Escolar Documentos

Profissional Documentos

Cultura Documentos

15530

Enviado por

sethu1091Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

15530

Enviado por

sethu1091Direitos autorais:

Formatos disponíveis

SECTION 15530 WET STANDPIPE AND HOSE SYSTEMS

PART I GENERAL 1.1 DESCRIPTION OF WORK The work of this Section includes the design and installation of a Class III (indoor) and Class II (outdoor) Wet Standpipe and Hose Systems as required under this contract. 1.2 A. QUALITY ASSURANCE The installation shall conform to local codes, ordinances and laws having jurisdiction over this project. In the event of conflict between these specifications and the mentioned codes, the most stringent shall govern. Reference Codes and Standards: 1. 2. 3. 4. RC/Marafiq Fire Code NFPA 13 Installation of Sprinkler Systems NFPA 14 Installation of Standpipe and Hose Systems NFPA 24 Installation of Private Fire Service Mains and Their Appurtenances NFPA 72 National Fire Alarm Code NFPA 70 -National Electrical Code ANSI -American National Standards Institute ASTM American Standards for Testing and Materials

B.

5. 6. 7. 8. C.

Related Sections: 1. 2. 3. 4. 5. Section 02713A: Firewater Distribution System Section 16721: Fire Alarm and Detection System Section 01086: Color Codes and Color Standards Section 15050: Basic Materials and Methods -Mechanical. Division 16: Electrical.

P.O. Number : 7200018725

1.3 A. B.

SUBMITTALS Submit product data on all equipment and accessories. Submit certificates from the manufacturer as evidence that the products meet the specifications and referenced standards. Submit hydraulic calculations as follows: 1. Hydraulic calculations shall be prepared on forms that include a summary sheet, detailed worksheets, and a graph sheet similar with procedures required by NFPA 14. Computer-run hydraulic calculations shall provide same format print-outs. Hydraulically calculated system demand shall include a hose stream allowance of 1893 lit/min (500 gpm) designed in accordance with the water supply available at the tapping point of connection specified in Section 02713A. Water supply curves and system requirements plus hose demand shall be plotted to present a graphic summary of the complete hydraulic calculation. The total designed water demand with number of systems designed to operate simultaneously at a reference point (tapping point) including hose streams and other fire protection equipment as evaluated on the fire risk assessment.

C.

2.

3.

4.

D.

Shop Drawings: Submit shop drawings including the following: 1. 2. 3. 4. 5. 6. 7. Engineering Documents list Piping lay-out drawing and section details. Isometric Drawings P&ID drawings Hanger locations and details Hydraulic reference Equipment Data sheet

E.

Submit maintenance and operating manuals in accordance with Section 01750.

P.O. Number : 7200018725

PART 2 PRODUCTS 2.1 A. GENERAL All material covered by this specification shall be procured, when available, from an in-Kingdom manufacturer and/or supplier. All equipment shall be the required capacity and type as specified and meet the requirements of Underwriters Lab. (UL) and/or National Fire Protection Association (NFPA). Piping, fittings, hangers, bracket, and attachment hardware including fasteners shall be hot-dipped galvanized steel per ASTM A 153 or other materials having a superior corrosion resistance. Exposed pipe threads and bolts on fittings shall be protected against corrosion. All other components shall be corrosion resistant or protected against corrosion by a suitable coating. MATERIALS Pipe (50 mm and Smaller): ASTM A53 Standard weight, (Schedule 40,) galvanized steel pipe. Fittings (50 mm and Smaller): 1. ANSI B16.3, 1.21 Mpa minimum rating (Class 150), galvanized malleable iron, threaded. Threads: ANSI B2.1 -Pipe Threads.

B.

C.

2.2 A.

B.

2. C. D.

Pipe (60 mm and Larger): ASTM A53 Standard weight. Fittings (60 mm and Larger): ANSI B16.9, Factory-made wrought steel buttwelding fittings -standard weight. Flanges (60 mm and Larger): ANSI B16.5 Steel pipe flanges. Gaskets: Ring or full face type, 1.5 mm thick, compressed fiber; `suitable for the fluid temperature and pressure and flange face type for which they will be used. Nuts and Bolts (For Flanged Joints): Steel ASTM A307 Gr. A regular square or hex head machine bolts shall be threaded U.S. National Coarse Threads Series, ANSI B1.1, Class 2 Fit, per ANSI B18.2.1 and shall be furnished with heavy pattern unfinished hex nuts, ANSI B18.2.2. Threads shall be coated with a rust preventative lubricant. Sleeves: Schedule 40, galvanized steel pipe. Unions (50 mm and smaller): ANSI B16.39 Malleable Iron Unions. Galvanized, female pattern, brass to iron seat, and ground joint. Unions shall be rated not less than 1.2 MPa working pressure (Class 150).

E. F.

G.

H. I.

P.O. Number : 7200018725

J.

Gate Valves: Gate valves shall be rising stem; outside screw and yoke type; bronze body and bronze or brass trim; solid wedge bronze or brass disc and steel hand wheel; threaded inlet and outlet for 50 mm and smaller; valves 60 mm and larger shall be as above with iron body, bronze trim, outside screw and yoke type, rated for 1.3 MPa water working pressure; capability of being repacked while under pressure; complete with monitoring switch with SPST normally closed contacts. Check Valves: Check valve shall be horizontal swing check type, non-slamming design having bronze body and bronze or brass trim. Check valves 60 mm and larger may be iron body. Check valve shall have bronze or brass disc, and flanged inlet and outlet and shall be rated for 2 MPa water working pressure. Waterflow Switches: Waterflow switch shall be paddle type, micro-switch with DPST contacts and adjustable pneumatic retard mechanism. Alarm Check Valve: Alarm Check Valve shall be the variable pressure type, 175 lbs. class for fire protection service. Valve shall come complete with trimmings, retard chamber, water motor alarm gong etc. Fire Department Connection: Fire Department Connection (FDC) shall be provided for every standpipe that comes complete with 65 mm dia. hose connections. The FDC shall be sized according to the calculated system demand of every system. Every FDC shall be fitted with UL listed check valve. Indoor Fire Hose Station (Class III): Fire hose cabinet shall be recessed trimless or surface-mounted type; minimum 1 mm thickness steel cabinet and trim finished in white baked enamel; door shall have piano hinge, latch, handle and plate glass vision window; 30 meters of 38 mm lined white linen fire hose with brass couplings attached; 63 mm -2 MPa chrome plated brass angle hose valve with 38 mm removable hose connector coupling and pressure restriction disc/regulator; chrome plated escutcheon; spanner wrench; chrome plated steel semi-automatic hose rack with nipple and escutcheon and a chrome plated electrical fire approved (tested up to 250KV) brass fog nozzle. Outdoor Fire Hose Station (Class II): Self-contained, pre-piped foam hose reel station features: fixed mounted continuous flow hose reel containing 30 meters of 38 mm hard rubber hose and a 95 gpm @ 100 psi non-air aspirating straight/fog adjustable handline nozzle with ball shut off, 60 gal. capacity foam storage fiberglass tank, in-line eductor pick-up tube, water/foam selectable manual ball valve and a galvanized hose reel. Each unit shall come complete with filled 3% foam concentrates (AFFF). CONTROLLING UNITS Each standpipe alarm check valve shall be provided with a local control panel of the analog addressable type. The control panel shall provide alpha-numeric visual indication and remote control as follows: 1. Fire, trouble and supervisory system alarms

K.

L.

M.

N.

O.

P.

2.3 A.

P.O. Number : 7200018725

2. 3. 4. B.

Defects in electrical wiring to alarm check valve and control circuits. Standpipe system in operation. Control valve supervision

Local panel shall be annunciated to the Fire Alarm Signaling and Monitoring System via networked fire alarm system communication.

PART 3 EXECUTION 3.1 A. INSPECTION Prior to all work of this Section, carefully inspect the installed work of all other trades and verify that all such work is complete to the point where this installation may properly commence. INSTALLATION Piping: 1. Installed piping, valves and fittings shall meet or exceed the requirements of NFPA Standards 14 and acceptable to the Marafiq/Engineer. Refer to Section 15050 "Basic Materials and Methods" for general piping installation instructions. Hose cabinets shall be mounted in or on wall as shown on the drawings and shall be level and true. Mounting height shall be 1500 mm from the top of the cabinet to finish floor.

3.2 A.

2.

3.

B.

Supports: 1. Approved supports shall be installed and sized as required to carry the weight of pipe and contents and shall be arranged to prevent vibration transmission of the building. Support piping and equipment independently. Support all risers at each floor level. Welded supports for steel piping shall be secured to walls as indicated. Sleeves and Sealing: a. Provide sleeves for all pipes passing through floors, walls, partitions, and any other building construction, of adequate diameter to allow minimum of 20 mm clearance all around between sleeve and pipe.

2. 3. 4. 5.

P.O. Number : 7200018725

b.

Work shall be laid out prior to concrete forming. Sleeves shall be reinforced to prevent collapse during forming and pouring. All floor sleeves shall extend 40 mm above finished floor level. Wall sleeves shall be flush with face of wall unless otherwise indicated. Sleeves shall permit free thermal expansion of pipe without binding or contact with structure. Do not support pipes by resting pipe clamps on floor sleeves. Supplementary members shall be provided so pipes are floor supported. All welding shall be as specified in Section 15057. All welded pipe assemblies shall be hot dip galvanized per ASTM A53 after fabrication. Welding shall not be permitted on welded assemblies after galvanizing.

c. d.

e.

f.

g. h.

C.

Signs: Permanent signs with appropriate nomenclature, as approved by the Marafiq/Engineer, shall be installed at each control valve (hydraulic sign), drain, inspector's test station, alarm horn, etc. TESTING Piping system shall be capped and subjected to a minimum static water pressure of 1.6 MPa (226 psig) and maintained for two hours with no leaks or loss of pressure. The test source shall be isolated before conducting pressure tests. Test procedures and acceptance shall fully comply with NFPA 14 requirement. + + END OF SECTION 15530 +

3.3 A.

P.O. Number : 7200018725

Você também pode gostar

- Saer 5711Documento161 páginasSaer 5711sethu1091100% (1)

- HAZOP Saudi Aramco HAZOP GuidelinesDocumento92 páginasHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- Saer 5895Documento18 páginasSaer 5895sethu1091Ainda não há avaliações

- Method Statement UG GRE R.3Documento46 páginasMethod Statement UG GRE R.3sethu1091100% (16)

- Method Statement For GRE PipingDocumento16 páginasMethod Statement For GRE PipingJaveed Shaikh100% (3)

- GRE Pipe InstallationDocumento32 páginasGRE Pipe Installationelkhatri100% (3)

- Sabp A 012Documento92 páginasSabp A 012sethu1091Ainda não há avaliações

- Best Practice: Saudi Aramco Desktop StandardsDocumento19 páginasBest Practice: Saudi Aramco Desktop Standardssethu1091100% (4)

- Sabp A 016Documento60 páginasSabp A 016sethu1091100% (6)

- Sabp A 015Documento58 páginasSabp A 015sethu1091100% (5)

- Sabp A 011Documento27 páginasSabp A 011aamirtec301Ainda não há avaliações

- Exhibit B-30 InsulationDocumento7 páginasExhibit B-30 Insulationsethu1091Ainda não há avaliações

- Sabp A 002Documento49 páginasSabp A 002sethu1091Ainda não há avaliações

- Sabp A 009Documento208 páginasSabp A 009sethu1091100% (2)

- Best Practice: Load Management For Energy Efficiency: Heat Transfer EquipmentDocumento75 páginasBest Practice: Load Management For Energy Efficiency: Heat Transfer Equipmentsethu1091Ainda não há avaliações

- Best Practice: Quick Energy Assessment Methodology For Energy Efficiency OptimizationDocumento54 páginasBest Practice: Quick Energy Assessment Methodology For Energy Efficiency Optimizationsethu1091100% (1)

- Sabp A 001Documento20 páginasSabp A 001Shahid Basha Syed100% (2)

- Menp 2 TS 605Documento16 páginasMenp 2 TS 605sethu1091Ainda não há avaliações

- Exhibit B-28 PipingDocumento7 páginasExhibit B-28 Pipingsethu1091Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Solar Module CellDocumento4 páginasSolar Module CellVinod BabhaleAinda não há avaliações

- PORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairDocumento34 páginasPORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairHarleen KlairAinda não há avaliações

- 1 Xpower Safirus Owners Manual enDocumento8 páginas1 Xpower Safirus Owners Manual enMarianela MasyRubiAinda não há avaliações

- Dynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass DcpsDocumento2 páginasDynamic Cone Penetrometers: In-Situ CBR in 10 Minutes With Dual-Mass Dcpsd'Hell CaesarAinda não há avaliações

- Huawei ACU2 Wireless Access Controller DatasheetDocumento12 páginasHuawei ACU2 Wireless Access Controller Datasheetdexater007Ainda não há avaliações

- Meai Mar 2010Documento36 páginasMeai Mar 2010Daneshwer VermaAinda não há avaliações

- EN 1991-1-4 NA enDocumento4 páginasEN 1991-1-4 NA enanuj3936100% (1)

- Mauser 98K - Model 48 Rifle ManualDocumento20 páginasMauser 98K - Model 48 Rifle ManualMeor Amri96% (28)

- Design For Manufacturing Course - by DFRDocumento257 páginasDesign For Manufacturing Course - by DFRhlgc63100% (2)

- Doing Hot Work On Gas ShipDocumento5 páginasDoing Hot Work On Gas ShipAnonymous icnhaNsFAinda não há avaliações

- Kinematics-03-Subjective SolvedDocumento11 páginasKinematics-03-Subjective SolvedRaju SinghAinda não há avaliações

- Eje Delantero BMW F10Documento94 páginasEje Delantero BMW F10Daniel Muñoz SotomayorAinda não há avaliações

- Selenium-75 Sources and Source Holders: ApplicationsDocumento2 páginasSelenium-75 Sources and Source Holders: ApplicationsTanpreet SinghAinda não há avaliações

- Skytrain Avia Services: Emergency Procedures ManualDocumento32 páginasSkytrain Avia Services: Emergency Procedures ManualEndro RastadiAinda não há avaliações

- Applying Six Sigma at 3MDocumento13 páginasApplying Six Sigma at 3MdchAinda não há avaliações

- Prospects For Alkaline Zero Gap Water Electrolysers For Hydrogen ProductionDocumento16 páginasProspects For Alkaline Zero Gap Water Electrolysers For Hydrogen Productionkhan47pkAinda não há avaliações

- 25252525Documento38 páginas25252525Ivan GonzalezAinda não há avaliações

- 6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFDocumento31 páginas6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFOwen PerrinAinda não há avaliações

- Understanding Low Voltage Power Distribution SystemsDocumento64 páginasUnderstanding Low Voltage Power Distribution SystemsJorge Luis Mallqui Barbaran100% (1)

- Concept of Circulation in A Free Vortex FlowDocumento55 páginasConcept of Circulation in A Free Vortex FlowAnil KumarAinda não há avaliações

- Efficia Infant WarmingDocumento8 páginasEfficia Infant WarmingNurhidayat MursalinAinda não há avaliações

- Philips Aquatrio FC7070 - 01 Esploso ManualeDocumento9 páginasPhilips Aquatrio FC7070 - 01 Esploso ManualeRocco Mangione0% (1)

- Man 2563XX 07Documento232 páginasMan 2563XX 07trance1313Ainda não há avaliações

- UMTS AircomDocumento20 páginasUMTS AircomDũng PhạmAinda não há avaliações

- A Sample of Wet Soil Has A Volume of 0Documento8 páginasA Sample of Wet Soil Has A Volume of 0eph0% (1)

- SMP Gateway SoftPLC Reference ManualDocumento47 páginasSMP Gateway SoftPLC Reference Manualswalker948100% (1)

- SinxbyxDocumento9 páginasSinxbyxGreeshmaAinda não há avaliações

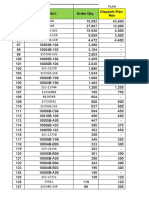

- Order Qty Vs Dispatch Plan - 04 11 20Documento13 páginasOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPAinda não há avaliações

- Electronic Dice Using LEDs Electrical Engineering ProjectDocumento16 páginasElectronic Dice Using LEDs Electrical Engineering Projectprakhar agarwal33% (3)