Escolar Documentos

Profissional Documentos

Cultura Documentos

2005

Enviado por

Radha KrishnanDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2005

Enviado por

Radha KrishnanDireitos autorais:

Formatos disponíveis

Advances in Engineering Software 36 (2005) 325337 www.elsevier.

com/locate/advengsoft

An expert system for mix design of high performance concrete

Muhammad Fauzi Mohd. Zain*, Md. Nazrul Islam1, Ir. Hassan Basri2

Department of Civil and Structural Engineering, Faculty of Engineering, Universiti Kebangsaan Malaysia, 43600 UKM Bangi, Selangor Darul Ehsan, Malaysia Received 5 March 2004; received in revised form 20 August 2004; accepted 14 October 2004 Available online 10 December 2004

Abstract This paper describes a prototype expert system called HPCMIX that provides proportion of trial mix of High Performance Concrete (HPC) and recommendations on mix adjustment. The knowledge was acquired from various textual sources and human experts. The system was developed using hybrid knowledge representation technique. It is capable of selecting proportions of mixing water, cement, supplementary cementitious materials, aggregates and superplasticizer, considering the effects of air content as well as water contributed by superplasticizer and moisture conditions of aggregates. Similar to most expert systems, this system has explanation facilities, can be incrementally expanded, and has an easy to understand knowledge base. The system was tested using a sample project. The systems selection of mix proportions and recommendations regarding mix adjustment were compared favourably with those of experts. The system is user-friendly and can be used as an educational tool. q 2004 Elsevier Ltd. All rights reserved.

Keywords: High performance concrete; Mix design; Mix adjustment; Expert systems; Knowledge-based systems; Hybrid knowledge representation

1. Introduction The selection of mix proportions is the process of choosing suitable ingredients of concrete and determining their relative quantities with the object of producing as economically as possible concrete of certain minimum properties, notably strength, durability, and a required consistency [1]. Because the ingredients used are essentially variable and many of the material properties cannot be assessed truly quantitatively, selecting proportions for concrete can also be dened as the process of nding the optimum combination of these ingredients on the basis of some empirical data as stated in relevant standards, experience, and some rules of thumb [2]. Concrete mix design involves complicated issues, and the correct ways to perform this can be achieved with

* Corresponding author. Tel.: C603 89216223; fax. C603 89216147. E-mail addresses: fauzi@vlsi.eng.ukm.my (M.F. Mohd. Zain), nazrul@vlsi.eng.ukm.my (M. Nazrul Islam), drhb@vlsi.eng.ukm.my (I. Hassan Basri). 1 Tel.: C603 89216819; fax: C603 89216147. 2 Tel.: C603 89216100; fax: C603 89216147. 0965-9978/$ - see front matter q 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.advengsoft.2004.10.008

experts advice and experience [3]. Mix design of High Performance Concrete (HPC) is more complicated because HPC includes more materials, like superplasticizer and supplementary cementitious materials (e.g. silica fume, y ash, llers, etc.). In addition, maintaining a low waterbinder ratio with adequate workability makes the design process more complicated. Traditionally, experienced civil engineers, largely based on their experiential knowledge, do the job of mix design [4]. However, experts are not always available, nor do they always have time to consult all possible references, review available data, and so on. Some companies do not have personnel with the experience to make necessary decisions regarding concrete mix design. The conventional computer programs are useful only in manipulating the numerical data and providing mathematical reasoning for the nal selection. They lack the intuitive reasoning based on heuristic knowledge such as experience and rules of thumb [5]. Many factors inuence concrete mix design, and their mutual relationship is so complicated that it is impossible to formulate mathematical models to express their mutual actions and reactions [6]. In addition, adjustments of trial mixes are always performed by taking into account the information

326

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

from concrete quality tests, experts advice and experience. It is believed that the problem of mix design and adjustment of HPC can be alleviated if the engineers knowledge can be augmented with some expert system for afrming his judgment. This paper describes a prototype expert system called HPCMIX. The purposes of developing HPCMIX were to improve the process of selecting and proportioning HPC constituents and to make the knowledge of HPC easily available to the concrete industry. It is also capable of diagnosing causes of mix performance failure and giving recommendations on corresponding performance adjustment. However, like other expert systems, the developed expert system will serve as a decision support system; it will not replace completely human experts decision making.

2. Expert systems and concrete mix design An expert system is dened as a computer program designed to model the problem-solving ability of a human expert [7]. It utilises observed or available information to produce high grade knowledge and solves problems by qualitative reasoning using the heuristic knowledge of the human expert [8]. Expert systems are most useful when the knowledge is based on heuristics, which is often the case in concrete mix design. Since concrete mix design and adjustments are somewhat complicated, time-consuming and tedious tasks, and also because it is not always possible to be helped by the experts, there were some efforts to develop expert system for concrete mix design. These systems [2,3,9,10] give proportion of concrete mix especially for normal concrete. A brief review of these systems is available elsewhere [11]. Most of these systems are rule-based systems, work using DOS operating system and do not consider the cost of concrete mix selected. None of these systems can diagnose causes of performance failure of trial mix and give recommendations on corresponding performance adjustment. Most importantly, they do not consider the criteria of mix design for HPC such as maintaining a low water-binder ratio and use of superplasticizer, silica fume, and so on. Therefore, these systems cannot be used for mix design and adjustment of high performance concrete.

3. Development of the HPCMIX 3.1. Knowledge acquisition Knowledge for the HPCMIX was acquired from textbooks and manuals written by experts and related professional institutions [1,1221], research papers from journals and conference proceedings [3,2229] and experts involved in concrete production. Thus knowledge was

acquired by text analysis (i.e. collection of knowledge from the literature) and interviewing experts. Only unstructured interviews of several experts involved in teaching, research and consultation of concrete production were performed in this project. Experts were asked to describe their knowledge about the selection of concrete proportions, diagnosing the problems in mix design and adjustments, and their solutions. However, the main source of knowledge was the literature mentioned above. By analysing the knowledge from these sources, a more objective perspective of the most appropriate expertise was achieved, instead of being restricted to a single view preferred by a particular expert. It may be relevant to mention here that acquiring knowledge from these sources was felt to be the most difcult and time-consuming task in the prototype development process. The mix design procedure for HPC developed by Aitcin [15] was used as the mix design procedure for the HPCMIX because of its wide acceptability among the experts in Malaysia (Alternatively, in future, any other state-of-the-art mix design method can be added to the system as a new module without affecting overall performance of the system). The Aitcin method follows the same approach as ACI Committee 211 [18]. It is a combination of empirical results and mathematical calculations based on the absolute volume method. A ow chart of this method is presented latter in this paper (Section 4.4). The procedure is initiated by selecting ve different mix characteristics or materials proportions in the following sequence: water-binder ratio, water content, superplasticizer dosage, coarse aggregate content and entrapped air content. The suggested water-binder ratio is obtained from a compressive strength vs. water-binder ratio graph for a given 28-day compressive strength. The mixing water content is determined on the basis of saturation point of superplasticizer. The superplasticizer dosage is deduced from the dosage at the saturation point. The coarse aggregate content is obtained as a function of the typical particle shape. The method suggests using 1.5% as an initial estimate of entrapped air content, and then adjusting it on the basis of the result obtained with trial mix. The ow diagram developed for the acquired knowledge regarding mix performance adjustment is shown in Fig. 1. The diagram shows that three criteria were considered for judging the performance of a mix, i.e. strength, workability and durability. For example, if a mix fails in strength performance, then information is required about test results regarding any of the following to nd out possible causes of performance failure: (i) fracture pattern, (ii) bond failure pattern, (iii) passage of fracture surface, and (iv) effect of water-binder ratio. On the other hand, if the workability performance is inadequate then it is required to know which workability performance of the following is inadequate: (i) rapid slump loss, (ii) low slump, or (iii) inadequate workability. The ow diagram developed for the purpose of cost estimation of a designed mix is shown in Fig. 2.

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

327

Fig. 1. Flow diagram of mix performance adjustment.

The gure shows that unit cost of ingredients, mix composition and batch size are the required information for cost estimation of a concrete mix. 3.2. Knowledge representation Through the efforts of researchers in articial intelligence, a number of effective ways of representing knowledge in a computer were developed [7]. The selection from these knowledge representation techniques depends on the nature of the expertise to be computerized, as well as the practical capabilities and facilities of the expert system tool used [30]. In developing HPCMIX, a hybrid approach of knowledge representation (i.e. rule and frame systems) was followed using Kappa-PC expert system shell [31]. Thus, the domain of mix design of HPC was modelled using object-oriented approach and production rules. As an illustration of object-oriented approach, Fig. 3 shows the object hierarchy of Binder class. It consists of two subclasses namely Cement and SupplCemMats (Supplementary Cementitious Materials). Each of these subclasses includes several instances. For example, SupplCemMats subclass consists of SilicaFume, FlyAsh, GGBS (ground granulated blast-furnace slag), RiceHuskAsh and Others instances. The attributes of objects were dened as object

slots. Slots can be thought of as descriptions of a particular object. They add detail structure, list attributes or properties which can be single or multiple-valued, textual strings or numeric, or even Boolean. Slot values can be pre-dened, restricted to a range or set of pre-specied possible values, user-dened or determined from user consultations with

Fig. 2. Flow diagram of cost estimation.

328

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

Where, CoarseAgg is an instance representing coarse aggregate; ShapeOfAgg is a slot of CoarseAgg instance representing the shape of the coarse aggregate; Cubic is the value of the slot ShapeOfAgg representing that the shape of the coarse aggregate is cubic; and so on. There are two approaches for evaluating production rules: backward chaining and forward chaining [7,3234]. The HPCMIX uses a forward-chaining or data-driven inference mechanism.

4. Knowledge base modules of the HPCMIX The HPCMIX knowledge base consists of three design related modules namely Mix Design, Mix Performance Adjustment and Cost Estimation modules and an accessory module named General Information module. The modules can be accessed from the main interface window shown in Fig. 4. A brief description of each of the above modules is given in the following sections. 4.1. Mix Design module The objective of Mix Design module is to proportion HPC mixes. It consists of four submodules namely First Trial Batch, Trial Batch for Laboratory, One Cubic Metre SSD Composition (SSD stands for saturated-and-surfacedry) and Batch Composition as shown in Fig. 5. The First Trial Batch submodule computes proportions of concrete mixes according to the data supplied by the user. It gives composition of one cubic metre of concrete for eld conditions of aggregates. The Trial Batch for Laboratory submodule helps in computing quantities for making concrete samples for laboratory testing. This gives the user opportunity to test mix design results in a laboratory for desired performance requirements for a small amount of proportioned ingredients. The One Cubic Metre SSD Composition submodule calculates proportions for one cubic metre of concrete for SSD conditions of aggregates. The Batch Composition submodule activates a function to calculate amounts for batch quantities for eld conditions of aggregates. 4.2. Mix Performance Adjustment module The Mix Performance Adjustment module helps in adjusting mix proportions after laboratory testing. The interface window of this module is shown in Fig. 6. Incorporating the knowledge that experts use in diagnosis, the Mix Performance Adjustment module diagnoses possible causes of performance failure of concrete mix and recommends corresponding remedial measures. The Quantitative Advice button (Fig. 6) of this module gives specic quantitative recommendations on achieving various performances of HPC mix. The module also displays reasons for giving any recommendation.

Fig. 3. Object hierarchy of the Binder class.

the system. For example, the slots of the instance FlyAsh (Fig. 3) includes, among others, content in percent, specic gravity and content in kg/m3 (kilogram per cubic metre). Table 1 shows these slots and the corresponding slot values. Interactions among objects, instructions from one object to another, and processes of objects were codied in the form of methods, functions and rules. The rst approach involves enhancing objects so that they represent the behaviour of the things to which they correspond. Methods are written in KAL (Kappa-PC Application Language) and stored within the object. The next approach to representing processes involves functions. Functions are also written in KAL and can either be user-dened or built-in the system. Kappa-PC provides a library of over 300 functions that allow for the manipulation of its knowledge base. The third approach involves using rules to represent the relationship between causes and effects which species the conditions under which a particular action or inference can occur. The syntax for methods, functions and rules is identical; therefore, the same syntax can be used to add an object, to write a method or to create a rule. An example of a simple rule written for the coarse aggregate content of the mix design module is shown below. If: Shape of the coarse aggregate is cubic Then: Coarse aggregate content of the mix should be 1100 kg/m3. In KAL format, this rule was written as: If: CoarseAgg: ShapeOfAgg #ZCubic Then: CoarseAgg: ContentKgPerM3 #Z1100;

Table 1 Description of an Instance using Slots Instance: FlyAsh, Parent Class: SupplCemMats Slot Name ContentPercent SpecicGravity ContentKgPerM3 Slot Value 10.00 2.50 53.19 Comment User dened value User dened value System derived value

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

329

Fig. 4. Main interface window of the HPCMIX.

Fig. 5. Interface window of the Mix Design module.

330

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

Fig. 6. Interface window of the Mix Performance Adjustment module.

4.3. Cost Estimation module If the cost estimation is felt to be necessary, it can be carried out using the Cost Estimation module. The rst step is to input unit cost of the proportioned ingredients. A transcript image in the Cost Estimation interface window helps the user by displaying information about the ranges of unit cost of concrete ingredients. Although these values vary from country to country, this information will help the user in getting idea about approximate unit cost of ingredients. After inputting the unit cost of ingredients, the user gets the costs of one cubic metre of concrete and of a particular batch size by pressing appropriate buttons. 4.4. General Information module Fig. 7 shows the interface window of the General Information module. The objective of this module is to assist the user in the efcient utilisation of the HPCMIX prototype. The module provides a user-friendly environment whereby the various guidelines and information are available to the user. The User Guide button assists the user in the efcient consultation process. The user gets advice on the fundamentals of HPC and the approaches of mix design and adjustment of HPC through HPC Technology and Principle of Mix Design buttons of this module. A knowledge dictionary is also available through Knowledge Dictionary button to assist the user with unfamiliar technical terms. This dictionary is also useful as an educational

feature. The dictionary includes: basic denitions of concrete mix design, HPC and expert system; types of tests for evaluation of fresh and hardened concrete; and statistical measures used in assessment of concrete mix design. In addition, a general conceptual ow diagram of HPC mix design using Aitcin method (see Fig. 7) and various photographs showing the testing of fresh and hardened concretes are also accessible through appropriate buttons of this module.

5. Case study and evaluation of the HPCMIX The objective of this case study was to evaluate the performance of the HPCMIX consultation process and results when it was applied to a HPC mix. The case study was carried out on an example mix design of HPC from a classical textbook [15]. This example was selected because the author of this textbook is considered as one of the wellknown experts in the domain of HPC. Another expert (Dr Hilmi Mahmud, Associate Professor, University of Malaya, Malaysia), who has been involved in teaching, research and consultation in the production of concrete for past fteen years, was asked to perform concrete mix design based on the information of this textbook. The results of the design obtained from HPCMIX were compared with those reported in this textbook (referred to as Expert-1) and those calculated by Dr Hilmi Mahmud (referred to as Expert-2).

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

331

Fig. 7. Interface window of the General Information module showing mix design ow diagram.

The user clicked on Mix Design button of the main interface window (Fig. 4) for mix design purpose. This opened the interface window of the Mix Design module (Fig. 5). From that window, the user learned about the functions of the buttons regarding mix design submodules and got advice about each submodule by pressing on appropriate Advice button. The input data, consultation process and explanation of results of each submodule of the mix design module as well as mix performance adjustment module are described in the following sections. These sections also include description about user-friendliness, advantages, disadvantages and an overall evaluation of the system. 5.1. First trial batch Data for the rst trial batch composition of the present case study is described in Appendix A. In this example, a 100 MPa concrete mix was designed with Type I Portland cement, a naphthalene-type superplasticizer, a dolomitic limestone, a siliceous natural sand and silica fume. For each concrete ingredient of Appendix A, a related window appeared one after another as the user continued with data input process. For example, window that appeared for data input related to silica fume is shown in Fig. 8. The system provided information about each concrete ingredient similar to that shown for silica fume (Fig. 8). Each of these windows also displayed several buttons namely Data Input, Advice, Main Screen, Mix Design Screen, Back and Exit. If the user wanted to input

data about an ingredient, he pressed on the Data Input button. As a result, the system prompted the User Request form such as shown in Fig. 9. This form displayed the limits of the value of the desired input parameter. After entering the value of the parameter, the user pressed on OK button and, as a consequence, the window for the next input parameter automatically appeared. If the user was not sure about the value of the parameter, he could press on Comment button (Fig. 9) for usual range of values as shown in Fig. 10, which also gave the sources of information. For the beginners or students of concrete technology who are not familiar about the parameter may press Advice button (see Fig. 8). This operation gives detailed information about the parameter in the second transcript image (see Fig. 8 for advice on silica fume). Moreover, the beginners can access to knowledge dictionary through Knowledge Dictionary button (see Fig. 7). These facilities make the system very user-friendly and suitable for using as an educational tool. At the end of data input session, the Summary of Input Data window appeared. From that window, the user could verify input data. If there was any inconsistency, the user could go back and modify it. After verifying input data, the user could see design values (i.e. First Trial Batch composition) by pressing on Final Design button. The design values after moisture adjustment as proportioned by the HPCMIX are shown in Fig. 11. This gure also shows the key input parameters that were input by the user. From this window, the user might request for explanation about the mix design process, might go back to main screen or

332

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

Fig. 8. A typical window during data input process.

might exit the mix design session by pressing on appropriate buttons. Table 2 shows the comparison of the trial batching mix design selected by the developed system and the experts. It can be observed from Table 2 that the results of the three mix designs are very close except cement and ne aggregate contents. The cement content suggested by the system is the lowest (i.e. 464.38 kg/m3) and that suggested by Expert-1 is the highest (i.e. 470.00 kg/m3). This was because the system maintained high precision in computation by considering up to ten digits after decimal point. But Expert-1 rounded off the gures to integer values for convenience. For example, total binder content was rounded off from 518.5 to 520 kg/m3 and silica fume content was rounded off from

51.85 to 50 kg/m3 by Expert-1. On the other hand, cement content suggested by Expert-2 was of intermediate value (i.e. 466.67 kg/m3) because he considered only two digits after decimal point in his calculation. Due to the variation in cement content, the variation in ne aggregate content was also observed among the three mix designs (i.e. 777.51 kg/m3 by HPCMIX, 772.00 kg/m3 by Expert-1 and 775.17 kg/m3 by Expert-2) in order to maintain the total displaced volume according to absolute volume method. However, Expert-2 indicated that the differences among the three mix designs were not critical. Expert-2 also indicated that the concrete proportions selected by the system were accurate enough for the rst trial batching. It may be relevant to mention here that, for a particular mix design, there are always several answers, which can satisfy the requirements of the specication [3]. Thus the concrete proportions selected by the system were accurate enough for

Fig. 9. A typical User Request form during data input (after pressing Data Input button of Fig. 8.

Fig. 10. A typical explanation window during data input (after pressing Comment button of Fig. 9.

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

333

Fig. 11. Window showing composition and key data of First Trial Batch submodule.

the rst trial batching. The developed system is, therefore, capable of proportioning the rst trial batch of HPC mix with acceptable accuracy. 5.2. Trial batch for laboratory The calculated mixture proportions should be checked by means of trial batches prepared and tested for the intended performance requirements [15]. These tests and observation on the designed mix are usually performed in the laboratory by using a small portion of the designed mix, i.e. by laboratory trial batch. For the purpose of validation of

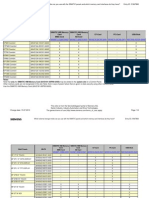

Table 2 Comparison of results of First Trial Batch Item Water-Binder Ratio Water (l/m3) Cement (kg/m3) Silica Fume (kg/m3) Coarse Aggregate (kg/m3) Fine Aggregate (kg/m3) Superplasticizer (l/m3) Air Content (%)

a b

the system, data used for an example laboratory testing is described in Appendix B. The results computed by the system and those of the experts are compared in Table 3. It can be observed that the proportions selected by the HPCMIX were close enough to those selected by the experts. The highest variation was observed in ne aggregate content, which was only 0.69 kg/m 3 (i.e. 72.4271.73Z0.69). According to the experts opinion, the variations among the three mix designs were negligible. Thus the present system can be used for the calculation of laboratory trial mix of HPC with acceptable accuracy.

Table 3 Comparison of results of Laboratory Trial Batch Item HPCMIX 0.27 11.49 43.26 4.81 99.33 72.42 0.99 1.50 Expert-1a 0.27 11.53 43.70 4.70 99.10 71.80 0.99 1.50 Expert-2b 0.27 11.42 43.18 4.80 98.68 71.73 0.99 1.50

HPCMIX 0.27 123.38 464.38 51.60 1066.40 777.51 10.66 1.50

Expert-1a 0.27 124.00 470.00 50.00 1066.00 772.00 10.70 1.50

Expert-2b 0.27 123.40 466.67 51.85 1066.40 775.17 10.72 1.50

Water-Binder Ratio Mixing Water (litre) Cement (kg) Silica Fume (kg) Coarse Aggregate (kg) Fine Aggregate (kg) Superplasticizer (litre) Air Content (%)

a b

Expert-1: Aitcin [15] (see reference). Expert-2: Dr Hilmi Mahmud, University of Malaya, Malaysia.

Expert-1: Aitcin [15] (see reference). Expert-2: Dr Hilmi Mahmud, University of Malaya, Malaysia.

334

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337 Table 5 Comparison of results of Batch Composition Item Water-Binder Ratio Mixing Water (litre) Cement (kg) Coarse Aggregate (kg) Fine Aggregate (kg) Superplasticizer (litre)

a b

5.3. One cubic metre SSD composition This submodule can be used to compute composition of one cubic metre of concrete for SSD conditions of aggregates using the data of laboratory trial batch. It can also be used for conversion of concrete composition from eld conditions of aggregates to SSD conditions of aggregates. During computation, it takes into account moisture conditions of aggregates in the bins as well as water hidden in liquid superplasticizer. The data for a sample example are presented in Appendix C. The results are compared in Table 4 that shows good agreement between the results of the HPCMIX and those of the experts. The highest variation was only 0.88 kg/m 3 (i.e. 1074.511073.63Z0.88) in coarse aggregate content. The system gave proportions closer to those of Expert-2. Expert-2 was consulted and he agreed that the variation was negligible and the concrete proportions selected by the system were accurate enough to make the trial batching. These results serve as a means of verication of the accuracy of knowledge base of the developed system. 5.4. Batch composition This submodule computes batch composition for a concrete construction project for eld conditions of aggregates. The system collects following data from the user in order to compute batch composition: one cubic metre SSD composition, moisture conditions of aggregates in the eld, and the expected batch size. It was assumed, for example, that a concrete batch plant was to produce 8 m3 of HPC on the basis of the SSD composition shown in Appendix D. The user input those data by pressing appropriate buttons of the Batch Composition interface window. After the completion of data input, the user got results of the batch composition for eld conditions of aggregates. The results are compared with those of the experts in Table 5. Again, it can be seen that the results of the HPCMIX compared well with those of the experts.

Table 4 Comparison of results of One Cubic Metre SSD Composition Item Water-Binder Ratio Water (l/m3) Cement (kg/m3) Fly Ash (kg/m3) Coarse Aggregate (kg/m3) Fine Aggregate (kg/m3) Superplasticizer (l/m3) Air Content (%)

a b

HPCMIX 0.29 875.08 3600.00 8400.00 6120.00 64.00

Expert-1a 0.29 872.00 3600.00 8400.00 6120.00 64.00

Expert-2b 0.29 875.12 3600.00 8400.00 6120.00 64.00

Expert-1: Aitcin [15] (see reference). Expert-2: Dr Hilmi Mahmud, University of Malaya, Malaysia.

The only variation with the result of Expert-1 was observed in mixing water requirement (i.e. 875.08872.00Z3.08 l). Expert-1 rounded off the water contributed by liquid superplasticizer from 5.6 to 6.0 l in one cubic metre SSD composition calculation. This excess water contributed by superplasticizer (i.e. 6.05.6Z0.4 l) in one cubic metre composition was multiplied by 8 for getting 8 m3 composition (i.e. 0.4!8Z3.2 l). On the other hand, this excess water (i.e. 3.2 l) was subtracted from the required mixing water and hence the value was less (i.e. 872 l instead of 875.2 l). Again Expert-2 was consulted and he agreed that the performance of the HPCMIX in computing batch composition was satisfactory. This comparison also gives a positive indication of the accuracy of knowledge base of the system. 5.5. Mix performance adjustment The purpose of this module is to diagnose possible causes of performance failure of a HPC mix and to recommend on corresponding remedial measures in order to achieve the desired performance. These features are demonstrated in this portion of the case study. It was assumed, for example, that the strength performance of the mix was not achieved in the laboratory testing of the rst trial batch. Careful examination of the failure pattern of the test specimen revealed that fracture surface passed through hydrated cement paste. After getting these data from the user, the inference engine of the HPCMIX forward chained through its knowledge base and produced recommendation as stated ahead (see Fig. 6): Use lower water-binder ratio. The system also explained the reason for giving this recommendation (see Fig. 6): If the fracture surface passes almost entirely through the hydrated cement paste around the aggregates, a stronger concrete can be made with the same aggregates by lowering further the water-binder ratio. The system also recommended, when the user pressed on Quantitative Advice button, that increasing the 28-day compressive strength of concrete by 1 MPa necessitate the addition of approximately 8.66 kg/m3 of extra cement to

HPCMIX 0.27 144.61 478.70 53.19 1074.51 723.65 9.57 1.50

Expert-1a 0.27 144.88 478.35 53.15 1073.63 722.84 9.57 1.50

Expert-2b 0.27 144.57 478.72 53.19 1074.57 723.72 9.57 1.50

Expert-1: Aitcin [15] (see reference). Expert-2: Dr Hilmi Mahmud, University of Malaya, Malaysia.

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

335

the mix. These recommendations and explanation exactly matched with those of the experts [3,15] and these recommendations were better than the recommendation from any individual of these experts. Thus the performances of the prototype to diagnose mix performance failure and to give recommendation on corresponding performance adjustment are considered to be satisfactory. 5.6. User-friendliness and the user interface The HPCMIX user interface was designed for user friendliness to enable its efcient utilization in the following ways. (i) Due to the exibility in determining ow of consultation, the user may need to be advised on the most appropriate sequence of design steps. In order to achieve this goal, the User Guide button in the General Information module gives brief information of the overall consultation steps. On the other hand, the rst Transcript Image in the beginning of each consultation session provides information regarding the steps to follow for that session (for example, see Fig. 5). In addition, Advice buttons are available in most of the modules (see Fig. 5, for example) to guide the user about design procedure. Moreover, each consultation window contains some buttons to guide the user for the next design steps. (ii) The advantages and disadvantages of each alternative solution are made easily available to the user so that he can interact with the HPCMIX with better perspective. For example, the Advice button in the Binder Types window during the data input for binder types opens text information on binders (similar to Silica Fume window in Fig. 8). It explains the advantages and disadvantages of using cement only and cement and pozzolans as binder. The user will then be able to have a better understanding of the alternative use of these binders. (iii) Each User Request form of data input has a Comment button attached to it as described earlier (see Fig. 9). This helps the user by expanding the meaning of a question and thus aids the user in responding more efciently to the prompts of the design procedure. (iv) One of the distinguishing characteristics of an expert system such as the HPCMIX is the transparency of its reasoning process and knowledge base. This advantage is available to the user through Explain button (for example, see Fig. 11), which displays the rules that have been used by the inference mechanism, thus explaining the reasons for arriving at a particular recommendation. Another example of explanation facility is shown in the second transcript image of the Mix Performance Adjustment module (Fig. 6), which explains the reasons for giving any recommendation regarding mix performance adjustment.

(v) As mentioned earlier, the General Information module contains a Knowledge Dictionary. Basic knowledge about HPC, mix design and expert system is available there. It also contains some statistical information. This dictionary is very useful as an educational feature. Moreover, concrete mix design ow diagram (see Fig. 7) and several photographs are included in the General Information module to enhance the educational performance of the HPCMIX.

5.7. Advantages, disadvantages and overall evaluation of the system It may be mentioned, by considering all these features, that the consultation process of the HPCMIX is reasonably satisfactory and systematic. The ow of consultation is exible, allowing the user to reset data, to go back for a new consultation, to review input values and other procedures until he is satised with the results. The ability of the HPCMIX to run using Windows operating system, to give recommendation on possible causes of performance failure of the mix, and the facility of knowledge dictionary make this system superior to similar other systems in the domain. The system-user interaction is very interactive with explanatory facilities available throughout the consultation session. Moreover, the system gives information of data at every stages of data input, which makes it superior to conventional programs of concrete mix design. It has facilities like Explain, Advice and Comment buttons as well, which make the system very user-friendly. The main disadvantage of the developed system is that it is applicable for concrete compressive strength from 40 to 160 MPa for which Aitcin method is valid. Another limitation of the system is that it is not platform independent. The user will need a runtime version of Kappa-PC in order to use the system. However, in future, these limitations can be handled by incorporating another state-of-the-art mix design method and by using another state-of-the-art expert system shell if they are proved to be useful. In order for expert systems not to become obsolete, they must be nurtured and kept current [35]. All expert systems, the HPCMIX included, cannot claim completeness in their knowledge bases; they are always subject to upgrading, modication and correction. It should be recognized that HPCMIX is a research prototype; and hence, it must be rened and tested further for commercial use. The existing knowledge base of the prototype can be improved by rening, expanding, and reinforcing its knowledge base using new ndings as reported in literature or new experience from domain experts. It must also be kept in mind that, like other expert systems, HPCMIX will serve as a decision support system; it will not replace completely human experts decision making.

336

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

6. Conclusions This paper presented a prototype expert system called the HPCMIX developed for mix design of HPC. The HPCMIX is capable of selecting proportions of mixing water, cement, supplementary cementitious materials, superplasticizer and aggregates, considering the effects of air content as well as water contributed by superplasticizer and moisture conditions of aggregates. Using an expert system shell, HPCMIX was developed according to the mix design method proposed by Aitcin. Alternatively, in future, any other state-of-the-art mix design method of HPC can be added to the system as a new module without affecting overall performance of the system. In addition to proportioning concrete mixes, the system is also capable of giving recommendations on mix performance adjustment. It was found that it is feasible, efcient and effective, to use an expert system approach for the proportioning of HPC mix. The ability of the system to give comments and advice about an input data, together with the facility of knowledge dictionary, makes this expert system very useful for the educational environment. Additional knowledge to expand the scope of the system can be added without major modication of the structure of the program. The best approach to making a mix design of HPC, of course, is to use proportions previously established for similar concrete using the same materials. In addition, rules-of-thumb and past experience should also be used, wherever possible. Where such prior information is limited or unavailable, the HPCMIX can be used to assist the user in the mix design of HPC.

moistureZ3.5%. Silica fume at 10% replacement (of total cementitious material) was to be used; its specic gravity was 2.20. The dosage of solids superplasticizer at the saturation point was 1.0%.

Appendix B. Data for laboratory trial batch In order to test First Trial Batch of HPC mix, the following specimens are needed [15]: three 100!200 mm cylinders for tests at 1, 7, 28 and 91 days in compression; three 150!300 mm cylinders for tests at 28 days in compression; three 150!300 mm cylinders for tests for elastic modulus at 28 days; and three beams 100! 100!400 mm for tests for modulus of rupture at 28 days. A slump test, an air content test and a unit mass test will be done on the fresh concrete. Except the air content test, the concrete used for these tests will be recovered. Knowing that an air test needs 15 kg, the amount of concrete to make this trial batch needs to be calculated, assuming 10% extra materials to compensate for losses.

Appendix C. Data for one cubic metre SSD composition A trial batch with an adequate consistency and adequate initial and nal slumps was made using the following quantities of materials [15]: waterZ12 l, cementZ45 kg, Fly ashZ5 kg, coarse aggregateZ100 kg, ne aggregateZ 70 kg, and superplasticizerZ0.9 l. The air content of this trial batch was 1.5%. The materials used to make this trial batch had the following properties: coarse aggregatespecic gravity (SSD)Z2.75, absorptionZ1.0%, and eld moistureZ0%; and ne aggregate-specic gravity (SSD)Z2.65, absorptionZ1.0%, and eld moistureZ 3.9%. The y ash used had a specic gravity of 2.50. The superplasticizer was naphthalene based one with a specic gravity of 1.21 and a solid content of 42%. What is the composition of 1 m3 of such concrete?

Acknowledgements The authors would like to express sincere gratitude to Universiti Kebangsaan Malaysia for providing the fund for the research and MBT (Malaysia) Sdn. Bhd for the supply of materials and technical support throughout the research program. The authors would like to thank Dr Hilmi Mahmud (University of Malaya, Malaysia) for his invaluable input and patience.

Appendix D. Data for batch composition A concrete batch plant is to produce 8 m3 of HPC on the basis of the following SSD composition [15]: w/cZ0.29, waterZ130 l, cementZ450 kg, coarse aggregatesZ 1050 kg, ne aggregatesZ750 kg, and superplasticizerZ 8 l (liquid) and 4 kg (solid). The aggregates having the following water contents are in the bins: coarse aggregatespecic gravity (SSD)Z2.75, absorptionZ0.8%, and eld moistureZ0.8%; and ne aggregate-specic gravity (SSD)Z2.65, absorptionZ1.0%, and eld moistureZ 3.0%. The superplasticizer is a naphthalene superplasticizer containing 42% solids and having a specic gravity of 1.21. What are the masses of materials that must be weighed to make 8 m3 of concrete?

Appendix A. Data for rst trial batch It was supposed that a 100 MPa concrete had to be made with the following data [15]: a Type I Portland cement; a naphthalene-type superplasticizer with a total solids content of 40% and specic gravity of 1.21; a dolomitic limestone having maximum sizeZ10 mm, specic gravity (SSD)Z2.80, absorptionZ0.8%, eld moistureZ0%, and the shape of the particles can be described as between average and cubic; a siliceous natural sand of specic gravity (SSD)Z2.65, absorptionZ1.2%, and eld

M.F. Mohd. Zain et al. / Advances in Engineering Software 36 (2005) 325337

337

References

[1] Neville AM. Properties of concrete, 4th ed. Essex: Longman Group Limited; 1995. [2] Akhras G, Foo HC. A knowledge-based system for selecting proportions for normal concrete. Ex Sys Appl 1994;7(2):32335. [3] Bai Y, Amirkhanian SN. Knowledge-based expert system for concrete mix design. J Cons Eng Mngt, ASCE 1994;120(2):35773. [4] Islam MN, Al-Mattarneh HMA, Zain MFM, Basri HB. Towards an expert system for HPC mix design. Proceedings of the world conference on concrete materials and structures, Shah Alam, Malaysia, May; 2002. [5] Foo HC, Akhras G. Expert systems and design of concrete mixtures. Conc Int 1993;15(7):426. [6] Oh J, Lee I, Kim J, Lee G. Application of neural networks for proportioning of concrete mixes. ACI Mat J 1999;96(1):617. [7] Durkin J. Expert systems design and development. New Jersey: Macmillan; 1994. [8] Hickey JP, Aldridge AJ. An expert system for the prediction of aquatic toxicity of contaminants. In: Hushon JM, editor. Expert systems for environmental applications. Washington: American Chemical Society; 1990. [9] Smith LM. Interim report on COMIX: an expert system for concrete mix design, Report No. M4.87/1, Central Laboratories, New Zealand; 1987. [10] Malasri S, Maldonado S. Concrete mix designer. Comp Appl Conc Tech, ACI 1988;SP113-3:3341. [11] Islam MN, Al-Mattarneh HMA, Zain MFM, Basri HB. Expert systems and concrete mix design: a review. Proceedings of the sixth international conference on concrete technology for developing countries, Amman, Jordan, October; 2002. [12] Malier Y, editor. High performance concrete: from material to structure. London: E and FN Spon; 1992. [13] Shah SP, Ahmad SH, editors. High performance concrete and applications. London: Edward Arnold; 1994. [14] Nawy EG. Fundamentals of high strength high performance concrete. London: Longman Group Limited; 1996. [15] Aitcin PC. High-performance concrete. London: E and FN Spon; 1998. [16] Sauddin M. Inuence of different curing methods on the mechanical properties and durability of HPC exposed to medium temperature. MSc Thesis, Universiti Kebangsaan Malaysia, 1998. [17] Day KW. Concrete mix design, quality control and specication, second ed. London: E and FN SPON; 1999. [18] ACI Committee 211. Standard practice for selecting proportions for normal, heavyweight, and mass concrete (ACI 211.1-91). Detroit: American Concrete Institute; 1991. [19] ACI Committee 363. State-of-the-art report on high-strength concrete (ACI 363R-92). Detroit: American Concrete Institute; 1992.

[20] ACI Committee 211. Guide for selecting proportions for high strength concrete with Portland cement and y ash (ACI 211.4R-93). Detroit: American Concrete Institute; 1993. [21] ACI Committee 201. Guide to durable concrete. ACI Manual of Concrete Practice: Part 1 (ACI 201.2R-92). Detroit: American Concrete Institute; 1995. [22] de Larrard F. A method for proportioning high-strength concrete mixtures. Cem Conc Agg 1990;12(2):4752. [23] Mehta PK, Aitcin PC. Principles underlying production of highperformance concrete. Cem Conc Agg 1990;12(2):708. [24] Rougeron P, Aitcin PC. Optimisation of the composition of highperformance concrete. Cem Conc Agg 1994;16(2):11524. [25] Mehta PK, Aitcin PC. Microstructural basis of selection of materials and mix proportions for high-strength concrete. Proceedings of the one-day short course on concrete technology/HPC: Properties and Durability, University Malaya, Kuala Lumpur, May; 1997. [26] Aitcin PC. Durable concrete: current practice and future trends. Proceedings of the one-day short course on concrete technology/HPC: Properties and Durability, University Malaya, Kuala Lumpur, May; 1997. [27] Aitcin PC. The durability of high performance concrete. Proceedings of the one-day short course on concrete technology/HPC: Properties and Durability, University Malaya, Kuala Lumpur, May; 1997. [28] Mahmud H. Cement replacement materials in concrete- for strength, durability and economy. Proceedings of the one-day short course on concrete technology/HPC: Properties and Durability, University Malaya, Kuala Lumpur, May; 1997. [29] Neville A, Aitcin PC. High-performance concretean overview. Materials and Structures 1998;31:1117. [30] Islam MN, Zain MFM, Basri HB. Development of an expert system for high performance concrete mix design. Proceedings of the international conference on robotics, vision, information and signal processing, Penang, Malaysia, January, 2003. [31] IntelliCorp Inc. KAPPA-PC Ver. 2.4 Users Manual, IntelliCorp Inc., CA, 1997. [32] Basri HB. An expert system for preliminary landll design in developing countries. PhD Thesis, Department of Civil Engineering, University of Leeds; 1994. [33] Basri HB. An expert system for landll leachate management. Env Tech 2000;21:15766. [34] Basri NEA. An expert system for the design of composting facilities in developing countries. PhD Thesis, Department of Civil Engineering, University of Leeds, 1999. [35] Kaetzel LJ, Clifton JR, Klieger P, Snyder K. Highway concrete (HWYCON) expert system user reference and enhancement guide. Gaithersburg: National Institute of Standards and Technology (BFRL); 1993.

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- ChatGPT For Higher Education and Professional Development - A GuidDocumento134 páginasChatGPT For Higher Education and Professional Development - A GuidMukAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Geh-6721 Vol I Control OvervwDocumento152 páginasGeh-6721 Vol I Control OvervwBouazza100% (1)

- (PDF) Eee-Viii-Power System Operation and Control (10ee82) - NotesDocumento130 páginas(PDF) Eee-Viii-Power System Operation and Control (10ee82) - NotesAbhinavAinda não há avaliações

- Pegasystems Pega 7Documento41 páginasPegasystems Pega 7SunnyAinda não há avaliações

- SINAMICS G120 PN at S7-1200 DOCU V1d0 enDocumento63 páginasSINAMICS G120 PN at S7-1200 DOCU V1d0 engerman_renkAinda não há avaliações

- WLKATA Mirobot F1 User Manual: Date: Mar 30th 2020Documento62 páginasWLKATA Mirobot F1 User Manual: Date: Mar 30th 2020Jorge Nieto PrietoAinda não há avaliações

- Instructions Admin Ui Backend AuthenticationDocumento18 páginasInstructions Admin Ui Backend AuthenticationAhlam HanaAinda não há avaliações

- Embedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDocumento27 páginasEmbedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDhirenKumarGoleyAinda não há avaliações

- Datapro Series: Process Control and Data Management SystemsDocumento6 páginasDatapro Series: Process Control and Data Management Systemsjorge eduardoAinda não há avaliações

- Ofin Open InterfaceDocumento736 páginasOfin Open InterfaceSurendra ReddyAinda não há avaliações

- Automation in DrivingDocumento27 páginasAutomation in Drivingscribduserme123Ainda não há avaliações

- ReexamRequest 326Documento59 páginasReexamRequest 326Jennifer M GallagherAinda não há avaliações

- CODESYS Visualization enDocumento15 páginasCODESYS Visualization enAbdelali KhalilAinda não há avaliações

- Simatic Hmi Memory Card MMC-Card Simatic Hmi Memory Card SD-Card CF-Card PC-Card USB-Stick MLFB Comfort PanelsDocumento8 páginasSimatic Hmi Memory Card MMC-Card Simatic Hmi Memory Card SD-Card CF-Card PC-Card USB-Stick MLFB Comfort PanelsrrebollarAinda não há avaliações

- ADAPT-Builder 2018 Release Notes PDFDocumento3 páginasADAPT-Builder 2018 Release Notes PDFJuan Paulo MarceloAinda não há avaliações

- Z 00 OpenText Business Center For SAPSolutions 16.3 SP1 Release NotesDocumento16 páginasZ 00 OpenText Business Center For SAPSolutions 16.3 SP1 Release NotesFidel Zamorano MosqueraAinda não há avaliações

- Canon IR 2230Documento62 páginasCanon IR 2230qinq.ieee481Ainda não há avaliações

- BRUSH PRISMIC Brochure - 11Documento8 páginasBRUSH PRISMIC Brochure - 11Charles RobiansyahAinda não há avaliações

- New Custom Connector InterfaceDocumento16 páginasNew Custom Connector InterfacekiritoAinda não há avaliações

- MicrocorTools 4 4-5-100156 Rev JDocumento104 páginasMicrocorTools 4 4-5-100156 Rev JEdgar I RamirezAinda não há avaliações

- ChangeLog ArchiveDocumento370 páginasChangeLog ArchiveffffffAinda não há avaliações

- Elcad Prospect Eng PDFDocumento5 páginasElcad Prospect Eng PDFnam buiAinda não há avaliações

- Istanbul Technical University Graduate SchoolDocumento138 páginasIstanbul Technical University Graduate Schoolelif erkolAinda não há avaliações

- LFS-PM-T43 Operating ManualDocumento29 páginasLFS-PM-T43 Operating ManualJuan Carlos CosmeAinda não há avaliações

- DELTA User Interface Guide - 103202 - R2.5.15Documento90 páginasDELTA User Interface Guide - 103202 - R2.5.15Dennis ChaiAinda não há avaliações

- 1 s2.0 S2468502X23000190 MainDocumento12 páginas1 s2.0 S2468502X23000190 MainAsry Kartika DwyAinda não há avaliações

- Autonomous Drilling Robot For Landslide Monitoring and ConsolidationDocumento12 páginasAutonomous Drilling Robot For Landslide Monitoring and Consolidationsanga90Ainda não há avaliações

- ESP32 Display HMI User ManualDocumento8 páginasESP32 Display HMI User ManualDorel ManAinda não há avaliações

- AET Cookbook v1 3Documento14 páginasAET Cookbook v1 3Twesigomwe Gilbert GabrielAinda não há avaliações

- M4272IBDocumento334 páginasM4272IBAmit KumarAinda não há avaliações