Escolar Documentos

Profissional Documentos

Cultura Documentos

Earthing Conductor Sizing-Tsl - Pellet

Enviado por

SwasrikanthDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Earthing Conductor Sizing-Tsl - Pellet

Enviado por

SwasrikanthDireitos autorais:

Formatos disponíveis

EARTHING CONDUCTOR SIZING CALCULATION SHEET

This sheet is the cover sheet for all subsequent sheets having the same document number. The revision index and a brief description of the revision shall be entered on the cover sheet. The last revision index shall be added to the document number on the cover sheet an equally applies to all sheets having that document number. The new revision index is shown on all sheets.

Table of Contents

Free Area for Client Logo and Data

RMS/JRY Name

09.6.2009 Date

HKM Name Checked

DNB Name

09.6.2009 Date Released

Reference

First Issue

Rev.

Prepared/Changed

Status

Kind of Revision

Copying of this document, and disclosure of it to others and the use or communication of the contents thereof, are forbidden without express written authority by Lurgi Metallurgie GmbH. Offenders are liable to the payment of damages All

Plant Module Assembly

Technology GmbH

Component

DG

Eng.Serv.-No.

Eng.Serv.Title

Larsen & Toubro Limited

Original Size Scale

MEF

Calculation Sheet

CALCULATION :

A4

DCC

_

Basis Document

EARTHING CONDUCTOR SIZING CALCULATION

_

Job name:

_

Job-No.: Document-No.: Page : Rev.

TATA PELLET

O8121

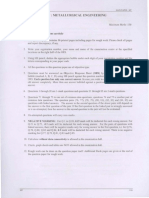

Calculation of Conductor Size of Subsoil Ground Grid

REFERENCE : IEEE Std 80 - 2000 - IEEE Guide for safety in AC Substation Grounding

A mm 2

Ix

tc x r x r x 10 4 / TCAP l n [(K 0 +T m ) / (K 0 +T a )]

Parameters

Value 3

Unit Sec

tc=durationoffaultcurrentforcalculatingconductorsizeofsubsoilground

grid.

Remarks As per TISCO spec.

ar=Thermalcoefficientofresistivityatreferencetemparetureof20Deg.Cof

subsoilgroundgridconductormaterial.

0.0016

Per OC

Refer Table - 1 of IEEE - 80 - 2000 For Steel

r=Resistivityofsubsoilgroundgrodconductormaterialatreferecce

temperatureof20Deg.C TCAP=Thermalcapacityperunitvolume

15.9

Refer Table - 1 of micro Ohm Cm IEEE - 80 - 2000 For Steel Refer Table - 1 of IEEE - 80 - 2000 For Steel Refer Table - 1 of IEEE - 80 - 2000 For Steel Refer Table - 2 of IEEE - 80 - 2000 For Steel Assumed As per TISCO spec.

3.28

J / (cm3.OC)

K0 Tm=Maximumallowabletemperatureforsubsoilgroundgridconductor

material.

605

1510

Ta=designgroundtemperature

I=Symmetricalsinglelinetogroundfaultcurrentforcalculating conductorsizeofsubsoilgroundgrid.

50

40

KA

Amm2=Conductorsizeofsubsoilgroundgrid(min)

Concidured conductor size is 75x10 Sqmm This size is ok, if value of Amm < Concidered conductor size is TRUE

2

563.5676423 750 TRUE

Sqmm Sqmm

IEEE Std 80-2000

IEEE GUIDE FOR SAFETY

Table 1Material constants

Fusinga temperature Tm (C) 1083

Description

Material conductivity (%)

r factor at 20 C (1/C)

Ko at 0 C (0 C)

r 20 C (cm)

TCAP thermal capacity [J/(cm3C)]

Copper, annealed soft-drawn Copper, commercial hard-drawn Copper-clad steel wire Copper-clad steel wire Copper-clad steel rodb Aluminum, EC grade Aluminum, 5005 alloy Aluminum, 6201 alloy Aluminum-clad steel wire Steel, 1020 Stainless-clad steel rodc Zinc-coated steel rod Stainless steel, 304

100.0

0.003 93

234

1.72

3.42

97.0

0.003 81

242

1084

1.78

3.42

40.0

0.003 78

245

1084

4.40

3.85

30.0

0.003 78

245

1084

5.86

3.85

20.0

0.003 78

245

1084

8.62

3.85

61.0

0.004 03

228

657

2.86

2.56

53.5

0.003 53

263

652

3.22

2.60

52.5

0.003 47

268

654

3.28

2.60

20.3 10.8 9.8

0.003 60 0.001 60 0.001 60

258 605 605

657 1510 1400

8.48 15.90 17.50

3.58 3.28 4.44

8.6

0.003 20

293

419

20.10

3.93

2.4

0.001 30

749

1400

72.00

4.03

aFrom ASTM standards. bCopper-clad steel rods based on 0.254 mm (0.010 in) copper thickness. cStainless-clad steel rod based on 0.508 mm (0.020 in) No. 304 stainless

steel thickness over No. 1020 steel core.

Equation (37) and Equation (38), in conjunction with Equation (39) (which denes TCAP), reect two basic assumptions a) b) That all heat will be retained in the conductor (adiabatic process). That the product of specic heat (SH) and specic weight (SW), TCAP, is approximately constant because SH increases and SW decreases at about the same rate. For most metals, these premises are applicable over a reasonably wide temperature range, as long as the fault duration is within a few seconds.

42

Copyright 2000 IEEE. All rights reserved.

IEEE Std 80-2000

IEEE GUIDE FOR SAFETY

tc Kf

is the current duration in s is the constant from Table 2 for the material at various values of Tm (fusing temperature or limited conductor temperature based on 11.3.3) and using ambient temperature (Ta) of 40 C Table 2Material constants

Material Conductivity (%) 100.0 97.0 97.0 40.0 30.0 20.0 61.0 53.5 52.5 20.3 10.8 9.8 8.6 2.4 Tm a (C) 1083 1084 250 1084 1084 1084 657 652 654 657 1510 1400 419 1400 Kf 7.00 7.06 11.78 10.45 12.06 14.64 12.12 12.41 12.47 17.20 15.95 14.72 28.96 30.05

Copper, annealed soft-drawn Copper, commercial hard-drawn Copper, commercial hard-drawn Copper-clad steel wire Copper-clad steel wire Copper-clad steel rod Aluminum EC Grade Aluminum 5005 Alloy Aluminum 6201 Alloy Aluminum-clad steel wire Steel 1020 Stainless clad steel rod Zinc-coated steel rod Stainless steel 304

aSee

11.3.3 for comments concerning material selection.

Examples: Using Equation (42) for a 20 kA, 3 s fault a) For soft drawn copper Akcmil = 20 7.00 3

= 242.5 kcmil use 250 kcmil b) For 40% conductivity copper-clad steel conductor Akcmil = 20 10.45 = 362.0 kcmil use 19/#7 conductor 3

44

Copyright 2000 IEEE. All rights reserved.

Você também pode gostar

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsAinda não há avaliações

- Jamalpur Earthing Calculation Final PDFDocumento10 páginasJamalpur Earthing Calculation Final PDFarafinAinda não há avaliações

- D2.07 Non Segregated Phase Bus DuctsDocumento3 páginasD2.07 Non Segregated Phase Bus DuctsSaraswatapalitAinda não há avaliações

- Wastegate Turbochargers - Description, OperationDocumento17 páginasWastegate Turbochargers - Description, OperationHamilton Miranda100% (1)

- รายการคำนวณถังน้ำมันกลมIKEA PDFDocumento3 páginasรายการคำนวณถังน้ำมันกลมIKEA PDFGooddayBybs0% (1)

- 33 KV Cable Sizing CalculationDocumento3 páginas33 KV Cable Sizing CalculationmohanadsamaraAinda não há avaliações

- Is 10118 2 1982Documento63 páginasIs 10118 2 1982kpr_02161371Ainda não há avaliações

- NTDC Requirement For 132kV & 220kV GridsDocumento8 páginasNTDC Requirement For 132kV & 220kV GridsmuzammiliqbalAinda não há avaliações

- Oil Soak Pit CalculationDocumento2 páginasOil Soak Pit CalculationROHIT MCAinda não há avaliações

- REC Construction Standards: Name of The SpecificationDocumento9 páginasREC Construction Standards: Name of The SpecificationJasmin ShethAinda não há avaliações

- Cal-Mn Dastur T2117 Rev 2Documento4 páginasCal-Mn Dastur T2117 Rev 2Shubham BaderiyaAinda não há avaliações

- 2240 162 Pve U 004 SHT 3 3 01Documento13 páginas2240 162 Pve U 004 SHT 3 3 01Anagha DebAinda não há avaliações

- 132kv Malana Ekd-Section-Rev01 ModifiedDocumento1 página132kv Malana Ekd-Section-Rev01 ModifiedannuvyasAinda não há avaliações

- DSLP (Control Room) DhamraiDocumento3 páginasDSLP (Control Room) DhamraiarafinAinda não há avaliações

- NGR Brochure 2009Documento7 páginasNGR Brochure 2009Amit sahaAinda não há avaliações

- Earthing System PDFDocumento24 páginasEarthing System PDFasexyguyAinda não há avaliações

- Aluminium Pipe Bus PDFDocumento6 páginasAluminium Pipe Bus PDFaviral mishraAinda não há avaliações

- CT Sizing For MalawiDocumento2 páginasCT Sizing For MalawiDharmenderSinghChoudharyAinda não há avaliações

- List of Is Standards For Substation EquipmentsDocumento9 páginasList of Is Standards For Substation EquipmentsRajj Pruthivi100% (1)

- 66 - KV - CT - PT - R5 - Metering - Jan - 10 GETCO PDFDocumento33 páginas66 - KV - CT - PT - R5 - Metering - Jan - 10 GETCO PDFRupesh ChowdaryAinda não há avaliações

- IEEE STD 80 2013 Guide For Safety of ACDocumento20 páginasIEEE STD 80 2013 Guide For Safety of ACadel zrafiAinda não há avaliações

- Earth Design-33kV-Assignment-Rev1Documento9 páginasEarth Design-33kV-Assignment-Rev1Vipinraj KrishnanAinda não há avaliações

- Is 13235.1991 PDFDocumento32 páginasIs 13235.1991 PDFAnil MarturiAinda não há avaliações

- Best Practices - Earthing Installations - Myths & FactsDocumento43 páginasBest Practices - Earthing Installations - Myths & FactskapilAinda não há avaliações

- GTP For TransformerDocumento5 páginasGTP For TransformerSatheesh Kumar NatarajanAinda não há avaliações

- Earthing Design & CalculationDocumento10 páginasEarthing Design & CalculationarafinAinda não há avaliações

- CT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5Documento20 páginasCT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5goalex100% (1)

- Design of Insulator - 07.11.11Documento1 páginaDesign of Insulator - 07.11.11Natarajan RamakrishnanAinda não há avaliações

- Substation Earthing by JGNDocumento49 páginasSubstation Earthing by JGNrupamAinda não há avaliações

- KNR Brochure PDFDocumento8 páginasKNR Brochure PDFAlauddin khanAinda não há avaliações

- Technical Standards For Connectivity To The Grid (CEA)Documento14 páginasTechnical Standards For Connectivity To The Grid (CEA)Sanjay RoutAinda não há avaliações

- Type 2 Coordination Chart TeSys IE3-IE4 PDFDocumento28 páginasType 2 Coordination Chart TeSys IE3-IE4 PDFDevendra RawalAinda não há avaliações

- REC Spec.Documento128 páginasREC Spec.Sanjay RoutAinda não há avaliações

- How To Determine Correct Number of Earthing ElectrodesDocumento7 páginasHow To Determine Correct Number of Earthing ElectrodesjayabalkcetAinda não há avaliações

- Short-Circuit AC V2.0Documento15 páginasShort-Circuit AC V2.0Terefe TadesseAinda não há avaliações

- NGR Sizing Calculation As Per IEEE 32Documento3 páginasNGR Sizing Calculation As Per IEEE 32Soumya MukherjeeAinda não há avaliações

- VR La Batterie Edited 15Documento8 páginasVR La Batterie Edited 15SOMU_61Ainda não há avaliações

- W&E Oct 2022 - CompressedDocumento84 páginasW&E Oct 2022 - CompressedVijayendra VKAinda não há avaliações

- Calculation For Earthing MatDocumento11 páginasCalculation For Earthing Matpvpavan0% (1)

- KEC LT XLPE Cables BrochureDocumento28 páginasKEC LT XLPE Cables Brochureabhishek_918100% (1)

- Technical Specs Distribution BoardsDocumento55 páginasTechnical Specs Distribution Boardsnavinchopra1986Ainda não há avaliações

- Technical Specification: Odisha Power Transmission Corporation LimitedDocumento55 páginasTechnical Specification: Odisha Power Transmission Corporation LimitedPritam SinghAinda não há avaliações

- Calculation of Earthing System As Per Ieee 80Documento10 páginasCalculation of Earthing System As Per Ieee 80Fateh Khemissi MilasAinda não há avaliações

- 4-D03108-0 - Conductor Sizing & BPI Cantilever Strength CalculationDocumento13 páginas4-D03108-0 - Conductor Sizing & BPI Cantilever Strength CalculationunnvishnuAinda não há avaliações

- CC-SC Current Calculation Moose-ZebraDocumento4 páginasCC-SC Current Calculation Moose-ZebraSomen SarkarAinda não há avaliações

- CEADocumento34 páginasCEAsubhra100% (1)

- 12 220 KV 4400pF CVTDocumento13 páginas12 220 KV 4400pF CVTAshwin SevariaAinda não há avaliações

- RTCC Cable ScheduleDocumento11 páginasRTCC Cable SchedulearafinAinda não há avaliações

- IS Standard For Isolators and DisconnectorsDocumento44 páginasIS Standard For Isolators and DisconnectorsdillehAinda não há avaliações

- Acsr Panther Conductor Sizing Xls 0 PDFDocumento6 páginasAcsr Panther Conductor Sizing Xls 0 PDFRavindra GoyalAinda não há avaliações

- DSLP CalculationDocumento7 páginasDSLP Calculationravi shankar100% (1)

- 50/75/100 MVA, 220/132 KV & 50/75/100 MVA, 22/33 KV Outdoor SubstationDocumento16 páginas50/75/100 MVA, 220/132 KV & 50/75/100 MVA, 22/33 KV Outdoor Substationdeepthik27Ainda não há avaliações

- Busbar Size CalculationDocumento5 páginasBusbar Size Calculationdermasdemo100% (6)

- Brazing Camara TermograficaDocumento5 páginasBrazing Camara TermograficaKyle BennettAinda não há avaliações

- Temperature Rise Estimations in Rogers High Frequency Circuit Boards Carrying Direct or RF CurrentDocumento2 páginasTemperature Rise Estimations in Rogers High Frequency Circuit Boards Carrying Direct or RF Currentrahul05singhaAinda não há avaliações

- Mechanical Engineering Journal - Experimental Studies and Modeling of Heat Generation in Metal MachiningDocumento29 páginasMechanical Engineering Journal - Experimental Studies and Modeling of Heat Generation in Metal MachiningsleekerableAinda não há avaliações

- 2 B 02 Al59 Cond Equiv Zebra MooseDocumento28 páginas2 B 02 Al59 Cond Equiv Zebra MoosevgovaAinda não há avaliações

- Wake Frequency CalcDocumento4 páginasWake Frequency Calcteban09Ainda não há avaliações

- Toughness Problems in Steel Welded Joints During Fabrication and Service For Thick ComponentsDocumento6 páginasToughness Problems in Steel Welded Joints During Fabrication and Service For Thick Componentsandreahank100% (1)

- Conductors Damage Curves CablesDocumento4 páginasConductors Damage Curves Cablesnegrin100% (1)

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocumento12 páginas02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical Applicationsivanmatijevic100% (1)

- Eirez Vibratory Feeders and Conveyors BrochureDocumento20 páginasEirez Vibratory Feeders and Conveyors BrochureJay Ryan SantosAinda não há avaliações

- Kekuatan Material: Oleh: Drs. Djony Izak Rudyardjo, M.Si Prodi S-1 TeknobiomedikDocumento34 páginasKekuatan Material: Oleh: Drs. Djony Izak Rudyardjo, M.Si Prodi S-1 TeknobiomedikEva FahmadiyahAinda não há avaliações

- SoP Kanmani ChockalingamDocumento3 páginasSoP Kanmani ChockalingamPrakharKulshreshtha100% (1)

- Plastic Analysis AssignmentDocumento6 páginasPlastic Analysis AssignmentLeo DoeAinda não há avaliações

- ENA - 12 - 24 TS For Ducts - Buried Electric CablesDocumento17 páginasENA - 12 - 24 TS For Ducts - Buried Electric CablessdvijayAinda não há avaliações

- Cu Xlpe PVC 0.6 1 KV (N2xa)Documento1 páginaCu Xlpe PVC 0.6 1 KV (N2xa)Fani Dwi PutraAinda não há avaliações

- CBLM Use Hand ToolsDocumento55 páginasCBLM Use Hand ToolsJon Snow75% (12)

- RCD Lecture Note 4 - USD of Non-Rectangular Beams PDFDocumento2 páginasRCD Lecture Note 4 - USD of Non-Rectangular Beams PDFAugosto FraceAinda não há avaliações

- Zinc Chromate PaintDocumento2 páginasZinc Chromate PaintBash MatAinda não há avaliações

- How Disassemble and Reassemble A ComputerDocumento35 páginasHow Disassemble and Reassemble A ComputertheoremineAinda não há avaliações

- 1800cpb2 Series Regulators American MeterDocumento11 páginas1800cpb2 Series Regulators American Meterultron2099ultronAinda não há avaliações

- SEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06Documento20 páginasSEMIKRON Technical Explanation SEMITOP® Classic EN 2021-07-30 Rev-06carlosmitecAinda não há avaliações

- NYYHYDocumento1 páginaNYYHYCiwa DoankAinda não há avaliações

- Parts Plastic Mold Design and Preparation ProcessDocumento19 páginasParts Plastic Mold Design and Preparation ProcessKodhansAinda não há avaliações

- Strip Tensile Properties of Reinforced Geomembranes: Standard Test Method ForDocumento2 páginasStrip Tensile Properties of Reinforced Geomembranes: Standard Test Method ForLupita RamirezAinda não há avaliações

- Reactive Dye PrintingDocumento15 páginasReactive Dye Printingsandipsoni221811Ainda não há avaliações

- Basic PaperDocumento20 páginasBasic PaperRavi Kumar VatturiAinda não há avaliações

- Cars 2 Activity Book Printable 0511 PDFDocumento5 páginasCars 2 Activity Book Printable 0511 PDFGustavo VydraAinda não há avaliações

- Form Inspeksi Mesin MillingDocumento17 páginasForm Inspeksi Mesin MillingSasa MonicaAinda não há avaliações

- Clarify: 740 Premium SeriesDocumento7 páginasClarify: 740 Premium SeriesnodyyyAinda não há avaliações

- GATE Metallurgical Engineering 2008 PDFDocumento12 páginasGATE Metallurgical Engineering 2008 PDFdrashokyvuceAinda não há avaliações

- PCI Chapter 14Documento20 páginasPCI Chapter 14Sergio Adolfo ParedesAinda não há avaliações

- 04 Vertical Roller MillsDocumento12 páginas04 Vertical Roller MillsaktaserdincAinda não há avaliações

- 8.3 Preparation of Salts QPDocumento9 páginas8.3 Preparation of Salts QPjanithaAinda não há avaliações

- BS en 62305-3Documento0 páginaBS en 62305-3Petranthos100% (1)

- 21 Time Guide Old Generation 2012 07 09 - GBDocumento336 páginas21 Time Guide Old Generation 2012 07 09 - GBRezha0% (1)

- Triple Only Static ElectricityDocumento32 páginasTriple Only Static ElectricityMary Ann MaherAinda não há avaliações

- Ishrae - 365 - 2009Documento16 páginasIshrae - 365 - 2009babudevanandAinda não há avaliações