Escolar Documentos

Profissional Documentos

Cultura Documentos

Denso Marine Piling Tape

Enviado por

ryanbkseahDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Denso Marine Piling Tape

Enviado por

ryanbkseahDireitos autorais:

Formatos disponíveis

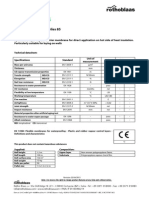

P R O D U C T

D A T A

S H E E T

DENSO MARINE PILING TAPE

Marine Petrolatum Tape with HDPE Backing All Purpose Petrolatum Tape

Description

Denso Marine Piling Tape is composed of a non-woven synthetic fabric carrier, fully impregnated with a compound based on petrolatum containing inert llers, water displacing agents and wide spectrum biocides. It is backed with a thin high density polyethylene lm.

Uses

Denso Marine Piling Tapes are designed to be used without primer to protect dry, wet or submerged surfaces. The tapes provide long term protection to pipes, pilings, risers, anges, valves and related surfaces.

Features

Applied to marginally prepared surfaces (SSPC SP 2-3) Conforms to irregular shapes and proles UV resistant Can be applied to cold, wet surfaces Not effected by water, acid, salts or soil organics Encapsulation of lead paint Contains no solvents Easy application from arctic to tropical temperatures Ready for immediate service after application Does not require a primer Over a sixty-ve year history of proven applications

Application

Prepare surfaces by removing all loose scale, rust or other foreign matter in accordance to SSPC SP2 Hand Tool Cleaning or SP3 Power Tool Cleaning. High pressure water wash of 3,000 - 7,000 psi (20.68-48.26 MPa) is also suitable. Spirally wrap the tape with a minimum 1" (25 mm) overlap. For severely corrosive environments, a 55% overlap is recommended. While wrapping, press air pockets out and smooth all lap seams. For additional mechanical protection, an overwrap may be used to increase impact strength and electrical resistance. Irregular surfaces such as valves, anges, etc. may require the use of Densyl Mastic or Denso Proling Mastic. Refer to the product sheets for these specic products for information on application and selection.

Denso Marine Piling Tape

PROPERTY SPECIFICATIONS

PROPERTIES

Thickness (ASTM D1000) Weight Breaking Strength (ASTM 1000) Water Vapor Transmission (ASTM E96 - 66 Procedure A) Elongation @ Break Breakdown Voltage (55% overlap) Resistance to Cathodic Disbonding (ASTM G-8 - 30 days) Resistance to Acids, Alkalies and Salts Maximum Service Temperature Roll Length

ENGLISH

51 mils .33 lbs/ft 2 22.5 lbf/in. 0.006 perms avg. 10% avg. 16 kV min. .28 in 2 avg. Excellent 125F 33 ft

METRIC

1.3 mm avg. 1.62 kg/m 2 avg. 200 N/50 mm min. 0.006 perms avg. 10% avg. 16 kV min. 180 mm 2 avg. Excellent 52C 10 m

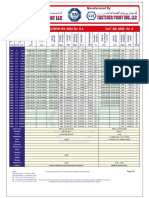

Quantity Estimates

Tape Width in. 2" 4" 6" 8" 12" Rolls*/ Case ea. 36 18 12 8 6 Coverage with 1" Overlap ea. 87 ft 2/case (8.08 m 2) 145 ft2/case (13.47 m 2) 162 ft2/case (15.05 m 2) 150 ft2/case (13.94 m 2) 177 ft2/case (16.44 m 2) Coverage with 55% Overlap ea. 87 ft2/case (8.08 m 2) 87 ft2/case (8.08 m 2) 87 ft2/case (8.08 m 2) 77 ft2/case (7.15m 2) 87 ft2/case (8.08 m 2)

*All rolls are 33 feet (10 meters) in length.

DENSO NORTH AMERICA

HOUSTON: TORONTO: 9747 Whithorn Drive, 90 Ironside Crescent, Houston, Texas, Unit 12, Toronto, U.S.A. 77095 Ontario, Canada M1X1M3 Tel: 281-821-3355 Tel: 416-291-3435 Fax: 281-821-0304 Fax: 416-291-0898 www.densona.com

A Member of Winn & Coales International

The information given on this sheet is intended as a general guide only and should not be used for specication purposes. We believe the information to be accurate and reliable but do not guarantee it. We assume no responsibility for the use of this information. Users must, by their own tests, determine the suitability of the products and information supplied by us for their own particular purposes. No patent liability can be assumed.

VER 11.11M1

Você também pode gostar

- TDS Densyl TapeDocumento4 páginasTDS Densyl TapemukulsareenAinda não há avaliações

- English Trenton Wax Tape SystemsDocumento16 páginasEnglish Trenton Wax Tape SystemsTaylorAinda não há avaliações

- T-Tape Detalii OkDocumento20 páginasT-Tape Detalii OkGrigore DanaAinda não há avaliações

- Polyken 1600 High TempDocumento2 páginasPolyken 1600 High TempKyaw Kyaw AungAinda não há avaliações

- Waterproofing Membrane Installation GuideDocumento5 páginasWaterproofing Membrane Installation GuideatharkAinda não há avaliações

- Denso Glass Outerwrap TDSDocumento3 páginasDenso Glass Outerwrap TDSIwan AgusAinda não há avaliações

- Polyken 932 TapeDocumento2 páginasPolyken 932 TapeKyaw Kyaw AungAinda não há avaliações

- Firestone MembraneDocumento2 páginasFirestone MembraneKrish DoodnauthAinda não há avaliações

- 3M Pipeline Tape Coating System Data SheetDocumento4 páginas3M Pipeline Tape Coating System Data SheetWarlexAinda não há avaliações

- Polyken Utility Tape 900 910 908 911 920Documento2 páginasPolyken Utility Tape 900 910 908 911 920Tracy EvansAinda não há avaliações

- Titanium UDL-50 BROCHURE PDFDocumento2 páginasTitanium UDL-50 BROCHURE PDFHRroofingAinda não há avaliações

- New Guard Coatings Group Protects with Epoxy PrimersDocumento8 páginasNew Guard Coatings Group Protects with Epoxy PrimersshunanlatheefAinda não há avaliações

- 12 TapeDocumento2 páginas12 TapeImtiyaz KhanAinda não há avaliações

- J CreteDocumento8 páginasJ CreteWilber Rojas PilcoAinda não há avaliações

- WCD Viscotaq PE Outerwrap TDSDocumento3 páginasWCD Viscotaq PE Outerwrap TDSvissupleAinda não há avaliações

- Retrowrap HD Specifications (2014)Documento15 páginasRetrowrap HD Specifications (2014)Alfredo Solorzano MaloAinda não há avaliações

- Proofex Torchseal 3P and 4P : Constructive SolutionsDocumento2 páginasProofex Torchseal 3P and 4P : Constructive SolutionsmilanbrasinaAinda não há avaliações

- TEC - TA-550 - Power Grout Spec SheetDocumento2 páginasTEC - TA-550 - Power Grout Spec SheetMark MehnerAinda não há avaliações

- Nukote XT Plus TdsDocumento4 páginasNukote XT Plus TdsAnsar AliAinda não há avaliações

- ESD Tape ApplicationsDocumento6 páginasESD Tape Applicationslordycarlos8588Ainda não há avaliações

- Sigmaprime® 200 Series: Product Data SheetDocumento7 páginasSigmaprime® 200 Series: Product Data SheetkaleshAinda não há avaliações

- Adhesive Film & TapeDocumento6 páginasAdhesive Film & TapeJothi Vel MuruganAinda não há avaliações

- Wavistrong Installation ManualDocumento63 páginasWavistrong Installation ManualRenganathan Prabunath0% (1)

- Polifelt CatalogDocumento28 páginasPolifelt CatalogCreanga CristinaAinda não há avaliações

- Gulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsDocumento6 páginasGulf-O-Flex Insulation Tube & Coil: Dimensions of Box: 50x50x20 CmsRiyas UdheenAinda não há avaliações

- Nitoproof 600Documento4 páginasNitoproof 600sandeepuaeAinda não há avaliações

- en-US 7416Documento7 páginasen-US 7416Movie LoverAinda não há avaliações

- DS HLTP 60 Rev12 1107Documento2 páginasDS HLTP 60 Rev12 1107Luisito Aguilar RojasAinda não há avaliações

- Geotextil TencateDocumento2 páginasGeotextil TencateHugo HiddAinda não há avaliações

- PDS Na GTS80 PDFDocumento2 páginasPDS Na GTS80 PDFAnant RubadeAinda não há avaliações

- Surface Prep & Application of MI-DTI Insulating CoatingDocumento2 páginasSurface Prep & Application of MI-DTI Insulating CoatingYing Kei ChanAinda não há avaliações

- Ups At5 At6 At7 At8 v2 UkDocumento3 páginasUps At5 At6 At7 At8 v2 UkJoe VergheseAinda não há avaliações

- TDS145Documento1 páginaTDS145sompongtAinda não há avaliações

- Tds - Penguard Express - English (Uk) - Issued.24.05Documento4 páginasTds - Penguard Express - English (Uk) - Issued.24.05wey5316Ainda não há avaliações

- Shower Waterproofing SystemDocumento2 páginasShower Waterproofing SystemLoz101Ainda não há avaliações

- Filler For Contraction JointsDocumento5 páginasFiller For Contraction JointsAshok Maan100% (1)

- Infinity NBR PVC Insulation Sheet TubeDocumento2 páginasInfinity NBR PVC Insulation Sheet TubeKumar JbsAinda não há avaliações

- Foster 32-17Documento2 páginasFoster 32-17Mostafa AymanAinda não há avaliações

- Mastic CarbowrapDocumento2 páginasMastic CarbowrapGlishna Peushan WidanapathiranaAinda não há avaliações

- Rothoblaas - Vaporvlies 85.technical Data Sheets - enDocumento2 páginasRothoblaas - Vaporvlies 85.technical Data Sheets - enAndrei GheorghicaAinda não há avaliações

- Targa II 10 Data Sheet Rev 13 1Documento2 páginasTarga II 10 Data Sheet Rev 13 1chandravadiyaketanAinda não há avaliações

- DP490Documento6 páginasDP490transervuk2013Ainda não há avaliações

- Anti-Slip Tapes: Technical Data SheetDocumento2 páginasAnti-Slip Tapes: Technical Data SheetSabuhi JafarliAinda não há avaliações

- PVC Sheetpile-1Documento6 páginasPVC Sheetpile-1Angelica CarreonAinda não há avaliações

- TDS - Masterflow 980Documento4 páginasTDS - Masterflow 980Venkata RaoAinda não há avaliações

- DENSO 50 Heat Shrink Sleeve (DENSO 50HSS)Documento3 páginasDENSO 50 Heat Shrink Sleeve (DENSO 50HSS)jay2kay5793Ainda não há avaliações

- Proofex Torchseal 3S 4S 5S PDFDocumento2 páginasProofex Torchseal 3S 4S 5S PDFmilanbrasinaAinda não há avaliações

- Mileflex Technical SpecificationDocumento2 páginasMileflex Technical SpecificationAaron Homing NiAinda não há avaliações

- 0 LXCwy F5 VH UVe PYf RNkoy 5 A 7 CDocumento28 páginas0 LXCwy F5 VH UVe PYf RNkoy 5 A 7 CAmit ChahandeAinda não há avaliações

- Dynamelt PUR Series Adhesive Bag MelterDocumento2 páginasDynamelt PUR Series Adhesive Bag MelterITWDynatecAinda não há avaliações

- Application Instructions Denso Butyl Tape System1Documento4 páginasApplication Instructions Denso Butyl Tape System1Khoh Kai ShengAinda não há avaliações

- Guxiandao E BrochureDocumento18 páginasGuxiandao E Brochurehamidrahmany3657Ainda não há avaliações

- Proofex Torchseal (PE)Documento2 páginasProofex Torchseal (PE)kalidindivenkatarajuAinda não há avaliações

- Dr. Fixit Prebond: Hdpe Pre Applied Fully Bonded MembraneDocumento3 páginasDr. Fixit Prebond: Hdpe Pre Applied Fully Bonded Membranevelmurug_balaAinda não há avaliações

- Sikaflex®-11 FC: Product Data SheetDocumento3 páginasSikaflex®-11 FC: Product Data SheetHaradhon DattaAinda não há avaliações

- Dr. Fixit Roofseal Top Coat WaterproofingDocumento3 páginasDr. Fixit Roofseal Top Coat WaterproofingreshmitapallaAinda não há avaliações

- Geotextiles and Geomembranes HandbookNo EverandGeotextiles and Geomembranes HandbookT.S. IngoldNota: 5 de 5 estrelas5/5 (1)

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsNo EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsNota: 5 de 5 estrelas5/5 (1)

- 4.3 Overview For Splash ProDocumento4 páginas4.3 Overview For Splash ProryanbkseahAinda não há avaliações

- SR en 10025-04Documento8 páginasSR en 10025-04pukla100% (2)

- Water Proofing by Impregnation With Isobutyltriethoxy SilaneDocumento3 páginasWater Proofing by Impregnation With Isobutyltriethoxy SilaneryanbkseahAinda não há avaliações

- Water Proofing by Impregnation With Isobutyltriethoxy SilaneDocumento3 páginasWater Proofing by Impregnation With Isobutyltriethoxy SilaneryanbkseahAinda não há avaliações

- Tide Table Bintulu Port 2012Documento6 páginasTide Table Bintulu Port 2012ryanbkseahAinda não há avaliações

- Bureau of Engineering Manual Structural Design Loads GuideDocumento23 páginasBureau of Engineering Manual Structural Design Loads Guidetali_bergerAinda não há avaliações

- Semiconductor PhysicsDocumento37 páginasSemiconductor Physicsgirishkumardarisi254Ainda não há avaliações

- Tutorial 5 HExDocumento16 páginasTutorial 5 HExishita.brahmbhattAinda não há avaliações

- Pile Cap For 1 PilesDocumento5 páginasPile Cap For 1 Pileshemantkle2u80% (5)

- 08 Deforming Solids 08Documento4 páginas08 Deforming Solids 08Ashani0001Ainda não há avaliações

- PPTCHAEN21 - Lecture Unit 2. Material Property ChartsDocumento20 páginasPPTCHAEN21 - Lecture Unit 2. Material Property ChartsLady PenalozaAinda não há avaliações

- Industrial Materials and ProcessesDocumento14 páginasIndustrial Materials and ProcessesMNM100% (1)

- BinderDocumento253 páginasBinderJohnny Mopada Jr.Ainda não há avaliações

- HW21Documento4 páginasHW21李長青Ainda não há avaliações

- Plastic Roads: A Solution for Waste Disposal and Stronger Road ConstructionDocumento27 páginasPlastic Roads: A Solution for Waste Disposal and Stronger Road ConstructionChandu CKAinda não há avaliações

- Retrievable ExtensometerDocumento2 páginasRetrievable ExtensometerDeora AwangAinda não há avaliações

- Concrete Pouring RequestDocumento2 páginasConcrete Pouring RequestAYUS BUILDERS & ENTERPRISESAinda não há avaliações

- Brayton Cycle 920 381Documento43 páginasBrayton Cycle 920 381superaluddinAinda não há avaliações

- BE FANS Brochure PUBL7588Documento9 páginasBE FANS Brochure PUBL7588Carlos Ramon Brito RaveloAinda não há avaliações

- Astm17 0301Documento4 páginasAstm17 0301singaravelan narayanasamyAinda não há avaliações

- Marriott Fire ProtectionDocumento19 páginasMarriott Fire ProtectionjulchabAinda não há avaliações

- Translated Doors and Windows Construction MethodologyDocumento12 páginasTranslated Doors and Windows Construction MethodologyOlan PrinceAinda não há avaliações

- Precast Technology - Rev5Documento38 páginasPrecast Technology - Rev5SravanAinda não há avaliações

- Understanding The Yield Behaviour of L12 Ordered Alloys (3885)Documento11 páginasUnderstanding The Yield Behaviour of L12 Ordered Alloys (3885)Ramses AguilarAinda não há avaliações

- Materials Research Bulletin: Xiaolian Chao, Zhongming Wang, Ye Tian, Yanzhao Zhou, Zupei YangDocumento10 páginasMaterials Research Bulletin: Xiaolian Chao, Zhongming Wang, Ye Tian, Yanzhao Zhou, Zupei YangSamah SamahAinda não há avaliações

- Tutorial Sheets SOMDocumento20 páginasTutorial Sheets SOMPriyanshu Sharma100% (1)

- Scaffold Erect ProceduresDocumento4 páginasScaffold Erect ProceduresDak SerikAinda não há avaliações

- USP Presentation MunicipalDocumento20 páginasUSP Presentation Municipalcoolvishal2003Ainda não há avaliações

- Bolt Standard BS 3692Documento1 páginaBolt Standard BS 3692Mai Xuan Truong0% (1)

- Water Curtain Installation RequirementsDocumento2 páginasWater Curtain Installation RequirementsKapal TerbangAinda não há avaliações

- RCD 9 1 PDFDocumento5 páginasRCD 9 1 PDFCristan RetuermaAinda não há avaliações

- Drawing Seimens BRKRDocumento14 páginasDrawing Seimens BRKRrajeshAinda não há avaliações

- HMTDocumento4 páginasHMTsumeetsharma270% (1)

- CHOUGULE Et Al (2011) - Synthesis and Characterization of Polypyrrole (Ppy) Thin FilmsDocumento5 páginasCHOUGULE Et Al (2011) - Synthesis and Characterization of Polypyrrole (Ppy) Thin FilmsAdriano SilvaAinda não há avaliações

- 03-Clay Bricklaying Made EasyDocumento4 páginas03-Clay Bricklaying Made Easysantoshkumar gurmeAinda não há avaliações

- Sainitary Drainage SystemDocumento10 páginasSainitary Drainage Systemajaydce05Ainda não há avaliações