Escolar Documentos

Profissional Documentos

Cultura Documentos

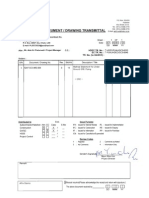

Earthwork

Enviado por

sethu1091Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Earthwork

Enviado por

sethu1091Direitos autorais:

Formatos disponíveis

SECTION 02200 EARTHWORK PART 1 GENERAL 1.1. A.

. DESCRIPTION OF WORK The extent of excavation, filling, compacting, and grading shall be performed as required for construction of all items of work included in the scope of work, as shown on the drawings and/or as specified herein. Related Work: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Section 02100 Section 02232 Section 02445 Section 02453 Section 02575 Section 02610 Section 02615 Section 02617 Section 02619 Section 02622 Section 02623 Site Clearing Roadway Base Wire Fences and Gates Traffic Signs Roadway Cutting Repair and Resurfacing Pipe and Pipe Fittings Ductile Cast Iron Pipe (DCI) Steel Pipe Asbestos Cement Pipe (AC) Plastic Pipe (PVC) Glass Fiber Reinforced Plastic Pipe (GRP) [For other than Seawater Pipe System] Glass Fiber Reinforced Plastic Pipe [For Seawater Pipe] Water Distribution System Sanitary, Industrial Waste Water and Storm Sewer System Underground Telecommunications Duct Banks and Jointing Chambers Cast-in-Place Concrete

B.

12.

Section 02625

13. 14.

Section 02713 Section 02723

15.

Section 02813

16.

Section 03300

P.O. Number : 7200018725

1.2 A.

QUALITY ASSURANCE Codes and Standards: Perform excavation work in compliance with applicable requirements of the Ministry of Communication General Specifications Part 2 except as herein modified. Testing Service: Employ an approved testing service, as specified in the General Requirements, to perform soil testing during earthwork operations. Quality Control Testing during Construction: Test and approve subgrades and fill layers before further construction work is performed. Testing and approval of each layer shall be done to demonstrate conformance to compaction and other requirements. 1. Perform tests in accordance with the following: Code/Std. ASTM D2487 D422 D423 D424 D3282 Type of Test Classification Sieve Analysis Liquid Limit Plastic Limit Classification Density in Place Minimum Frequency 1000 m3* " " " " Every 2000 m2 or less, for each layer Every 10 of D 1556 or E-24** Every 10 of D 1556 or E-24** As required

B.

C.

Description Backfill and Fill

Compacted Fill

ASTM D 1556 or D 2167 or D 2922 or E-24 ***D1557 D 4253 & D 4254

Moisture Density Relative Density Dry prep. of Soil samples

All Areas * **

D 421

Or every 2,000 m2 if quantity of material is less than 1000 m3. Earth Manual, USBR - United States Bureau of Reclamation Designation E-24 (Density in place) and Designation E-8 (Soluble Salts Content)

P.O. Number : 7200018725

***

Maximum dry density determined by ASTM D1557 shall be corrected for coarse particle content in accordance with AASHTOT224. Subgrade and Base Fill under Paved Areas and Building Slabs: Make at least one field density test of subgrade for every 2000 m2 of paved area or building slab, but in no case less than 3 tests. In each compacted fill layer, make one field density test for every 2000 m2, but in no case less than 3 tests for each layer. Backfill: For backfill on natural soil, around valve chambers, culverts, ductbanks, concrete structures and trenches take at least 2 field density tests, at locations and elevations as directed, for every 2000 m2 of each layer and 1 every 200 linear meter of each layer for trenches. However, trenches crossing or under paved areas and slabs shall require 1 field density test for every 30 linear meter of each layer. Perform 1 field density test per 100 m2 per lift under foundations.

2.

3.

1.3 A.

SUBMITTALS Test Reports - Excavating, Filling, and Grading: Submit copies of the following reports. 1. 2. 3. 4. Test reports on soil material. Verification of suitability of subgrade for footing. Field density test reports. One optimum moisture versus maximum density relationship curve and maximum/minimum relative density data, as applicable, for each type of soil to be used for fill or backfill.

B.

If excavations over 1.5 meters in depth will be sheeted and shored, submit working drawings and calculations for the design of the sheeting and shoring. Where new utilities cross under existing utilities or structures, submit method statements, supported by sketches and calculations, how the existing utilities (pipes, ductbanks, direct buried cables, etc.) will be supported during construction for uninterrupted operation of existing systems.

C.

P.O. Number : 7200018725

1.4 A.

JOB CONDITIONS Existing Utilities: If utilities are to remain in place, provide adequate means of protection during earthwork operations. 1. Should unanticipated utilities be encountered during excavation, cease work and consult MARAFIQ immediately. Resume work only after agreement has been reached as required by the General Conditions. Repairs damaged utilities to satisfaction of MARAFIQ. Demolish and completely remove from site existing underground utilities, end caps/plugs, end of the line thrust blocks and other items which are indicated on the drawings as to be removed.

2.

B.

Barricade open excavations and post warning lights. Operate warning lights from dusk to dawn of each day.

PART 2 PRODUCTS 2.1 A. SUITABLE SOIL MATERIALS General: 1. Suitable materials shall comprise select backfill, general backfill, base fill, subgrade fill, sand backfill, embedment backfill, structural and drainage fill. All materials suitable for use as backfill shall be free from organic matter, expansive clay, rubbish, debris, coral or any other deleterious materials of any kind. Materials suitable for use as backfill shall be obtained from required excavations to the extent possible, supplemented by offsite borrow areas outside MARAFIQ property. Contractor shall be responsible for locating suitable fill and backfill material sources and for obtaining, supplying, and transporting material to the site in sufficient quantities to complete the work. The water soluble salts content, determined in accordance with USBR Test Designation E-8, of representative samples of the backfill material shall not exceed 1% prior to placement. After all placing, compacting, and application of water has been completed on a particular layer, its water soluble salts content shall not exceed 2%.

2.

3.

4.

5.

B.

Subbase Material for Concrete Slabs on Grade: AASHTO M147, Grade B.

P.O. Number : 7200018725

C.

Asphalt Paved Roadway and Shoulder Base Material: See Section 02232,Roadway Base. Drainage Fill: Washed, uniformly graded mixture of crushed stone, or crushed or uncrushed gravel, with 100% passing a 38 mm sieve and not more than 5% passing a No. 4 sieve. Backfill and Fill Material Types: Material shall be of the types listed below. All material shall be free of rock or gravel larger than 100 mm in any dimension (except in rock fill and fill work for subgrade grading where rock or gravel up to a maximum of 150 mm in any dimension may be allowed), debris, waste, organic material, and other deleterious matter. The portion of the materials passing the No. 200 sieve size (0.074 mm) shall be non- plastic as defined in accordance with ASTM D 4318. 1. Type I: Graded sands and gravels, gravel-sand/ silty-sand mixtures, crushed graded rock; little or no fines, no well-defined moisture versus maximum density relationship (GW, SW, GP, SP). Plasticity Index - NP to 5 Gradation Less than 12% passing No. 200 sieve. 2. Type II: Clayey gravels and sands, poorly graded mixture of sand, gravel and clay, clays (inorganic) of low to medium plasticity, sandy clays, silty clays, lean clays (CM, SM, GC, SC, CL). Liquid limit - 20 - 50 Plasticity Index - 5 to 22 maximum 3. The following tests shall be used to ensure the fill meets the above requirements: ASTM D1557 Maximum Density & Optimum Moisture Content of soils Classification of soils for Engineering Purposes Particle-size analysis of soils Liquid limit of soils Plastic limit and plasticity - Index of soils

D.

E.

ASTM D2487

ASTM D422 ASTM D423 ASTM D424

P.O. Number : 7200018725

4.

Select backfill and structural backfill material shall be Type I. Do not use select backfill material with particles larger than 20 mm within 600 mm of structures and in the bottom 200 mm of trenches. General backfill material above the pipe zone in pipe trenches shall be Type I of Type II. General fill materials for subgrade grading work shall be of Type II. Sand Backfill: (a) Material suitable for use as sand backfill shall consist of natural sand, manufactured sand, or a combination thereof and shall conform to the requirements for fine aggregate specified in ASTM C33, Standard Specification for Concrete Aggregate. Gradation limits shall be as follows: Sieve Size (ASTM E 11) 9.5 mm (3/8 in.) 4.75 mm (No. 4) 2.36 mm (No. 8) 1.18 mm (No. 16) 0.60 mm (No. 30) 0.30 mm (No. 50) 0.15 mm (No. 100) Percentage Passing (by Weight) 100 95 to 100 80 to 100 50 to 85 25 to 60 10 to 30 2 to 10

5.

6.

(b)

7.

Embedment Backfill for Seawater Pipes: Materials suitable for use as embedment backfill shall consist of well-graded crushed stone or crushed gravel meeting the requirement of ASTM C 33, Gradation 67.

Gradation limits shall be as follows: Sieve Size (ASTM E 11) 25.0 mm (1.0 in.) 19.0 mm (3/4 in.) 9.5 mm (3/8 in.) 4.75 mm (No. 4) 2.36 mm (No. 8) F. Percentage Passing (by Weight) 100 90 to 100 20 to 55 0 to 10 0 to 5

Rock Fill: Sound, dense rock and boulders up to 200 mm containing sufficient gravels, sands, crushed or broken rock and

P.O. Number : 7200018725

other fine materials to fill all interstices. Material passing U.S. No.40 Sieve, liquid limit 30% maximum. G. Borrow Materials: Borrow materials shall be satisfactory soil materials obtained from borrow pits designated by MARAFIQ or selected by Contractor and approved by MARAFIQ. Contractor shall obtain from the Owners the right to procure such borrow materials and pay all royalties, and bear all expenses of developing the sources and of handling, hauling and placing such material. Gravel Surfacing: Where shown on drawings, gravel surfacing material shall meet the requirements of size 67 in accordance with ASTM C-33. Unless otherwise shown on the drawings, thickness of the gravel surfacing layer shall be 100 mm, minimum.

H.

2.2 A.

WATER Water provided for earthwork compaction shall be as approved by MARAFIQ.

PART 3 EXECUTION 3.1 A. EXCAVATION Excavate all material of whatever nature encountered to the lines and grades as shown. 1. Excavation includes removal and disposal of pavements and other obstructions on ground surface, underground structures and utilities indicated to be demolished and removed, and all other materials encountered. Unauthorized excavation consists of removal of materials beyond indicated subgrade elevations or dimensions without specific direction of MARAFIQ. Unauthorized excavation shall be at Contractor's expense. (a) Under footings, foundation bases, or retaining walls, fill unauthorized excavation by extending the indicated bottom elevation of the footing or base to the excavation bottom, without altering required top elevation. Elsewhere, backfill and compact unauthorized excavations as specified for authorized excavations unless otherwise directed by MARAFIQ.

2.

(b)

P.O. Number : 7200018725

B.

Additional Excavation: When excavation has reached required subgrade elevations, MARAFIQ will make an inspection of conditions. 1. If unsuitable bearing materials are encountered at the required subgrade elevations, carry excavations deeper (300 mm) and replace the excavated material with specified subbase materials as directed by MARAFIQ. In areas of unsuitable material where over excavating to 300 mm does not remove the unsuitable bearing material, excavate down as required and construct a "working platform" using specified subbase materials for 300 mm in depth then use rockfill material. Bring rockfill to 300 mm below the finished subgrade shown on the drawings in layers not exceeding 200 mm in depth. Continue backfilling to subgrade elevation or to final grade elevation using specified backfill material shown on drawings or as directed by MARAFIQ.

2.

C.

Stability of Excavations: Slope sides of excavations to the natural angle of repose for material in dry state. Shore and brace where sloping is not possible because of space restrictions or stability of material excavated. Maintain sides and slopes of excavations in a safe condition until completion of backfilling. Shoring and Bracing: Provide materials for shoring and bracing, such as sheet piling, uprights, stringers, and cross-braces, in good serviceable condition. 1. Establish requirements for trench shoring and bracing to comply with safe operating procedures. Maintain shoring and bracing in excavations. Carry down shoring and bracing as excavation progresses. (a) Provide permanent steel sheet piling or pressure creosoted timber sheet piling wherever subsequent removal of sheet piling might permit lateral movement of soil under adjacent structures. Steel sheet piling intended to be left in place shall required cathodic protection. Cut off tops at (400 mm) below final grade and leave permanently in place.

D.

2.

(b)

3.

Contractor must insure that the bracing sheet piling, sheeting and shoring operation does not have any adverse effect on existing adjacent pipelines, structures and facilities. As a part of the operation, Contractor must measure particle velocity and acceleration produced by sheet piling installation at locations

P.O. Number : 7200018725

determined by MARAFIQ. All particle velocity and acceleration must not exceed critical limits as recommended by the pipeline manufacturer. E. Dewatering: Prevent surface water and subsurface or ground water from flowing into excavations and from flooding project site and surrounding area. 1. Do not allow water to accumulate in excavations. Remove water to prevent softening of foundation bottoms, undercutting footings, and soil changes detrimental to stability of subgrades and foundations. Provide and maintain pumps, well points, sumps, suction and discharge lines, and other dewatering system components necessary to convey water away from excavations. Convey water removed from excavations and rain water to collecting or run-off area. Establish and maintain temporary drainage ditches and other diversions outside excavation limits for each structure. Do not use trench excavations as temporary drainage ditches.

2.

F.

Material Storage: Stockpile suitable excavated materials until required for backfill or fill. 1. 2. Locate and retain soil materials away from edge of excavations. Dispose of excess soil materials and waste materials.

G.

Excavation for Structures: Conform to elevations and dimensions shown within a tolerance of plus or minus 30 mm, and extending a sufficient distance from footings and foundations to permit placing and removal of concrete formwork, installation of services, other construction, and for inspection. 1. In excavating for footings and foundations, take care not to disturb bottom of excavation. Trim bottoms to required lines and grades to leave solid base to receive concrete. In the event unsuitable bearing materials are encountered, follow the over excavation and fill directions in paragraph 3.1.B or as instructed by MARAFIQ.

2.

H.

Excavation for Trenches: Dig trenches to the uniform width shown for the particular item to be installed. Excavate trenches to the indicated width at all points below a horizontal plane 200 mm above the top of pipe. Excavation above this plane may exceed the indicated width if approved by MARAFIQ. Where width is not indicated, make the width not less than 150 mm or more than 450 mm from the outside of the pipe. If excavation exceeds the permissible dimensions, install a higher

P.O. Number : 7200018725

strength pipe or encase pipe in concrete as determined by MARAFIQ and at no cost to MARAFIQ. 1. Excavate trenches to the width and depth required and establish the indicated invert elevations. Where rock is encountered, carry the excavation 150 mm below the required elevation and backfill with 150 mm layer of approved crushed stone or gravel prior to installing pipe. Grade bottoms of pipe trenches as indicated, notching under pipe bells to provide solid bearing for the entire body of the pipe.

2.

3.

3.2 A.

COMPACTION General: Control soil compaction during construction providing maximum percentage of density specified for each area classification. Control the moisture content of soils so that at the time of compacting the moisture content is within 2% above or below the optimum as determined by ASTM D1557, Method D. Percentage of Maximum Density Requirements: Compact soil to not less than the following percentages of maximum dry density or relative density determined in accordance with ASTM D1557, Method D, or ASTM D2049. 1. Structures: Compact top 300 mm of subgrade and each layer of backfill or fill material to 95% maximum dry density or 75% relative density. Under Pavements and Shoulders: Compact each 200 mm loose layer of base course fill and each layer of subgrade fill to 100% maximum dry density or 78% minimum relative density. Cut Areas and Natural Ground (Where construction is to be accomplished): Scarify and compact the top 150 mm of cutroadway to 95% dry maximum density or 75% minimum relative density. Rough Grading (Where no construction is to be accomplished): In cut and natural ground areas compact the top 150 mm of earth to 90% maximum dry density or 70% minimum relative density. Specific Type of Fill/Backfill Materials: Percentage requirements for field compaction densities (compaction around foundations, equipment, pipes, minor structures, etc.) shall be as follows, or as recommended by the piping or equipment manufacturer as percentage of Maximum Dry Density:

B.

2.

3.

4.

5.

P.O. Number : 7200018725

Minimum Acceptable Percentage Compaction Density) Backfill or Surface ASTM D1557 or ASTM D2922 ASTM4253/D4254 Relative Density

(Field

Select Backfill/Structural Backfill 95 75 General Backfill 90 70 Embedment Backfill 90 70 Sand Backfill 90 70 Trench Bottom 95 70 Base Fill/Subgrade Fill 100 78 3.3 A. BACKFILL AND FILL Backfill excavations as promptly as work permits, but not until completion of the following: 1. Acceptance by MARAFIQ of construction below finish grade including, where applicable, dampproofing, waterproofing, and perimeter insulation. Inspection, testing, approval, and recording locations of underground utilities. Removal of trash and debris.

2.

3. B.

Ground Surface Preparation: Remove vegetation, debris, unsatisfactory soil materials, obstructions, and deleterious materials from ground surface prior to placement of fills. 1. Bench slope surfaces shall not be steeper than 1 vertical to 4 horizontal. When existing ground surface has a density less than that specified under "Compaction" for the particular area classification, break up the ground surface to depth of 300 mm and compact to required density as directed by MARAFIQ.

2.

C.

Placement and Compaction: 1. Place backfill and fill materials in layers not more than 200 mm in loose depth, unless compaction equipment can accomplish uniform specified density for thicker layers, as demonstrated by a test strip. Compact each layer to required percentage of maximum density or

2.

P.O. Number : 7200018725

relative density for each area classification. Do not place additional layers if the previous layers have not attained the required compaction. 3. Do not place backfill or fill material on surfaces that are muddy or soft, unless the construction of a working platform is necessary. Place backfill and fill materials evenly adjacent to structures, to required elevations. Carry the material uniformly around structure to approximately same elevation in each lift. General Fill Areas: Initially a test strip (min. size 300 m2) shall be established to determine the methods, number of passes, type of equipment etc. required to obtain the specified compaction for each type of fill material. The fill shall be placed in layers not exceeding 200 mm over this area. The area shall be tested by the following methods: (a) Material Type II shall be tested by using ASTM D1557 as a laboratory standard to determine the optimum moisture content and maximum density. At least three moisturedensity curves shall be established for the test strip and the mean value used. Following this the field density shall be determined using ASTM D1556 (sandcone method), ASTM D2922 (Nuclear Method) or E-24, as applicable, for the test strip. At least five tests shall be taken and the maximum density achieved shall equal or exceed the specified percentage of the maximum density corrected for coarse particle content in accordance with AASHTO T224 (e.g. 95% max. density). Material Type I shall be tested using ASTM D2049 as a laboratory standard to determine the maximum and minimum density. At least three tests shall be carried out and the mean value used as a standard. Following this, the field density shall be determined using ASTM D1556 (sand-cone method), or ASTM D2922 (Nuclear Method). At least five tests shall be carried out and the minimum relative density shall be calculated from laboratory tests. This shall equal or exceed the specified value (e.g. 75% relative density). Type I or Type II material having particle sizes in excess of 50 mm shall be tested by E-24 or ASTM D1556 (with a larger sand-cone). The entire fill area shall be compacted in the same manner as the test strip and tested at the frequencies listed in paragraph 1.2

4.

5.

(b)

(c)

(d)

P.O. Number : 7200018725

"Quality Assurance." 6. Backfill: (a) Structural Backfill: Structural backfill shall not be placed until the walls, footings, piers or other portions of the structure have been inspected by MARAFIQ and approved for backfilling. No backfill shall be placed until the concrete has developed a strength of not less than 13 MPa in compression as determined by test cylinders. (1) Fill material shall be placed with density control in successive horizontal layers of not more than 200 mm in depth, loose. Each layer shall be spread uniformly, wetted or dried as required, and rolled with an approved tamping or power roller. The backfill shall be brought up uniformly on all sides of the structure. Unless otherwise specified, each layer of backfill shall be compacted to 95%, maximum density as determined by ASTM D1557 or 75% relative density as determined from ASTM D2049. Unless otherwise approved by MARAFIQ, heavy equipment for spreading and compacting backfill shall not be operated closer to a wall than a distance equal to the height of the backfill above the top of footing, the area remaining shall be compacted in layers not more than 150 mm in compacted thickness with power driven hand tamper suitable for the material being compacted.

(2)

(3)

(b)

Placement and Compaction for Seawater Cooling System: (1) Place backfill and fill materials in layers not more than 200 mm in loose depth. Compact each layer to required percentage of maximum density or relative density for each area classification. Do not place additional layers if the previous layers have not attained the required compaction. Mechanical compaction shall strictly comply with the pipe manufacturers recommendations where allowed and approved. Place backfill and fill materials evenly adjacent to structures, to required elevations. Carry the material uniformly around structure to approximately same elevations in each lift. Pipe zone bedding shall be embedment backfill placed under bottom of pipe and extend up to 300 mm above the

(2)

(3)

(4)

P.O. Number : 7200018725

top of pipe. Pipe bedding shall be placed and compacted according to pipe manufacturers recommendations subject to approval of MARAFIQ. (5) General backfill or subgrade material for roads, as applicable shall be used above embedment backfill up to the subbase or adjacent natural soil grade. Backfill shall be placed in uniform layers not exceeding 300 mm loose depth measure prior to completion and compacted to 90% M.D.D. or 100% if within a planned future roadway up to the elevation specified. No stones larger than 50 mm shall be placed within 300 mm of the pipe. Moisture content of the backfill materials shall be as uniform as practical throughout the thickness of each layer and shall be maintained within the limits of +2% of the optimum moisture content determined in accordance with ASTM D1557. Sand or Type I backfill shall be used under piping or chambers to replace over excavated unsuitable soils (soft clays, soft and loose sand and loose silt) where encountered. Placement shall be in uniform horizontal layers not exceeding 200 mm loose depth and compacted to densities specified in this specification.

(6)

(7)

(c)

Placement and compaction for utility systems other than seawater cooling system. See related work sections listed in paragraph 1.1.B: (1) Bedding: Pipe trenches in sand, sandy loam, or granular soil shall not require special bedding. Pipe trenches in clay, shale or rock shall be a compacted sand layer 150 mm minimum thickness under bottom and extending up to one-fourth of diameter of pipe. The sand fill shall meet the requirements of ASTM C-33 Fine Aggregates or be clean, well-graded not exceeding 10 mm size, approved aggregate containing not over 15 percent fines (under No. 200 sieve), carefully placed in 100 to 150 mm lifts and tamped to 95 percent maximum density, at optimum moisture content or 75% relative density. Backfill: Trenches shall be hand tamped sand backfilled after testing of pipe to a minimum depth of 300 mm above the top of the pipe with care being taken not to injure or disturb the pipeline or the joints.

(2)

(3)

(4)

P.O. Number : 7200018725

(5)

Fill material for backfilling pipe trenches shall consist of: a. Initial sand fill shall meet the requirements of ASTM C-33 Fine Aggregates or be clean, wellgraded not exceeding 10 mm size, approved aggregate containing not over 15 percent fines (under No. 200 sieve), carefully placed in 100 to 150 mm lifts and hand tamped to a height of at least 300 mm above the top of the pipe. Final soil fill as specified earlier, placed in 200 mm lifts and compacted to 95% maximum density as determined by ASTM D1557. See Royal Commission Standard RC-C-2 for typical trench detail. For trenches located within three (3) meters from buildings or structures, all fill and backfill material shall be selected fill material and shall be compacted to 95% maximum density as determined by ASTM D1557 or 75% relative density as determined by ASTM D2049.

b.

c.

3.4 A.

GRADING General: Grade areas within limits of grading including adjacent transition areas. Smooth surface to the slopes and elevations shown, within specified tolerances. 1. Grade areas adjacent to structures to drain away from structures and prevent ponding.

B.

Finish Surfaces to the Following Tolerances: 1. Open or Unpaved Areas: Finish areas to receive gravel surfacing or topsoil to within not more than 25 mm above or below the required subgrade elevation. Pavements: Shape surfaces of areas under pavement to line, grade cross-section with finished surface not more than 20 mm above or below the required subgrade elevation for pavement thickness over 250 mm and 10 mm for pavement having a thickness less than 250 mm. For fine grading the tolerance shall be limited to + 6 mm for both line and level. The slope of fine grading areas to meet adjacent existing ground level shall be 1:10 or flatter. See Section 02232 for Roadway Base Grading and Tolerance.

2.

3.

4.

P.O. Number : 7200018725

3.5 A.

PAVEMENT BASE COURSE Placing: Place base course material on approved subgrade in layers of uniform thickness, confirming to indicated cross-section and thickness. Maintain optimum moisture content + 2% for compacting base material during placement operations. 1. When a compacted base course is shown to be 150 mm thick or less, place material in a single layer. When shown to be more than 150 mm thick, place material in equal layers, except no single layer more than 150 mm or less than 75 mm in thickness when compacted.

B.

Shoulders: Place shoulders along edges of base course. Construct shoulders of acceptable soil materials, placed in such quantity to compact to thickness of each base course layer. Compact and roll at least a 300 mm width of shoulder simultaneously with compacting and rolling of each layer of base course. 1. Compact each layer of base to 100% of maximum dry density as determined by ASTM D1557, Method D and field tested by ASTM D2922 or ASTM D1556.

3.6. A.

PLACEMENT OF DRAINAGE FILL Placement against Walls: 1. Place drainage fill against walls, fire hydrants and other areas where shown on drawings. Place material concurrently with adjacent soil backfill. Take precautions to avoid contamination of drainage fill by soil backfill.

3.7 A.

MAINTENANCE Protection of Graded Areas: Protect newly graded areas from traffic and erosion. Keep free of trash and debris and provide temporary drainage as required. Repair and re-establish grades in settled, eroded, and rutted areas to specified tolerances. Reconditioning Compacted Areas: Where completed compacted areas are disturbed by subsequent construction operations or adverse weather, scarify surface, reshape, and compact to required moisture and density prior to further construction. Remove saturated or softened soil as directed by MARAFIQ.

B.

C.

P.O. Number : 7200018725

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- HAZOP Saudi Aramco HAZOP GuidelinesDocumento92 páginasHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- GRE Pipe InstallationDocumento32 páginasGRE Pipe Installationelkhatri100% (3)

- Saer 5711Documento161 páginasSaer 5711sethu1091100% (1)

- Saer 5895Documento18 páginasSaer 5895sethu1091Ainda não há avaliações

- Method Statement UG GRE R.3Documento46 páginasMethod Statement UG GRE R.3sethu1091100% (16)

- Sabp A 016Documento60 páginasSabp A 016sethu1091100% (6)

- Sabp A 015Documento58 páginasSabp A 015sethu1091100% (5)

- Method Statement For GRE PipingDocumento16 páginasMethod Statement For GRE PipingJaveed Shaikh100% (3)

- Best Practice: Saudi Aramco Desktop StandardsDocumento19 páginasBest Practice: Saudi Aramco Desktop Standardssethu1091100% (4)

- Sabp A 011Documento27 páginasSabp A 011aamirtec301Ainda não há avaliações

- Sabp A 001Documento20 páginasSabp A 001Shahid Basha Syed100% (2)

- Sabp A 009Documento208 páginasSabp A 009sethu1091100% (2)

- Best Practice: Load Management For Energy Efficiency: Heat Transfer EquipmentDocumento75 páginasBest Practice: Load Management For Energy Efficiency: Heat Transfer Equipmentsethu1091Ainda não há avaliações

- Best Practice: Quick Energy Assessment Methodology For Energy Efficiency OptimizationDocumento54 páginasBest Practice: Quick Energy Assessment Methodology For Energy Efficiency Optimizationsethu1091100% (1)

- Sabp A 012Documento92 páginasSabp A 012sethu1091Ainda não há avaliações

- Sabp A 002Documento49 páginasSabp A 002sethu1091Ainda não há avaliações

- Exhibit B-30 InsulationDocumento7 páginasExhibit B-30 Insulationsethu1091Ainda não há avaliações

- Menp 2 TS 605Documento16 páginasMenp 2 TS 605sethu1091Ainda não há avaliações

- Exhibit B-28 PipingDocumento7 páginasExhibit B-28 Pipingsethu1091Ainda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- AASHTO ASTM CODE NameDocumento2 páginasAASHTO ASTM CODE NamekashifAinda não há avaliações

- File13572 PDFDocumento52 páginasFile13572 PDFZhwan AnwarAinda não há avaliações

- Plaxis Settlement Water TableDocumento6 páginasPlaxis Settlement Water Tableyin hoe ongAinda não há avaliações

- Landfill DesignsDocumento35 páginasLandfill DesignsnathychidazAinda não há avaliações

- NAVFAC Handbook For Marine Geotechnical EngineeringDocumento457 páginasNAVFAC Handbook For Marine Geotechnical Engineeringumair baigAinda não há avaliações

- Niyobuhungiro DominiqueDocumento70 páginasNiyobuhungiro DominiqueNiyobuhungiro DominiqueAinda não há avaliações

- 1 PT CBRDocumento18 páginas1 PT CBRmihiretu TeferaAinda não há avaliações

- Job Procedure For Earthwork Excavation and BackfillingDocumento6 páginasJob Procedure For Earthwork Excavation and BackfillingJitesh SahiAinda não há avaliações

- Aggregate Tests For Hot Mix Asphalt: State of The PracticeDocumento22 páginasAggregate Tests For Hot Mix Asphalt: State of The PracticeProf. Prithvi Singh KandhalAinda não há avaliações

- GTEL01E: Physical Properties of Soil: Modules inDocumento14 páginasGTEL01E: Physical Properties of Soil: Modules inHatsuieeAinda não há avaliações

- Stabilization of Expansive Clayey Soil Modified by Lime With An Emulsified Asphalt AdditionDocumento19 páginasStabilization of Expansive Clayey Soil Modified by Lime With An Emulsified Asphalt AdditionYasser AlghrafyAinda não há avaliações

- Temperature-Accelerated Strength Development in Stabilized Marine Soils As Road Construction MaterialsDocumento13 páginasTemperature-Accelerated Strength Development in Stabilized Marine Soils As Road Construction MaterialsHocine HocineAinda não há avaliações

- Lecture 5 Soil+ClassificationDocumento66 páginasLecture 5 Soil+ClassificationBruhAinda não há avaliações

- Soil Mechanics and Foundation MCQDocumento15 páginasSoil Mechanics and Foundation MCQtarun23007Ainda não há avaliações

- Low Cost Housing Methods Final PPT Batch A2 FinalDocumento50 páginasLow Cost Housing Methods Final PPT Batch A2 FinalVaishnavi BhalekarAinda não há avaliações

- Design Working Manual Part1Documento93 páginasDesign Working Manual Part1Ken LiewAinda não há avaliações

- Geotechnical Design Manual FinalDocumento190 páginasGeotechnical Design Manual FinalBrhane W Ygzaw100% (4)

- 40S Be 0258Documento89 páginas40S Be 0258Saleh HassanAinda não há avaliações

- Basic Soil and Rock CharacteristicsDocumento31 páginasBasic Soil and Rock CharacteristicsShadin Asari ArabaniAinda não há avaliações

- QCS 2010 Part 6.03 EarthworksDocumento21 páginasQCS 2010 Part 6.03 EarthworksRotsapNayrb100% (2)

- 05 PusitDocumento11 páginas05 Pusitflower lilyAinda não há avaliações

- Sand Eqivalent TestDocumento4 páginasSand Eqivalent TestVishwas Rao100% (1)

- Preliminary Geotechnical Investigations Report at The Site Proposed For Construction of Office Block at Plots 2-12, Sir ApoDocumento23 páginasPreliminary Geotechnical Investigations Report at The Site Proposed For Construction of Office Block at Plots 2-12, Sir ApoTwino KartelAinda não há avaliações

- New CATS-MIST Laboratory Test Rates PDFDocumento6 páginasNew CATS-MIST Laboratory Test Rates PDFNazmul HasanAinda não há avaliações

- Strength, Durability and Shrinkage Characteristics of Cement Stabilised Soil BlocksDocumento10 páginasStrength, Durability and Shrinkage Characteristics of Cement Stabilised Soil BlocksSam ChongAinda não há avaliações

- Geotextile-Reinforced Embankments On Soft ClaysDocumento21 páginasGeotextile-Reinforced Embankments On Soft Claysi7mpAinda não há avaliações

- Complete GT Investigation Report Dt. 22.05.2013Documento26 páginasComplete GT Investigation Report Dt. 22.05.2013parvez100% (1)

- Pavement Design Report Jigjiga Lot 1Documento23 páginasPavement Design Report Jigjiga Lot 1Dhaabar SalaaxAinda não há avaliações

- 1.1 Expansive SoilDocumento9 páginas1.1 Expansive SoilYatin JethiAinda não há avaliações

- Direct Shear Test of Soils Under Consolidated Drained ConditionsDocumento6 páginasDirect Shear Test of Soils Under Consolidated Drained ConditionsAhmed AbidAinda não há avaliações