Escolar Documentos

Profissional Documentos

Cultura Documentos

Operation and Maintenance Regulation For Finishing Mill

Enviado por

Abhijitkar89Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Operation and Maintenance Regulation For Finishing Mill

Enviado por

Abhijitkar89Direitos autorais:

Formatos disponíveis

SHANGHAI HEAVY MINING MACHINERY LTD.

Operation and maintenance regulation of 150,000 ton / annual rolling mill line for wire rod RASHMI, INDIA

SHANGHAI HEAVY MINING MACHINERY LTD

2010.12

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 0 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

Chapter 1. Regulation

I. Parameter for equipment 1. Pinch roll before no-twist mill Diameter of pinch roller: Max distance of pinch roller: Min distance of pinch roller: Motor model: Power: Voltage: Rotary speed: Ratio: Rolling speed: Cylinder: Working pressure: 295mm310mm 335mm 298mm Z4-160-31 22kw DC 440V 10002000 r/min 0.963 6~12m/s 125x200mm 0.40.63mpa

2. Crop shear Motor model: Power Voltage Rotary speed Rotary diameter of blade Ratio Overlap of blade: Rolling speed Cutting temperature ZFQZ-315-081 112kw DC 440v 5001000 r/min 800mm 1 0.250.75mm 15 m/s 850

Rev : 0 Date: 6/27/2011 Item: Page: 2 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

Cutting section

max 17

3. Chopping shear Motor model Power Voltage Rotary speed Distance between centers of Rotary blade and pinch roller: Diameter of pitch circle Ratio: Distance between centers of Rotary blade: Diameter of pitch circle Ratio: Diameter of piston Diameter of piston rod Stroke: Diameter of rotary blade: Overlap of blade: Chopping length: 250mm 250mm 1 160mm 40mm 40mm 250mm 0.250.75mm 260mm 443.5mm 164mm 1 Z4-225-11 75kw DC 440v 10002000r/min

4. Side looper Working pressure Diameter of piston 0.4 0.6 MPa 130mm

Rev : 0 Date: 6/27/2011 Item: Page: 3 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

Piston stroke Forming range

254 mm 300600mm

5. Snap shear Working temperature: Rolling piece speed Cylinder diameter & stroke Cylinder working pressure 850 68 m/s 63mm x 70mm 0.4Mpa

6. 8-stand heavy duty no-twist mill Motor model Power Rotary speed Voltage Cascade connection for 2 motors Roller ring size N0.1 N0.3 N0.4 N0.8 Rolling torque 200 rolling mill stand 150 rolling mill stand Rolling force 200 rolling mill stand 150 rolling mill stand P = 152 KN P = 107.8 KN M = 2.86 KNm M = 1.61 KNm 210.5(max)189.5(min) x 72 mm 158.8(max)142.91(min) x 62 mm Z710-320 1300KW 10001300 r/min DC 750V

Rolling mill stand type and quantity: 45 top cross 8-stand centralized drive

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 4 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

Cooling water working pressure Cooling water consumption Speed-up gear box Ratio for high speed output shaft Ratio for low speed output shaft

0.5 0.6 Mpa3 max 30m/h for each stand

0.2866 0.3503

Ratio for each stands Stands No. No1 200 No2 200 No3 200 No4 150 No5 150 No6 150 No7 150 No8 150 Lubrication Oil working pressure Oil consumption Oil model Cleanliness Cooling water for roller Working pressure Water consumption 0.5~0.6mpa Max.830m/h Ratio 1.01206818 0.80487113 0.66878989 0.40239947 0.32262096 0.25726428 0.20520449 0.16346826 centre oil lubrication 0.35mpa 800 l/min Mobil 525 10

Hydraulic system for protecting jacket Working pressure 15mpa

Rev : 0 Date: 6/27/2011 Item: Page: 5 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

System flow Working pressure for load the roller: Working pressure for unload the roller:

20 l/min max22.5mpa max 60mpa

7. Pinch roll before lying head Motor model Power Voltage Rotary speed Gear box ratio Max pinch force Cooling water pressure Water flow Lubrication oil pressure Oil flow Pressed air pressure Air flow Z4-180-41 55 KW DC 440v 1500 3000 r/min 1/4.247 3350 N 0.40.6 MPa 10 m/h 0.35 MPa 25L/min 0.40.6 MPa 10 m/h

8. Lying head Product size Diameter of coil Max produce speed Motor model Power Voltage 5.5mm 16mm 1080mm 65 m/s Z4-200-31 90 KW DC 440V

Rev : 0 Date: 6/27/2011 Item: Page: 6 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

Rotary speed Ratio Diameter of cylinder piston Diameter of cylinder piston rod Cylinder stroke Working pressure

15003000 r/min 1.538 200 mm 50 mm 610 mm 0.6 MPa

9. Cooling roller table Roller table driven motor Power Rotary speed Quantity Ratio Diameter of roller Roller center distance YTSP132M-4 7.5KW 1480 r/min 7 set 7 120mm 295mm

Lifting motor model Power Rotary speed Ratio Diameter of roller Roller center distance

Y132M-4 7.5KW 1440 r/min 24 120mm 127mm

Push rod motor model

Y112M-6

Rev : 0 Date: 6/27/2011 Item: Page: 7 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

Power Rotary speed Diameter of roller Roller center distance

2.2KW 1480 r/min 120mm 295mm

Roller length Line speed of roller table Drop height between sections

1450 mm 0.251.5m/s 250mm

10. Blower Motor model Power Rotary speed Quantity Air volume Air pressure Cooling bearing water consumption Water pressure Y2-315M-6 90KW

980 r/min 5 sets max 110000 m/h 1900 Pa 1.52t/h 0.20.4 MPa

11. Reform station Inside diameter of coil collecting device Elevating distance Air cylinder for finger Inside diameter of cylinder 200mm

Rev : 0 Date: 6/27/2011 Item: Page: 8 of 67 CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

1250 mm 50 mm

SHANGHAI HEAVY MINING MACHINERY LTD.

Stroke Working pressure Hydraulic cylinder Stroke Coil plate lifting motor model Power Rotary speed Brake torque: Ratio Hydraulic cylinder for coil plate Inside diameter of cylinder Stroke Double-support arm spindle motor model Power Rotary speed Brake torque

320mm 0.40.6 MPa 40 x 28mm 290mm YTSZ280S-6 55KW 975 r/min 1600 NM I = 27.96

80mm 440mm

YTSZE200L1-4 30KW 1470 r/min 300 NM

12. Coil transport car Coil transport car motor model Power Rotary speed Brake torque Transport speed Ratio YTSZ225S-8 22KW 735 r/min 400 630 NM 300 mm/s I = 9.75

Rev : 0 Date: 6/27/2011 Item: Page: 9 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

13. Bundling machine Tying coil motor model Power Rotary speed Quantity Driving supporting motor model Power Rotary speed Diameter of hydraulic cylinder Stroke Force Max bundling length Min bundling length Y100L1-4 2.2KW 1480 r/min 4 Y132S-4 5.5KW 1480 r/min 200mm 1700mm 40 t 3650mm 600mm

14. Coil weighing scale Hydraulic cylinder stroke weigh range accuracy scale mark coiloutside diameter / inside diameter / thickness max coil weight 1250/850/1800 mm 2000 Kg

Rev : 0 Date: 6/27/2011 Item: Page: 10 of 67

125 x90 mm 500mm 0 2500 Kg 1 Kg 1 Kg

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

II. Regulation for operation 1. Pinch roll before no-twist mill Feature Pinch roll before no-twist mill located before crop shear, and it pinch the rolling piece to no-twist mill while normally rolling. It consists of body, gear shaft, arm and a pair of rollers, and the rollers could adjust by an air cylinder. The air cylinder controlled by electromagnetic valve.

Function 1) Pinch roll pinch the rolling piece while the crop shear crop the head of rolling piece by signal send from HMD, it will not release until the rolling piece be conveyed into block mill. 2) Pinch the rolling piece the whole rolling time 3) Pinch the tail of rolling piece

1.1 Pinch rolls speed is 100%~120% of rolling pieces speed, and the pinch force could adjust according to motors output torque. The setting pinch force make the motor get the max output torque when motor speed is 10% of rated motor speed.

1.2 It will pinch the rolling piece immediately while accident happens, and it should release the rolling piece when the problem is solved.

1.3 It could choose whether pinch the rolling piece the whole rolling time or not when normally rolling.

1.4 It should pinch the head of rolling piece after a time delay when HMD

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 11 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

detect the head of rolling piece.

1.5 It could release the rolling piece after the rolling piece be conveyed into block mill.

1.6 When the lubrication oil flow detected by oil flow indicator is lower than 3L/min, the system alarms, and the pinch roller must stop when alarm last 2 minutes. When the lubrication oil flow detected by oil flow indicator is lower than 1.5L/min and last 30s, pinch roll must stop immediately.

1.7 When the lubrication oil pressure detected by pressure gauge is lower than 0.25Mpa, system alarms, and the pinch roll must stop when the alarm last 2 minutes. When the lubrication oil pressure detected by pressure gauge is lower than 0.15MPa and last 30s, pinch roll must stop immediately.

1.8 When the pressed air pressure detected by pressure gauge is lower than 0.35Mpa, system alarms, and pinch roll must stop when the alarm last 2 minutes.

1.9 Vulnerable part list:

No. 1 2 3 description entrance duct exit duct ogalloy type / model drawing No. / standards HC2010-004 HC2010-005 HC2010-002-16 material Q235 Q235 iron-base Qty 1 piece 1 piece 2 pieces

Rev : 0 Date: 6/27/2011 Item: Page: 12 of 67

remarks welded part welded part

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No. 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

description ogalloy ogalloy liner roller sealing ring joint bearing sealing ring bearing 46211 O ring O ring bearing 32514 O ring bearing 3511 nozzle pressure relief valve electromagnetic valve one-way throttle valve triple unit

type / model

drawing No. / standards HC2010-002-25 HC2010-002-29 HC2010-002-34 HC2010-002-54 HC2010-002-56

material iron-base iron-base ZQA19-4 45/alloy Fluoro-rubber

Qty 4 pieces 2 pieces 4 pieces 2 pieces 2 pieces 3 pieces 1 piece 4 pieces

remarks

UG30 PD70x95x12 55x100x21 d=3.1 L=6900 70x3.1 70x125x70 165x3.1 55x100x25 ZG3/4

GB304-64 HG4-696-67 GB293-64 GB1235-76 GB1235-76 GB283-64 GB1235-76 GB286-64 PZ86908 PJ-L25-51 rubber 1-2 rubber 1-2 rubber 1-2

product product product product product product product product product product product product product

1 piece 4 pieces 2 pieces 4 pieces 4 pieces 2 pieces 1 piece 1 piece 2 pieces 1 piece

AC220V

25D2-25-L1 LA-L25-L1

398-293

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 13 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

2. Crop shear Feature Crop shear located between pre-finishing mill and block mill, it using for rolling pieces head cut, rolling pieces tail cut and accident cut. Crop shear adopt rotary structure and driven by a 112Kw motor through gear coupling without mechanical braking. Two blades assemble on two parallel shafts which connected by a pair of gears. The gear ratio is 1:1, and that makes the two shafts as same rotary speed but reverse rotary direction. The blades overlap and cut the rolling piece once a cycle driven by motor through the gear coupling. After cutting, the shaft hold in the prepare position controlled by proximity switch and the location detector on motor.

2.1 Crop shear could operate automatic or manually. Manual: controlled by operator press buttons Automatic: controlled by computer for non-link cut and accident cut

2.2 The blades hold the prepare position at 90in coordinates, when get the cut signal, the blades start clockwise rotary and speed-up to the cutting speed according to the rolling speed. The rolling speed about 6 12 m/s is detected from the exit of pre-finishing mill, and the cutting speed could add a adjustable overspeed to the rolling speed. Blades depart from rolling piece before it get 30in coordinates, then start braking by motor. Blades go to the prepare position with creeping speed (motor rotary speed about 5060 rpm) with precision 1.

2.3 There are an oil flow indicator and a pressure gauge for the crop shear

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 14 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

to ensure the normally lubrication. It will alarm while the oil flow and oil pressure are lower than the setting value.

2.4 Rolling pieces head cutting While HMD detect the rolling pieces head, the pulser which located between duct and pinch roll starts to work. When the pulse counter achieves the setting value, the HMD send the signal to crop shear, and the crop shear starts the cutting period. When blades cut the rolling piece, the blades' speed is 520 faster than the rolling speed and adjustable. After the rolling pieces head is cut, the rolling piece goes into the switcher which located after crop shear. The switcher is on the crop position before the rolling piece head into the block mill through side looper. As soon as rolling piece enter into the block mill, the switcher turn to the chop position and get ready for chopping if the accident happens. While the rolling piece tail depart from pinch roll and rolling normally, switcher turn back to crop position and ready for cut the rolling pieces tail and cut next rolling pieces head.

2.5 Rolling pieces tail cutting While HMD detect the rolling pieces head, the pulser which locate between duct and pinch roll starts work. When the pulse counter achieves the setting value, the HMD send the signal to crop shear, and the crop shear starts the cutting period. When blades cut the rolling piece, the blades speed is equal the rolling speed even slower than the rolling speed. The switcher is on the crop position and the cut off piece being guided to the chute.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 15 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

2.6 Accident cut Accident cut start by detecting system automatic or manual. The cut speed should 515 faster than rolling speed while accident cut, and the switcher should turn to the chop position and ensure guide the rolling piece to the chopping shear. It should set the cut speed by pulpit when manual setting.

2.7 Non-link cut There is a button in the local box that could act the non-link cut when permissible. It could finish once cut period after press the button once, and the cut speed is set by pulpit. This function is for test run usually.

2.8 Installation and adjustment for crop shear 2.8.1 Installation: It should follow technical requirement on drawings and listed standards: (1) Metallurgical mechanical equipment installation and acceptance check standard General: YBJ201-83 (2) Metallurgical mechanical equipment installation and acceptance check standard - Hydraulic, pneumatic and lubrication system: YBJ207-85 (3) Metallurgical mechanical equipment installation and acceptance check standard rolling equipment: YB9249-93 The crop shear installation precision adopt class I (4) The installation of electrical equipment on crop shear should follow the national standards or profession standards.

2.8.2 Adjustment: the adjust must after equipment installed completely

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 16 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

and acceptance check qualified. The adjustment should follow the drawing and list requirement: (1) The gap between two blades should in 0.2 0.25 mm, and the overlap of two blades should less than 0.75 mm. It should adjust the gear backlash of gear first, then adjust the gap to 0.2 0.25 mm by regrinding the washer. The overlap of blades should adjust by regrinding the blade and adding washer. (2) The adjustment for entrance and exit guide plate should ensure the rolling piece enter and exit crop shear smoothly. (3) Each rotary part should act smoothly, and could adjust the bearing gap if necessary. (4) It should ensure the oil distribution system distribute the oil to each lubrication point with right flow, and make sure there is no jamming and leakage. (5) Driven the crop shear several cycles manually, and make sure that the blades not crash.

2.9 Examination

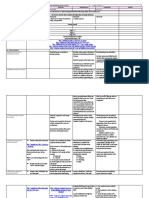

location box body bearing lubrication pipes blade blade blade blade aim leakage working pressure and leakage wear gap loose or not loose or not part / place seal place bearing state working working period each shift each shift way Humans eye hear voice and measure the temperature humans eye Humans eye feeler gauge humans eye humans eye

Rev : 0 Date: 6/27/2011 Item: Page: 17 of 67

pressure gauge working each shift and pipes blades edge unworking each shift between blades unworking each shift bolt bolt unworking each shift unworking each shift

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

location gear

aim wear

part / place tooth face

state

period

way humans eye

unworking half a year

2.10. Vulnerable parts list

No. 1 2 3 4 5 6 description blade bearing 3053720 sealing bearing 240308 bearing 3003130 sealing 100x165x52 B170x200x15 150x225x75 150x225x56 B22x40x7 model / specification drawing No./ standard HB2100-007-04R GB288-87 GB9877.1-88 NTN GB288-87 GB9877.1-88 rubber I-1 rubber I-1 material 5cr5WM Vsi Qty 2 pieces 4 pieces 3 pieces 2 pieces 2 pieces 1 piece remarks

product product product product product

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 18 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

3. Switcher Feature Switcher located after crop shear and guides the rolling piece to side looper while normally rolling and guide to chopping shear while accident happens. Switcher consists of switcher body and air cylinder. 3.1 Switcher has two working positions, one is crop position, and another is chop position, and switch position by a change valve. The rolling piece will be guided to side looper while switcher is on crop position, and will be guided to chopping shear while switcher is on chop position. There are two proximity switches to detect the switchers working position.

3.2 Vulnerable part list

No. 1 2 3 4 5 6 7 8 description bearing 311 bearing 314 air cylinder scraper seal one-way throttle valve electromagnetic valve triple-unit muffler (M27x2) model / specifications 55x120x29 70x150x35 JB160x80-S FA80x90x6.3 LA-L20-L1 25D2-20-L1 399-283 X5-L20-L1 2 material quantity 1 1 1 1 2 1 remarks product product product product product product product product

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 19 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

4. Chopping shear Feature Chopping shear chop the rolling piece while accident happens after chopping shear on rolling line. Chopping shear consist of shear body and motor. Three blades on both the blade base, that makes 3 cut while the shaft run a cycle. The pinch roll on chopping shear driven by shaft through belt, and pinch act by air cylinder.

4.1 Chop the rolling piece come from crop shear while accident happens.

4.2 Three blades on both the blade base, that makes 3 cut while the shaft run a cycle. The pinch roll on chopping shear driven by shaft through belt, and pinch act by air cylinder. Chopping length: Diameter of rotary blade: 260mm 380mm

4.3 Pulpit, MMI and local box near CT could control chopping shear, and should have list functions a. Pinch roll on chopping shear start button with lamp b. Pinch roll on chopping shear stop button with lamp c. Chopping shear start button with lamp d. Chopping shear start bottom with lamp

4.4 Control and interlock Chopping shear could operate automatic or manually. Manual: controlled by operator press button Automatic: controlled by computer with non-link cut and accident cut

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 20 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

4.4.1 Control In manual model, chopping shear start by pressing the start button and stop by pressing the stop button. The cutting speed is controlled by the speed-up / stop / speed-down knob. In automatic model, chopping shear start by pressing the start button and will not stop while rolling. The cutting speed is same as the crop shears cutting speed, which means cutting speed is faster 5-15% than the rolling speed. 4.4.2 Interlock A. When the lubrication oil pressure is lower than 0.3Mpa, the system alarms, and block mill must stop when alarm last 2 minutes. When the lubrication oil pressure is lower than 0.25Mpa and last 30s, block mill must stop immediately. B. When the lubrication oil flow is 0 and last 30s, block mill must stop. C. When the pressed air pressure is lower than 0.3Mpa, system alarms, and block mill must stop when alarm last 2 minutes. When the pressed air pressure is lower than 0.25Mpa and last 30s, block mill must stop immediately.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 21 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

4.5Vulnerable part list

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 description blade sealing O ring bearing 3053222 bearing 53518 air cylinder belt bearing 53516 O ring sealing O ring O ring sealing sealing signaler indicator one-way throttle valve electromagnetic valve muffler triple-unit PD125x60x4 210x7 110x200x 69.8 90x160x4 0 160xS40 B-13700mm 80x140x3 3 140x5 PD125x50x2 170x6 160x5 PD100x30x2 PD70x50x2 YXG-20 0.5KW GZQ-10 LA-L10-S1 K25D-10 XS-L10-L1 399-253 model / specifications Qty 6 2 2 2 2 1 6 4 4 2 4 2 2 2 1 2 2 1 2 1 rubber-4 rubber-4 rubber-4 material 5Cr5WMoVSi drawing No. / standard HB2200-024R JB2600-80 JB/ZQ4224-86 GB288-87 GB288-87 JB1448-74 GB11544-89 GB288-87 GB3452.1 JB2600-80 JB/ZQ4224-86 GB3452.1 JB2600-80 JB2600-80 GB/ZQ4596-86 GB/ZQ4597-86 remarks

product product product product product product product product product product product product product product product product product product product

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 22 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

5. Side looper Feature Side looper located between crop shear and block mill, it could provide non-tension or micro-tension for rolling, and also provide a buffer space for rolling piece. Looper consist of form roller, guide roller, looper body and loop scanner, the looper acted by air cylinder and controlled by loop scanner. Form roller has two positions, one is working position, and another is unworking position. Rolling piece could go through the looper straight while the form roller is on unworking position. Form roller will cross the rolling line when turn to working position from unworking position, and make rolling piece form a loop. The loop will be formed while the rolling pieces head into the block mill with right speed setting.

5.1 Form roller control The form roller be controlled by signal send from detector at upstream (such as looper scanner, HMD), and it should set the advance. The automation system sends the delay signal according to the rolling speed. Form roller could also controlled manual with reach and regain button. Form roller must stay at the unworking position until rolling pieces head into the block mill, it must turn to working position immediately while the rolling pieces head into the block mill. Form roller must stay at the unworking position while accident happens at looper. Form roller must stay at the working position until the rolling pieces tail depart from the block mill, and must turn to the unworking position immediately while rolling piece tail depart from the block mill. It may s cause the loop fall down, rolling piece enter the guide after looper

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 23 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

overlapped and accident if form roller turn to unworking position while rolling piece still in block mill.

5.2 Forming automatic control Forming controlled by loop scanner and loop adjuster, loop scanner detects the forming situation and generate location signal. This location signal is compared with the base valve in the loop adjuster and get deviation signal, and the deviation signal be transformed to speed signal. Controlled by the speed signal, rolling speed be adjusted to make the forming as a setting value.

5.3 Vulnerable part list

No. 1 2 3 4 5 6 7 8 9 10 11 description air cylinder roller assembly (1) roller assembly (2) form roller assembly roller assembly (3) roller assembly (4) one-way throttle valve electromagnetic valve muffler triple-unit nozzle quantity 1 2 1 1 1 1 2 1 2 1 2 KLA-L25 K25D2-25 FXS-L25 398-293 Q235A HC3001-041-01 material drawing No. HC3001-021 HC3001-034 HC3001-035 HC3001-036 HC3001-038 HC3001-039 product product product product remarks

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 24 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

6. Snap shear Feature Snap shear located after the side looper. It will cut off the rolling piece when block mill or equipment after block mill failure to prevent rolling piece into the block mill. It also prevents the rolling piece into the block mill for safety when protecting jacket for block mill is open. Snap shear have two blades and the cutting acted by air cylinder. There is a spring in the cylinder for cutting in case of non-pressure and a proximity switch in the cutting position.

6.1 Control and operation Snap shear could work manually by pulpit and local box or automatic. In manual model, snap shear cut by press close button and release by press open button.

6.2 Interlock 6.2.1 Snap shear must not open while any of list situation happens when automatic model. (1). Main motor for block mill is power off. (2). Block mill lubrication system is failure. (3). Air-oil lubrication system for entrance guide is failure. (4). Protecting jacket for block mill is open. (5). There is no flow of cooling water for roller or low pressure of cooling water for roller. (6). Protection jacket for laying head is open.

6.2.2 Snap shear could open while the all list situation are satisfied.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 25 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

(1). Protecting jacket for block mill is closed. (2). Oil lubrication system for block mill is working normally. (3). Air-oil lubrication system is working normally. (4). Main motor for block mill is working normally. (5). The situation of coiling water for roller is normal. (6). Block mill is working normally, cobble detector is normal. (7). Pinch roll before laying head and laying head are working normally. (8). The open button be pressed.

6.2.3 Snap shear will stop when any of list situations happens when automatic model: (1). The close button be pressed. (2). Main motor for block is stop or the rotary speed is slower than 200 rpm (3). The motor for lubrication shut off suddenly or the pressure of oil is low. (4). Pinch roll before laying head is stop. (5). The situation of cooling water for roller is abnormal. (6). Protecting jacket for block mill is open. (7). Accident happens in block mill. (8). Block mill is abnormal. (9). The cooling roller table is stop.

6.3 Interlock to other equipment 6.3.1 Protecting jacket for block mill must not open until the snap shear is close. Snap shear must not open until protecting jacket for block mill is close.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 26 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

6.3.2 Protecting jacket for laying head must not open until the snap shear is close. Snap shear must not open until protecting jacket for laying head is close. 6.3.3 The form roller in looper must stay the unworking position when the snap shear is close. 6.3.4 The extractor must not eject the billet from the furnace when the snap shear is close.

6.4 Control While the accident happens at downstream in automatic model, the chopping shear should chop the rolling piece and the snap shear should cut the rolling piece. It should follow list process: 6.4.1 Snap shear must not close until chopping shear works. 6.4.2 Snap shear could close after chopping shear works 2s later. And this time is adjustable. 6.4.3 Above process suit for manual model while press the close button meanwhile HMD detect the rolling piece.

6.5 Vulnerable part list

No. 1 2 3 4 5 6 description Air cylinder Blade ogalloy electromagnetic valve Muffler Triple-unit Qty 1 2 4 1 2 1 5Cr5WMoVSi Iron-base 25ZVD-L15-L1 XS-L15-L1 398-263 material Drawing No. HC3002-008 HC3002-013 HC3002-024 product product product remarks

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 27 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

7. Block mill Feature Rolling piece be rolled by 8 stands heavy duty no-twist mill (Block mill) from 13~20 to product 5.5~12. The design speed is 60m/s and the guarantee speed is 50m/s.

These central driven 8 stands adopt 45 top cross structure, them consist of 3 stands of 200 which roller rings dimension is 210.5 / 189.5 72mm and 5 stands of 150 which roller rings dimension is 158.75 / 142.91 62mm. The last 2 stands of 150 are high speed stand. Block mill consist of 8 stands, speed-up gear box, base plate, gear coupling, water fender, protecting jacket and so on. The stands consist of gear boxes and bevel gear boxes, and the roller is cantilever structure.

7.1 Feature for structure 7.1.1 Block mill consist of 3 stands of 200 and 5 stands of 150, and that reinforce the intensity. 7.1.2 The last 2 stands of 150 are super-high speed stand, could increase the exit speed and the guarantee speed could achieve 50m/s. 7.1.3 Stands adopt 45top cross structure, which increase the stability and decrease the equipments weight, and that make the operation and maintenance easier. 7.1.4 The neighbor stands arrange 90(perpendicular) to each other, which makes the no-twist rolling. 7.1.5 The roller adopt cantilever structure, and using the taper sleeve to fix the roller ring in the shaft end. The gear box using eccentric mechanism which has oil-film bearing and roller shaft to adjust the

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 28 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

roller gap. 7.1.6 Bevel gear box consist of body, driving shaft, bevel gear pair, and synchronous gear pair. All gears are hard tooth gear with grade 5 precision to ensure the stable working in high speed. 7.1.7 Gear box and bevel gear box are connected with bolts. During assembling, insert the head of bevel gear box to the gear box, make sure two heads and two roller shaft gears mesh with each other. 7.1.8 By using the thrust bearing, could settle the roller shaft s axial float problem and ensure the dimensional precision of product 7.1.9 Adjustment of roller gap is realized with a screw bar with left and right screw-thread, which will make the eccentric mechanisms rotate in different direction, and the roller gap will change by the eccentric movement of the eccentric mechanism relative to the rolling line, and the location of the original rolling line and the guide are maintained. 7.1.10 The roller ring is made of tungsten carbide, and it is connected to the shaft of roller through the taper sleeve. It should be reload with special hydraulic tool, which makes the reload process easy and fast.

7.2 Assembling and test run Rolling stand and other parts assemble at manufactory, it should follow the standard YB/T036.1892 and technical requirement on drawings. Them will not allow to leave the factory until them pass the no-load test run.

7.2.1 Preparation 1) Clean the parts, remove the dirty and rust, dredge the pipes and holes, coat with rust preventative oil.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 29 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

2) Check the dimensional tolerance of fitting parts. 3) Prepare the measures and tools. 4) Mark the each stands number on because of the different ratio. 7.2.2 Stand assembling 1) bevel gear box The assembling of bevel gear and shaft suggest adopt the pressing fit because of the small range of interference and the disassembling suggest adopt extracting. Adjust the contact pattern and backlash carefully while installing the bevel gear. Increasing contact pattern and suitable backlash will extend the gears life. 2) Oil-film bearing assembling Heat the eccentric sleeve to 120, cool the bearing bush to -80 in dry ice or liquid nitrogen. Correspond the separation line of bearing bushes with the mark line on the eccentric sleeve, and align the oil hole on bearing bush and oil hole on the eccentric sleeve.. Push the bearing bushes into the eccentric sleeve with the guiding of taper guide sleeve. Check the alignment of oil hole on the bearing bush and oil hole on the eccentric sleeve, make sure there is no damage on bearing bushes. 3) Rolling bearing assembling in stands The rolling bearing used in gear box and bevel gear box are all high speed bearing made by MRC. The assembling of rolling bearing and shaft suggesting the different temperature method. The rolling bearing on roller shaft is thrust ball bearing, its backlash should be 0.012~0.038 mm to guarantee the rolling product s quality.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 30 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

4) Assembling and disassembling the roller ring It should using assembly tools with 22.5MPa pressure for assembling the roller ring. It should using disassembly tools with <60MPa pressure for disassembling the roller ring. 5) Other There must no beating to the shaft shoulder and end of baffle ring which using for axial locating while assembly. It should adjust the axial compressing suitably for sealing ring in the rollers neck area, make sure not too tight cause the damage of the sealing ring and not too loose cause leakage. All lubrication pipes should be firm and will not be crashed by the rotary parts. The lubrication pipes must lubricate the gears and bearings well. It should check the list dimensions and satisfy the requirements after assembling

200 stand A B CD 836.60.08 4320.06

150 stand 836.60.08 3800.012

CD<0.1mm

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 31 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

7.2.3 Block mill assembling 1) Assembling order Install the base plate, speed-up gear box and main motor on their position. Install the No.1 No.8 stands on the their position. Install the coupling between motor and speed-up gear box, coupling between speed-up gear box and No.7 stand, coupling between speed-up gear box and No.8 stand and couplings between each stands. Adjust the location accurately of main motor, speed-up gear box and stands, then fasten all parts. Install the water fender and buffer box. Install the cobble detecting device. Install the protecting jacket for block mill. Install the pipes for oil lubrication, hydraulic system and cooling water.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 32 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

2) Guarantee after assembling Gradient of couplings both ends should less than 1/2000, radial displacement should less than 0.06mm. The long shaft s proper alignment on whole length should less than 0.08mm after couplings between stands be installed. The displacement of the center line should less than 0.1mm for neighbor stand, and should less than 0.3mm for whole stands.

7.2.4 No-load test run for single stand 1) It should driven by humans hand firstly for each stand and speed-up gear box after assembling, and make sure all parts run smoothly. The adjustment of roller gap should flexible. 2) Each stand install on the base plate and connect with test run motor after hand driving. The rotary speed of stands input shaft is 1000 r/min and last for 3 hours after all lubrication pipes be connected. Check the joggling voice of gear, the contact pattern and backlash, the temperature rise of oil-film bearing, and the leakage situation of sealing places. 3) The roller should be cooled by cooling water while test run. 4) To make sure the lubrication oil volume is ~100 L/min oil pressure is 0.35MPa, filter precision is 10 and oil temperature is ~38 for each stand. 5) Speed-up gear box connect with test run motor after hand driving. The rotary speed of input shaft is 1000 r/min and last for 3 hours after all lubrication pipes be connected. Check the joggling voice of gear, the contact spot and backlash, the temperature rise of oil-film bearing, and the leakage situation of sealing places.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 33 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

6) To make sure the lubrication oil volume is ~200 L/min oil pressure is 0.35MPa, filter precision is 10 and oil temperature is ~38 for speed-up gear box.

7.2.5 No-load test run for block mill It should run no-load test run after block mill assembling. 1) Necessary condition for block mills test run All oil lubrication points get oil supply according to the requirement of pressure, oil flow, temperature, cleanliness, and oil grade. Apply lubrication grease on each coupling Apply lubrication grease on all lubrication surfaces Supply cooling water onto the roller. Close protecting jacket while the test run. 2) Scheme of test run Test run procedure: start manual operation first, then switch to auto mode; stepping movement before continuous movement; low speed running at first, then switch to middle speed and high speed. No-load test run of the equipment should last for 4 hours continuously for min. Equipment and components should shuttle 5~10 times in stroke range. Adjustment region should be tested 5 times each for min. 3) Requirement for test run Rotary speed of the speed-up gear boxs input shaft should be 1000 r/min during the test run. Vibration strength of the block mill should be lower than 4.5mm/s. Noise level should be lower than 85dB (checked at 10m length of the

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 34 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

block mill). Temperature rise of each rolling bearing should be lower than 40 , and the highest temperature of each rolling bearing should not exceed 80. There should be no oil leakage and water penetration.

7.3 Operation before DC motor start 7.3.1 Check the signals of lubrication system, cooling system, electrical system, pneumatic system and so on. Check the pressure, flow, temperature, cleanliness, oil grade, oil situation of lubrication system. 7.3.2 Apply lubrication grease on each coupling 7.3.3 Apply lubrication grease on all lubrication surfaces 7.3.4 Supply cooling water onto the roller. 7.3.5 Check the grooves abrasion and adjust them. 7.3.6 Make sure all guides clean, check the guide rollers rotary situation. 7.3.7 Make sure the guides center line correspond with the rolling line. 7.3.8 Check the situation of cooling water for groove and nozzles position. 7.3.9 Check the function of control system. 7.3.10 Check the alarm system, controlled by the pulpit. 7.3.11 Check the hydraulic system, and the interlock function to other equipment. 7.3.12 Check the operation of cooling water system. 7.3.13 Check the leakage. (oil lubrication system, cooling water system, hydraulic system, grease lubrication system and so on) 7.3.14 Make sure the parameters setting follow the rolling schedule list.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 35 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

7.3.15 DC motors could adjust speed in cascade model. The rolling speed is accordant with the setting. 7.3.16 Protecting jacket is safe and trustworthy. It is close while rolling. After all mentioned operations be done, the DC motor could start.

7.4 Operation while running 7.4.1 Stepping movement before continuous movement; low speed running at first, then switch to middle speed and high speed. 7.4.2 Make sure the tension situation is normal, and check the situation of cascade control and motors current. 7.4.3 Make sure the vibration intensity of block mill should 4.5mm/s. 7.4.4 Check the situation of rollers and guides, adjust the guides center correspond with the rolling line. 7.4.5 Make sure the rollers axial and radial adjustment smoothly. 7.4.6 Make sure the grooves and guides be cooled well. 7.4.7 There must no leakage and infiltration in joints, pipes and sealing places. 7.4.8 The noise must 85dB (10m far away). 7.4.9 The temperature rise must 40, and the max temperature must 80 7.4.10 Check the situation of oil lubrication and air-oil lubrication every 1~2 hours. 7.4.11 It should stop the cooling water supply before stop the equipment and stop the supply of oil lubrication and air-oil lubrication after equipment been stopped 5 minutes.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 36 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

7.5 Vulnerable part list 7.5.1200 gear box(HB3111-000)

No. 1 2 3 4 5 6 Description Half bushing of oil-film bearing 172050JA Half bushing of oil-film bearing 172050KA Half bushing of oil-film bearing 172050A Half bushing of oil-film bearing 172050B Protecting sleeve O ring model/material Load-bearing end Unload-bearing end Load-bearing end Unload-bearing end 2Gr13 Oil resistant and high-temperature resistant rubber -2 Oil resistant and high-temperature resistant rubber -2 Oil resistant and high-temperature resistant rubber -2 Oil resistant and high-temperature resistant rubber -2 Oil resistant and high-temperature resistant rubber -2 Oil resistant rubber asbestos plate Product Oil resistant and high-temperature resistant rubber -2 Qty Drawing No. 6 6 6 6 6 6 HB3111-022 GB3452.1-82 remark MRC MRC MRC MRC

Sealing ring

12

HB3111-037

O ring 253.55

16

GB3452.1-82

O ring 1953.55

GB3452.1-82

10 11 12 13

O ring 1853.55 washer Damping washer Sealing 385612

6 3 12 6

GB3452.1-82 HB3111-0012 HB3111-011

7.5.2150 gear box(HB3112-000)

No. 1 2 description Half bushing of oil-film bearing 172050E Half bushing of oil-film Model/material Load-bearing end Unload-bearing Qty Drawing No. remarks 10 10 MRC MRC

Rev : 0 Date: 6/27/2011 Item: Page: 37 of 67

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No.

description bearing 172050FB

Model/material

Qty Drawing No. remarks

3 4 5 6 7 8

Half bushing of oil-film bearing 172050A Half bushing of oil-film bearing 172050BB Cover (protecting sleeve) O ring 283.1 Reinforce sealing ring Sealing ring

Load-bearing end Unload-bearing ZG1Cr17Ni2 Oil resistant and high-temperature resistant rubber -2 assembly Oil resistant and high-temperature resistant rubber -2 Oil resistant and high-temperature resistant rubber -2 Oil resistant and high-temperature resistant rubber -2 Oil resistant rubber asbestos plate assembly

10 10 10 10 10 10 HB3112-001 GB3452.1-82 GB9877.1-88 HB3112-019

MRC MRC

O ring 140.62.2

10

GB3452.1-82

10 11 12

O ring 88.92.2 Asbestos pad Washer

10 5 20

GB3452.1-82 HB3112-022 HB3112-010

7.5.3couplings between stands

No. 1 2 3 description coupling (1) coupling (2) coupling (3) material assembly assembly assembly Qty 6 1 1 Drawing No. HB3115-000 HB3116-000 HB3116-000A remark

7.5.4Stand

No. 1 description Entrance duct(1) Model/material Welded part Qty 1 Drawing No. HB3117-001

Rev : 0 Date: 6/27/2011 Item: Page: 38 of 67

remark

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No. 2 3 4 5 6 7 8 9

description Exit duct(1) Exit duct(2) Guide duct(1) Guide duct (2) Guide duct (3) Guide duct (4) Lower guide duct(1) Upper guide duct (1)

Model/material Welded part Welded part 16Mn 16Mn 16Mn 16Mn QT600-3 QT600-3 QT600-3 QT600-3 25-1100 A 38-1800 25-2000 YX-100 KF-L8/20E C25ZB100/70 YB-D-C20L XQZD-050

Qty 2 2 1 1 1 1 1 1 1 1 8 8 8 21 21 2 2 8

Drawing No. HB3117-018-03 HB3117-018-06 HB3117-018-01-01 HB3117-018-01-02 HB3117-018-01-07 HB3117-018-01-08 HB3118-005 HB3118-006 HB3118-009 HB3118-008 JB1885-77 JB/T6142.1-92 JB/T6142.1-92

remark

10 Lower guide duct (2) 11 12 13 14 15 16 17 18 19 Upper guide duct (2) Hose unit Hose unit Hose unit Pressure gauge Pressure gauge switch Hydraulic cylinder Proximity switch bearing

cooling lubrication lubrication lubrication lubrication Protecting jacket Protecting jacket Protecting jacket

0-1MPaDC24V

7.5.5Speed-up gear box

No. 1 2 3 4 description Rolling bearing Rolling bearing Rolling bearing Rolling bearing Model/material 6226 N128VAA QJ234N2 NU234EC Qty 2 4 1 1 Drawing No./ standard SKF ROIIWay SKF SKF

Rev : 0 Date: 6/27/2011 Item: Page: 39 of 67

remark

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No. 5 6 7 8 9 10

description Rolling bearing Rolling bearing Rolling bearing O ring Pressure relief valve Electromagnetic valve

Model/material NU1040 NU228EC QJ228N2 38.7x2.65 PJ-25-S1 22JD-25-Wx1

Qty 1 2 1 1 1 1

Drawing No./ standard SKF SKF SKF GB3452.1-82

remark

butadiene-nit rile rubber pneumatic pipes pneumatic pipes

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 40 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

8. Pinch roll before laying head and laying head Feature Pinch roll before laying head and laying head located after the cooling water box. Rolling piece be pinched into the laying head by pinch roll before laying head and be laid onto the cooling roller table as 1080mm coils by laying heads movement. Pinch roll before laying head and laying head are independent equipments to another. Pinch roll before laying head located before the entrance of laying head. The pinch rollers are cantilever structure, and arranged horizontally. Rolling piece could be pinched and released by upper roller and lower roller acted by a pneumatic cylinder through a link mechanism. The rollers are driven by a DC motor through a gear box. The open width for rollers is adjustable, and the body of pinch roll is welded. The gears, oil-film bearings and high-speed rolling thrust bearing are lubricated by centralized lubrication. While normally working, the pinch roller always rotary with the speed set according to the rolling technology. Pinch roll could pinch the rolling pieces head, rolling pieces tail and the rolling piece whole the time according to the rolling technology. Laying head is inclined 10to horizontal. It consists of laying pipe which fixed on the rotary hollow shaft unit and transmission unit. The hollow shaft unit is driven by DC motor through a pair of bevel gears. The laying pipe rotary with setting speed and lay the coils out with satisfied size. Rotary hollow shaft unit consist of hollow shaft and pipe support assembly which used to fix the laying pipe. Hollow shaft is driven through bevel gear. There has sleeve unit between the hollow shaft and duct which in the hollow shaft, the sleeve unit could cool the duct and prevent the heat

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 41 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

from rolling piece to the bearings on the hollow shaft. The gear box is welded structure, the gears and bearings which in the gear box are lubricated by centralized lubrication. Protecting jacket of laying head is outside of the pipe support assembly. It is barrel structure and incline 10to horizontal same as the laying head. The upper part could open by hydraulic cylinder when change the laying pipe. But the upper part must close when normally working. It should do the static balancing test first for the rotary hollow shaft unit and parts which assembled on the rotary hollow shaft. According the test result, adjust the balance of shaft assembly. Then do the dynamic balancing test with rotary speed 2000r/min, the precision of dynamic balance should grade G2.5. Do the test run after equipment assembling. Measure the vibration at the front bearing cover and the back bearing cover, make sure the vibration both are 5mm/s. After the adjustment, weld the stop dog on the base plate to keep the laying heads gear box.

8.1 Assembling and test run Pinch roll before laying head and laying head assemble at manufactory, it should follow the standard JB/T5000.10-1998, standard

JB/T5000.11-98 and technical requirement on drawings. Them will not allow to leave the factory until them pass the no-load test run.

8.1.1 Preparation 1) Clean the parts, remove the dirty and rust, dredge the pipes and holes, coat with rust preventative oil. 2) Check the dimensional tolerance of fitting parts.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 42 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

3) Prepare the measures and tools.

8.1.2 Assembling 1) Bevel gear assembling The assembling of bevel gear and shaft suggest adopt the pressing fit consider of the small range of interference, and the disassembling suggest adopt extracting. Adjust the contact area and backlash carefully while installing the bevel gear. Increasing contact pattern and suitable backlash will extend the gears life. The backlash should be Cn=0.30~0.592mm, and the contact pattern should 75%. 2) Oil film bearing assembling for upper roller Heat the shaft sleeve of upper roller to 120, and cool the bearing bush to -80 with dry ice or liquid nitrogen. Correspond the separation line of bearing bushes with the mark line on the eccentric sleeve, and align the oil hole on bearing bush and oil hole on the eccentric sleeve.. Push the bearing bushes into the eccentric sleeve with the guiding of taper guide sleeve. Check the alignment of oil hole on the bearing bush and oil hole on the eccentric sleeve, make sure there is no damage on bearing bushes. 3) Rolling bearing assembling The rolling bearing be used in gear box made by FAG, MRC, SKF. The assembling of rolling bearing and shaft suggesting the different temperature method. The rolling bearing on roller shaft for pinch roll is thrust ball bearing,

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 43 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

its backlash should be 0.012~0.038 mm to guarantee the rolling products quality. The axial float should 0.05mm, and the radial runout should0.08mm.

8.1.3 Assembling and disassembling the roller 1) It should using assembly tools with 22.5MPa pressure for assembling the roller ring. 2) It should using disassembly tools with <60MPa pressure for disassembling the roller ring. 3) It should use the special tool for assembling and disassembling.

8.1.4 Other 1) There must no beating to the shaft shoulder and end of baffle ring which using for axial locating while assembly. 2) It should adjust the axial compressing suitably for sealing ring in the upper rollers neck area, make sure not too tight cause the damage of the sealing ring and not too loose cause leakage. 3) All lubrication pipes should be firm and will not be crashed by the rotary parts. The lubrication pipes must lubricate the gears and bearings well.

8.1.5 No-load test run 1) It should driven by humans hand firstly after assembling, and make sure all parts run smoothly. The adjustment of roller gap should flexible. 2) The rotary speed are 1500 r/min for pinch roll and laying head both, and last for 3 hours after all lubrication pipes be connected. Check

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 44 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

the joggling voice of gear, the contact pattern and backlash, the temperature rise of oil-film bearing, and the leakage situation of sealing places. 3) The roller should be cooled by cooling water while test run, and the water flow should 6.75Ton/h 4) To make sure the lubrication oil volume is ~50 l/min oil pressure is 0.35MPa, filter precision is 10 and oil temperature is ~38 for pinch roll and laying head both.

8.1.6 No-load test run It should run no-load test run after pinch roll before laying head and laying head assembling. 1) Necessary condition for test run All oil lubrication points get oil supply according to the requirement of pressure, oil flow, temperature, cleanliness, and oil grade. Apply lubrication grease on each coupling Apply lubrication grease on all lubrication surfaces Supply cooling water onto the roller. Close protecting jacket while the test run. 2) Scheme of test run Test run procedure: start manual operation first, then switch to auto mode; stepping movement before continuous movement; low speed running at first, then switch to middle speed and high speed. No-load test run of the equipment should last for 4 hours continuously for min. Equipment and components should shuttle 5~10 times in stroke range.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 45 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

Adjustment region should be tested 5 times each for min. 3) Requirement for test run Rotary speed of the pinch roll before laying head and laying head should be 1500 r/min during the test run. Vibration intensity of the block mill should be lower than 5mm/s. Noise level should 85dB (checked at 10m far away from equipment). (noise level should 105dB at 1m far away from equipment) Temperature rise of each rolling bearing should be lower than 40 , and the highest temperature of each rolling bearing should not exceed 80. There should be no oil leakage and water penetration.

8.2Vulnerable part list 8.2.1. Vulnerable part list for pinch roll before laying head HC4100-000

No. 1 2 3 4 5 6 7 8 9 10 description O ring 87.52.65 O ring 1853.55 O ring 1323.55 O ring 302.65 6 oil-film bearing 6 oil-film bearing Reinforce sealing B90.120.12 Electromagnetic valve Pressure relay Cooling nozzle Qty 4 1 1 1 2 2 1 2 1 2 Material / specific SF7433 HN7443 HN7443 JM7443 Product product SN7443 23JD-24V HED10A-20/5 HC4100-006-05R 7381651 7381652 Drawing No. Remark GB3452.1-82 GB3452.1-82 GB3452.1-82 GB3452.1-82 MRC MRC GB9877.1-88 Product Product Welded part

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 46 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

8.2.2. Vulnerable part list for laying headHC4200-001

No. description Qty Material / specific Specific / drawing No. 1 2 O ring Rubber plate 1 1 515X7 2.5X280X500 307X7 95X2.65 487X7 307X7 PG85X110X12 175X5.3 60X3.1 106x2.65 400x5.30 568906 N226EC 7040MPUA 110x140x15 GVA002000 GSC30130 25x2.5 65 Mn NBR NBR NBR HC4200-001-47 Oil resistant rubber Oil resistant rubber plate Rubber-1 Rubber-1 Oil resistant rubber Oil resistant rubber Oil resistant rubber Oil resistant rubber Rubber-4 neoprene neoprene FAG SKF FAG GB5574-85 GB3452.1-82 GB3452.1-82 GB3452.1-82 GB3452.1-82 JB7600-80 GB3452.1-82 JB/ZQ4433-86 Product Product 400x500x46 130x230x40 200x310x51 Product 180x15x25 130x160x15 GB3452.1-82 Nonstandard part GB3452.1-82 Remark

3 4 5 6 7 8 9 10 11 12 13 14 15

O ring O ring O ring O ring Sealing O ring O ring O ring O ring Bearing Bearing Bearing Reinforce sealing

1 2 1 1 1 1 2 1 1 1 1 2 1

16 17

Sealing Reinforce sealing

1 2

18 19

O ring spring

1 6

8.2.3. Vulnerable part list for protecting jacket for laying head HC4100-000

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 47 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

No . 1

description

Qty

Material / specific

Drawing No. / standard

Remark

Pneumatic cylinder QGB

200x610-MP2 Product

2 3 4 5

Bearing 30E Joint bearing Bearing 60G One way throttle valve

1 1 2 2

8x38x45 GE45DS 7x70x60 KCA-L20

FZ1360 GB9163-90 FZ1360 (pneumatic)

Product Product Product Product

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 48 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

9. Cooling roller table Feature The chain type cooling roller table convey the coils to reform station. It could use the standard cooling model and retarded cooling model to cool the coil. Standard cooling model: faster convey speed with blowers; Retarded cooling model: slower convey speed without blower. This chain type cooling roller table adopt standard cooling model, and convey the 1200mm1250mm coil formed by laying head to the reform station uniformly. By adjusting the air volume and quantity of blowers, cool the coil to get coil which satisfy the requirement. The 7 sections are entrance section (1 set), main cooling section (5 sets) and exit section (1 set). Each section driven by a VVVF motor independently through chain. Each sections roller could adjust speed independently. The rollers supported by bearing supports. The entrance section which next the laying head supported by an elevator with motor. The angle of rake of roller table could adjust by elevation of elevator, to get the suitable form of coil. The elevation stroke is 200mm, and be controlled by 2 sets of proximity switch which located at the highest position and lowest position to prevent damage by incorrect operation. There are 2 steps in main cooling section, the step height is 250mm. The step makes the coils tensile strength uniformity. There have a independent blower with motor for both 1st and 4th section in main cooling section. There have 3 independent blowers with motor for 2ed and 3rd section.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 49 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

There has no blower for 5th section (retarded cooling zone) Blowers connect to cooling roller table through air chambers. The exit section which before reform station has wheels and is supported by rails. The exit section could traverse that driven by a pushing rod with motor to adjust the distance between end of exit section and coil collecting devices center. The traversing stroke is 150mm. The side aprons which on the exit section could align the coils center and the roller tables center, to ensure the coil fall into the coil collecting device smoothly. The coil pressing device located at the end of exit section could make sure the coil fall into the coil collecting device horizontally. A proximity switch connected with the signal rod on cantilever could send the signal of coils head and tail coming.

9.1 Preparation 9.1.1 Make sure all lubrication points be lubricated 9.1.2 Make sure all proximity switches work normally 9.1.3 Make sure all reducers oil level are normal. 9.1.4 Make sure the coil pressing device has suitable distance to rollers. It will not allow running the rollers until mentioned requirements are satisfied. 9.1.5 Start run the rollers after the signal ring ( long-time ) in jogging model. It will restart after everything is normal. 9.1.6 Check the function of all electric equipments, make sure they are same as the instruction. Make sure the order of action is correct. Make sure all interlock and self-lock are effective. 9.1.7 Make sure each sections convey speed is satisfy the requirement and match for each other. Send the signal after check.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 50 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

9.1.8 Make sure all lubrication points on blower are lubricated well. Make sure the rotary direction of motor for blower is correct. Adjust the air volume and quantity of blower according to the requirement of technical process.

9.2 Vulnerable part list for cooling roller table 9.2.1Vulnerable part list (1)

No. 1 2 3 4 5 6 7 8 9 10 11 12 Bearing with support Bearing with support Bearing with support UCP205 Roller chain 12A--42 Roller chain 08B--43 Roller chain 08B--46 Roller chain 12A--50 Roller chain 12A--52 Bearing support description Bearing 6308-2LS Bearing support Drawing No. SM1002.2.1.1.00 SM1002.2.1.1.00 SM1002.2.1.2.00 SM1002.2.1.3.00 SM1002.2.1.4.00 SM1002.2.1.5.00 SM1002.2.1.3.00 SM1002.2.1.5.00 SM1002.2.1.3.00 SM1002.2.1.5.00 SM1002.2.1.5.00 SM1002.2.1.3.00 Qty 8 58 112 100 56 28 8 6 8 6 2 12 Assembly Assembly Product Product With transition chain With transition chain With transition chain With transition chain With transition chain

Rev : 0 Date: 6/27/2011 Item: Page: 51 of 67

Material 409023 Cast steel

Remark

Cast steel

13

SM1002.2.1.1.00

29

Product

14

SM1002.2.1.5.00

Product

15 16 17 18

SM1002.2.1.5.00 SM1002.2.1.2.00 SM1002.2.1.3.00 SM1002.2.1.4.00

6 56 48 28

Product Product

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No. 19 20 21 22 23

description

Drawing No. SM1002.2.1.5.00 SM1002.2.1.2.00 SM1002.2.1.3.00 SM1002.2.1.4.00 SM1002.2.1.5.00

Qty 8 56 50 28 14

Material

Remark

Roller

Welded part

9.2.2Vulnerable part list (2)

No. 1 2 3 4 5 6 7 description Roller Roller Roller Roller Roller Alignment roller Drawing No. SM1002.2.1.1.00 SM1002.2.1.3.00 SM1002.2.1.5.00 SM1002.2.1.3.00 SM1002.2.1.5.00 SM1002.2.1.5.00 SM1002.2.1.3.00 Qty 29 4 2 4 2 2 12 material QT500-7 Welded part Welded part Welded part Welded part QT500-7 remark

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 52 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

10. Reform station Feature (1) Coil collecting device after cooling roller table consist of upper barrel body, lower barrel body, nose cone, fingers and hydraulic supporting device. The nose cone is inside of the barrel. The hydraulic supporting device is used for support the nose cone, and the fingers are used for hold the coils. Coil collecting device collect the coil and store for a short time, and it will provide a buffer time for transportation. (2) Coil plate assembly consist of elevation device, main support assembly, transmission device, idler assembly, coil plate acted by hydraulic cylinder, chain wheel, chain and so on. Coil plate collect the coil come from coil collecting device, while get the full of coil signal, coil plate descend to the unload position with fast speed. (3) Double arm spindle receive the coil and transport from vertical position to horizontal position by the two arms which are perpendicular. The rotary shaft is 45to horizontal, and this make one arm move from vertical to horizontal and another arm move form horizontal to vertical while shaft rotate half-cycle. (4) Transport car consist of coil basket device, elevation device, car assembly, base assembly and towline. Transport car transport the coil from double arm spindles to hook, and the cars lifting by hydraulic and moving by motor.

10.1 Operation for coil collecting device 10.1.1 make sure all lubrication points get lubricated well.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 53 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

10.1.2 Make sure all oil, air, electric lines are correct and smooth. 10.1.3 Make sure all oil pipes, air pipes and electric wires are fastening, and the function is same as the introduction. 10.1.4 Make sure the equipments action is same as design. 10.1.5 A group of fingers hold the coils, they will retract when coil is full and will not stretch out until the collected coils all unload. All fingers are linked and acted by an air cylinder. The nose cone could go up and down acted by 3 sets of hydraulic cylinder for rotary action of double arm spindles.

10.2 Operation for coil plate assembly 10.2.1 Make sure all chains could work normally. 10.2.2 Make sure the elevating device could elevate smoothly without tilt. 10.2.3 Make sure the coil plate could open and close smoothly. 10.2.4 Make sure the hydraulic cylinder could work normally. 10.2.5 Make sure all oil pipes and joints are tight without damage. 10.2.6 Make sure all chains are lubricated well. 10.2.7 Make sure the braker could work well. 10.2.8 Make sure all electric parts all work well. 10.2.9 Make sure the idler mesh well with chain.

10.3 Operation for double arm spindle 10.3.1 Make sure all lubrication points get lubricated well. 10.3.2 Make sure all oil, air, electric lines are correct and smooth. 10.3.3 Make sure all oil pipes, air pipes and electric wires are fastening, and the function is same as the introduction. 10.3.4 Make sure the equipments action is same as design.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com Rev : 0 Date: 6/27/2011 Item: Page: 54 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

10.3.5 Make sure the interlock could work well. 10.3.6 The two arms are perpendicular. 10.3.7 The rotary shaft is 45to horizontal, and this make one arm move from vertical to horizontal and another arm move form horizontal to vertical while shaft rotate half-cycle.

10.4 Operation for transport car 10.4.1 Make sure all lubrication points get lubricated well. 10.4.2 Make sure all oil, air, electric lines are correct and smooth. 10.4.3 Make sure all oil pipes, air pipes and electric wires are fastening, and the function is same as the introduction. 10.4.4 Make sure the equipments action is same as design. 10.4.5 Make sure the interlock could work well. 10.4.6 Operation must follow the instruction. 10.4.7 The arm spindle, transport car and hook must not interfere with each other.

10.5 Vulnerable part list 10.5.1 Vulnerable part list (1)

No. 1 2 3 4 5 6 7 description Coil collecting device Block Sleeve Sleeve Cushion Joint bearing GE40ES Angle contact ball bearing Drawing No. SM1002.2.3 SM1002.2.3.1.00 SM1002.2.3.1.00 SM1002.2.3.1.00 SM1002.2.3.1.00 SM1002.2.3.1.00 SM1002.2.3.1.00 3 6 6 6 10 12 42CrMo ZCuAl10Fe3 ZCuAl10Fe3 H62 40/62-28 Assembly

Rev : 0 Date: 6/27/2011 Item: Page: 55 of 67

Qty

material

remark

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No. 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

description 12570-24 Sleeve Cushion Joint bearing GEG50E Double arm spindle assembly Wear resistant plate Wear resistant plate Wear resistant plate Coil plate assembly Wear resistant plate Bearing 32026X/DF Cushion Cushion Bearing 6313 Bearing 6313 Bearing 22214E

Drawing No. SM1002.2.3.1.00 SM1002.2.3.1.00 SM1002.2.3.1.00 SM1002.2.3 SM1002.2.3.2.2.00 SM1002.2.3.2.2.00 SM1002.2.3.2.2.00 SM1002.2.3 SM1002.2.3.3.00 SM1002.2.3.3.00 SM1002.2.3.3.00 SM1002.2.3.3.00 SM1002.2.3.3.00 SM1002.2.3.3.00 SM1002.2.3.3.00

Qty 2 2 1

material ZCuAl10Fe3 H62 50/90-56

remark

3 3 3 4 2 2 2 8 8 4

QT420-12 QT420-12 QT420-12 40CrMnMo

Asbestos plate Q235-A

10.5.2Vulnerable part list (2)

No. 1 2 3 4 5 6 7 8 9 description Transport car Wear resistant plate Wear resistant plate Bearing with support (GB/T7810-1995) Wear resistant plate Wear resistant plate Bush Bush Bearing NUTR40 Drawing No. SM1002.2.3 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 2 2 4 2 1 2 4 12 16Mn 16Mn UCFLU313 20Mn 20Mn ZCuAl10Fe3 ZCuAl10Fe3 Product

Rev : 0 Date: 6/27/2011 Item: Page: 56 of 67

Qty

material

remark

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

SHANGHAI HEAVY MINING MACHINERY LTD.

No. 10 11 12 13 14 15 16

description Bearing NUTR25 Eccentric shaft Roller shaft Bush Shaft sleeve Bearing GE70ES Bearing with support (GB/T7810-1995) Bearing with support (GB/T7810-1995) Bearing 23122CC/W33 Bearing 23022CC/W33 Bearing NH2210 Bearing 32015 Wheel

Drawing No. SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.1.00 SM1002.2.3.4.2.00 SM1002.2.3.4.2.00 SM1002.2.3.4.2.00 SM1002.2.3.4.2.00

Qty 8 4 4 8 2 1 2

material Product 45 Welded part ZCuAl10Fe3 Seamless pipe 20 Product UCP322

remark

17 18 19 20 21 22

SM1002.2.3.4.2.00 SM1002.2.3.4.3.00 SM1002.2.3.4.3.00 SM1002.2.3.4.3.00 SM1002.2.3.4.3.00 SM1002.2.3.4.3.00

2 1 1 4 8 4

UCP322 Product Product Product Product 45

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 57 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

11. Bundling machine Feature Bundling machine compact the coil come from the reform station, tie the coil, and bundle the coil. Bundling machine consist of base assembly, compact device and supporting roller device. Base assembly is welded structure and fixed on the ground. Compact device consist of support, hydraulic cylinder, wheel and car. The wheel is support by the base assembly and the shaft which fixed on the car through rolling bearing. Supporting roller device which fixed on the ground consist of gearmotor, roller and support. Supporting roller device should not work until compact device is not working, and compact device should not work until the supporting roller device is not working. After the coil convey to bundling machine by crane, tying device works when it get the signal send by the compactor, and compactor will not stop compacting until the coil be compacted. After the coil be bundled manually, compactor release, and the crane take the compacted coil away when get the signal sent by compactor.

11.1 Operation 11.1.1 Make sure all lubrication points all get well lubricated, and hydraulic system is normal. 11.1.2 Adjust the position of proximity switch according to the traverse speed. 11.1.3 Make sure all function and action are same as instruction, the order of action is correct, the interlock and self lock are effective.

CopyrightSHMM 705 6 200083, Web: www.shme.com.cn ADD6F, 705 Zhongshan North 1Rd. HaiJian Building, Shanghai P.R. China TEL86-021-51089131 FAX86-021-55396312 E-mail: shmie@vip.163.com

Rev : 0 Date: 6/27/2011 Item: Page: 58 of 67

SHANGHAI HEAVY MINING MACHINERY LTD.

11.2Vulnerable part list