ng ends between

t orque pin bushi n gs, (fi gure 2-C-S)

16

CHCCIt TO

DCTCRMINC

CO/,/ [) lTlQ/,/

FIGURE 2-C-S

FIGURE 2-C-4

SERVlCING MODEL 880 DRIVE PULLEY

Z-D-l Use pulle r 70Z9Z5 to r emov e dri ve pulley

from c r a nkahaft . Clean and exam i n e .

Z- O-Z Disassemble b y u nscrewing ramp plate

from fi.xed face. Clamp cente r hub p rotruding

beyo nd fixed fac e in vi s e . (figure Z-O-1) Use

s t r a p wrench. Turn ramp plate counter clock-

wise.

Z-0-3 L ift oU r amp plate and movable face .

Note position of spring. spring cup, thrust wash-

e rs, a n d idler tire . All pa rt. muat have f ree fi t ,

replace if exc e s sively l oos e . (figur e Z- D-Z)

2.- 0 -4 Examine the l evers , they must pivot fr e e -

l y but not have side play. l eve r and

pi vot pin if worn. Repla ce ramp if lever

guides are wo rn. (fi gure Z-0-4)

Z-D-5 Pos i ti on lever bra c ket on tubular s u p -

port and drive out pivot pin with hammer and

drift. Repla ce pin by supporti.ng i n same man-

ner.

2.-0-6 Assembl e idler tire bushing spring cup

a nd spri ng on fixed fa ce clampe d in vi s e. Place

movable face into r a m p plate so that levers s e a t

i nto inserts in r a m p plate. (fi gure Z- 0-4) Hold

movable face and r a m p plate together as as s em-

bly a nd s c r e w onto fixed face hub. Turn clock-

wi s e . Use strap wrench t o tighten.

Z-D- 7 U 6e a good grade fa stene r to r e tai n pul -

l e y t o c r a nkahaft. At l e a st G rade SOl' better,

i n dica t e d by three marks on bolt h ead .

17

T1,1a:< ro

pu,,

ItOUlLOwa /

unOF Hl,.'B

FIGUR E 200-1

FIGURE Z-0-4

" utiD

,.... ce

U :'VE.ll

SERVICING SPEED SENSITIVE

DRIVEN PULL E YS

3 - A-l Examine the pulle y and detennine if s p ring

cups a re r e stri cted in movement b y links. Vi ew

from edge o f pulley. (fi gure s 3 - A I, 3- A-4)

U pulley has links , flatten lock tabs on nuts and

r emove cove r. (f i gure 3-A- ll

MOVABLE

rACE

COVER

FIXE D FA CE

o

U pulley does not have links, do not r e m ove nuts

until s p ring tension s ecured wi th tool. (figu r es

3 -A- 4, 3-A-6)

3- A- Z Us e at least a lZ inch length of t h r ~ d e d

stock, two nut s and washer s. A drive pulley

s pide r i s also used to compres s the spring below

the c e nt e r hub. (fi gu r es 3 - A- Z. 3 - A-6)

3 -A-3 After positioning the tool s and pulley, com -

pre55 spring to r el ea s e links or outs. (figu.res

3-A-Z, 3- A- 6) Turn nut to release spring te n-

sion. (fi gure 3- A-3)

3- A- 4 Clean all parts and r e pbc e if WOTn . Ex-

ami ne bus hi ngs for wear.

3- A- 5 P o si tio n parts and rc cds , align bolt hol e s

and link seats. (fi gure s 3 -A- 3, 3 - A- 5)

19

FIGURE 3 - A- l

OU-IlE:TWEt1

T WO WASHEA'

FIGURE 3 -A-Z

FIGURE 3-A- 3

3- A- 8 Drive n pulleys with i nt r e gal shafts will

r e qui r e u se of a rbor p ress a nd tubular adapte r

F ollow p r ocedur e . beginni ng wi t h parag r a ph 3-A-

1, mo dify for i.nt regal s haft .

3 - A-6 Li nk type , c om p r e ss s p ring com pletely

(fi gure 3-A-2) seat link pins. Release assembly

from tool, s li de movable face oU hu b, pos i t i on

tube s pa c e r s in movable face , place on hu b and

secu re with nuts. Nut s must be locked with lock

plate .

3- A-7 Bolt s are insert e d f r om the spring e nd of

both uni ts when equipped wi th b rake dntms . Nut

lockpla t e i sthe brake d rum. Modify di sasse m bly

and a s sembly proc e dures to sui t .

SERVICE HlNT: Place short bolts i n l o cking plat e ,

fi gure s 3- A- 5, 3-A-6 to ma i ntain bolt hole ilign-

m ent i n lock plat e and spring cup.

20

L.OCII P ~ T

FIGURE 3-A-4

FIGURE 3 -A-6

SHOIIT aoLT5

AUGN JlOLT

HO'....._ ~

FIGUR E 3 - A- 5

I)jl; !Vi: PUL.L.EY

SPWER

00 NOT R MOVE

NUTS UNTI L SPRING

TNSIO:-.l RETAt.."ED

SERVlCJNG TORQUE SENSITIVE

DRIVEN PULLE YS

3- B- l Clean thoroughl y before disassembly. Ex-

a mine for wear and o pera t i on. Re pla ce wor n

part s . Note position of s pring anchor points.

3-B-2

b racket.

det ve r ,

Releas e s pring from anchor i n t orqu e

(fi gu r e 3-B-l) Unhook with screw-

nXED

F,\C(;

FIGURE 3-B-l

3-B-3 Place on bench, fixed face down, poslUon

heels of hands on torque bracket. Pre s s down to

clear ke y in hub and tu rn to lock unde r key. (fig-

u re 3- B- 2)

3- B- 4 Remove s nap r i ng. Turn torque b racket

s lowly t o release and slide up bub. Hold secure-

l y to pre vent sudde n spring r ele a s e . Model 330-

(fi gu r e 3-B- l ) Hold torque b r acket whil e r e m ov-

ing s ocket head screws . Ca r efull y r el e a s e s pring

tens ion.

3- B- S Clean and examine all pa.rts, r eplace if

wor n. Do not l ubricat e during r e a s s e m bly.

F IGURE 3-B-3

FIGURE 3- B- 2

~ ..

'"==========1--.....

TO

Oll &

I- "....CKI:T

-

TU.N

MQ V"' "L&

, , ~

COlffl TDl

CJ,.OCKWIS&

shoe i n movable fa ce

Service in sam e m a n -

Comp reu s pring until 1/ 16 to 1/ 8 i nch clear ance

between r a mp s . (fi gure 3-B- 3) Turn m ovabl e

face 1/ 3 turn counter clo ckwise, or 120 de gr e e s,

pre s s t orque b r a cke t down hub and l ock unde r ke y.

paragraph 3-B-3. Replac e s na p ring. Rele a s e

torque b racket t o s e at against snap rin g.

3-B-6 Pla ce m ova ble fa ce on hub; r epla ce key.

Enga ge s pring with anchor point in t orque br acket,

para gra ph 3- B- 2, a nd a nchor point in m ovabl e

fa c e .

3- B- 7 Drive pulleys wit h integral shafts a re se r -

viced in the same manner. Some models use a

c i rcle type r e tainer rather than a s nap ring.

Some m odels have ramp

por ti on of torque bracket.

ne r o

Zl

o

l

I

I

J

._ -

-.. .-

Tight

...,

.-

tance will aho have t he s a m e affe ct as a loose

o r tight belt . (fi gu r e s Z, 3) See Master Servi ce

Manual, Belts Section, lor recommende d belts

a nd dimensi ons.

4b). FiRUre 4b i llus t rates maximum travel of

the movabl e face . worn be lt, (h ollow, l ower)

unable to m ov e to g r eatest diamete r of d r i ve

pulley. Vehi cle performanc e is also affected if

belts a re c oa t e d with g r e ase, oil o r water.

..............

'on

23

FIGURE 4-A- I Cor rect Be lt Size

FIGUR E 4-A- 3

F IGUR E 4-A- 4

-

..,.

F IGURE 4-A-Z Loos e

--

--

--

4-A-l Belts ' a r e a very important part of the

ove r all design of th e Salsbury Torque Converter .

Use only the specified belt for each appli cation.

(fi gur es I, Z, 3) A change in shaft center db-

4-A-Z Bel te that are excessively worn wi ll r e -

quirea hi gher engine speed f o r engageme nt a nd

the maximum g r ou nd s peed o f the ve hicle wi ll

be r e du c e d. (figure 4) The s e r vice a ble bel t

moves to the outer diameter resulting i n a " high

gea r " r ati o. (Uppe r s olid bel t , fi gures 4a and

Você também pode gostar

- Jetaway Service GuideDocumento185 páginasJetaway Service Guideralleman1Ainda não há avaliações

- HP LaserJet 5P - 6P Service Manual (Proper)Documento116 páginasHP LaserJet 5P - 6P Service Manual (Proper)maroudasp100% (1)

- Eightspeed Guide 2022 CompressedDocumento14 páginasEightspeed Guide 2022 CompressedCarlos0% (1)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesNo EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesNota: 5 de 5 estrelas5/5 (1)

- Millrite MVN ManualDocumento54 páginasMillrite MVN Manual68mule100% (4)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheNo EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheNota: 4.5 de 5 estrelas4.5/5 (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Older Wheel Horse AttachmentsDocumento54 páginasOlder Wheel Horse AttachmentsKevins Small Engine and Tractor Service100% (1)

- Volvo Repair Manual TP30000-1 Front Wheel SuspensionDocumento56 páginasVolvo Repair Manual TP30000-1 Front Wheel SuspensionDarrin SmithAinda não há avaliações

- MFG'S DREMEL WISCONSIN WORKSHOPDocumento4 páginasMFG'S DREMEL WISCONSIN WORKSHOPegizio60100% (1)

- Prestolite Starter MMDocumento155 páginasPrestolite Starter MMleather_nun100% (2)

- Sioux 7192 PDFDocumento22 páginasSioux 7192 PDFJeff LetcherAinda não há avaliações

- Refrigerador Haier Service Manual Mother ModelDocumento32 páginasRefrigerador Haier Service Manual Mother Modelnibble1974100% (1)

- Bolens Husky 600Documento8 páginasBolens Husky 600Len BenschopAinda não há avaliações

- Huawei E5885ls 93a Mobile Wifi DatasheetDocumento22 páginasHuawei E5885ls 93a Mobile Wifi DatasheetMohammed ShakilAinda não há avaliações

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Cable HoistDocumento4 páginasCable HoistUrip S. SetyadjiAinda não há avaliações

- IGCSE Math (Worked Answers)Documento22 páginasIGCSE Math (Worked Answers)Amnah Riyaz100% (1)

- X 09 CDX 09 High Security LocksDocumento8 páginasX 09 CDX 09 High Security LocksBenoit CarrenandAinda não há avaliações

- Single Line Hose Reels: Nstallation InstructionsDocumento12 páginasSingle Line Hose Reels: Nstallation InstructionsLuisYaguiAinda não há avaliações

- Ordinary Dierential Equations Principles and ApplicationsDocumento349 páginasOrdinary Dierential Equations Principles and ApplicationsSokratis Spyrou100% (1)

- Text Linguistics and Classical Studies - Facebook Com LinguaLIBDocumento129 páginasText Linguistics and Classical Studies - Facebook Com LinguaLIBEnglish Buzz100% (1)

- Research Methods in PsychologyDocumento2 páginasResearch Methods in PsychologyHillaryAinda não há avaliações

- 4650 and 4850 Section 55Documento100 páginas4650 and 4850 Section 55josephmw0308Ainda não há avaliações

- Winche Neumatico JoyDocumento6 páginasWinche Neumatico JoyWilliam QuilicheAinda não há avaliações

- Installation: A.E RreDocumento1 páginaInstallation: A.E Rresopian320Ainda não há avaliações

- Electrical System: Service ManualDocumento4 páginasElectrical System: Service ManualEdin HadzicAinda não há avaliações

- Engine Disassembly GuideDocumento44 páginasEngine Disassembly GuideMoto TOWAinda não há avaliações

- Mecanisme Cu BileDocumento39 páginasMecanisme Cu BileNicu PaveleanAinda não há avaliações

- Operating Instructions Dixie Cerradora de LatasDocumento22 páginasOperating Instructions Dixie Cerradora de LatasMario Amieva BalsecaAinda não há avaliações

- Owners manual for Craftsman 15-inch motorized scroll saw/sander provides safety rules and operating instructionsDocumento7 páginasOwners manual for Craftsman 15-inch motorized scroll saw/sander provides safety rules and operating instructionsrlrubenkingAinda não há avaliações

- TM9-1706 JXD Gas EnginesDocumento331 páginasTM9-1706 JXD Gas Enginesferdockm100% (1)

- Control Linkage AdjustmentDocumento42 páginasControl Linkage Adjustmentcampollano14Ainda não há avaliações

- En Es FR de PT RuDocumento24 páginasEn Es FR de PT RuAlejandroAinda não há avaliações

- C15 & B40 Service Sheets Book 00-4082 X PDFDocumento90 páginasC15 & B40 Service Sheets Book 00-4082 X PDFLos Ángeles Customs GarageAinda não há avaliações

- 2005 RockShox WartungshandbuchDocumento99 páginas2005 RockShox Wartungshandbuchpsagnes3142Ainda não há avaliações

- Install and Adjust Shift Cables for Gasoline Stern DriveDocumento15 páginasInstall and Adjust Shift Cables for Gasoline Stern Drivesandie2121Ainda não há avaliações

- 4650 and 4850 Section 55Documento100 páginas4650 and 4850 Section 55josephmw0308Ainda não há avaliações

- Main Bearing 'B & W'Documento5 páginasMain Bearing 'B & W'aliakbar tavafiAinda não há avaliações

- Sterndrive Unit Installation: Description Where Used Part NumberDocumento13 páginasSterndrive Unit Installation: Description Where Used Part NumberĐặng MinhAinda não há avaliações

- 4650 and 4850 Section 50Documento100 páginas4650 and 4850 Section 50josephmw0308Ainda não há avaliações

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocumento12 páginasInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146Ainda não há avaliações

- Toyota Tercel 1986Documento885 páginasToyota Tercel 1986yorgo7002Ainda não há avaliações

- 1953 Lucas Dynamos E3L E3LM E3NDocumento7 páginas1953 Lucas Dynamos E3L E3LM E3NedelapolloAinda não há avaliações

- Atlas MFC ManualDocumento14 páginasAtlas MFC ManualgilrpinheiroAinda não há avaliações

- W R H Main Manual PDFDocumento14 páginasW R H Main Manual PDFjaikolangaraparambilAinda não há avaliações

- Banks ManualDocumento27 páginasBanks Manualchuckles1313Ainda não há avaliações

- Clodhopper: FiberfabDocumento23 páginasClodhopper: FiberfabShalon Melo100% (2)

- Repair Manual MP 1Documento11 páginasRepair Manual MP 1Tiffany DacinoAinda não há avaliações

- Royal Enfield Bullet Workshop Manual PDFDocumento110 páginasRoyal Enfield Bullet Workshop Manual PDFdyna1450hotmail.frAinda não há avaliações

- LRE Propshaft MaintenanceDocumento2 páginasLRE Propshaft Maintenancestef2122177Ainda não há avaliações

- Install, Operate and Maintain Vertical Inline PumpsDocumento18 páginasInstall, Operate and Maintain Vertical Inline Pumpspaul czAinda não há avaliações

- Installation - Service Instructions: Front Brake KitsDocumento2 páginasInstallation - Service Instructions: Front Brake KitsCokhiducminh VinhphucAinda não há avaliações

- Adjust Horizontal Bandsaw Blade & Guide for Accurate CutsDocumento16 páginasAdjust Horizontal Bandsaw Blade & Guide for Accurate CutsKelvin TyhAinda não há avaliações

- Proclimb Procross Torsional Conversion KitDocumento8 páginasProclimb Procross Torsional Conversion KitcpcracingAinda não há avaliações

- Valvula DireccionDocumento8 páginasValvula DireccionVictor Manuel Lozada ObessoAinda não há avaliações

- Equalizer Bar - InstallDocumento1 páginaEqualizer Bar - InstallJACOB MUDONHIAinda não há avaliações

- Lambretta 175 TV - Owners Manual - #3676Documento32 páginasLambretta 175 TV - Owners Manual - #3676Mariano KokoAinda não há avaliações

- Removing Push Rods and Shroud Tubes from Engines with Top Exhaust CylindersDocumento3 páginasRemoving Push Rods and Shroud Tubes from Engines with Top Exhaust CylinderscarlAinda não há avaliações

- REV SPEED METER Vehicle Wiring DiagramsDocumento47 páginasREV SPEED METER Vehicle Wiring Diagramsallenchen777Ainda não há avaliações

- WPKT 0005Documento3 páginasWPKT 0005José BenavidesAinda não há avaliações

- Buku Manual Mesin Kisar UniversalDocumento26 páginasBuku Manual Mesin Kisar Universalhill_me87Ainda não há avaliações

- CSL 1007Documento11 páginasCSL 1007oscar horacio flores100% (1)

- Camshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLDocumento12 páginasCamshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLGabriel ChiavettoAinda não há avaliações

- Owners Manual for The Transcriptor Skeleton TurntableDocumento20 páginasOwners Manual for The Transcriptor Skeleton TurntableMatt RichmondAinda não há avaliações

- Tilt CylinderDocumento7 páginasTilt Cylinderluis tocoraAinda não há avaliações

- INSTALL HY-ROAD HYDRAULIC DISC BRAKEDocumento2 páginasINSTALL HY-ROAD HYDRAULIC DISC BRAKETo KuAinda não há avaliações

- The Road Beyond 5G: A Vision and Insight of The Key TechnologiesDocumento7 páginasThe Road Beyond 5G: A Vision and Insight of The Key TechnologiesSaurav SarkarAinda não há avaliações

- Xy6112 EtcDocumento4 páginasXy6112 EtcJalal AsadianAinda não há avaliações

- Guide For Dynamic Report Generator - EndsfsdfsdfsdfsdfDocumento15 páginasGuide For Dynamic Report Generator - Endsfsdfsdfsdfsdfmtech structuresAinda não há avaliações

- PD05P XXX XXX B SeDocumento2 páginasPD05P XXX XXX B SemaaoeAinda não há avaliações

- PI ControllerDocumento5 páginasPI Controllerdanuega1Ainda não há avaliações

- Echotrac Mkiii: Operator'S ManualDocumento48 páginasEchotrac Mkiii: Operator'S ManualKhắc PhongAinda não há avaliações

- Yr 6 Maths G-6 E P-I PDFDocumento168 páginasYr 6 Maths G-6 E P-I PDFdina171279Ainda não há avaliações

- Lecture 1-5 Atomic and Molecular Physics by Nek M ShaikhDocumento25 páginasLecture 1-5 Atomic and Molecular Physics by Nek M Shaikh125-The Legend StarAinda não há avaliações

- 5.1.2. Biological Indicators of SterilisationDocumento1 página5.1.2. Biological Indicators of SterilisationSurendar KesavanAinda não há avaliações

- Technical Guide R-410A ZJ/ZR/ZF Series 15 - 25 TON 60 Hertz: DescriptionDocumento103 páginasTechnical Guide R-410A ZJ/ZR/ZF Series 15 - 25 TON 60 Hertz: DescriptionmanthoexAinda não há avaliações

- Design of Bulk CarrierDocumento7 páginasDesign of Bulk CarrierhoangductuanAinda não há avaliações

- On Handwritten Digit RecognitionDocumento15 páginasOn Handwritten Digit RecognitionAnkit Upadhyay100% (1)

- 11 - Biennial - Form/3 Component Uphole Survey For Estimation of SHDocumento5 páginas11 - Biennial - Form/3 Component Uphole Survey For Estimation of SHVishal PandeyAinda não há avaliações

- RMI Verif NAFEMS 3 2 PDFDocumento28 páginasRMI Verif NAFEMS 3 2 PDFFernando MartinezAinda não há avaliações

- NFRC 200-2010Documento45 páginasNFRC 200-2010reynolds534100% (1)

- Chapter 2 - Exercises - Econometrics2Documento2 páginasChapter 2 - Exercises - Econometrics2Mai AnhAinda não há avaliações

- Sand, Salt, IronDocumento1 páginaSand, Salt, IronKevin ChoyAinda não há avaliações

- HP Application Lifecycle Management Readme: What's New Installation InstructionsDocumento36 páginasHP Application Lifecycle Management Readme: What's New Installation InstructionsBrandon GarciaAinda não há avaliações

- Project PBLDocumento19 páginasProject PBLAdam LuqmanAinda não há avaliações

- Inverse Laplace Transformation Ex 11 2 Umer Asghar MethodDocumento34 páginasInverse Laplace Transformation Ex 11 2 Umer Asghar MethodSikandar Khan100% (1)

- TCL 55P607 CNET Review Calibration ResultsDocumento3 páginasTCL 55P607 CNET Review Calibration ResultsDavid KatzmaierAinda não há avaliações

- Welcome To Cosc 3101/ Internet Programming: Five Cookies and Session Management in PHPDocumento18 páginasWelcome To Cosc 3101/ Internet Programming: Five Cookies and Session Management in PHPSerkalem NegusseAinda não há avaliações