Escolar Documentos

Profissional Documentos

Cultura Documentos

Mechanical seal details

Enviado por

Salsa AmorirDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mechanical seal details

Enviado por

Salsa AmorirDireitos autorais:

Formatos disponíveis

MECHANICAL SEAL

stem of your sy strong link A

SA

MECHANICAL SEAL

SA

13 3 9 2 1 10

CAT006 ENG REV 12.09

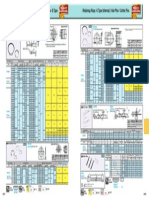

ELEMENTS:

Mass produced mechanical seals

are widely used in pumps and machinery operating at low pressure. The SA is a single component seal, with a type A pinned stationary seat, manufactured in accordance with UNI EN 12756 (ex DIN 24960). It is manufactured with a tapered helical spring with deep coils to reduce the risk of clogging in particularly dirty and/or viscous liquids. Dependent on the direction of shaft rotation it can run either clockwise or anticlockwise. It is more forgiving on installation errors.

1 2 3 9

STATIONARY SEAT ROTARY FACE THRUST RING ROTARY FACE O RING

10 STATIONARY SEAT O RING 13 SPRING

OPERATING CONDITIONS:

DIAMETER: DIAMETER

(mm)

SPEED: SPEED

(m/sec)

PRESSURE: PRESSURE

(bar)

TEMPERATURE: TEMPERATURE

(C)

80 20

10 0

10 0

+220 50

CHARACTERISTICS:

SINGLE MONO-DIRECTIONAL

J

UNIVERSAL APPLICATION HIGH POSITIONING COMPENSATION

UNI

UNI EN 12756

DIRTY & VISCOUS LIQUIDS

MECHANICAL SEAL

SA

STATIONARY SEAT:

SOLID TYPE A

1

l1 l3 l4

l7

Cr-Mo Steel: Y1 Silicon Carbide: U31

TYPE A WITH INSERT

d4 d5 d1 d3 d6 d7

AISI 316+tungsten Carbide: K22

SOLID TYPE C (3) l4

l5x20 l6

R l8

l5x20 l6 5

Spina d8

Graphite Resins impregnated: Z31

STATIONARY SEAT O RING:

Nitrile Rubber: G Ethylene Propylene: D Fluoroelastomer: V Perfluoroelastomer: G711 PTFE: T

d6

d7

10

d1 Seal Diameter h6

20 22 24 20 22 24 25 28 30 32 33 35 38 40 43 45 48 50 53 55 58 60 63 65 68 70 75 80

d3

34 36 38 39 42 44 46 47 49 54 56 59 61 64 66 69 71 78 80 83 85 88 90 99 104

d4

min.

d5

min.

d6

H11

d7

H8

d8

3 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

l1

1

l3

1

l4

10 10 10 10 10 10 10 10 10 11 11 11 11 11 13 13 13 13 13 13 13 15 15 15 15,5

l5

2 2 2 2 2 2 2 2 2 2 2 2 2 2 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 3

l6

5 5 5 5 5 5 5 5 5 6 6 6 6 6 6 6 6 6 6 6 6 7 7 7 7

l7

9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9

l8

4,5 4,5 4,5 4,5 4,5 4,5 4,5 4,5 4,5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5

R

1,5 1,5 1,5 1,5 1,5 1,5 1,5 1,5 1,5 1,5 1,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5 2,5

36 38 40 41 44 46 48 49 51 58 60 63 65 68 70 73 75 83 85 88 90 93 95 104 109

24 27 29 30 33 35 38 39 41 44 47 50 52 55 58 61 63 67 69 72 74 77 80 85 90

29 31 33 34 37 39 42 42 44 49 51 54 56 59 62 65 67 70 72 75 77 81 83 88 95

35 37 39 40 43 45 48 48 50 56 58 61 63 66 70 73 75 78 80 83 85 90 92 97 105

37,5 37,5 40 40 42,5 42,5 42,5 42,5 42,5 45 45 45 45 45 47,5 47,5 47,5 52,5 52,5 52,5 52,5 52,5 60 60 60

27,5 27,5 30 30 32,5 32,5 32,5 32,5 32,5 34 34 34 34 34 34,5 34,5 34,5 39,5 39,5 39,5 39,5 37,5 45 45 44,5

ROTARY FACE:

SOLID

25 28 30 32 33

Cr-Mo Steel: Y1

(Only SC version)

35 38

WITH INSERT

40 43 45

AISI 316+Graphite Resins impr.: Z32 AISI 316+Silicon Carbide: U32 AISI 316+Tungsten Carbide: K22

48 50 53 55 58 60 63 65 68 70 75 80

ROTARY FACE O RING:

Nitrile Rubber: G Ethylene Propylene: D Fluoroelastomer: V Perfluoroelastomer: G711

PTFE with AISI 316 spring: T3

SPRING:

AISI 316: E

13

Dimensions subject to modifications without notice.

RIGHT SPRING R Clockwise rotation looking the seal from the stationary ring side

Example:

To order the seals shown on this page for shaft 40 mm, right spring and material shown in the table below:

2 1 9 10 13 3

U32

LEFT SPRING L Anticlockwise rotation looking the seal from the stationary ring side

U31

E

(4)

The code will be: SA040R - U32U31VEE

OTHER METAL PARTS:

AISI 316: E

NOTES: 1) The material shown on this page is only part of the available range, for other products stock items, please call our Technical Sales Office. 2) The material should be chosen according to the operating conditions. All queries should be sent to our Technical Sales Office. 3) The last letter of the product code SA shows the type A stationary seat with a slot for an antirotation pin: or if a short stationary seat without a slot is required, please request type C. The product code will then be SC. This type is not suitable for seals in PTFE. 4) When the material of the seal on the stationary seat O ring is the same as the seal on the rotary face O ring the product code is not repeated.

FLUITEN ITALIA SpA 20016 PERO (Milano) Italy Via L. da Vinci, 14 Tel. +39 02.339403.1 Fax +39 02.3538641 E-mail: info@fluiten.it www.fluiten.it

Você também pode gostar

- TYCO Keystone F14.Lined - Butterfly.valve enDocumento4 páginasTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuAinda não há avaliações

- Ex Junction BoxDocumento26 páginasEx Junction BoxMiky MooseAinda não há avaliações

- Fits & TolerancesDocumento6 páginasFits & Tolerancessuperman92makAinda não há avaliações

- Hydraulic Rod EndsDocumento10 páginasHydraulic Rod EndsRolffoTelloAinda não há avaliações

- Bringing valuable water solutions to various applicationsDocumento32 páginasBringing valuable water solutions to various applicationsAhmadMoaazAinda não há avaliações

- Shimpo Able VRL BrochureDocumento4 páginasShimpo Able VRL BrochureElectromateAinda não há avaliações

- bl01 Aa0104 4Documento6 páginasbl01 Aa0104 4chris110Ainda não há avaliações

- 26 HHW Katalog 2010 Eng UniversaleDocumento10 páginas26 HHW Katalog 2010 Eng Universalecos2012Ainda não há avaliações

- Fender Accessories (Panels, Chains, Brackets) Catalogue en V1.3Documento10 páginasFender Accessories (Panels, Chains, Brackets) Catalogue en V1.3loicdertyAinda não há avaliações

- Catalogo HydacDocumento392 páginasCatalogo HydacFrancisco Hernandez0% (1)

- Drill Stem Components GuideDocumento28 páginasDrill Stem Components Guidechonubobby100% (1)

- Actuator BARDocumento16 páginasActuator BARRohit GadekarAinda não há avaliações

- Parts Manual Rexel Shredder 1400 & 4000Documento24 páginasParts Manual Rexel Shredder 1400 & 4000Raltec Ltd100% (2)

- Service and Parts Manual Rexel Shredder 1350-3250 Heavy DutyDocumento50 páginasService and Parts Manual Rexel Shredder 1350-3250 Heavy DutyRaltec Ltd67% (3)

- Hydraulic Cylinder Parker 3lDocumento48 páginasHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- Maintenance Arpex enDocumento39 páginasMaintenance Arpex enPatrick BaridonAinda não há avaliações

- Seguros R - Hairpin Cotter Pin p2017Documento1 páginaSeguros R - Hairpin Cotter Pin p2017MAZM17Ainda não há avaliações

- Manual Rotex CouplingDocumento21 páginasManual Rotex CouplingAndrei MorariuAinda não há avaliações

- TS Apollo 50Documento8 páginasTS Apollo 50Carlos GonzalezAinda não há avaliações

- QF Series - Metric Compact CylindersDocumento1 páginaQF Series - Metric Compact Cylindersalex araAinda não há avaliações

- Spidex OperatingDocumento10 páginasSpidex Operatingwalk001Ainda não há avaliações

- Acoples FalkDocumento3 páginasAcoples FalkluispereirapAinda não há avaliações

- Rexnord Elastomer CouplingDocumento20 páginasRexnord Elastomer Couplingidontlikeebooks100% (1)

- Annovi Reverberi Sprayer Pump AR 115 BPDocumento2 páginasAnnovi Reverberi Sprayer Pump AR 115 BPGörögh ImreAinda não há avaliações

- DIN 3015 ClampsDocumento20 páginasDIN 3015 ClampsRasheshAinda não há avaliações

- Butterfly Valve Features and SpecsDocumento4 páginasButterfly Valve Features and SpecsteacgAinda não há avaliações

- Spur Gears 9: Series 101Documento52 páginasSpur Gears 9: Series 101Aiam PandianAinda não há avaliações

- Centrifugal PumpDocumento32 páginasCentrifugal PumpAshok SrivatsanAinda não há avaliações

- TTM Post TensioningDocumento103 páginasTTM Post Tensioninghorea67100% (2)

- FLURO Motor Sport Cataloque EnglishDocumento16 páginasFLURO Motor Sport Cataloque EnglishRMCsportAinda não há avaliações

- 132kV Cable Installation Tools List and Transformer Accessories ListDocumento8 páginas132kV Cable Installation Tools List and Transformer Accessories Listvsureshkumar.eeeAinda não há avaliações

- Shimpo Able VRS BrochureDocumento4 páginasShimpo Able VRS BrochureElectromateAinda não há avaliações

- Heavy Duty Dixon Valves Model DX PN16 1-PC Stainless Steel Flange EndDocumento1 páginaHeavy Duty Dixon Valves Model DX PN16 1-PC Stainless Steel Flange Endjavier carvajalAinda não há avaliações

- Im 350 PartsDocumento4 páginasIm 350 Partsmrdjordan1100% (1)

- Clutch-Brake Coupling: Stationary Field Bearing Mounted Pin Drive Model 308Documento2 páginasClutch-Brake Coupling: Stationary Field Bearing Mounted Pin Drive Model 308ElectromateAinda não há avaliações

- 07Documento133 páginas07ROboii FavelaAinda não há avaliações

- SKF Bearing Fitting Tool TMFT 33Documento2 páginasSKF Bearing Fitting Tool TMFT 33Nang Dapi100% (1)

- Parts Guide Manual Bizhub C552 - Bizhub C652Documento214 páginasParts Guide Manual Bizhub C552 - Bizhub C652Hugo Luis Escalante88% (8)

- ValvesDocumento10 páginasValvesInigoAinda não há avaliações

- AMRI ISORIA 16 Type Series Booklet DataDocumento20 páginasAMRI ISORIA 16 Type Series Booklet Datarudiskw456Ainda não há avaliações

- Cilindros Hidráulicos Parker - 2H - 1110-UkDocumento42 páginasCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroAinda não há avaliações

- Bizhub c252 Parts ManualDocumento107 páginasBizhub c252 Parts ManualAdrian Araujo100% (1)

- WNT Catalogue 2016 - 07 Thread Turning PDFDocumento47 páginasWNT Catalogue 2016 - 07 Thread Turning PDFMani StoqnovaAinda não há avaliações

- PVH Sight Glass Data SheetDocumento11 páginasPVH Sight Glass Data SheetANIKET PATILAinda não há avaliações

- Roller Screw BrochureDocumento8 páginasRoller Screw BrochureRjgandhi65Ainda não há avaliações

- Protect equipment and processes with a compact line strainerDocumento3 páginasProtect equipment and processes with a compact line strainersanthoshkrishnaAinda não há avaliações

- Tecumseh Model Oh140 160027a Parts ListDocumento9 páginasTecumseh Model Oh140 160027a Parts ListpaulpaulAinda não há avaliações

- Single: GLE Range ofDocumento8 páginasSingle: GLE Range ofNghia HuynhAinda não há avaliações

- A63 A64 Cylinder PDFDocumento5 páginasA63 A64 Cylinder PDFhdaamirAinda não há avaliações

- 37° Flared Tube Fitting GuideDocumento13 páginas37° Flared Tube Fitting GuidehernychtAinda não há avaliações

- Plummer Block Housings: FeaturesDocumento3 páginasPlummer Block Housings: FeaturesrefeiAinda não há avaliações

- Din Reactors CEDocumento3 páginasDin Reactors CEvallamreddyAinda não há avaliações

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityAinda não há avaliações

- ImmortalDocumento4 páginasImmortalMaNithyaVishalanandaAinda não há avaliações

- Connorized Classical CatalogDocumento37 páginasConnorized Classical CatalogPablo Olea RodríguezAinda não há avaliações

- Elcometer Wet-Film Gage 115 Spec SheetDocumento2 páginasElcometer Wet-Film Gage 115 Spec SheetMary CasillasAinda não há avaliações

- RFIADocumento11 páginasRFIAMary Joy TorresAinda não há avaliações

- D-Glucitol (420i) Dextrose MonohydrateDocumento3 páginasD-Glucitol (420i) Dextrose MonohydrateSilvia Melendez HAinda não há avaliações

- CBSE Class 11 English Sample Paper Set 5Documento8 páginasCBSE Class 11 English Sample Paper Set 5Shantam BasuAinda não há avaliações

- Design Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Documento36 páginasDesign Basis Events FOR Pressurised Heavy Water Reactor: Aerb Safety Guide No - Aerb/Sg/D-5Anuj DeoAinda não há avaliações

- Operator Identities 2Documento3 páginasOperator Identities 2jasmonAinda não há avaliações

- Output Configurations and Connections: NPN Open CollectorDocumento2 páginasOutput Configurations and Connections: NPN Open Collectordorin serbanAinda não há avaliações

- The War Archives - Machinery of Conflict. British Military Trucks of WWIIDocumento84 páginasThe War Archives - Machinery of Conflict. British Military Trucks of WWIISebastijan Kerše100% (10)

- Chapter 1 Engineering ManagementDocumento4 páginasChapter 1 Engineering ManagementGeorge Russell80% (5)

- Fischer Carbene Complexes in Organic SynthesisDocumento9 páginasFischer Carbene Complexes in Organic SynthesisNorah AltayyarAinda não há avaliações

- TOEFL Module 1 - ReadingDocumento65 páginasTOEFL Module 1 - ReadingImam NurviyantoAinda não há avaliações

- Lesson Plan 2aDocumento5 páginasLesson Plan 2aapi-332424736Ainda não há avaliações

- June 2023 BillingDocumento10 páginasJune 2023 BillingEsther AkpanAinda não há avaliações

- Qanooneislamorcu 00 JafaDocumento646 páginasQanooneislamorcu 00 JafaawAinda não há avaliações

- Ring OnlyDocumento2 páginasRing Onlyapi-3834777Ainda não há avaliações

- 13.phase Feeding and Feeding SystemsDocumento21 páginas13.phase Feeding and Feeding SystemsAsfand Ali SheikhAinda não há avaliações

- Porphyria's Lover - Robert BrowningDocumento9 páginasPorphyria's Lover - Robert Browningdearkatie6688Ainda não há avaliações

- EM 385-1-1 Chapters 20-26Documento179 páginasEM 385-1-1 Chapters 20-26MusabAinda não há avaliações

- DVRP Newsletter Resilience Vol. 2, Issue 2Documento6 páginasDVRP Newsletter Resilience Vol. 2, Issue 2Lucius Doxerie Sr.Ainda não há avaliações

- Raise The Limits: Eppendorf Research PlusDocumento12 páginasRaise The Limits: Eppendorf Research PlusZahia Slama Ep AchourAinda não há avaliações

- The Evolution of Order DiprotodontiaDocumento35 páginasThe Evolution of Order DiprotodontiaMarianne Michelle Quiambao de la RosaAinda não há avaliações

- EV1116 Manual 146251999-4DDocumento32 páginasEV1116 Manual 146251999-4Danitha ferryAinda não há avaliações

- Adept Conveyor Technologies Product ManualDocumento32 páginasAdept Conveyor Technologies Product ManualBagus Eko BudiyudhantoAinda não há avaliações

- M.E. (Mechanical - Heat Power Engineering) SyllabusDocumento37 páginasM.E. (Mechanical - Heat Power Engineering) SyllabusKapil KotangaleAinda não há avaliações

- SWZ Upgrade Points 062022Documento19 páginasSWZ Upgrade Points 062022IcyAviatorAinda não há avaliações

- Climate Change & Disaster Risk Management: Razon, Lovelyn Rivera, Meg Anne Sta. Ines, MaricrisDocumento56 páginasClimate Change & Disaster Risk Management: Razon, Lovelyn Rivera, Meg Anne Sta. Ines, MaricrisMeg Anne Legaspi RiveraAinda não há avaliações

- Sir ClanDocumento109 páginasSir ClanJames AbendanAinda não há avaliações