Escolar Documentos

Profissional Documentos

Cultura Documentos

PROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01

Enviado por

Tushar NaikDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

PROJECT STANDARDS and Specifications Offshore Skid Packages Piping Design Rev01

Enviado por

Tushar NaikDireitos autorais:

Formatos disponíveis

Page : 1 of 10

KLM Technology Group

Project Engineering Standard

Rev: 01 April 2011

www.klmtechgroup.com

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru Malaysia

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

TABLE OF CONTENT

SCOPE REFERENCES ENVIRONMENTAL DESIGN CRITERIA AND UTILITIES Seismic and Transportation Loads Design Life Dimensions DESIGN REQUIREMENTS FLEXIBILITY ANALYSIS CRITERIA & GENERAL GUIDELINES FIRE SUPPRESSION SYSTEM

2 2 6 6 7 7 7 9 10

KLM Technology Group

Project Engineering Standard

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

Page 2 of 10

Rev: 01

April 2011

SCOPE This Project Standard and Specification outlines to the minimum and mandatory requirements of designs activities for piping, piping components, piping specialties including piping within battery limits of various skids/ package/ modules etc. All piping assemblies, specialties & materials supplied or installed under these specifications shall be in accordance with sound engineering principles. Any omission from this specification shall not relieve the contractor from his responsibility of furnishing equipment or materials to meet the specific process parameters, environmental parameters, safety parameters and any other applicable statutory laws or relevant codes & standards. REFERENCES Throughout this Standard the following dated and undated standards/codes are referred to. These referenced documents shall, to the extent specified herein, form a part of this standard. For dated references, the edition cited applies. The applicability of changes in dated references that occur after the cited date shall be mutually agreed upon by the Company and the Vendor. For undated references, the latest edition of the referenced documents (including any supplements and amendments) applies. 1. ASME B1.20.1 Pipe threads 2. ASME B16.5 Pipe flanges and flanged fittings 3. ASME B16.9 Factory made wrought steel butt-welding fittings 4. ASME B16.10 Face-to-face & end-to-end dimensions of valves 5. ASME B16.11 Forged fittings (socket welding and threaded) 6. ASME B16.20 Metallic Gaskets for pipe flanges: Ring joint spiral wound and jacketed. 7. ASME B16.21 Non-metallic flat gaskets for pipe flanges 8. ASME B16.25 Butt welding ends 9. ASME B16.34 Valves- flanged, threaded & welding ends 10. ASME B31.3 Process piping 11. ASME B31.4 Pipe line transportation systems for liquid hydro carbons and other liquids. 12. ASME B31.8 Gas transmission and distribution piping system 13. ASME B36.10 M Welded and seamless wrought steel pipe 14. ASME B36.19 M Stainless steel pipe

KLM Technology Group

Project Engineering Standard

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

Page 3 of 10

Rev: 01

April 2011

15. ASME SEC.VIII 16. ASME SEC.IX 17. ASTM A105 18. ASTM A106 19. ASTM A 153 20. ASTM A 182

21. ASTM A193 22. ASTM A 194 23. ASTM A216 24. ASTM A234 25. ASTM A262 26. ASTM A 312 27. ASTM A370 28. ASTM A403 29. ASTM A453

30. ASTM A578 31. ASTM A 694

32. ASTM A 790 33. ASTM A 799

Pressure vessel code Welding and brazing qualifications Specification for forgings. Carbon steel, for piping components Specification for seamless carbon steel pipe for high temperature service Zinc coating (hot dip) on iron & steel hardware Specification for forged or rolled alloy steel pipe flanges, forged fittings & valves and parts for high temperature service. Specification for alloy steel & stainless steel bolting materials for high temperature service. Specification for carbon & alloy steel nuts for bolts for high pressure & high temperature service Specification for carbon steel casting suitable for fusion welding for high temperature service. Specification for piping fittings of wrought carbon steel & alloy steel for moderate & elevated temperature Recommended practice for detecting susceptibility to inter granular corrosion attack in stainless steels Specification for seamless & welded austenitic stainless steel pipe Test methods and definitions for mechanical testing of steel products Specification for wrought, austenitic stainless steel, piping fittings Specification for bolting materials high temperature 50 to 120 ksi with expansion coefficient comparable to austenitic steels Straight beam ultrasonic examination of plain & clad steel for special applications. Std specs. For forgings, carbon and alloy steel for pipe flanges, fittings, valves & parts for high-pressure transmission service Seamless and welded ferritic/austenitic stainless steel pipe Std. practice for steel castings, stainless instrument calibration for estimating ferrite content.

KLM Technology Group

Project Engineering Standard

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

Page 4 of 10

Rev: 01

April 2011

34. ASTM B42 35. ASTM B 124 36. ASTM B 165 37. ASTM B 337 38. ASTM B 363 39. ASTM B 366 40. ASTM B 423 41. ASTM B 425 42. ASTM B466 43. ASTM D 1785 44. ASTM D 2665 45. ASTM E18 46. ASTM E 45 47. ASTM E 92 48. ASTM B 142 49. ASTM E 165 50. ASTM E 709 51. API 5 L 52. API 6A 53. API 6D / ISO 14313 54. API 6FA 55. API RP 14C 56. API RP 14E

Std. spec. For seamless copper pipe Std. spec. For copper and copper alloy forging rod, bar and shapes. Std. spec. For nickel copper alloy (UNS4400) seamless pipe and tube Std. spec. For seamless and welded titanium and titanium alloy pipe Std. spec. for unalloyed titanium and titanium alloy welding fittings Std. spec. for factory made wrought nickel and nickel alloy welding fittings. Std. specs. for nickel-iron-chromiummolybdenum copper alloy (UNS no.8825&8221) seamless pipe and tube Std. spec. for NI-FE-CR-MO- CU alloy (UNS no. 8825 & 8221) rod & bar. Std spec. for seamless copper nickel pipe and tube Spec. for poly vinyl chloride (PVC) plastic pipe Spec. for poly vinyl chloride (PVC) plastic drain, waste and vent pipe fittings Rockwell hardness testing of metallic materials Determining inclusion content of steel Vickers hardness of metallic materials Controlling quality of radiographic testing Liquid penetrant inspection method Recommended practice for magnetic particle examination. Line pipe Specification Wellhead and Chrismas tree Equipment Petroleum and natural gas industries-Pipeline Transportation system Pipeline valves Fire test for valves Analysis, design, installation testing for basic surface safety system Design and installation of offshore production platform piping system

KLM Technology Group

Project Engineering Standard

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

Page 5 of 10

Rev: 01

April 2011

57. API RP 14G 58. API 598 59. API 600 / ISO 10434

Fire prevention and control on open type offshore production platform. Valve inspection and testing

Steel gate valves, flanged and butt-welded ends (nps 1 through nps 24) 60. API 607 Fire test for soft-seated Quarter turned valves 61. BS 1868 Spec. for steel check valves (flanged &butt welding ends) for the petroleum petrochemical & allied industries 62. BS 1873 Spec. for steel globe and globe stop and check valves (flanged & butt welding ends) for the petroleum, petrochemical & allied industries. 63. BS EN 1092-3 Flanges and their joints. Circular flanges for pipes, valves, fittings and accessories, PN designated Copper Alloy Flanges. 64. BS EN ISO 17292 Metal Ball Valve For The Petroleum, Petrochemical And Allied Industries 65. BS EN ISO 5761 Steel Gate, Globe & Check valves For DN 100 and Smaller, For Petroleum and Natural Gas Industries 66. BS 5353 Specification For Steel Plug Valve 67. BS 6755-2 Testing Of Valves. Specification for Fire Type-Testing requirements. 68. MSS SP 44 MSS Steel Pipe Line Flanges 69. MSS SP 75 Spec. For High Test Wrought Butt Welding Fittings 70. NACE MR 01-75/ ISO 15156-1/2/3 Material for use in H2S containing environments in Oil and Gad Production. Part-1: General principles for Selection of Cracking resistant Materials. Part-2: Cracking resistant Carbon and Low Carbon Steels, and the use of Cast irons. Part-3: Cracking resistant CRAs ( Corrosion Resistant alloys) and other alloys. 71. NACE TM-01-77 Laboratory-Testing Of Metals For Resistance To Sulfide Stress Cracking and stress corrosion cracking in H2S Environments

KLM Technology Group

Project Engineering Standard

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

Page 6 of 10

Rev: 01

April 2011

72. NACE-TM-02-84 Evaluation Of Pipeline and pressure vessel steels for Resistance To Hydrogen induced Cracking 73. NFPA-Volume-6 National Fire Code For Sprinklers, Fire Pumps And Water Tanks 74. NFPA Volume 8 National Fire Code For Portable And Manual Fire Control Equipment. 75. NFPA 15 Standard for Water spray fixed systems for fire protection. 76. ASTM D 2996 Specifications For Filament Wound Reinforced Thermosetting Pipes & Fittings. 77. ASTM D 2992 Method For Obtaining Hydrostatic Design Basis For Reinforced Thermosetting Resin Pipes & Fittings. 78. ASTM A 815 Specification for wrought ferritic, ferritic/austenitic and martensitic stainless steel piping fittings. 79. ASTM G 36 Performing stress corrosion-cracking tests in a boiler magnesium chloride 80. ASTM G 48A/B Standard Test Method For Pitting & Crevice Corrosion Resistance of Stainless Steel & Related Alloy By Use Of Ferritic Chloride Solution 81. ASME B16.24 Cast Copper Alloy Pipe Flanges and flanged fittings Classes 150, 300, 400, 600, 900, 1500 and 2500. 82. ASME B 16.18 Cast Copper Alloy Solder Joint Pressure Fittings 83. MSS-SP-80 Bronze Gate, Globe, Angle and Check Valve 84. MSS-SP-97 Integrally reinforced forged branch outlet Fittings-Socket Welding, Threaded and Butt Welding Ends ENVIRONMENTAL DESIGN CRITERIA AND UTILITIES Seismic and Transportation Loads All equipment supports and braces, pipe supports and other support steel work, including temporary braces, shall be designed to withstand seismic loads applicable to the present location. Refer to the Structural Basis of Design for seismic design considerations. All equipment supports and braces, pipe supports and other support steel work, including temporary braces, shall be designed to withstand the operating, lifting, transport (by road and by sea) and hydro-test loads specified in Project Standard and Specification.

KLM Technology Group

Project Engineering Standard

OFF SHORE SKID PACKAGE PIPING DESIGN CRITERIA (PROJECT STANDARDS AND SPECIFICATIONS)

Page 7 of 10

Rev: 01

April 2011

Design Life The process facilities design life requirement is 25 years. Dimensions SI units shall be used. Dimensions shall be in mm and be related to the Platform datums or reference lines. DESIGN REQUIREMENTS All materials shall conform to Project Standard and Specification and the identified API, ASME, ASTM, BS and NACE codes and Standards. Design and fabrication shall conform to this Specification and ASME B31.3, API RP14E. In case, any other applicable codes are proposed/ referred the same shall be complied with sufficient information/justification after approval by company. From piping of pig-barrel of Launcher/Receiver up to piping-pipeline interface shall be designed as a minimum to ASME B 31.4 and ASME B 31.8. For smooth pigging operation, attempts shall be made to keep the ID of the piping from reducer of pig-Barrel to pipelinepiping interface as close as possible to the ID of the riser in splash zone. In case, ID of the topside is more than the the ID of the riser, thickness of the topside piping shall be increased to match the IDs. If the ID of the topside piping is less than that of riser in splash zone, thickness of the topside piping may be adjusted to match the IDs by: - Considering the actual design conditions of the line in place of class conditions for pipe wall thickness calculations. - Reducing the corrosion allowance for topside piping but not less than the internal corrosion allowance in corresponding pipeline. In case, the difference in IDs still exists, ID of the topside piping shall be checked for the passage of gauge plate with out interference. The gauge plate Diameter shall be calculated by the formula given in the specification of submarine pipelines. All cupro-nickel piping shall be supplied in 14-bar system. Velocity in Cu-Ni piping shall not exceed 1.6 m/sec for 2 NB and below and 3.3 m/sec. for 3 NB and above. Fluid velocities in copper piping shall not exceed 1.5 m/sec.

Você também pode gostar

- Moreira LNG Mini PlantDocumento6 páginasMoreira LNG Mini PlantPramadi AbdulganiAinda não há avaliações

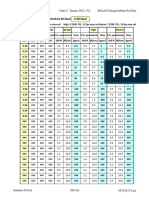

- 11 - Pipe Sizing Data.75102626Documento50 páginas11 - Pipe Sizing Data.75102626Zelalem MengistuAinda não há avaliações

- ABSA PipingDocumento1 páginaABSA Pipingcorreen100% (1)

- Corrosion Monitoring TechniquesDocumento34 páginasCorrosion Monitoring TechniquesMubarik AliAinda não há avaliações

- FOCUS REPORT: U.S. Shale Gale under Threat from Oil Price PlungeNo EverandFOCUS REPORT: U.S. Shale Gale under Threat from Oil Price PlungeNota: 2 de 5 estrelas2/5 (1)

- Mechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestNo EverandMechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestAinda não há avaliações

- Concept of Design Cryogenic PipingDocumento3 páginasConcept of Design Cryogenic PipingSiampol FeepakphorAinda não há avaliações

- Codes and Standards DocumentDocumento4 páginasCodes and Standards DocumentOvaisAinda não há avaliações

- Corrosion Failure Analysis of L485 Natural Gas Pipeline in CO2 EnvironmentDocumento7 páginasCorrosion Failure Analysis of L485 Natural Gas Pipeline in CO2 EnvironmentRagerishcire KanaalaqAinda não há avaliações

- Ansi/Asme ASME B31.3 ASME B31.1: Power PlantDocumento60 páginasAnsi/Asme ASME B31.3 ASME B31.1: Power PlantMercyAinda não há avaliações

- Nu Flow Powerpoint PresentationDocumento47 páginasNu Flow Powerpoint PresentationNu FlowAinda não há avaliações

- Piping Q&ADocumento3 páginasPiping Q&AVijay KumarAinda não há avaliações

- Design of Parallel Pipelines in Second West-East Natural Gas Pipeline ProjectDocumento10 páginasDesign of Parallel Pipelines in Second West-East Natural Gas Pipeline ProjectAleksObrAinda não há avaliações

- Best Management Practice For Fugitive Emissions ManagementDocumento59 páginasBest Management Practice For Fugitive Emissions Managementmihahudea100% (1)

- Ashrae Handbook Hvac ApplicationsDocumento9 páginasAshrae Handbook Hvac Applicationsliza mae remorozaAinda não há avaliações

- Power Plant Costing-Iii-IndusDocumento9 páginasPower Plant Costing-Iii-IndusgmsangeethAinda não há avaliações

- Bills ConversionsDocumento20 páginasBills ConversionssudhirbmaliAinda não há avaliações

- Materials Selection Modeling & SimulationDocumento21 páginasMaterials Selection Modeling & Simulationleila hanjani hanantoAinda não há avaliações

- Code and Standard in OGDocumento8 páginasCode and Standard in OGTatit P. PrapancaAinda não há avaliações

- Valve Cast Forged Material PDFDocumento1 páginaValve Cast Forged Material PDFFendik Newbie100% (1)

- Gas Turbine PerformanceDocumento11 páginasGas Turbine PerformancerenumaheshAinda não há avaliações

- The Design of Natural Gas PipelinesDocumento7 páginasThe Design of Natural Gas PipelineshiyeonAinda não há avaliações

- Vol45-4 PDFDocumento268 páginasVol45-4 PDFGoh Aik WeiAinda não há avaliações

- 1.03 Engineering Calculations PDFDocumento93 páginas1.03 Engineering Calculations PDFJannel PaetAinda não há avaliações

- DBB CatalogueDocumento20 páginasDBB Cataloguerawrr90Ainda não há avaliações

- 2.gas Turbine Operation, Maintenance & TroubleshootingDocumento3 páginas2.gas Turbine Operation, Maintenance & TroubleshootingMowaten MasryAinda não há avaliações

- Presentation .... Chapter 8 .... Prepared by Mohamad KhattabDocumento51 páginasPresentation .... Chapter 8 .... Prepared by Mohamad KhattabAhmed MoustafaAinda não há avaliações

- Gas Tech 2008 FLN G Business PresentationDocumento25 páginasGas Tech 2008 FLN G Business PresentationNirma Afrisanti KinasihAinda não há avaliações

- DR Engp I 1.1 R.11Documento1.093 páginasDR Engp I 1.1 R.11HEFTOS P-55100% (1)

- Power System Engineering Lecture 1Documento16 páginasPower System Engineering Lecture 1nnvpratapAinda não há avaliações

- Natural Gas Transmission Pipeline Temperature Drop CalculationDocumento5 páginasNatural Gas Transmission Pipeline Temperature Drop CalculationCarina QuibinitAinda não há avaliações

- TDW Distribution Systems CatalogDocumento144 páginasTDW Distribution Systems CatalogSIMON S. FLORES G.100% (1)

- Alberta Pipeline ActDocumento56 páginasAlberta Pipeline ActFredrick Martin100% (1)

- Canadian Hydrogen Futures - Publication EditionDocumento152 páginasCanadian Hydrogen Futures - Publication Editionlyb0005Ainda não há avaliações

- R435319004PB PDFDocumento9 páginasR435319004PB PDFMuhammed SulfeekAinda não há avaliações

- Basic Process Calculations and SimulatioDocumento28 páginasBasic Process Calculations and SimulatioDilipAinda não há avaliações

- Process Equipment Design Guidelines Chapter Ten Pressure Relief Valve Selection and Sizing (Engineering Design Guidelines)Documento31 páginasProcess Equipment Design Guidelines Chapter Ten Pressure Relief Valve Selection and Sizing (Engineering Design Guidelines)einsten777Ainda não há avaliações

- Sizing Criteria PDFDocumento6 páginasSizing Criteria PDFAshwin DuhonarrainAinda não há avaliações

- Lawal KA 2011 PHD ThesisDocumento327 páginasLawal KA 2011 PHD Thesispedro aguilar100% (1)

- Lecture Notes 00 - Mech 6561 PDFDocumento14 páginasLecture Notes 00 - Mech 6561 PDFVi GaneshAinda não há avaliações

- Gas Liquid Separation Technology SulzerDocumento24 páginasGas Liquid Separation Technology SulzerCH1253100% (1)

- Kut Epoxy Coating Sf1Documento2 páginasKut Epoxy Coating Sf1Arun Chandra BabuAinda não há avaliações

- ValveDocumento9 páginasValveAdhie_ginthinkAinda não há avaliações

- Rotary PipeCLADDocumento7 páginasRotary PipeCLADsafari7Ainda não há avaliações

- US Vs EU Material Strengths PDFDocumento23 páginasUS Vs EU Material Strengths PDFAbhijeet SahuAinda não há avaliações

- Carbon Capture Final ReportDocumento9 páginasCarbon Capture Final Reportapi-385958959Ainda não há avaliações

- Appendix A - Sizing and Capacities of Gas PipingDocumento4 páginasAppendix A - Sizing and Capacities of Gas PipingTohid KarimiAinda não há avaliações

- Alloy 20, UNS N08020, Carpenter 20, 20Cb-3, Incoloy Alloy 20Documento1 páginaAlloy 20, UNS N08020, Carpenter 20, 20Cb-3, Incoloy Alloy 20osto72Ainda não há avaliações

- GMR RFQDocumento142 páginasGMR RFQumamahesh259Ainda não há avaliações

- Galvanic Corrosion PDFDocumento16 páginasGalvanic Corrosion PDFdraj1875977Ainda não há avaliações

- Pipeline Engineering Syllabus PDFDocumento2 páginasPipeline Engineering Syllabus PDFAfroz KhanAinda não há avaliações

- 9 CNG Cost Components PDFDocumento9 páginas9 CNG Cost Components PDFReno SaibihAinda não há avaliações

- 2-Column Tray DesignDocumento9 páginas2-Column Tray DesignmuhardinurAinda não há avaliações

- Optimization of Natural Gas Pipeline Design PDFDocumento10 páginasOptimization of Natural Gas Pipeline Design PDFrasnowmah2012Ainda não há avaliações

- r050210803 Chemical Process CalculationsDocumento8 páginasr050210803 Chemical Process CalculationsSrinivasa Rao GAinda não há avaliações

- 2015 Below Ground ProductsDocumento140 páginas2015 Below Ground Productsstalin_83100% (1)

- GLOMACS Materials of Constr. For Process Equipment and Piping SystemsDocumento6 páginasGLOMACS Materials of Constr. For Process Equipment and Piping SystemsRoo FaAinda não há avaliações

- Swagelok Fitting PDFDocumento16 páginasSwagelok Fitting PDFmattuiffAinda não há avaliações

- Avoiding Common Pitfalls in CO2 Corrosion Rate Assessment For Upstream Hydrocarbon IndustriesDocumento15 páginasAvoiding Common Pitfalls in CO2 Corrosion Rate Assessment For Upstream Hydrocarbon IndustriesKen's CornerAinda não há avaliações

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988No EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockAinda não há avaliações

- Fundamentals of Gas CompressionDocumento304 páginasFundamentals of Gas Compressionmihahudea100% (1)

- MSA Flame & Gas For Oil & GasDocumento8 páginasMSA Flame & Gas For Oil & GasmihahudeaAinda não há avaliações

- Fugitive Emissions WebDocumento11 páginasFugitive Emissions WebmihahudeaAinda não há avaliações