Escolar Documentos

Profissional Documentos

Cultura Documentos

All Case Study

Enviado por

Prashant KashyapDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

All Case Study

Enviado por

Prashant KashyapDireitos autorais:

Formatos disponíveis

CASE STUDY: 1 AMSTERDAM AIR CRASH

1.1 INTRODUCTION Separation of an engine from a 747-200 cargo aircraft resulted in a catastrophic aircraft accident near Amsterdam. The engine separated, together with its pylon owing to fatigue and fracture of components connecting the pylon to the wing. These components were high strength steel lugs and two "fuse pins". One fuse pin was not recovered, but the other one and the lugs were investigated to find the most probable cause and sequence of damage leading to separation. The #3 engine and pylon separated from the right wing in an outboard and rearward direction. The #3 engine hit the #4 engine, causing this engine and its pylon also to separate from the wing. During engine separation the right wing leading edge was extensively damaged. This damage, together with loss of the engines, made control of the aircraft extremely difficult and aircraft became uncontrollable and crashed into an apartment block in a suburb 13 km east of Schiphol. 1.2 INVESTIATION Fig 1.1 is a schematic of the engine pylon-to-wing connections. The design incorporates six "fuse pins" which are less strong than other parts of the connections. If extreme loads occur on an engine and pylon, the fuse pins made from 4330M, a high strength low alloy steel, are supposed to shear off and allow a clean separation from the wing, thereby precluding damage to the wing and possible rupture of the wing fuel tank.

Fig: 1.1 Pylon-to-wing connections However, as found in the present case, and at least one other, engine and pylon separation was accompanied by severe damage to the wing leading edge. Macroscopic inspection of the components indicated that the upper link and diagonal brace had broken away owing to overload as the # 3 engine and pylon separated in an outboard direction. Fig: 1.2 shows the mid-spar pylon fittings. Each has two lugs that had been connected via fuse pins to two male lugs on each mid-spar wing fitting. The lugs on the outboard pylon fitting were unbroken but had witness marks indicative of scraping, as did the base of the throat between the lugs. However, the outer lug of the inboard pylon fitting was broken.

Detailed examination by the NLR showed that this lug had failed by a combination of tensile and bending overload. From these results two main conclusions were drawn: The missing inboard mid-spar fuse pin must have failed such that the outer lug of the inboard mid-spar pylon fitting took the entire load at this connection. Only thus is it possible to explain overload failure of the lug by tension and bending During failure of the inboard mid-spar connection the male lugs of the wing fitting moved outward from the throat of the lugs on the pylon fitting. On the other hand, failure of the outboard mid-spar connection resulted in the male lugs of the wing fitting moving into the throat of the lugs on the pylon fitting, thereby producing witness marks.

(a): Inboard

(b): outboard

(c): failed fuse pin

Fig 1.2: The lugs of the mid-spar pylon fittings. Fig: 1.2(c) gives two macroscopic views of the outboard fracture surface of the fuse pin. The partially separated sliver in figure contains a fatigue crack originally parallel to the coarse machining grooves on the inside wall of the fuse pin. Fig: 1.2(c) is a detail of the fatigue crack, which initiated at multiple origins along one or more machining grooves and progressed to at least half the wall thickness before overload. The stresses causing fatigue crack initiation were due to fuse pin bending. Fig: 1.3 shows the most probable sequence of events

Fig: 1.3 Sequence of failure 1.3. REMEDIAL ACTIONS Boeing instituted several remedial actions for the pylon-to-wing connections, some of which are shown in figure 8. These actions were:

A new design fuse pin made from corrosion resistant stainless steel and without thinwalled locations, compare Fig 1.4(a) and (b). This type of pin has a much improved resistance to fatigue.

(a): Old design (b): New design Fig 1.4: Fuse pin Two extra connections between the mid-spar pylon fittings. Larger mid-spar pylon fittings and stronger diagonal brace and upper link. These remedial actions are to prevent an engine and pylon separating from the wing under extreme loads in flight, i.e. the concept of clean separation during flight has been abandoned.

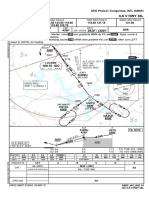

CASE STUDY: 2 CRASH LANDING AT SIUONX CITY

2.1 INTRODUCTION Date: July 19, 1989 Type: Uncontained engine failure, complete loss of flight controls Site: Sioux City. United States Passengers 285 Crew: 11. Injuries: 174. Fatalities: 112. Survivors: 184 Aircraft type McDonnell Douglas DC-10-10. Flight origin: Stapleton International Destination: Philadelphia International Airport 2.2 INVESTIGATION 2.2.1 ACCIDENT SEQUENCE The Safety Board determined that the accident sequence was initiated by a catastrophic separation of the stage 1 fan disk from the No. 2 engine during cruise flight. The separation, fragmentation, and forceful discharge of uncontained stage 1 fan rotor assembly parts from the No. 2 engine led to the loss of the three hydraulic systems shown in fig 2.1 (a) and (b) that powered the airplane's flight controls. The flight crew experienced severe difficulties controlling the airplane and used differential power from the remaining two engines for partial control. The airplane subsequently crashed during an attempted emergency landing at Sioux Gateway Airport. Upon ground contact, the airplane broke apart and portions of it were consumed by fire.

(b) Damage caused by fractured disc Fig 2.1 2.2.2 ANALYSIS OF FAN DISK FRACTURE Examination of the fracture surfaces of the fan disk disclosed that the near-radial, bore-to-rim fracture was the primary fracture. The fracture initiated from a fatigue region on the inside diameter of the bore. The remaining portions of the disk fractures were typical of overstress separations resulting from the fatigue failure. Because of the geometry of the fan disk and the load paths within the disk, the near-radial fracture created a bending moment in the disk arm and web that overstressed the disk, leading to rupture and release of a segment

(a) Three hydraulic system of aircraft

2.3 RECOMMENDATION Intensify research in the nondestructive inspection field. Use of fuse to stop excess amount of hydraulic fluid from ruptured parts CASE STUDY: 3 CUTTING EDGE: 3.1 INTRODUCTIION Date: January 31, 2000. Type: Mechanical failure, maintenance error Site: Pacific Ocean near Anacapa Island, California Passengers: 83 Crew: 5 Fatalities: 88 (all) Aircraft type: McDonnell Douglas MD-83 Flight origin: Lic. Gustavo Daz Ordaz International Airport Destination: Seattle-Tacoma International Airport 3.2INVESTIGATION A McDonnell Douglas MD-83, which crashed into the Pacific Ocean about 2.7 miles north of Anacapa Island, California Safety issues discussed in this report include lubrication and inspection of the jackscrew assembly, extension of lubrication and end play check intervals, jackscrew assembly overhaul procedures, the design and certification of the MD-80 horizontal stabilizer trim control system. As the jackscrew rotates it moves up or down through the (fixed) acme nut. This up and down motion moves the horizontal stabilizer for the trim system. The jackscrew was

found with metallic filaments wrapped around it; these were later determined to be remnants of the threads from the acme nut.

(a) Lead screw Fig : 3.1

(b) Acme nut

(a) Schematic diagram of screw jack for horizontal stabilizer Fig no 3.2

(b) Mechanism of screw jack for horizontal stabilizer

Later analysis estimated that 90% of the threads in the acme nut had been previously worn away, and that they were then completely sheared off during the accident flight. Once the threads failed, the horizontal stabilizer assembly was then subject to aerodynamic forces that it could not withstand, and ultimately failed. Based on the time since the last inspection of the jackscrew assembly, the NTSB determined that the wear had occurred at a much faster than average rate (0.012 inch per 1,000 flight hours, when the expected wear was 0.001 inch per 1,000 flight hours). The NTSB considered a number of potential reasons for this excessive wear, including the substitution by Alaska Airlines of Aeroshell 33 grease instead of the previously approved lubricant, Mobilgrease 28. The use of Aeroshell 33 was found not to be a factor in this accident. Insufficient lubrication of the components was also considered as a reason for the wear. Examination of the jackscrew and acme nut revealed that no

effective lubrication was present on these components at the time of the accident. Ultimately the lack of lubrication, and resulting excessive wear of the threads, was determined to be the direct causes of the accident. 3.3 RECOMMENDATIONS In the event of an inoperative or malfunctioning flight control system, if the airplane is controllable they should complete only the applicable checklist procedures and should not attempt any corrective actions beyond those specified. Identify means to eliminate the catastrophic effects of that single-point failure mode and, if practicable, require that such fail-safe mechanisms be incorporated in the design of all existing and future airplanes that are equipped with such horizontal stabilizer trim systems Proper lubrication system should be design for screw jack

CASE STUDY: 4 HANGING BY THREAD

4.1 INTRODUTION Date: April 28, 1988. Type: Explosive decompression caused by fatigue failure. Site: Kahului, Hawaii. Passengers: 90. Crew: 5. Injuries: 65. Survivors: 94. Aircraft type: Boeing 737-297. Operator: Aloha Airlines. Flight origin: Hilo International Airport. Destination: Honolulu International Airport. 4.2 INVESTIGATION Around 13:48, as the aircraft reached its normal flight altitude of 24,000 feet (7,300 m) about 23 nautical miles (43 km) south-southeast of Kahului, a small section on the left side of the roof ruptured. The resulting explosive decompression tore off a large section of the roof shown in fig 4.1 (a) and (b), consisting of the entire top half of the aircraft skin extending from just behind the cockpit to the fore-wing area.

Fig 4.1 (a)

Fig 4.1 (b)

As part of the design of the 737, stress may be alleviated by controlled area breakaway zones. The intent was to provide controlled depressurization that would maintain the integrity of the fuselage structure. The age of the plane and the condition of the fuselage (that had corroded and was stressing the rivets beyond their designed capacity) appear to have conspired to render the design a part of the problem; when that first controlled area broke away, according to the small rupture theory as shown in fig 4.2 (a) and (b), the rapid sequence of events resulted in the failure sequence. This has been referred to as a zipper effect.

(a) Basic construction of roof

(b) Small rupture theory Fig 4.2

(c) Fatigue crack near rivet

Investigation by the United States National Transportation Safety Board (NTSB) concluded that the accident was caused by metal fatigue exacerbated by crevice corrosion causing fatigue cracks around riveted area as shown in fig 4.2(c) (the plane operated in a coastal environment, with exposure to salt and humidity).The root cause of the problem was failure of an epoxy adhesive used to bond the aluminum sheets of the fuselage together when the B737 was manufactured. Water was able enter the gap where the epoxy failed to bond the two surfaces together properly, and started the corrosion process. The age of the aircraft became a key issue (it was 19 years old at the time of the accident and had sustained a remarkable number of takeoff-landing cycles of 89,090, the second most cycles for a plane in the world at the time of well beyond the 75,000 trips it was designed to sustain) 4.3 RECOMMENDATION Discontinue classification of fuselage skin as "malfunction evident" or "damage obvious" on supplemental structural inspection documents. In addition, review all the remaining structurally significant items in the damage obvious category for possible inclusion in the Supplementary Inspection Program. Initiate a corrosion prevention and control program designed to afford maximum protection from the effects of harsh operating environments

CASE STUDY: 5 OUT OF CONTROL

5.1 INTRODUCTION Date: 12 August 1985 Type: Explosive decompression due to Maintenance Error Site: Mount Osutaka. Passengers: 509 Crew: 15

Fatalities 520 Aircraft type: Boeing 747-SR46 Flight origin Tokyo International Airport Destination Osaka International Airport

5.2 INVESTIGATION The official cause of the crash according to the report published by Japan's then Aircraft Accidents Investigation Commission is as follows: The aircraft was involved in a tail strike incident at Osaka International Airport on 2 June 1978, which damaged the aircraft's rear pressure bulkhead shown in fig 5.1

The subsequent repair of the bulkhead did not conform to Boeing's approved repair methods. The Boeing technicians fixing the aircraft used two separate doubler plates, one with two rows of rivets and one with only one row as shown in fig 5.1 (a) and (b), while their procedure calls for one continuous doubler plate with three rows of rivets to reinforce the damaged bulkhead. This reduced the part's resistance to metal fatigue by 70%. According to the FAA, the one "doubler plate" which was specified for the job (the FAA calls it a "splice plate" - essentially a patch) was cut into two pieces parallel to the stress crack it was intended to reinforce, "to make it fit".[14] This negated the effectiveness of two of the rows of rivets. During the investigation Boeing calculated that this incorrect installation would fail after approximately 10,000 pressurizations; the aircraft accomplished 12,318 take-offs between the installation of the new plate and the final accident.

(a) Two row riveting

(b) One row riveting Fig 5.2

(c) failure due to single row riveting

When the bulkhead gave way, the resulting explosive decompression ruptured the lines of all four hydraulic systems. With the aircraft's flight controls disabled, the aircraft became uncontrollable.

CASE STUDY 6: CHINA AIRLINES FLIGHT 611

6.1 INRODCTION Date: 25 May 2002 Type: Flight structural failure (Metal fatigue), Explosive decompression, Maintenance error. Site: Taiwan Strait (37 km northeast of Makung, Penghu Islands). Passengers: 207 Crew: 18. Fatalities 225 (all) Aircraft type: Boeing 747-209B Operator China Airlines Flight origin: Chiang Kai-shek International Airport. Destination: Hong Kong International Airport 6.2 INVESTIGATION Searchers recovered 15% of the wreckage, including part of the cockpit, and found no signs of burns, explosives or gunshots. There was no distress signal or communication sent out prior to the crash. Radar data suggests that the aircraft broke into four pieces while at FL350. This theory is supported by the fact that articles that would have been found inside the aircraft were found up to 80 miles (130 km) from the crash site in villages in central Taiwan. The flight data recorder from Flight 611 shows that the plane began gaining altitude at a significantly faster rate in the 27 seconds before the plane broke apart, although the extra gain in altitude was well within the plane's design limits. 6.2.1 Metal Fatigue The final investigation report found that the accident was the result of metal fatigue as shown in fig 6.1(a) caused by inadequate maintenance after a previous incident. The report finds

that on 7 February 1980, the accident aircraft suffered damage from a tail strike accident while landing in Hong Kong. The aircraft was then ferried back to Taiwan on the same day de-pressurized, and a temporary repair done the day after. A permanent repair was conducted by a team from China Airlines from 23 May through 26 May 1980. However, the permanent repair of the tail strike was not carried out in accordance with the Boeing SRM (Structural Repair Manual). The area of damaged skin was not removed (trimmed) and the repair doubler which was supposed to cover in excess of 30% of the damaged area did not extend beyond the entire damaged area enough to restore the overall structural strength. Consequently, after repeated cycles of depressurization and pressurization during flight, the weakened hull gradually started to crack and finally broke open in mid-flight on 25 May 2002, exactly 22 years to the day after the faulty repair was made upon the damaged tail. An explosive decompression of the aircraft occurred once the crack opened up, causing the complete disintegration of the aircraft in mid-air as shown in fig 6.1(b).

Fig 6.1(a)

Fig 6.1(b)

One piece of evidence of the metal fatigue is contained in pictures that were taken during an inspection of the plane years before the disaster. In the pictures, there are visible brown stains of nicotine around the doubler plate. This nicotine was deposited by smoke from the cigarettes of people who were smoking about seven years before the disaster (smoking was allowed in a pressurized plane at that time). The doubler plate had a brown nicotine stain all the way around it that could have been detected visually by any of the engineers when they inspected the plane. The stain would have suggested that there might be a crack caused by metal fatigue behind the doubler plate, as the nicotine slowly seeped out due to pressure that built up when the plane reached its cruising altitude. The stains were apparently not noticed and no correction was made to the doubler plate, which eventually caused the plane to disintegrate in mid air. 6.3 RECOMMENDATION Aviation industries around the world immediately inspect the scratch on aircraft pressure vessel, especially if covered under doubler plate as it could have hidden damage that might develop into fatigue crack.

CASE STUDY 7: DERAILMENT AT ESCHEDA

7.1 INTRODUCTION Date: 3 June 1998. Time: 10:59. Location: Eschede, Germany. Operator: Deutsche Bahn AG. Type of incident: Derailment. Passengers: 287. Deaths: 101. Injuries: 88. 7.2 INVESTIGATION 7.2.1 Chronology of Events Wheel fracture

Six kilometres south of central Eschede, near Celle, the steel tire on a wheel on the third axle of the first car broke, peeled away from the wheel, and punctured the floor of the car, where it remained embedded as shown in fig 7.1 (a) Derailment As the train passed over the first of two track switches, the embedded tire slammed against the guide rail of the switch, pulling it from the railway ties. This steering rail also penetrated the floor of the car, becoming embedded in the vehicle and lifting the axle carriage off the rails. At 10:59 local time, one of the now-derailed wheels struck the points lever of the second switch, changing its setting. The rear axles of car number 3 were switched onto a parallel track, and the entire car was thereby thrown away from track. Car number 4, likewise derailed by the violent deviation of car number 3. Bridge collapse Coaches one and two cleared the bridge. Coach three hit the bridge, which began to collapse. Coach four cleared the bridge, moved away from the track, and hit a group of trees. Fig 7.1 (b)

Fig 7.1 (a)

Fig 7.2(b)

7.2.2 CAUSES 7.2.2.1 WHEEL DESIGN The ICE 1 trains were equipped with single-cast wheels, known as monoblock wheels. Once in service it soon became apparent that this design could, as a result of metal fatigue and out-of-round conditions, lead to resonance and vibration at cruising speed In response, engineers decided that to solve the problem: the suspension of ICE cars could be improved with the use of a rubber damping ring between the tire and the wheel body as shown in fig7.1 (a) and (b) This new wheel, dubbed a "wheel-tire" design, consisted of a wheel body surrounded by a 20 mm thick rubber damper and then a relatively thin metal tire. The following factors, overlooked during design, were noted: 1. The tires were flattened into an ellipse as the wheel turned through each revolution (approximately 500,000 times during a typical day in service on an ICE train), with corresponding fatigue effects. 2. In contrast to the monoblock wheel design, cracks could also form on the inside of the tire. 3. As the tire became thinner due to wear, the dynamic forces were exaggerated, resulting in crack growth.

4. Flat spots and ridges or swells in the tire dramatically increased the dynamic forces on the assembly and greatly accelerated wear

. Fig 7.2 (a) Fig 7.2 (b)

7.2.2.2 MAINTENANCE Investigators discovered via a maintenance report generated by the train's on-board computer that, two months prior to the Eschede disaster, conductors and other train staff filed eight separate complaints about the noises and vibrations generated from the bogie with the defective wheel; the company did not replace the wheel. Deutsche Bahn said that its inspections were proper at the time and that the engineers could not have predicted the wheel fracture.

7.3 REMEDIES Within weeks, all wheels of similar design were replaced with monoblock wheels. The entire German railway network was checked for similar arrangements of switches close to possible obstacles. Rescue workers at the crash site experienced considerable difficulties in cutting their way through the train to gain access to the victims. Both the aluminum framework and the pressure-proof windows offered unexpected resistance to heavy rescue equipment. As a result, all trains were refitted with windows that have predetermined breaking points.

REFERENCES

http://www.ntsb.gov/ http://www.nationalgeographic.com/ http://web.archive.org/web/20080626181929/http://verkeerenwaterstaat.nl/kennisplei n/uploaded/MIN/2005-07/39448/ElAl_flight_1862.pdf http://libraryonline.erau.edu/online-full-text/ntsb/aircraft-accident-reports/AAR9006.pdf http://en.wikipedia.org/wiki/The_Cutting_Edge http://www.airdisaster.com/reports/ntsb/AAR89-03.pdf http://www.mlit.go.jp/jtsb/eng-air_report/JA8119.pdf

Você também pode gostar

- FAN BLADES CFM56-7B HISTORY FATIGUEDocumento14 páginasFAN BLADES CFM56-7B HISTORY FATIGUEBeyvi Ernesto Nevado DelgadoAinda não há avaliações

- Experimental Works For The Beter Understanding Failure Activity Aspects and ResultsDocumento16 páginasExperimental Works For The Beter Understanding Failure Activity Aspects and Resultsbagas prakosoAinda não há avaliações

- Agusta A109A tail rotor blade fractures during landingDocumento6 páginasAgusta A109A tail rotor blade fractures during landingbekhouche nasreddineAinda não há avaliações

- Fatigue and Fracture in An Aircraft Engine PylonDocumento15 páginasFatigue and Fracture in An Aircraft Engine PylonOSCARDELTAAinda não há avaliações

- Tp6980e 4 2010Documento32 páginasTp6980e 4 2010oguier100% (1)

- 2006 08 AlertDocumento93 páginas2006 08 AlertJoão AlmeidaAinda não há avaliações

- Aloha Airlines Flight 243 Boeing 737 - 200 April 28,1988 Honolulu, HIDocumento22 páginasAloha Airlines Flight 243 Boeing 737 - 200 April 28,1988 Honolulu, HIKe ChenAinda não há avaliações

- Final Assignment: Subject: Material Failure For Accident Investigation Course Code: ASI 6107Documento8 páginasFinal Assignment: Subject: Material Failure For Accident Investigation Course Code: ASI 6107Dipto SarkarAinda não há avaliações

- Boeing 737 Engineering Failure AnalysisDocumento4 páginasBoeing 737 Engineering Failure AnalysisShafell IsDreamingAinda não há avaliações

- 2010 04 AlertDocumento95 páginas2010 04 AlertTurk SoloAinda não há avaliações

- General Aviation Airworthiness Alerts 43-16 Alert 55 02-01-1983Documento14 páginasGeneral Aviation Airworthiness Alerts 43-16 Alert 55 02-01-1983JacksonAinda não há avaliações

- Aviation Maintenance Alerts June 2010 Issue Highlights Aircraft Engine IssuesDocumento55 páginasAviation Maintenance Alerts June 2010 Issue Highlights Aircraft Engine IssuesMr. Ehsanur Rahman FaizaniAinda não há avaliações

- General Aviation Airworthiness Alerts 43-16 Alert 54 01-01-1983Documento13 páginasGeneral Aviation Airworthiness Alerts 43-16 Alert 54 01-01-1983JacksonAinda não há avaliações

- AirTran Airways Flight 890 Accident ReportDocumento14 páginasAirTran Airways Flight 890 Accident Reportkithinji DanAinda não há avaliações

- A03C0068Documento7 páginasA03C0068vonmanoAinda não há avaliações

- Piper PA-34-200T Seneca II, G-ROLA Accident ReportDocumento7 páginasPiper PA-34-200T Seneca II, G-ROLA Accident ReportrayduxAinda não há avaliações

- Engineering Materials 2Documento13 páginasEngineering Materials 2Ysharath ChandramouliAinda não há avaliações

- Aviation Maintenance Alerts: Advisory CircularDocumento29 páginasAviation Maintenance Alerts: Advisory CircularJessie O.BechaydaAinda não há avaliações

- Advisory CircularDocumento42 páginasAdvisory Circularnabawi24Ainda não há avaliações

- Failed Fan Blade Causes Engine FailureDocumento21 páginasFailed Fan Blade Causes Engine FailurePDDELUCAAinda não há avaliações

- How Overwing Heaters and Ice Detection Systems Can Prevent Engine Power Loss from Wing Ice IngestionDocumento4 páginasHow Overwing Heaters and Ice Detection Systems Can Prevent Engine Power Loss from Wing Ice IngestionOleg TysiachnyiAinda não há avaliações

- Landing GearDocumento41 páginasLanding Geartarakae04100% (1)

- NTSB Report On July 4 Plane Crash in KilleenDocumento9 páginasNTSB Report On July 4 Plane Crash in KilleenKCEN-TV 6 NewsAinda não há avaliações

- Report - DCA21FA085 - 102652 - 9 - 8 - 2023 7 - 28 - 01 PMDocumento22 páginasReport - DCA21FA085 - 102652 - 9 - 8 - 2023 7 - 28 - 01 PMJose A. HerreraAinda não há avaliações

- Boeing 727 Safety Recommendation A-89-079 Decompression Due To Scribe LinesDocumento4 páginasBoeing 727 Safety Recommendation A-89-079 Decompression Due To Scribe LinesSawatkeaw Hudkul100% (1)

- Failure Analysis of An Aircraft Engine Cylinder Head PDFDocumento15 páginasFailure Analysis of An Aircraft Engine Cylinder Head PDFTchutAinda não há avaliações

- Airbus - A319-131 - G-EUPM - 06-17 AAIB BulletinDocumento15 páginasAirbus - A319-131 - G-EUPM - 06-17 AAIB BulletinMd NoMaN OmErAinda não há avaliações

- National Transportation Safety BoardDocumento3 páginasNational Transportation Safety BoardDita FebrianaAinda não há avaliações

- Aviation Maintenance Alerts July 2006 Issue Provides Updates on Aircraft, Engine, and Component IssuesDocumento192 páginasAviation Maintenance Alerts July 2006 Issue Provides Updates on Aircraft, Engine, and Component IssuesAllyamacita NaibahoAinda não há avaliações

- Cessna 750 Citation X, G-CDCX 10-11Documento12 páginasCessna 750 Citation X, G-CDCX 10-11Gerardo Alves0% (1)

- An Investigation of The Repetitive Failure in An Aircraft EngineDocumento15 páginasAn Investigation of The Repetitive Failure in An Aircraft EnginemanelouchkaAinda não há avaliações

- Ex 9A Add AAWT2Documento172 páginasEx 9A Add AAWT2Sk CisseAinda não há avaliações

- Main Landing Gear Wheel Failure Involving A Boeing 737, ZK-ZQBDocumento7 páginasMain Landing Gear Wheel Failure Involving A Boeing 737, ZK-ZQBTimothy IsholaAinda não há avaliações

- Case StudyDocumento5 páginasCase StudyMuhammad KamalAinda não há avaliações

- TSwift CometDocumento63 páginasTSwift CometRoberto LopezAinda não há avaliações

- Turbo Commander 690-A Training ManualDocumento114 páginasTurbo Commander 690-A Training ManualAndre Peli100% (10)

- CP No. 146 - Antenna FlutterDocumento24 páginasCP No. 146 - Antenna FlutterTodd HembreeAinda não há avaliações

- TASK 1.1 (Assessment Criteria P1) Describe The Importance of The Study of Human Factor Within The Aerospace IndustryDocumento9 páginasTASK 1.1 (Assessment Criteria P1) Describe The Importance of The Study of Human Factor Within The Aerospace IndustryRob SinathAinda não há avaliações

- AMA Sample Exam: Study Airframe Test QuestionsDocumento14 páginasAMA Sample Exam: Study Airframe Test QuestionsHemantkumar TungAinda não há avaliações

- Aviation Investigation Report A02P0179Documento12 páginasAviation Investigation Report A02P0179唐波Ainda não há avaliações

- AAIB Bulletin: 7/2015 G-Gava EW/C2014/08/02: FootnoteDocumento28 páginasAAIB Bulletin: 7/2015 G-Gava EW/C2014/08/02: FootnoteDuvan CoronadoAinda não há avaliações

- Fleet Impact ResultingDocumento12 páginasFleet Impact ResultingAmilcar SánchezAinda não há avaliações

- AMA sample exam questions and study guideDocumento13 páginasAMA sample exam questions and study guidePritamjit RoutAinda não há avaliações

- BOEING 777-333ER, C-FITW Toronto-Lester B. Pearson International Airport, OntarioDocumento17 páginasBOEING 777-333ER, C-FITW Toronto-Lester B. Pearson International Airport, OntarioMorgen GumpAinda não há avaliações

- Case Studies in Engineering Failure Analysis: Michael K. BudinskiDocumento11 páginasCase Studies in Engineering Failure Analysis: Michael K. BudinskijarnebergAinda não há avaliações

- Cessna Corvalis Models Empennage Failures from Extreme BrakingDocumento47 páginasCessna Corvalis Models Empennage Failures from Extreme BrakingNuttapol Fuangfoodamrongchai100% (1)

- A Project By: Darshak BhuptaniDocumento32 páginasA Project By: Darshak BhuptaniDarshak BhuptaniAinda não há avaliações

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachAinda não há avaliações

- The DeHavilland Comet CrashDocumento5 páginasThe DeHavilland Comet CrashKelvin lohAinda não há avaliações

- De Havilland Comet Crashes Due to Fatigue FailuresDocumento7 páginasDe Havilland Comet Crashes Due to Fatigue FailuresziqnisAinda não há avaliações

- NTSB Investigative UpdateDocumento10 páginasNTSB Investigative UpdateJeremy HarrisAinda não há avaliações

- Failure Analysis Report v3 - FinalDocumento15 páginasFailure Analysis Report v3 - FinalWarren Michael ArthurAinda não há avaliações

- Analisis de Fallas Del Eje Del Tren de Aterrizaje Frontal de Un AvionDocumento8 páginasAnalisis de Fallas Del Eje Del Tren de Aterrizaje Frontal de Un AvionSanti Osorio DiezAinda não há avaliações

- NTSB Preliminary Report on IAH Runway ExcursionDocumento8 páginasNTSB Preliminary Report on IAH Runway ExcursionGage GouldingAinda não há avaliações

- AMA Sample Study Guide for Aviation Maintenance Technician Airframe ExamDocumento13 páginasAMA Sample Study Guide for Aviation Maintenance Technician Airframe Examwaterholic broAinda não há avaliações

- BA Flight 5390 Windscreen FailureDocumento7 páginasBA Flight 5390 Windscreen FailureKaruAinda não há avaliações

- NTSB Aviation Investigation Preliminary Report For Crash of Bombardier N823KD (ERA24FA110)Documento7 páginasNTSB Aviation Investigation Preliminary Report For Crash of Bombardier N823KD (ERA24FA110)nickAinda não há avaliações

- 2001 07 AlertDocumento28 páginas2001 07 AlertMichi GeeAinda não há avaliações

- Aloha 243 Case Study AnalysisDocumento9 páginasAloha 243 Case Study AnalysisPalaDin100% (1)

- Air Crash Investigations - Inadvertent In-Flight Slat Deployment - The Near Crash of China Eastern Airlines Flight 583No EverandAir Crash Investigations - Inadvertent In-Flight Slat Deployment - The Near Crash of China Eastern Airlines Flight 583Ainda não há avaliações

- Arjun S Raghav Resume - Aerospace Engineer with Technical Design ExperienceDocumento3 páginasArjun S Raghav Resume - Aerospace Engineer with Technical Design ExperiencePrashant KashyapAinda não há avaliações

- Contract FormDocumento2 páginasContract FormPrashant KashyapAinda não há avaliações

- Quick Jet RequirementsDocumento4 páginasQuick Jet RequirementsPrashant KashyapAinda não há avaliações

- Overview of Computer Graphics and its Interactive and Passive TypesDocumento182 páginasOverview of Computer Graphics and its Interactive and Passive TypesNoorul AlamAinda não há avaliações

- Book 1Documento1 páginaBook 1Prashant KashyapAinda não há avaliações

- Quick Jet RequirementsDocumento4 páginasQuick Jet RequirementsPrashant KashyapAinda não há avaliações

- UK CAA Part 145 ExpositionDocumento49 páginasUK CAA Part 145 Expositiontotololo78Ainda não há avaliações

- ProjctDocumento1 páginaProjctPrashant KashyapAinda não há avaliações

- New Microsoft Word DocumentDocumento1 páginaNew Microsoft Word DocumentPrashant KashyapAinda não há avaliações

- ProjctDocumento1 páginaProjctPrashant KashyapAinda não há avaliações

- Air Compressor Types and ComponentsDocumento3 páginasAir Compressor Types and ComponentsAvinash VadivelAinda não há avaliações

- G1000 Pilot Training Guide Instructors PDFDocumento56 páginasG1000 Pilot Training Guide Instructors PDFlakshmimurugesan100% (1)

- Phase of Flight DefinitionsDocumento7 páginasPhase of Flight DefinitionsSaurabh VaishnavAinda não há avaliações

- Faa Publications PDFDocumento2 páginasFaa Publications PDFJackieAinda não há avaliações

- 1) Aero L-29 Delfín General Characteristics: WingspanDocumento7 páginas1) Aero L-29 Delfín General Characteristics: WingspanAjay DevaAinda não há avaliações

- Epic Flight Academy Airline Pilot Programming International Students Pricing 3Documento2 páginasEpic Flight Academy Airline Pilot Programming International Students Pricing 3Anita MukulaAinda não há avaliações

- Airfoils and WingsDocumento43 páginasAirfoils and WingsRaj ManovaAinda não há avaliações

- EGBB PlatesDocumento40 páginasEGBB PlatesGordon McKirnenAinda não há avaliações

- RL2011 02eDocumento48 páginasRL2011 02eHeiriAinda não há avaliações

- ADP Lab ManualDocumento34 páginasADP Lab ManualRevathiAinda não há avaliações

- Gom Whole ManualDocumento305 páginasGom Whole Manualarakotoarson804100% (1)

- Emergency Turn - SKYbrary Aviation SafetyDocumento6 páginasEmergency Turn - SKYbrary Aviation SafetyAnish ShakyaAinda não há avaliações

- Avia MGT 2015Documento2 páginasAvia MGT 2015api-300350313Ainda não há avaliações

- Aviation Sector PresentationDocumento16 páginasAviation Sector PresentationJitendra GuptaAinda não há avaliações

- AENG 411 Applied Subsonic Aerodynamics Activities 1-10Documento10 páginasAENG 411 Applied Subsonic Aerodynamics Activities 1-10Lowel LaurelesAinda não há avaliações

- Albatross - Regs QBDocumento47 páginasAlbatross - Regs QBtopgun320100% (1)

- (IAC) Ils V Rwy 35L: RNP 1 or Rnav 1 - Gnss ReqDocumento1 página(IAC) Ils V Rwy 35L: RNP 1 or Rnav 1 - Gnss ReqBoalboalboa NemiandosAinda não há avaliações

- Aerodynamics For Naval Aviators v3Documento433 páginasAerodynamics For Naval Aviators v3Johnathan Chandler100% (3)

- 1 2 5 A AerodynamicforcesDocumento2 páginas1 2 5 A Aerodynamicforcesapi-325609547Ainda não há avaliações

- Erj 190 PDFDocumento2 páginasErj 190 PDFTyrone0% (1)

- Oceanic Flight Phraseology ExampleDocumento3 páginasOceanic Flight Phraseology ExampleTariq khosoAinda não há avaliações

- Astra Pilot Training ManualDocumento547 páginasAstra Pilot Training ManualLuis Saldana100% (2)

- Jeppsen RomaniaDocumento166 páginasJeppsen RomaniaRadu CalinescuAinda não há avaliações

- Sabah Air Aviation SDN - Bhd. (24758-U) : Weight and Balance Loading FormDocumento1 páginaSabah Air Aviation SDN - Bhd. (24758-U) : Weight and Balance Loading FormsalihuddinAinda não há avaliações

- OEB ProceduresDocumento98 páginasOEB ProceduresQuynh NguyenAinda não há avaliações

- SF50 Vision Jet CheckListDocumento6 páginasSF50 Vision Jet CheckListfederico armellaAinda não há avaliações

- Replic Magazine IndexDocumento5 páginasReplic Magazine IndexmitchtanzAinda não há avaliações

- UAVDocumento5 páginasUAVZawAinda não há avaliações

- Mass and Ball For Dana Mod 3Documento49 páginasMass and Ball For Dana Mod 3Charles EbukaAinda não há avaliações

- FAA approves Bombardier CL-215 amphibious aircraftDocumento12 páginasFAA approves Bombardier CL-215 amphibious aircraftGeorgy100% (1)

- Essentials of Aviation ManagementDocumento30 páginasEssentials of Aviation ManagementAbid RanaAinda não há avaliações