Escolar Documentos

Profissional Documentos

Cultura Documentos

Deped K To 12 Technology and Livelihood Education - Carpentry

Enviado por

yachiru121Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Deped K To 12 Technology and Livelihood Education - Carpentry

Enviado por

yachiru121Direitos autorais:

Formatos disponíveis

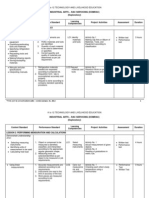

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project/ Activities

Assessment

Duration

LESSON 1: PREPARING CONSTRUCTION MATERIALS AND TOOLS Demonstrate understanding of/on: Types and uses of construction materials Kinds of carpentry tools Description of materials and tools Listing of materials as per company standards. . 1. Tools and materials are identified as per job requirements. 2. Tools are classified according to their functions per job requirements. 3. Materials are classified according to their uses in a specific construction project. 4. Tools and materials are selected per job requirement. 1. Needed materials and tools are listed as per job requirement. 2. Materials and tools are requested according to the list prepared. 3. Requests are done as per companys standard operating procedures (SOP). 4. Materials and tools are substituted and provided for unavailable ones without sacrificing cost and quality of work. LO1. Identify materials and tools applicable for a specific construction job. 1. Enumerating and describing the tools and materials used in carpentry works. Written test Performance test 6 hours

Different forms Job order slip Tools and materials requisition slip Borrowers slip Requisition procedures Use of hand tools

LO2. Request appropriate materials and tools.

1. Fill up necessary forms as per job requirement.

Written test Performance test

3 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

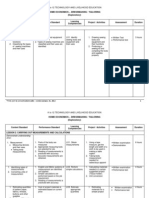

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard Procedures in receiving tools and materials Proper inspection of tools and materials received. Proper handling of tools and materials.

Performance Standard

Project/ Activities 1. Writing the possible defects and/or damages of materials and tools used in carpentry.

Assessment Written test Performance test

Duration 2 hours

1. Materials and tools as per LO3. Receive quantity and specification based and inspect on requisition are received and materials inspected. 2. Tools and materials are checked for damages and manufacturing defects. 3. Materials and tools received are handled with appropriate safety devices. 4. Materials and tools are stored in aside to appropriate locations nearest the workplace.

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project/ Activities

Assessment

Duration

LESSON 2: MAINTAINING TOOLS AND EQUIPMENT Demonstrate understanding of/on: Types of Tools and Equipment Classification of functional and non-functional tools Uses of Personal Protective Equipment (PPE). 1. Tools and equipment are identified according to classification/specification and job requirements. 2. Functional and non-functional tools and equipment are segregated and labeled according to classification. 3. Safety of tools and equipment are observed in accordance with manufacturers instructions. 4. Conditions of PPE are checked in accordance with manufacturers instructions. 1. Lubricants are identified according to types of equipment. 2. Tools and equipment are lubricated according to preventive maintenance schedule or manufacturers specifications. 3. Measuring instruments are checked and calibrated in accordance with LO1. Check condition of tools and equipment. 1. Performing the actual segregation of functional and non-functional tools and equipment. Performance test Written test 3 hours

Types and uses of lubricants Types and uses of cleaning materials/solvent Types and uses of measuring instruments and equipment. Preventive maintenance techniques and procedures

LO2. Perform basic preventive maintenance.

1. Performing the proper selection and application of lubricants used for preventive maintenance.

Written test Performance test

4 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

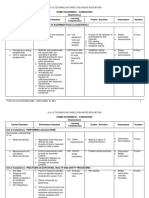

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard OSHC workplace regulations

Performance Standard manufacturers instructions. 4. Tools are cleaned and lubricated according to standard procedures. 5. Defective equipment and tools are inspected and replaced according to manufacturers specification. 6. Work place is cleaned and kept in safe state in line with OSHC regulations 1. Inventory of tools, instruments, and equipment are conducted and recorded as per company practices. Tools are inspected and replaced after use. Tools and equipment are stored safely in accordance with manufacturers specifications or company procedures.

Project/ Activities

Assessment

Duration

Inventory of tools and equipment Tools and equipment handling Tool safekeeping/storage

LO3. Store tools and equipment.

1. Applying proper storing of tools.

Written test Performance test

2 hours

2. 3.

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project/ Activities

Assessment

Duration

LESSON 3: PERFORM MENSURATION AND CALCULATION Demonstrate understanding of/on: Measuring instruments and tools Proper handling of measuring instruments 1. Measuring tools are selected/identified as per object to be measured or job requirements. 2. Correct specifications are obtained from relevant sources. 3. Measuring instruments are selected according to job requirements. 4. Alternative measuring tools are used without sacrificing cost and quality of work. 5. Measurements are obtained according to job requirements. 6. Accurate measurements are obtained according to job requirements. 7. Work pieces are measured according to job requirements LO1. Select measuring instruments. 1. Demonstrating the proper handling of measuring tools. Actual demonstration Direct observation Written test/questioning 2 hours

Kinds of measurement Dimensions Ratio and proportion Conversion

LO2. Carry out measurement and calculations.

1. Measuring lengths, width, and thickness of pieces of wood.

Written Test Performance Test

4 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project/ Activities

Assessment

Duration

LESSON 4: INTERPRETING DRAWINGS AND PLANS Demonstrate understanding of/on: Drawing symbols and signs 1. Signs, symbols, and data are identified according to job specifications. 2. Signs, symbols, and data are determined according to classification or appropriateness in drawing. 1. Necessary tools, materials, and equipment are identified according to the plan. 2. Components, assemblies or object are recognized as per job requirement. 3. Dimensions and specifications are identified according to job requirements. 4. Correct freehand sketching is produced in accordance with the job requirements LO1. Analyze signs, 1. Drawing and describing the symbols, and different signs and symbols data. used in the project plans. Written test Performance test 4 hours

Basic technical drawing Technical plans and schematic diagram

LO2. Interpret technical drawings and plans.

1. Explaining the specific uses of lines in the drawing.

Performance test Written test

2 hours

Correct freehand sketching

LO3. Apply freehand 2. Demonstrating freehand sketching sketching

Performance test Written test

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard

Performance Standard

Project/ Activities

Assessment

Duration

LESSON 5: PRACTICING OCCUPATIONAL HEALTH AND SAFETY PROCEDURES Demonstrate understanding of/on: Hazards and risks identification and control Organizational safety and health protocol Threshold limit value (TLV) OHS indicators 1. Workplace hazards and risks are identified and clearly explained. 2. Hazards/risks and their corresponding indicators are identified in accordance with the company procedures. 3. Contingency measures are recognized and established in accordance with organizational procedures. 1. Terms of maximum tolerable limits are identified based on threshold limit values (TLV) 2. Effects of hazards are determined. 4. OHS issues and concerns are identified in accordance with workplace requirements and relevant workplace OHS legislation. 1. OHS procedures for controlling hazards and risks are strictly followed. LO1. Identify hazards and risks. 1. Listing down the possible hazards and risks common in the workplace. Performance test Written test

TLV table Philippine OHS standards Effects of hazards in the workplace Ergonomics ECC Regulations

LO2. Evaluate hazards and risks.

1. Writing some possible remedies of known hazards and risks in the workplace

Performance test Written test

Safety regulations Clean air act Electrical and fire safety code

LO3.

Control hazards and risks.

1. Writing the importance of knowing the hazardous and risky objects/fixtures in the workplace.

Written test Performance test

4 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION INDUSTRIAL ARTS CARPENTRY (Exploratory)

Learning Competencies

Content Standard Waste management Disaster preparedness and management Contingency measures and procedures

Performance Standard 2. Procedures in dealing with workplace accidents, fire, and emergencies are followed in accordance with the organizations OHS policies. 3. Personal protective equipment (PPE) is correctly used in accordance with organizations OHS procedures and practices. 4. Procedures in providing appropriate assistance in the event of workplace emergencies are identified in line with the established organizational protocol. 1. Procedures in emergency related drill are strictly followed in line with the established organizational guidelines and procedures. 2. OHS personal records are filled up in accordance with workplace requirement 3. PPEs are maintained in line with organizational guidelines and procedures.

Project/ Activities

Assessment

Duration

Operational health and safety procedures, practices, and regulations Emergency-related drills and training

LO4.

Maintain occupational health and safety awareness.

1. Explain the advantages of practicing safety precautions in the work area.

Written test Performance test

3 hours

39 hours

*TWG on K to 12 Curriculum Guide version January 31, 2012

Você também pode gostar

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationNo EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationNota: 5 de 5 estrelas5/5 (1)

- Practical Project Management: Learning to Manage the Professional, Second EditionNo EverandPractical Project Management: Learning to Manage the Professional, Second EditionNota: 2.5 de 5 estrelas2.5/5 (2)

- Deped K To 12 Technology and Livelihood Education - MasonryDocumento8 páginasDeped K To 12 Technology and Livelihood Education - Masonryyachiru121Ainda não há avaliações

- Deped K To 12 Technology and Livelihood Education - PlumbingDocumento8 páginasDeped K To 12 Technology and Livelihood Education - Plumbingyachiru12175% (4)

- Deped K To 12 Technology and Livelihood Education - Tile SettingDocumento9 páginasDeped K To 12 Technology and Livelihood Education - Tile Settingyachiru121100% (1)

- Deped K To 12 Technology and Livelihood Education - Mechanical DrawingDocumento5 páginasDeped K To 12 Technology and Livelihood Education - Mechanical Drawingyachiru121100% (5)

- Deped K To 12 Technology and Livelihood Education - SmawDocumento6 páginasDeped K To 12 Technology and Livelihood Education - Smawyachiru121Ainda não há avaliações

- Deped K To 12 Technology and Livelihood Education - EimDocumento8 páginasDeped K To 12 Technology and Livelihood Education - Eimyachiru121100% (2)

- Deped K To 12 Technology and Livelihood Education - DomracDocumento6 páginasDeped K To 12 Technology and Livelihood Education - Domracyachiru121Ainda não há avaliações

- Deped K To 12 Technology and Livelihood Education - Bread and Pastry Production - 001Documento7 páginasDeped K To 12 Technology and Livelihood Education - Bread and Pastry Production - 001yachiru12183% (6)

- Deped K To 12 Technology and Livelihood Education - Novelty CraftsDocumento6 páginasDeped K To 12 Technology and Livelihood Education - Novelty Craftsyachiru12167% (3)

- Deped K To 12 Technology and Livelihood Education - Household ServicesDocumento6 páginasDeped K To 12 Technology and Livelihood Education - Household Servicesyachiru12191% (11)

- Deped K To 12 Technology and Livelihood Education - Nail CareDocumento6 páginasDeped K To 12 Technology and Livelihood Education - Nail Careyachiru12175% (4)

- Unit of Competency: Prepare Construction Materials and Tools Code: Module Title: Preparing Construction Materials and ToolsDocumento19 páginasUnit of Competency: Prepare Construction Materials and Tools Code: Module Title: Preparing Construction Materials and ToolsEva MarquezAinda não há avaliações

- Deped K To 12 Technology and Livelihood Education - Tailoring DressmakingDocumento5 páginasDeped K To 12 Technology and Livelihood Education - Tailoring Dressmakingyachiru121100% (1)

- Deped K To 12 Technology and Livelihood Education - Computer Hardware ServicingDocumento7 páginasDeped K To 12 Technology and Livelihood Education - Computer Hardware Servicingyachiru121100% (4)

- Deped K To 12 Technology and Livelihood Education - Agri-CropsDocumento7 páginasDeped K To 12 Technology and Livelihood Education - Agri-Cropsyachiru12193% (14)

- Deped K To 12 Technology and Livelihood Education - Commercial CookingDocumento5 páginasDeped K To 12 Technology and Livelihood Education - Commercial Cookingyachiru121100% (7)

- Learning OutcomeDocumento32 páginasLearning Outcomeivyjeanladlada20Ainda não há avaliações

- TG in PC Hardware ServicingDocumento5 páginasTG in PC Hardware ServicingZel Ocampo TuazonAinda não há avaliações

- K To 12 CG - Pchs - v1.0Documento5 páginasK To 12 CG - Pchs - v1.0Shaira Lhoan C. ReyesAinda não há avaliações

- CG Animal ProductionDocumento5 páginasCG Animal ProductionFrancis A. BuenaventuraAinda não há avaliações

- Budget of Work G 7-8Documento7 páginasBudget of Work G 7-8Marites Jolongbayan FloresAinda não há avaliações

- Deped K To 12 Technology and Livelihood Education - Care GivingDocumento14 páginasDeped K To 12 Technology and Livelihood Education - Care Givingyachiru121100% (1)

- PLM NC II CommonDocumento133 páginasPLM NC II CommonRegie Dumaran CubaAinda não há avaliações

- Heavy Equipment Servicing (Mechanical) NC IIDocumento63 páginasHeavy Equipment Servicing (Mechanical) NC IIMichael Cancho100% (2)

- Deped K To 12 Technology and Livelihood Education - AquacultureDocumento7 páginasDeped K To 12 Technology and Livelihood Education - Aquacultureyachiru121Ainda não há avaliações

- CPCCSF2003A Cut and Bend Materials Using Oxy LPG Equipment LR V1Documento141 páginasCPCCSF2003A Cut and Bend Materials Using Oxy LPG Equipment LR V1FfdsfdsAinda não há avaliações

- Maintain Tools and EquipmentDocumento23 páginasMaintain Tools and Equipmentray100% (1)

- K To 12 CG - Nail Care - v1.0Documento5 páginasK To 12 CG - Nail Care - v1.0Levi Lico PangilinanAinda não há avaliações

- Common 4 PipefittingDocumento29 páginasCommon 4 PipefittingValcy Madz100% (1)

- Deped K To 12 Technology and Livelihood Education - HorticultureDocumento5 páginasDeped K To 12 Technology and Livelihood Education - Horticultureyachiru121Ainda não há avaliações

- TESDADocumento77 páginasTESDAsarcastically-yours100% (1)

- Carpentry LessonDocumento118 páginasCarpentry LessonJessica RebodosAinda não há avaliações

- Mensuration and CalculationDocumento35 páginasMensuration and CalculationValcy Madz100% (3)

- Tle Plumbing LMDocumento131 páginasTle Plumbing LMAdrian Goze Reformina92% (13)

- PTS Module - Common - Uc1Documento10 páginasPTS Module - Common - Uc1mariaestercampos22Ainda não há avaliações

- Ict - Computer Hardware Servicing CGDocumento4 páginasIct - Computer Hardware Servicing CGnganodiliman100% (1)

- K To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Documento14 páginasK To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Bri CorpuzAinda não há avaliações

- Plumbing Y2Documento67 páginasPlumbing Y2Cygie Gador100% (1)

- Mecha Perform CalculationsDocumento8 páginasMecha Perform CalculationsvorexxetoAinda não há avaliações

- Y2 - Module 1 - Preparing Plumbing Materials and ToolsDocumento35 páginasY2 - Module 1 - Preparing Plumbing Materials and ToolsMichael ReyesAinda não há avaliações

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1No EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Nota: 4.5 de 5 estrelas4.5/5 (2)

- Materials Enabled Designs: The Materials Engineering Perspective to Product Design and ManufacturingNo EverandMaterials Enabled Designs: The Materials Engineering Perspective to Product Design and ManufacturingNota: 4 de 5 estrelas4/5 (1)

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignNo EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignNota: 4 de 5 estrelas4/5 (16)

- Cape Communication Studies: Practical Exercises for Paper 02 EssaysNo EverandCape Communication Studies: Practical Exercises for Paper 02 EssaysAinda não há avaliações

- ISO IEC 27001 Lead Implementer A Complete Guide - 2020 EditionNo EverandISO IEC 27001 Lead Implementer A Complete Guide - 2020 EditionAinda não há avaliações

- Construction Supervisor II: Passbooks Study GuideNo EverandConstruction Supervisor II: Passbooks Study GuideAinda não há avaliações

- Assess Notes Nursing AssessmentDocumento206 páginasAssess Notes Nursing Assessmenttostc100% (7)

- API Review Muscles f2009Documento1 páginaAPI Review Muscles f2009yachiru121Ainda não há avaliações

- Bacteriology ReviewDocumento47 páginasBacteriology ReviewDeti ParidlahAinda não há avaliações

- Anatomy Thorax ReviewDocumento18 páginasAnatomy Thorax Reviewyachiru121Ainda não há avaliações

- Anatomy and Physiology I Fall 2009 Exam I Study GuideDocumento1 páginaAnatomy and Physiology I Fall 2009 Exam I Study Guideyachiru121Ainda não há avaliações

- Anatomy Head ReviewDocumento34 páginasAnatomy Head ReviewJordan BrooksAinda não há avaliações

- Anatomy Lower Extr ReviewDocumento12 páginasAnatomy Lower Extr Reviewabuzeid5Ainda não há avaliações

- First Aid ManualDocumento225 páginasFirst Aid ManualHugo MartinsAinda não há avaliações

- Anatomy and Physiology Unit III: Objectives/RationaleDocumento16 páginasAnatomy and Physiology Unit III: Objectives/Rationaleyachiru121Ainda não há avaliações

- AP Review NotesDocumento15 páginasAP Review Notesyachiru121Ainda não há avaliações

- Anatomy Levels and Planes ReviewDocumento3 páginasAnatomy Levels and Planes Revieware4erAinda não há avaliações

- Anatomy Tables - Bones of The Thorax: Bone Structure Description Notes RibDocumento3 páginasAnatomy Tables - Bones of The Thorax: Bone Structure Description Notes Ribyachiru121Ainda não há avaliações

- DEPED - The K To 12 Basic Education Programv2 - 2012Documento38 páginasDEPED - The K To 12 Basic Education Programv2 - 2012yachiru121100% (1)

- Bones and Cartilages of The Head and NeckDocumento27 páginasBones and Cartilages of The Head and Neckyachiru121100% (1)

- Bones of The Pelvis and PerineumDocumento6 páginasBones of The Pelvis and Perineumyachiru121Ainda não há avaliações

- Bones of The Upper LimbDocumento14 páginasBones of The Upper Limbyachiru121Ainda não há avaliações

- Bones of The Lower LimbDocumento15 páginasBones of The Lower Limbyachiru121Ainda não há avaliações

- Bones of The Abdominal RegionDocumento7 páginasBones of The Abdominal Regionyachiru121Ainda não há avaliações

- Bones of The Back RegionDocumento9 páginasBones of The Back Regionyachiru121Ainda não há avaliações

- DEPED 2012 - K TO 12 - MTB RationaleDocumento30 páginasDEPED 2012 - K TO 12 - MTB Rationaleyachiru121100% (3)

- DEPED 2012 - K TO 12 - Learning DR VillanezaDocumento32 páginasDEPED 2012 - K TO 12 - Learning DR Villanezayachiru121100% (1)

- DEPED 2012 - K TO 12 - L1-L2-L3-Dr. GironDocumento56 páginasDEPED 2012 - K TO 12 - L1-L2-L3-Dr. Gironyachiru121Ainda não há avaliações

- DEPED 2012 - Classroom DR VillanezaDocumento17 páginasDEPED 2012 - Classroom DR Villanezayachiru121100% (1)

- GHCPregistrationform 2012Documento1 páginaGHCPregistrationform 2012yachiru121Ainda não há avaliações

- DEPED - K To 12 Assessment & Rating - 2012Documento44 páginasDEPED - K To 12 Assessment & Rating - 2012yachiru121Ainda não há avaliações

- HandbookDocumento48 páginasHandbookyachiru121100% (1)

- HandbookDocumento53 páginasHandbookyachiru121Ainda não há avaliações

- HandbookDocumento60 páginasHandbookyachiru121Ainda não há avaliações

- TESDA Post Test With Answers ReviewerDocumento13 páginasTESDA Post Test With Answers Reviewermaximrose93% (73)

- ACI JTA Concrete Field Technicican PDFDocumento4 páginasACI JTA Concrete Field Technicican PDFjerin sam kurianAinda não há avaliações

- Jee+main+2021 +math+mock+test+-+ (10) +complete+syllabus+Documento68 páginasJee+main+2021 +math+mock+test+-+ (10) +complete+syllabus+M.SHOURYA VARDHANAinda não há avaliações

- Yr 10 Term 4 Letter 2017 PDFDocumento2 páginasYr 10 Term 4 Letter 2017 PDFMrmr MeroAinda não há avaliações

- CIVE466 Syllabus 2016Documento3 páginasCIVE466 Syllabus 2016NgocTraiNguyenAinda não há avaliações

- s10639 018 9707 5 PDFDocumento13 páginass10639 018 9707 5 PDFKokak DelightsAinda não há avaliações

- Student BookDocumento72 páginasStudent BookAyyaz FakharAinda não há avaliações

- Faculty of Foreign Languages: Revision For Basic English 03 A. Speaking Test Format Duration FormatDocumento10 páginasFaculty of Foreign Languages: Revision For Basic English 03 A. Speaking Test Format Duration FormatNGUYỄN THỊ THÚY AN DHQT13A3HNAinda não há avaliações

- Percentile Rank of Grouped DataDocumento57 páginasPercentile Rank of Grouped Datageat gahgahgahshsh100% (1)

- Fundamentals of Computational Fluid DynamicsDocumento1 páginaFundamentals of Computational Fluid Dynamicsankit dimriAinda não há avaliações

- Syllabus For Negotiable Instruments LawDocumento11 páginasSyllabus For Negotiable Instruments LawmickAinda não há avaliações

- 2017 Sem 1 ENG467 Unit InformationDocumento5 páginas2017 Sem 1 ENG467 Unit InformationAmrit AcharyaAinda não há avaliações

- Asam 151W Asian Eats: Asian American Foodways: Industrial Tech Rm. 294Documento23 páginasAsam 151W Asian Eats: Asian American Foodways: Industrial Tech Rm. 294Jacquelaine WongAinda não há avaliações

- Diploma in Dairy TechnologyDocumento13 páginasDiploma in Dairy TechnologyLokesh LokiAinda não há avaliações

- CRISIL CCAP Programme FaqDocumento3 páginasCRISIL CCAP Programme FaqFidel GeorgeAinda não há avaliações

- Cuet (UG) - 2022: Common University Entrance Test (Undergraduate)Documento109 páginasCuet (UG) - 2022: Common University Entrance Test (Undergraduate)Diya SahaAinda não há avaliações

- Recovering The Humankind's Past and Saving The Universal HeritageDocumento5 páginasRecovering The Humankind's Past and Saving The Universal HeritagePaula ZorziAinda não há avaliações

- National Aptitude Test: NAT 2014-IDocumento4 páginasNational Aptitude Test: NAT 2014-Iquantum16Ainda não há avaliações

- Short Learning Programmes: Centre For Software Engineering (CENSE)Documento65 páginasShort Learning Programmes: Centre For Software Engineering (CENSE)BonginkosiAinda não há avaliações

- Mimin Test QDocumento7 páginasMimin Test QJessa Mine Bulawit Bracamonte100% (1)

- 9th Grade Ela Syllabus 2Documento6 páginas9th Grade Ela Syllabus 2adchy7Ainda não há avaliações

- DFDFDSFDocumento2 páginasDFDFDSFFarazAinda não há avaliações

- IT TG Normalisation To Third Normal Form 9626Documento18 páginasIT TG Normalisation To Third Normal Form 9626ahsan100% (1)

- The GaokaoDocumento19 páginasThe GaokaoJoseph Quarcoo50% (2)

- Quiz AppDocumento29 páginasQuiz AppSujit Khandare100% (1)

- Case 5Documento11 páginasCase 5Nicole SugayAinda não há avaliações

- Psycho Metric Assessment - Character, Ability, Motivation - RashmiDocumento16 páginasPsycho Metric Assessment - Character, Ability, Motivation - Rashmirashmi_shantikumar50% (2)

- GT 7 PDFDocumento20 páginasGT 7 PDFumair baigAinda não há avaliações

- PMI PBA Exam Prep QuestionsDocumento663 páginasPMI PBA Exam Prep QuestionsТанюшка Безушко100% (6)