Escolar Documentos

Profissional Documentos

Cultura Documentos

1 s2.0 S073519330600042X Main

Enviado por

ResearcherzDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1 s2.0 S073519330600042X Main

Enviado por

ResearcherzDireitos autorais:

Formatos disponíveis

A theoretical evaluation of the thermal performance of CPC

with flat one-sided absorber

Rn Tchinda

a,b,

, Nguijo Ngos

a

a

IUT FOTSO VICTOR of Bandjoun, University of Dschang, PO Box 134 Bandjoun, Cameroon

b

ICTP Strada Costiera 11, 34014 Trieste, Italy

Available online 29 March 2006

Abstract

Mathematical equations are developed to study thermal processes in a CPC collector with a flat one-sided absorber. An

expression for the temperature of the heat transfer fluid as a function of the space-co-ordinate in the flow direction and the time

dependent solar intensity is developed. The effects of various parameters on the thermal performance of such a CPC are studied.

The selectively coated CPC with flat one-sided collector is more efficient than the black painted one with the same condition. The

predicted results were also compared with the experimental results reported in the literature.

2006 Elsevier Ltd. All rights reserved.

Keywords: CPC collector; Flat one-sided absorber; Daily efficiency; CPC's length

1. Introduction

Since the invention of the compound parabolic concentrator (CPC) in 1974 [1], many papers have been published on

literature that deal with a wide range of design and analysis. Some of them are documented in Hsieh [1], El Assay [2],

Chakraverty et al. [3], Tchinda et al. [4], Fraidenraich et al. [5], Oommen and Jayaraman [6] and Collares Pereira and

Carvalho [7]. However, a close examination of these papers reveals that the great majority of them are devoted to

optical, geometrical and thermal analysis of the compound parabolic concentrator with tubular absorber. Other CPC

configurations like non-evacuated stationary CPC solar collector with flat bifacial absorber [8,9], asymmetric

compound parabolic concentrator [1012] have been proposed. Papers reporting thermal analysis of the CPC with flat

one-side absorber are rarely found, and those published are devoted to the effect of truncation on both optical, thermal

losses and collectible energy, or to increase the electrical energy output [13,14].

In this paper, the equations of the system are written by considering an energy balance for every individual

component of the CPC with flat one-sided absorber. The effect of some of the design parameters like the rate of the

fluid flow, the inlet temperature, the CPC length, the selective coating, the mirror reflectance, etc., are discussed.

International Communications in Heat and Mass Transfer 33 (2006) 709718

www.elsevier.com/locate/ichmt

Communicated by W.J. Minkowycz.

Corresponding author.

E-mail address: ttchinda@yahoo.fr (R. Tchinda).

0735-1933/$ - see front matter 2006 Elsevier Ltd. All rights reserved.

doi:10.1016/j.icheatmasstransfer.2006.01.019

2. Modelling of the thermal processes

The basic design of the evacuated CPC with a flat one-sided absorber is shown in Fig. 1. In order to simplify analysis,

some assumptions are made:

A-1 It is assumed that the CPC is ideal and free from fabrication errors.

A-2 The concentrator achieves a concentration ratio C

R

=A

C

/ A

P

.

Nomenclature

A area (m

2

)

C specific heat (J/kg K)

C

R

geometric concentrator ratio

e Thickness (m)

h heat transfer coefficient (W/m

2

K)

I solar intensity (W/m

2

)

L length of the tube (m)

l breadth (m)

M mass per unit area (kg/m

2

)

m mass flow rate (kg/s)

bnN number of reflection

q

f

heat flow (W/m

2

)

T temperature (K)

T

fm

1

L

_

L

0

T

f

x; tdx K

Greek letters

absorptance

reflectance

m

mirror reflectance

transmittance

StefanBoltzman's constant (W/m

2

K

4

)

dynamic viscosity (kg/ms)

emissivity

thermal efficiency

Thermal conductivity (W/m C)

Subscripts

a ambient

c cover 1

d daily

e inlet

f fluid

o outlet

p flat one-sided absorber

v cover 2

vp Cover 2-flat one-sided absorber

s sky

710 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

A-3 The concentrator does not produce an image of the light source.

A-4 For any given direction of light source, a certain fraction of the rays entering the aperture will reach the absorber

directly, while the other rays will reach the absorber after one or more reflections. Therefore one can define an

average number of reflections bnN for a CPC.

A-5 The cover 1, the cover 2 and the receiver have uniformtemperature distributions and CPCcomponent properties are

independent of temperature.

The energy balance equations for the cover 1, the cover 2, the flat one-sided absorber and the fluid can be written as:

For transparent cover 1

M

c

C

c

T

c

t

q

c

t h

r1

h

v=c

T

v

T

c

h

r2

T

c

T

s

h

c=a

T

c

T

a

1

Beam

e

insulation

l

v

Flat one-side absorber

Insulation

Cover 2

W

Optic axis

Cover 1

Reflector

l

p

e

f

e

vp

max

Fig. 1. CPC with a flat one-sided absorber.

711 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

Where

h

r1

rT

2

c

T

2

v

T

c

T

v

1

e

v

A

v

A

c

1

e

c

1

_ _

A

c

A

p

2

h

r2

re

c

T

2

c

T

2

s

T

c

T

s

A

c

A

p

3

and according to Hsieh's theory h

v/c

is given by [1]

h

v=c

3:25 0:0085

T

v

T

c

2D

v

_ _

A

v

A

p

4

with

D

v

21

v

e

f

e

pv

1

v

e

f

e

pv

4 a

For transparent cover 2

M

v

C

v

T

v

t

q

v

t h

r3

T

p

T

v

h

v=c

T

v

T

c

h

r1

T

v

T

c

5

h

r3

rT

2

p

T

2

v

T

p

T

v

1

e

p

A

p

A

v

1

e

v

1

_ _ 6

For flat one-sided absorber

M

p

C

p

T

p

t

q

p

t h

r3

T

p

T

v

h

pf

T

p

T

f

7

For the fluid

q

f

e

f

C

f

T

f

t

h

pf

T

p

T

f

m

:

C

f

l

p

T

f

x

U

0

T

f

T

a

8

This differential equation is subjected to the boundary condition:

T

f

x 0; t T

fe

9

q

c

(t), q

v

(t) and q

p

(t) have been expressed using the Hsieh's theory as [1]:

q

c

t I t a

c

a

c

s

c

q

v

q

2bnN

m

_

A

c

A

p

10

q

v

t Its

c

q

bnN

m

a

v

a

v

q

v

q

c

q

2bnN

m

A

v

A

c

a

v

q

p

s

v

_ _

A

c

A

p

11

q

p

t Its

c

q

bnN

m

s

v

a

p

a

p

q

p

q

v

A

p

A

v

_ _

A

c

A

p

12

With A

p

=l

p

L, A

c

=2WL and A

v

=l

v

L.

712 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

The factor h

pf

is the convective heat transfer coefficient between heat transfer fluid and the walls of the absorber is

calculated using the Mercer correlation's [15]:

N

u

h

pf

D

h

k

f

4:9

0:0606R

e

P

r

D

h

=L

1:2

1 0:0909R

e

P

r

D

h

=L

0:7

P

0:17

r

13

for laminar flow (R

e

b2100), and for turbulent flow (R

e

N2100) the Kays correlation presented in a mathematical form

by Duffie and Beckman [15] has been used:

N

u

h

pf

D

h

k

f

0:0158R

0:8

e

14

with

R

e

m

:

D

h

l

p

e

f

l

f

; P

r

l

f

C

f

k

f

and D

h

2l

p

e

f

l

p

e

f

15

The heat loss coefficient by convection h

c/a

between the cover 1 and the ambient is given by Duffie and Beckman [15]

h

c=a

5:7 3:8v

A

c

A

p

16

Since the absorptance of the cover 1 and the thermal capacities of the components of the collector are small, we

neglect them. However, the functioning of the collector remains variable with time because it depends on the unsteady

solar intensity. Eliminating T

c

, T

v

and T

p

from the simplified equations obtained, one gets:

m

:

C

f

T

f

x

l

p

FVS

p

U

L

T

f

T

a

17

With:

S

p

q

p

t

h

r3

h

r1

h

v=c

h

c=a

h

r2

q

v

t h

r3

h

r1

h

v=c

q

c

t6h

r3

h

r2

h

r1

h

v=c

h

r3

h

r1

h

v=c

h

c=a

h

r2

h

r1

h

v=c

h

c=a

h

r2

18

Where the overall heat loss coefficient is written as:

U

L

h

r3

h

pf

h

v=c

h

r1

h

c=a

h

r2

U

0

h

r3

h

pf

h

r1

h

r2

h

c=a

h

v=c

U

0

h

r3

h

pf

h

v=c

h

r1

h

c=a

h

r2

h

pf

h

v=c

h

r1

h

c=a

h

r2

h

r3

h

pf

h

r1

h

r2

h

c=a

h

v=c

19

and the collector efficiency factor is given by the relationship:

FV

h

r3

h

pf

h

r1

h

r2

h

v=c

h

c=a

h

pf

h

r1

h

v=c

h

r2

h

c=a

h

r3

h

pf

h

r1

h

r2

h

v=c

h

c=a

h

r3

h

pf

h

r1

h

v=c

h

r2

h

c=a

20

If we assume that F and U

L

are temperatures independent in position, then the solution for temperature at any

position x is:

T

f

x; tT

a

S

p

U

L

T

fe

T

a

S

p

U

L

exp

l

p

FVU

L

C

f

m

x

_ _

21

713 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

The instantaneous efficiency is found to be:

g

i

g

0

F

A

F

R

U

L

F

R

IC

R

T

fe

T

a

22

Where

F

R

m

:

C

f

C

R

U

L

A

c

1exp

A

c

U

L

FV

m

:

C

f

C

R

_ _ _ _

23

F

A

h

r3

h

r1

h

r2

h

v=c

h

c=a

s

c

q

bnN

m

a

v

s

v

q

2bnN

m

q

v

q

c

A

v

A

c

a

v

s

v

q

p

_ _ _ _

h

r3

h

r1

h

v=c

a

c

a

c

q

v

s

c

q

2bnN

m

6h

r2

IC

R

_ _

h

r3

h

r2

h

r1

h

v=c

h

c=a

h

r1

h

v=c

h

r2

h

c=a

24

a

The local temperature of the glycerol in the flow direction

0

50

100

150

200

250

300

x(m)

T

f

(

x

,

t

M

)

(

C

)

mass flow rate=0,0004 kg/s

mass flow rate=0,0008 kg/s

mass flow rate=0,0012 kg/s

Tfe=10C

Tfe=60C

Tfe=110C

b

The hourly variation of the outlet fluid temperature

0

6h 9h 12h 15h 18h

50

100

150

200

250

Hours

T

f

(

L

,

t

)

(

C

)

mass flow rate=0,0004 kg/s mass flow rate=0,0008 kg/s

mass flow rate=0,0012 kg/s Tfe=10C

Tfe=60C Tfe=110C

0.00 0.23 0.68 1.13

Fig. 2. Effect of the glycerol mass flow rate and of the glycerol inlet temperature, mirror reflectance=0.85; flat one-sided absorber emissivity=0.05.

714 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

The optical efficiency

0

is given by:

g

0

s

v

s

c

q

bnN

m

a

p

a

p

q

p

q

v

A

p

A

v

_ _

25

This optical efficiency is related to the process in which the beam or direct component of the incident solar radiation

is transmitted through the cover 1, reflected specularly on the mirror surface, transmitted through the cover 2, and

absorbed by the flat one-sided absorber. A close examination of Eq. (25) reveals that when C

R

tends to infinity,

0

tends

to

c

m

bnN

p

, its minimum value. For C

R

=1 (value of the concentration ratio of flat-plate collectors [1,2]),

0

is equal

to s

c

s

v

q

bnN

m

a

p

1 q

p

q

v

A

c

A

p

_ _

, its maximum value.

Effect of the glycerol mass flow rate

0

10

20

30

40

50

60

70

0

10

20

30

40

50

60

70

0.1 0.5 0.9 1.3

mass flow rate (10

-3

kg/s)

d

a

i

l

y

e

f

f

i

c

i

e

n

c

y

(

%

)

d

a

i

l

y

e

f

f

i

c

i

e

n

c

y

(

%

)

Effect of the inlet glycerol temperature

10 30 50 70 90 110 130

T

fe

(C)

a

b

Fig. 3. The daily efficiency of the CPC collector; flat one-side absorber emissivity=0.05; mirror reflectance=0.85.

715 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

The daily efficiency

d

of the CPC collector with the flat one-sided absorber is calculated from the relationship:

g

d

_

6p:m:

6a:m:

m C

f

T

fo

T

fe

dt

A

c

_

6p:m:

6a:m:

Itdt

26

3. Results and discussions

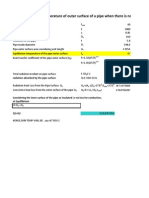

Numerical calculations are carried out by employing the values of the relevant parameters as follows: l

v

=0.13 m; l

p

=0.09 m;

W=0.1128 m;

c

=

v

=0.85;

c

=

v

=0.05;

c

=

v

=0.9;

c

=

v

=0.05;bnN=0.6;

f

=1.3153 W m

1

K

1

;

f

=1.11 kg m

1

s

1

;

C

pf

=1900 J/kg C; e

pv

=0.004 m; e

f

=0.02 m; 0.3 W m

2

C

1U

0

0.6 W m

2

C

1

[20]. Glycerol is used as heat transfer fluid.

The mean values of the ambient temperature and global radiation in May at Garoua (920 N; 1323 E; altitude 241 m) are used [16].

The sky temperatures is [1,4]: T

s

=T

a

6.

Effect of: I- the CPC'length,

II- the Flat one-sided absorber emissivity

III- the mirror reflectance

0

50

100

150

200

250

300

6h 9h 12h 15h 18h

Hour

T

e

m

p

e

r

a

t

u

r

e

(

C

)

I- L=1,5 m

II- mirror reflectance=0,95

III- flat one-sided absorber emissivity=0,1

I- L=1m

II- mirror reflectance=0,85

II- mirror reflectance=0,68

III- flat one-sided absorber emissivity=0,9

Predicted daily efficiency (I) and outlet glycerol temperature (II)

0

10

20

30

40

50

60

70

0.1 0.5 0.9 1.3 1.7

mass flow rate (10

-3

kg/s)

D

a

i

l

y

e

f

f

i

c

i

e

n

c

y

(

%

)

0

50

100

150

200

250

300

T

f

(

L

,

t

M

=

1

2

.

3

0

p

.

m

.

)

(

C

)

I- L=1,50 m

I- L=1,00 m

II- L=0,75 m

II- L=1,00 m

II- L=1,50 m

a

b

Fig. 4. Effect of the CPC's length.

716 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

An iterative procedure is adopted to bring the effect of the temperature, depending on various heat transfer coefficients. For

certain temperatures, they are first calculated by using the standard expressions given earlier. The equations are solved by assuming

constant heat coefficients and then determining new solutions which will be used to generate all the heat transfer coefficients again

till the values converge.

Figs. 2 and 3 illustrate the effect of the mass flow rates m and the inlet heat transfer fluid temperature on local temperature at the

instant t

M

=12.30 p.m. on the hourly variations of the outlet temperature and on daily efficiency

d

of the CPC. As expected, it is seen

that, the outlet temperature decreases with the increase of the mass flow rate (Fig. 2). When m increases, I(t) and T

a

(t) remaining

constant, the quantity of heat transfer fluid to be heated in the channel increases. Furthermore, the daily efficiency increases with m

(Fig. 3a), because an increase of m leads to an increase of heat transfer coefficient between the heat transfer fluid and the absorber.

Consequently greater will be the heat carried away from the receiver. The outlet heat transfer fluid temperature does not increase

significantly with increasing inlet heat transfer fluid temperature (Fig. 2). This is because, when T

fe

increase with solar intensity

being kept constant, thermal losses increase rapidly, and then, the augmentation of the outlet fluid enthalpy is reduced. This also

explains why the heat removal from the CPC and the daily efficiency

d

of the CPC decreases with increase of the inlet fluid

temperature T

fe

(Fig. 3b).

The outlet heat transfer fluid temperatures and the daily efficiency are shown in Fig. 4, for some values of L (Fig. 4a and b), of

m

and

p

(Fig. 4a). The total rise in temperature or total heat collected by the heat transfer fluid from the hot surface depends on the time

for which heat transfer fluid remains in contact with the hot surface. As L increases, the time of contact between heat transfer fluid

and hot plate increases, consequently T

fo

also increases. In Fig. 4b, we have plotted T

fo

at t

M

as function of m for some values of L.

For small CPC lengths, T

fo

quickly becomes constant whereas for larger CPC lengths it slowly approaches a constant value. In Fig.

4b, it is also shown that the daily efficiency decreases with an increase of L for a given m but increases with m for a given L. As the

fluid passes through the channel, it gains heat and T

f

increases. The energy gain will continue to decrease as T

f

rises. When T

f

is

small, the fluid collects a greater amount of the heat from the plates per unit area compared to the amount lost to the cover. However,

as L increases, this situation is reversed. Beyond a certain value of L, a larger portion of the heat received, per unit area of absorber,

will be transferred to the cover and little will be transferred to the fluid.

In order to study the effect of the mirror reflectance on the performance of the fluid outlet temperature T

fo

, calculations are

performed for three values of reflectance (

m

=0.68,

m

=0.85,

m

=0.95). These values approach the reflectance of clean non-

austenitic polished stainless steel (autonitic can achieve

m

=0.68), the reflectance of aluminium and plastic mirror (

m

=0.85)

and the reflectance of black-silvered glass mirrors (

m

=0.95) [17]. We note on Fig. 4a, that T

fo

is higher for black-silvered glass

mirrors and that the effect of mirror reflectance is not much in the early morning hours and the late evening hours as T

fo

is

small. Nevertheless, other factors such as mirror self-cleaning and manufacturing ease may be decisive in the choice of design

[18,19].

The effect of selective coating on the performance of the CPC was also studied. Calculations are performed for a black-painted

surface with

p

=0.9, and a selectively coated surface with

p

=0.1. In Fig. 4a, the outlet temperature for both types of surfaces is

plotted. The selective coating will be more effective in those cases where outlet temperature of the heat transfer fluid is higher. The

0

10

20

30

40

50

60

70

80

0.005 5.36E-02 1.08E-01 1.20E-01 1.17E-01

E

f

f

i

c

i

e

n

c

y

(

%

) Present study

[20]

(T

fm

-T

a

)/I (W/m

2

C)

Fig. 5. Comparison of collector efficiencies.

717 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

effect of selective coating will not be much in early morning hours and in the late evening hours as the outlet temperature of the fluid

for both types of surfaces practically coincides.

4. Validation of mathematical model

The theoretical model proposed in the present work has been validated by comparing the results of our calculations,

to those obtained from experimental studies, carried out by different authors such as Rabl [20]. The data were taken

from a collector having conditions sufficiently close to the ones given in Ref. [20]. Fig. 5 shows that the agreement

between predictions and experiment appears to be satisfactory.

5. Conclusions

In this work we have studied the effect of some parameters of the CPC with the flat one-sided absorber. The

following conclusions are obtained: (i) for a given L, the efficiency increases as m increases, and outlet temperature of

the heat transfer fluid decreases with an increase of m. The shorter length is more efficient than long CPC length, (ii)

outlet temperature of heat transfer fluid, daily efficiency decreases with an increase of the inlet temperature of the heat

transfer fluid, (iii) the selective coating changes the performance of the CPC considerably, (iv) the nature of the

reflector material, changes considerably the performance of the system.

References

[1] C.K. Hsieh, Thermal analysis of CPC collectors, Solar Energy 27 (1981) 1929.

[2] A.Y. El-Assay, J.A. Clark, Athermaloptical analysis of compound parabolic concentrator for single and multiphase flows, including superheat,

Wrme undstoffbertragung 21 (1987) 189198.

[3] S. Chakraverty, N.K. Bansal, H.P. Garg, Transient analysis of a CPC collector with time dependent input function, Solar Energy 38 (3) (1987)

179185.

[4] R. Tchinda, E. Kaptouom, D. Njomo, Study of the CPC collector thermal behaviour, Energy Conversion and Management 39 (13) (1998)

13951406.

[5] N. Fraidenraich, D.E.R.F. DE Lima, C. Tiba, E.M. Barbosa, Simulation model of CPC collector with temperature dependent heat loss

coefficient, Solar Energy 65 (2) (1999) 99110.

[6] R. Oommen, S. Jayaraman, Development and performance analysis of compound parabolic solar concentrators with reduced gap losses-V

groove reflector, Renewable Energy 27 (2002) 259275.

[7] M. Collares Pereiras, M.J. Carvalho, New low concentration CPC type collector with convection controlled by a honeycomb TIM material: a

compromise with stagnation temperature control and survival of cheap fabrication materials, ISES Solar World Congress, Solar Energy for

sustainable Future, 2003.

[8] Y. Tripanagnostopoulos, P. Yianoulis, S. Papaefthimiou, S. Zafeiratos, CPC solar collector with bifacial absorbers, Solar Energy 69 (3) (2000)

191203.

[9] M. Adsten, B. Hellstrom, B. Karlsson, Measurement of radiation on the absorber in an asymmetric CPC collector, Solar Energy 76 (2004)

199206.

[10] P.C. Eames, M. Smyth, B. Norton, The experimental validation of a comprehensive unified model for optics and transfer in line-axis solar

energy systems, Solar Energy 71 (2001) 121133.

[11] Y. Fang, P.C. Eames, T.J. Hyde, B. Norton, Thermal performance of complex multimaterial frames for evacuated glazing, ISES Solar World

Congress, 14th to 19th June 2003, Goteborg, Sweden.

[12] T.K. Mallick, P.C. Eames, T.J. Hyde, B. Norton, The design and experimental characterisation of an asymmetric compound parabolic

photovoltaic concentrator for buiding faade integration in th UK, Solar Energy 77 (2004) 319327.

[13] M.J. Carvalho, M. Collares-Pereira, J.M. Gordon, A. Rabl, Truncation of CPC solar collectors and its effect on energy collection, Solar Energy

35 (5) (1985) 393399.

[14] J.M. Gordon, Ideal solar concentrators for photoelectrohemical cells, Solar Energy 40 (4) (1988) 391395.

[15] J.A. Duffie, W.A. Beckman, Solar Engineering of Thermal Processes, John Wiley and Sons, New York, 1980.

[16] R. Tchinda, E. Kaptouom, Evaluation Thermique des Performances d'un Distillateur Solaire Fonctionnant en Mode Indirect, African Journal of

Science and Technology 5 (2004) 7991.

[17] D.R. Mills, I.M. Bassett, G.H. Derrick, Relative cost-effectiveness of CPC reflector designs suitable for evacuated absorber tube solar collectors,

Solar Energy 36 (3) (1986) 199206.

[18] W. Eisenmann, K. Vjen, H. Ackermann, On the correlations collector efficiency factor and material content of parallel flow-plate solar

collectors, Solar Energy 76 (2004) 381387.

[19] Th. Fend, B. Hoffschmidt, G. Jorgensen, H. Kuster, D. Kruger, R. Pitz-Paal, P. Rietbrock, K.J. Riffelmann, Comparative assessment of solar

concentrator materials, Solar Energy 74 (2003) 149155.

[20] A. Rabl, Optical and thermal properties of compound parabolic concentrators, Solar Energy 18 (1976) 497511.

718 R. Tchinda, N. Ngos / International Communications in Heat and Mass Transfer 33 (2006) 709718

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Steady Heat Conduction: Heat and Mass Transfer: Fundamentals & ApplicationsDocumento53 páginasSteady Heat Conduction: Heat and Mass Transfer: Fundamentals & ApplicationsMiguel RamirezAinda não há avaliações

- Development of Heat Transfer Coefficient Correlation For Concentric Helical Coil Heat ExchangerDocumento9 páginasDevelopment of Heat Transfer Coefficient Correlation For Concentric Helical Coil Heat ExchangerCaroline RodriguesAinda não há avaliações

- HTC Explained Star CCMDocumento25 páginasHTC Explained Star CCMramsinntAinda não há avaliações

- Combined Convection and Radiation Report - OdtDocumento9 páginasCombined Convection and Radiation Report - OdtPasindu MalithAinda não há avaliações

- 6753866-Project Helical Coil Heat ExchangerDocumento60 páginas6753866-Project Helical Coil Heat ExchangerP K MisraAinda não há avaliações

- Performance of An Industrial Solar Kiln For Drying TimberDocumento15 páginasPerformance of An Industrial Solar Kiln For Drying TimberResearcherzAinda não há avaliações

- Skin Temp of Pipe Exposed To SunDocumento8 páginasSkin Temp of Pipe Exposed To SunDebasis PalAinda não há avaliações

- 1994-A Convective Transport Theory For FluxesDocumento20 páginas1994-A Convective Transport Theory For FluxesResearcherzAinda não há avaliações

- Acoustics of Ducts and Mufflers-MunjalDocumento160 páginasAcoustics of Ducts and Mufflers-Munjalconcord1103100% (2)

- 1984-Financial Analysis of Solar Energy Applications WithDocumento10 páginas1984-Financial Analysis of Solar Energy Applications WithResearcherzAinda não há avaliações

- 1985-Solar Transmitance Charachterstic of ETC With Diffuse Back ReflectorsDocumento10 páginas1985-Solar Transmitance Charachterstic of ETC With Diffuse Back ReflectorsResearcherzAinda não há avaliações

- 1985-Materials Research For Passive Solar System - PCMDocumento56 páginas1985-Materials Research For Passive Solar System - PCMResearcherzAinda não há avaliações

- 1993-Low Mass Flow Rate in Flat-Plate LiquidDocumento17 páginas1993-Low Mass Flow Rate in Flat-Plate LiquidResearcherzAinda não há avaliações

- 1994-Measurment of The Exterior Convective Film Coeficint For Windows in Low Rise BuildingDocumento17 páginas1994-Measurment of The Exterior Convective Film Coeficint For Windows in Low Rise BuildingResearcherzAinda não há avaliações

- 1984-A Modification 2the F-Chart & F-Chart Method ForDocumento139 páginas1984-A Modification 2the F-Chart & F-Chart Method ForResearcherzAinda não há avaliações

- 1980-Aquifer Thermal Energy Storage-A SurveyDocumento52 páginas1980-Aquifer Thermal Energy Storage-A SurveyResearcherzAinda não há avaliações

- 1978-Commercial Applications of Total Solar Energy SystmsDocumento55 páginas1978-Commercial Applications of Total Solar Energy SystmsResearcherzAinda não há avaliações

- 1982-Solar Optical Properties of WindowsDocumento11 páginas1982-Solar Optical Properties of WindowsResearcherzAinda não há avaliações

- 1978-Solar Technology To Today's Energy NeedSDocumento519 páginas1978-Solar Technology To Today's Energy NeedSResearcherzAinda não há avaliações

- 1981-Tubular Solar Collector AnalysisDocumento267 páginas1981-Tubular Solar Collector AnalysisResearcherzAinda não há avaliações

- 1977-Analysis of Gaas & Si Solar Energy Hybrid SystemsDocumento92 páginas1977-Analysis of Gaas & Si Solar Energy Hybrid SystemsResearcherzAinda não há avaliações

- 2010-Efficient Solar Air Heater With Perforated Absorber For Crop DryingDocumento9 páginas2010-Efficient Solar Air Heater With Perforated Absorber For Crop DryingResearcherzAinda não há avaliações

- 1978-A Solar Test Collector 4 Evalutation of Both Selective N NonDocumento51 páginas1978-A Solar Test Collector 4 Evalutation of Both Selective N NonResearcherzAinda não há avaliações

- 2005-Developing A Theoretical Model To Investigate Thermal Performance of A Thin HPDocumento17 páginas2005-Developing A Theoretical Model To Investigate Thermal Performance of A Thin HPResearcherzAinda não há avaliações

- 2012-Study of A Solar Water Heater Using Stationary V-Trough CollectorDocumento9 páginas2012-Study of A Solar Water Heater Using Stationary V-Trough CollectorResearcherzAinda não há avaliações

- Development of Solar Technology For Drying Fruits andDocumento1 páginaDevelopment of Solar Technology For Drying Fruits andResearcherzAinda não há avaliações

- 1975-Flat-Plate Solar-Collector Performance EvaluationDocumento52 páginas1975-Flat-Plate Solar-Collector Performance EvaluationResearcherzAinda não há avaliações

- 2012-Applying Artificial Neural Network For Drying TimeDocumento10 páginas2012-Applying Artificial Neural Network For Drying TimeResearcherzAinda não há avaliações

- 2009-A Study of The Effect of Solar Drying System On Rice QualityDocumento8 páginas2009-A Study of The Effect of Solar Drying System On Rice QualityResearcherzAinda não há avaliações

- 2009-Indirect and Mixed Mode Solar Drying Mathematical ModelsDocumento10 páginas2009-Indirect and Mixed Mode Solar Drying Mathematical ModelsResearcherzAinda não há avaliações

- 2010-Mathematical Modeling of Forced Convection Thin LayerDocumento8 páginas2010-Mathematical Modeling of Forced Convection Thin LayerResearcherzAinda não há avaliações

- 2007-Modelling and Simulation of Pear DryingDocumento9 páginas2007-Modelling and Simulation of Pear DryingResearcherzAinda não há avaliações

- 2009-Solar Drying of Peeled Longan Using A Side LoadingDocumento11 páginas2009-Solar Drying of Peeled Longan Using A Side LoadingResearcherzAinda não há avaliações

- Effect of Temperature, Relative Humidity and Air On DryingDocumento6 páginasEffect of Temperature, Relative Humidity and Air On DryingResearcherzAinda não há avaliações

- Solar Kilns To Dry WoodDocumento5 páginasSolar Kilns To Dry WoodResearcherzAinda não há avaliações

- Solar Crop Drying DemonstrationsDocumento32 páginasSolar Crop Drying DemonstrationsResearcherzAinda não há avaliações

- Useful Tips For Designing Thermal Insulation SystemsDocumento25 páginasUseful Tips For Designing Thermal Insulation SystemsEddie FongAinda não há avaliações

- Donohue Method of Baffled Heat ExchangerDocumento28 páginasDonohue Method of Baffled Heat ExchangerArun VermaAinda não há avaliações

- 2 Shell and Tube ExchangerDocumento8 páginas2 Shell and Tube ExchangerarulrakkAinda não há avaliações

- Heat Transfer LabDocumento11 páginasHeat Transfer LabstopnaggingmeAinda não há avaliações

- Convective Heat Transfer PDFDocumento13 páginasConvective Heat Transfer PDFCarlos Eduardo Noreña OssaAinda não há avaliações

- Ramdas Osborne Ortt 1980 PDFDocumento10 páginasRamdas Osborne Ortt 1980 PDFSebastian PinzonAinda não há avaliações

- Prob. Sheet Basic ConceptsDocumento3 páginasProb. Sheet Basic ConceptsAnonymous mXicTi8hBAinda não há avaliações

- Chapter - 6 - Pengantar KonveksiDocumento46 páginasChapter - 6 - Pengantar KonveksiAldy GustaAinda não há avaliações

- T7COMDocumento487 páginasT7COMrudresh JmAinda não há avaliações

- Solar Water Distilator ProjectDocumento34 páginasSolar Water Distilator Projectas1510Ainda não há avaliações

- Question Bank On Unit 4Documento8 páginasQuestion Bank On Unit 4Zia AhmedAinda não há avaliações

- Lab Manual: Heat Transfer Lab 5ME4-22 Mechanical Engineering YearDocumento68 páginasLab Manual: Heat Transfer Lab 5ME4-22 Mechanical Engineering YearAbhishek SAinda não há avaliações

- 03 Reference Material HMT ME302 Steady Heat Conduction PDFDocumento38 páginas03 Reference Material HMT ME302 Steady Heat Conduction PDFhimanshu singhAinda não há avaliações

- Lecture Notes On Heat Mass TransferDocumento504 páginasLecture Notes On Heat Mass TransfervisAinda não há avaliações

- Natural Convection LatestDocumento38 páginasNatural Convection LatestPradyumna Dhamangaonkar50% (2)

- A Refined Two Zone Heat Release Model For Combustion Analysis in SI EnginesDocumento10 páginasA Refined Two Zone Heat Release Model For Combustion Analysis in SI EnginesCarlos Gilberto Villamar LinaresAinda não há avaliações

- Tutorial 2 Heat Transfer Answer Bmm3513 Sem 1-12-13Documento2 páginasTutorial 2 Heat Transfer Answer Bmm3513 Sem 1-12-13Suhadahafiza Shafiee100% (1)

- Alhusseini - Falling Film Evaporation of Single Component LiquidDocumento10 páginasAlhusseini - Falling Film Evaporation of Single Component LiquidNatrix2Ainda não há avaliações

- An Optimization Study On Soot-Blowing of Air Preheaters in Coal-Fired Power Plant BoilersDocumento15 páginasAn Optimization Study On Soot-Blowing of Air Preheaters in Coal-Fired Power Plant BoilersavgpaulAinda não há avaliações

- 10Documento66 páginas10Praveen100% (1)

- Finite Element Method Mid Term Exam Question PaperDocumento4 páginasFinite Element Method Mid Term Exam Question PaperSRES MECHAinda não há avaliações

- HMT Unit 3Documento26 páginasHMT Unit 3Muthuvel MAinda não há avaliações

- Problems: Heat TransferDocumento7 páginasProblems: Heat TransferKinna VnezhAinda não há avaliações

- Tube Banks Single-Phase Heat Transfer inDocumento22 páginasTube Banks Single-Phase Heat Transfer inarif aktaşAinda não há avaliações