Escolar Documentos

Profissional Documentos

Cultura Documentos

US India Composite and Plastic Opportunities

Enviado por

ChanakyaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

US India Composite and Plastic Opportunities

Enviado por

ChanakyaDireitos autorais:

Formatos disponíveis

Indian Composite and Reinforced Plastic Products Market Opportunities for US Companies

With a rapid growth in the manufacturing sector and heavy investments in infrastructure, the

$1.2 billion Indian composite industry is expected to grow at a rate of around 25% in the next 45 years. The key drivers of this growth will be transport, infrastructure, wind energy, and oil and gas industries in India. According to TIFAC, the total production of composites in India was about 75,000 tons in 2004-2005 and has risen to 110,000 tons in 2005-2006. The Indian composite industry has a strong manufacturing base with automated processes combined with robust design and development skills. Global companies like Dupont, DSM, Sabic, Georgia Pacific, Fibergrate, Saertex, Hepworth, Beluga Tanks, and Enercon have entered in the Indian market and have established a strong base for export as well as local demand. Several US companies are investing in newer technologies to improve productivity and quality to meet increasing demands of this growth market.

Use of Composites in Industrial Applications in India (tons)

20,000 18,000 16,000 14,000 12,000 10,000 8,000 6,000 4,000 2,000 0 2006 2007 Chemical Piping 2008 2009 2010

Cooling towers

There are significant opportunities for US Companies in the following industry segments in India: Wind Energy: India has made significant progress in the wind power sector and the composite consumption has exceeded that of China and Japan. India is the fourth largest generator of wind power in the world and Indian company Suzlon Energy Ltd. has emerged as one of the leading suppliers of wind turbines in the global market. It is estimated that roughly 100,000 MW of power can be produced in India from only small wind turbines of 10-500 KW capacity.

501 Fifth Avenue, Suite 302, New York, NY 10017 Tel: (646) 807-9290, Fax: (646) 395-1896 November 2009 www.ivgpartners.com Page 1 of 4

Chemical Equipment: The major use of composites in India began with the chemical industry because of excellent corrosion resistance of composites. Applications in this sector include chemical equipment, piping and fire fighting breathing apparatus. Composite pipes find applications in sea-water intakes and effluent discharge in desalination plants, as ducts in the chemical industry, as cross-country water transmission pipelines, sewer pipelines etc. Composites are also being used for fabricating cooling tower units where the composite materials resist the corrosive effects of moisture. Railways: Composites were identified as a potential material for application in the Indian Railways in the early 1980s for many passenger coach components such as louvre and glass shutters, window sills and frames, trays for battery boxes, ceilings, and flooring. The railways were working towards the complete elimination of timber and plywood in the coaches. The present consumption of composite materials by Indian Railways is estimated at about 8000 tons, with an annual growth rate of 20%.

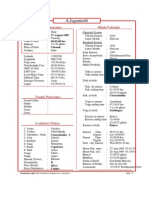

Indian composites market by market sector (in million tones). Sector 2006 2007 2008 2009 Wind energy 15,790 20,270 25,960 33,200 Industrial 26,000 29,100 32,590 36,510 Railways 8,000 9,600 11,520 13,820 Automobile 20,690 22,670 24,900 26,300 Oil & Gas 1,500 1,600 1,700 1,800 Building and Construction 35,000 39,500 44,650 48,9200 Marine 1,000 1,400 1,800 2,300 Total 107,980 124,140 143,120 162,850 (Source: TIFAC report Technology-linked Business Opportunities in Composites in India.) 2010 42,460 40,920 16,590 28,100 1,900 55,400 3,000 188,370

Automotive: There is a tremendous potential for use of composites in the Indian automobile industry, especially for catering to the transportation needs of the growing middle-class population. There would be a good market for hoods, cabs, frames, and cargo containers that could be used as part of these locally-built vehicles. Other opportunities for the Indian composites industry include refrigerated freight containers, pressure vessels, fishing boats, walkways and piles for building foundations, and air intake manifolds. Composite materials are used in passenger cars, scooters and helmets. Oil and Gas: Potential applications for composites in the oil and gas sector in India are primarily in high-pressure pipes and pipe fittings in the next years. Current offshore structural applications of composites include low-pressure pipe, gratings, handrails, equipment covers or enclosures and ladders. Because of their low weight, corrosion resistance, improved life-cycle costs and enhanced safety, it is predicted that composite materials can capture 50% of this market in the oil and gas sector in the next 5-6 years.

501 Fifth Avenue, Suite 302, New York, NY 10017 Tel: (646) 807-9290, Fax: (646) 395-1896 November 2009 www.ivgpartners.com Page 2 of 4

About IMaCS Virtus Global Partners

IMaCS Virtus Global Partners, Inc. (IVG Partners) offers advisory services to North American companies and private equity funds seeking India related growth, investment and sourcing opportunities. Our mission is to enable our clients to transform their business by adding India as a key part of their global footprint. Our clients benefit from our local presence, strong relationships, knowledge of local business practice, experience and financial expertise. We provide India related Strategy & Roadmap Consulting, Partner/ Target Search, Operation Setup & Support, Cross-border M&A Advisory, Project/ Bid Advisory and Transaction Advisory services. Our team possesses a deep understanding of the business environment both in the US and India and is well connected with companies, financial institutions, governmental agencies, and private equity firms in both markets. We have an established track record of over 15 years and 900 engagements providing advisory services to a diversified client base across manufacturing, infrastructure, energy, technology, industrial commodities, and retail. We also work with multilateral and bilateral government agencies, banks & financial institutions, and regulators. We are headquartered in New York with eight offices in India.

Our Services

Structural Composite Machinery & Equipment India Strategy & Roadmap

Market , Demand & Competition Analysis India Strategy & Investment Roadmap Local Regulatory Compliance Product Positioning Location Assessment Sourcing Strategy Operational Setup & Support

Plastic Products

Carbon Fiber Sales/ Channel Management

Establishing Sales Processes Distribution Footprint Analysis Sales Force Effectiveness Structuring Solutions to Address Payment and Other Risks Credit Risk Assessment Pricing/ Costing Model

Partner Search

Operation Setup & Support

Business and Legal Entity Setup Manufacturing Setup and Support Business Development Roadmap and Assistance Sourcing & Distribution Roadmap and Assistance Regulatory Framework

Partner Identification & Due Diligence Structuring & Negotiating M&A, JV, Sourcing or Licensing Agreement Transaction Advisory Technology/ IPR Protection Corporate Restructuring

501 Fifth Avenue, Suite 302, New York, NY 10017 Tel: (646) 807-9290, Fax: (646) 395-1896 November 2009 www.ivgpartners.com Page 3 of 4

Our Representative Experience

Below is a partial list of our engagements in the composites and manufacturing sector in India for our global clientele:

Diversification and growth strategy in India for a leading plastic products manufacturer including identification of new business opportunities. As part of the ongoing mandate, we scanned over 20 sub-sectors to identify profitable opportunities with long-term growth potential based on relative attractiveness of the sector, industry dynamics, strategic fit with clients business model Domestic and export market potential assessment of pre-coated sheets for a leading coatings company Evaluation of a copper cathode manufacturing project for a large manufacturing entity in India Viability study of a polyester manufacturing unit for a leading national bank in India Feasibility of establishing an engineering design centre for a global manufacturing company Market assessment for CNG engines for a large engine manufacturer Evaluation of options for corporate restructuring for a large engineering conglomerate Business planning for and valuation of a fabrication and foundry unit identified for acquisitions Valuation of an aluminium billet manufacturing unit for a multinational corporation Assessment of rehabilitation package for an engineering company Study of cash management system and investment policy for an aeronautical company Market feasibility for medical diagnostic centers in Eastern India Techno-economic feasibility study for a processed can manufacturer Study of automotive markets in the ASEAN countries and developing strategies for Indian companies to access the same Assessment and Due Diligence of joint venture partner for a global power project investor Financial strategy and roadmap for a rights issue for a manufacturer of material handling equipment, such as cranes and forklifts.

Our Offices

New York (HQ)

501 Fifth Avenue, Suite 302 New York, NY 10017 Tel: (646) 807-9290

New Delhi

Buildingo. 8, 2nd Floor, Twr A DLF Cyber City, Phase-II Gurgaon 122002

Mumbai

Electric Mansion, FL 4, Appasaheb Marathe Marg, Prabhadevi Mumbai 400 025

Bangalore

Vayudooth Chambers, Fl 2, Trinity Circle 15-16 MG Road, Bangalore 560 001

Kolkata

FMC Fortuna, A-10, FL 3, 234/3A AJC Bose Road Kolkata 700 020

Chennai

Karumuttu Centre, 5th Floor 634 Anna Salai, Nandanam Chennai 600 035

Pune

5A, 5th Floor, Range Hills Road, Shivaji Nagar, Pune 411 020

Hyderabad

301, Concourse Fl 3 No 7-1-58, Ameerpet Hyderabad 500 016

For further information, please contact Robin Hughes at rhughes@ivgpartners.com.

501 Fifth Avenue, Suite 302, New York, NY 10017 Tel: (646) 807-9290, Fax: (646) 395-1896 November 2009 www.ivgpartners.com Page 4 of 4

Você também pode gostar

- Schemes of Maharashtra State Agricultural Marketing Board (Msamb)Documento2 páginasSchemes of Maharashtra State Agricultural Marketing Board (Msamb)ChanakyaAinda não há avaliações

- IASbaba Prelims 60 Days PlanDocumento58 páginasIASbaba Prelims 60 Days PlanAmit MeherAinda não há avaliações

- Case Adhesives BrochureDocumento6 páginasCase Adhesives BrochureChanakyaAinda não há avaliações

- Lotryl: Ethylene - Methyl Acrylate CopolymerDocumento2 páginasLotryl: Ethylene - Methyl Acrylate CopolymerChanakyaAinda não há avaliações

- Exceed™ 1018 Series: Metallocene Polyethylene ResinDocumento2 páginasExceed™ 1018 Series: Metallocene Polyethylene ResinChanakyaAinda não há avaliações

- Medieval Class 7 Chapter 10Documento18 páginasMedieval Class 7 Chapter 10ChanakyaAinda não há avaliações

- Clariant FRDocumento28 páginasClariant FRChanakyaAinda não há avaliações

- Design Unlimited: Baydur & BayflexDocumento12 páginasDesign Unlimited: Baydur & BayflexChanakyaAinda não há avaliações

- Bioadimide 100 en RCRDocumento2 páginasBioadimide 100 en RCRChanakyaAinda não há avaliações

- Ebrochure EnglishDocumento13 páginasEbrochure Englishrandykotra100% (1)

- Tattva IIDocumento8 páginasTattva IIVisti LarsenAinda não há avaliações

- 36-Bhrighu Saral Paddathi - 7Documento8 páginas36-Bhrighu Saral Paddathi - 7SaptarishisAstrologyAinda não há avaliações

- Executive Director Rahul Sharma PDFDocumento2 páginasExecutive Director Rahul Sharma PDFjpsmu09Ainda não há avaliações

- All Horoscope-Dasha-Varshapala Charts and CalculationsDocumento88 páginasAll Horoscope-Dasha-Varshapala Charts and CalculationsChanakyaAinda não há avaliações

- 24-Bhrighu Saral Paddathi - 5Documento14 páginas24-Bhrighu Saral Paddathi - 5SaptarishisAstrology100% (1)

- Marketing of Agriculture InputsDocumento18 páginasMarketing of Agriculture InputsChanakyaAinda não há avaliações

- Marketing of Agriculture InputsDocumento18 páginasMarketing of Agriculture InputsChanakyaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Enron's Corporate Governance Failures and LessonsDocumento64 páginasEnron's Corporate Governance Failures and LessonsVînătoru Sorin0% (1)

- Bibliophile Warren Buffett's Letter 1957-2017Documento165 páginasBibliophile Warren Buffett's Letter 1957-2017Vishal Kedia0% (1)

- Nestle 2013 StatsDocumento7 páginasNestle 2013 StatsRabiaasadAinda não há avaliações

- 10 The Down Re It StructureDocumento13 páginas10 The Down Re It StructureCorkn BottlesAinda não há avaliações

- Southwest Airlines Business AnalysisDocumento16 páginasSouthwest Airlines Business Analysisapi-184659947Ainda não há avaliações

- Merger and AcqisitionDocumento8 páginasMerger and AcqisitionhaseebAinda não há avaliações

- Problems Audit of Investments PDFDocumento17 páginasProblems Audit of Investments PDFLove alexchelle ducut0% (1)

- Financial and Strategic ObjectivesDocumento1 páginaFinancial and Strategic ObjectivesQaseh EiyraAinda não há avaliações

- Relevant Decision FactorsDocumento7 páginasRelevant Decision FactorsFreya Dela Calzada0% (1)

- Week 5 C35 - MFRS 138 IntangiblesDocumento26 páginasWeek 5 C35 - MFRS 138 IntangiblesYong Arifin0% (1)

- 46 USC CHAPTER 573 Condensed Rev2Documento2 páginas46 USC CHAPTER 573 Condensed Rev2thenjhomebuyer100% (2)

- Title of The Paper:: Mergers and Acquisitions Financial ManagementDocumento25 páginasTitle of The Paper:: Mergers and Acquisitions Financial ManagementfatinAinda não há avaliações

- Chapter 20 - Transorganizational ChangeDocumento3 páginasChapter 20 - Transorganizational ChangeAzael May PenaroyoAinda não há avaliações

- 10-K 2008.2.22 687Documento473 páginas10-K 2008.2.22 687Sammy TangnesAinda não há avaliações

- K Kellogg Company 2018 Cagny Conference PresentationDocumento24 páginasK Kellogg Company 2018 Cagny Conference PresentationAla BasterAinda não há avaliações

- Brand ArchitectureDocumento8 páginasBrand ArchitectureNabeelah Moses100% (1)

- CS Executive Company Accounts Notes FinalDocumento41 páginasCS Executive Company Accounts Notes FinalShivam GuptaAinda não há avaliações

- Corporate RestructuringDocumento490 páginasCorporate RestructuringMohammed Zubair BhatiAinda não há avaliações

- Alantra Software Valuation Update Q4 2020Documento68 páginasAlantra Software Valuation Update Q4 2020Aniruddha RoyAinda não há avaliações

- Mergers Acquision and Corporate Restructuring: Indian Institute of Management AhmedabadDocumento6 páginasMergers Acquision and Corporate Restructuring: Indian Institute of Management AhmedabadasifanisAinda não há avaliações

- Merger Acquisition and Corporate RestructuringDocumento30 páginasMerger Acquisition and Corporate Restructuringtafese kuracheAinda não há avaliações

- Financial Slack and Mergers BibliographyDocumento4 páginasFinancial Slack and Mergers Bibliographyಡಾ. ರವೀಶ್ ಎನ್ ಎಸ್Ainda não há avaliações

- Godrej SBU - A Case StudyDocumento7 páginasGodrej SBU - A Case StudyKalpana Jain100% (1)

- FY12 Top Ops Webinar Talking Points 100411Documento6 páginasFY12 Top Ops Webinar Talking Points 100411Elliot S VolkmanAinda não há avaliações

- AMP Brochure 2022-23Documento24 páginasAMP Brochure 2022-23Rahul SinghAinda não há avaliações

- F5 202 - Pre-Sales Fundamentals Study Guide - IntroductionDocumento7 páginasF5 202 - Pre-Sales Fundamentals Study Guide - IntroductionAhmad ShaugiAinda não há avaliações

- IGCSE Economics-Do Consumers Benefit From Horizontal MergersDocumento1 páginaIGCSE Economics-Do Consumers Benefit From Horizontal MergersSmart Exam ResourcesAinda não há avaliações

- Accounting Notes ALL at MBADocumento43 páginasAccounting Notes ALL at MBABabasab Patil (Karrisatte)Ainda não há avaliações

- Strategic Management Process and Generic StrategiesDocumento12 páginasStrategic Management Process and Generic Strategiespankaj gupta50% (14)

- C220 Part0eDocumento88 páginasC220 Part0eGo AcqAinda não há avaliações