Escolar Documentos

Profissional Documentos

Cultura Documentos

2.1. Error Assessment: Human Factors and Training Olivier Nusbaumer Kernkraftwerk Leibstadt AG

Enviado por

Roger AbdalaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

2.1. Error Assessment: Human Factors and Training Olivier Nusbaumer Kernkraftwerk Leibstadt AG

Enviado por

Roger AbdalaDireitos autorais:

Formatos disponíveis

Human Factors and Training

Olivier Nusbaumer Kernkraftwerk Leibstadt AG

1.

Introduction

Human Reliability Analysis (HRA) is the incorporation of human interactions between operations staff and plant systems into the event sequence of probabilistic safety assessment of nuclear power plants. In practice this also includes the identification of critical human errors arising during both maintenance (pre-initiator actions) and emergency operations (post-initiator actions) and the quantification of these errors to assess their contribution to the overall failure probability of the system or accident sequence. This paper will focus on the assessment of pre-initiator human errors.

2.

Pre-initiator Human Errors Definition

Pre-initiator human errors are faults which occur before the beginning of an accident sequence, that is, before the initiating event. These human errors are generally associated with maintenance, testing and possibly operations. They are those in which one or more components of a safety system are left in a non-standard state as a result of human error. The fault is assumed to be undetected (or detected but not corrected). The fault only becomes apparent when a demand is placed on the relevant safety system (e.g. emergency situations or fault detection test). Partial or complete failure of the safety system may then occur as a result of the component misalignment. An example is a manually operated valve which should be open but is left closed in error after maintenance. The human error is of importance only while the fault remains undetected and uncorrected.

2.1.

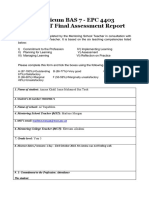

Error Assessment

THERP (Technique for Human Error Rate Prediction) [ Ref. 1 ] is a method to quantify Human Error Probabilities (HEP) and to evaluate the degradation of a man-machine system likely to be caused by human errors alone or in connection with equipment functioning, operational procedures and practices, or other system and human characteristics that influence the system behaviour. The method uses conventional reliability technology with modifications appropriate to the greater variability, unpredictability and interdependence of human performance as compared with that of equipment performance. The THERP method is the most widespread method for judging personal actions. THERP offers some flowcharts for the quantification procedure. In this method, the individual is treated in a manner similar to technical components. THERP provides voluminous tables for the determination of HEP. According to the specific tasks, one looks for the entries within the table compendium that correspond to the actions to be evaluated. Subsequently, the way a task is influenced by Performance Shaping Factors (PSF) is evaluated, with the help of correction factors pertaining to the HEP. Performance Shaping Factors assess for the training level, stress level and other factors which may influence the task success. Finally, the possibility of so-called recovery factors and conditions of dependence between tasks is examined. The possibility of detection and correction is taken into account in the calculation of the probability by so-called Recovery Factors (RF). Tasks are subject to certain degrees of dependence when the success or failure of a previously performed task directly influences the following or parallel task. Other more contemporary methods and references are now often used to evaluate human cognitive behaviours and dynamic operator responses after an initiating event occurs. However, the THERP handbook remains generally acknowledged as the

-1-

Human Factors and Training

Olivier Nusbaumer Kernkraftwerk Leibstadt AG

most comprehensive summary of human reliability data and applications currently available for system specific pre-initiator actions. It provides estimates for human error rates in numerous situations, and it discusses various factors that may affect human performance. Some of the handbook estimates are based on observed results from simulator testing, actual human performance in the power plant environment, and experience from similar activities in other industries. In order to quantify human errors probabilities, the THERP flow charts are followed scrupulously. Both errors of commission and omission are considered, for both maintenance errors and errors after test. The two HEPs whether procedures are used or not during the action are credited, resulting in a so-called joined HEP. In order to assess for post-maintenance testing, Recovery factors are systematically computed. The recovery factor for which the performance factors match the best is retained for quantification. Fault detection contingencies by means of function tests during plant operation (on-line tests) are credited with a so-called reduction factor.

2.2.

Uncertainty

Human Reliability Analysis is subject to substantially high uncertainties. Error distribution for HRA basic events usually follows a lognormal distribution. As may be surmised by the name, the lognormal distribution has certain similarities to the normal distribution. A random variable is lognormally distributed if the logarithm of the random variable is normally distributed. Like for almost all published generic data, HEP are assumed to be lognormally distributed. As a consequence, all applied correction factors are not discrete values, but probability distributions. As a result, any addition or multiplication should be computed using Monte-Carlo simulations. The lognormal distribution is given below:

(ln( x ) ) 2 2 2

f ( x) =

Where:

1 e 2 x

x f(x)

the lognormally distributed variable the probability density at x standard deviation mean of the natural logarithm of x

Other important lognormal distribution parameters are given below: Median (M):

M

f ( x) dx = 0.5 M = e

Mean ( x , EW):

x = EW := x f ( x) dx x = EW = e

0

2

2

ln 2 ( EF )

= M e

2

4 InvErf 2 ( 0.90 )

M e

ln 2 ( EF ) 5.41109

Where:

InvErf (x)

the inverse function of

Erf ( x) :=

e

0

t2 2

dt

Error Factor (EF):

M / EF

M EF

f ( x) dx = 0.05

f ( x) dx =0.95 EF = e

-2-

2 InvErf ( 0.90 )

e1.64485 (5)

Human Factors and Training

Olivier Nusbaumer Kernkraftwerk Leibstadt AG

Mode:

! df ( x) =0 dx x = mod e

mode =

e = M e

(6)

2.3.

Error Reduction via online testing

In a nuclear power plant, numerous function tests are performed in order to check for the system availability. The more often a function test is performed, the likelier the fault detection and the higher the system reliability. Once the equivalent HEP has been quantified for both omissional and commissional types of errors, for both test and maintenance activities, the error detections contingencies by the numerous fault detection tests (function tests) have to be credited. All function tests which are performed on a regular basis and which would surely detect the postulated fault (without causing it) have to be taken into account. For example, a human action which is performed 3 times a year (see figure below) is considered. This human action has an error probability HEP = HEP1. It is postulated that the corresponding fault is implicitly tested by function tests once a year. The resulting, yearly average HEP is therefore reduced by a factor 5/6, assuming that fault occurrence actions and fault detection tests (t) are randomly distributed over the year. It is also assumed that plant personal will identify and correct the fault, or shutdown the plant, if the error transgresses the Limited Condition of Operation (LCO). We call this factor reduction factor. The overall, yearly average HEP is then expressed by:

1 year

HEP =

p(t ) dt

0

Where:

p(t)

probability density at time t

1 year

p t

Fault detection Test

Time

Fault

Fault

Fault

This conditional expression can be analytically integrated for low fault detection / fault occurrence frequencies, but cannot be generalized for higher frequencies. Numerical integration of equation 10 can be performed with the following numerical algorithm:

-3-

Human Factors and Training

Olivier Nusbaumer Kernkraftwerk Leibstadt AG

The relation between fault detection / fault occurrence frequencies and the resulting reduction factor is shown below:

Reduction Factors

1.00 0.90 0.80 0.70

Reduction factor 1 2 4 6 8

Fault occurence frequency

3 5 7

0.60 0.50 0.40 0.30 0.20 0.10 0.00 0 1 2 3 4 5 6 7

Fault detection frequency

-4-

Human Factors and Training

Olivier Nusbaumer Kernkraftwerk Leibstadt AG

2.4.

Dependencies

Two events are called dependent if the HEP of one event changes if the other event has occurred. Dependence between human errors are assessed and quantified. The following criteria are considered for assessing the dependence level of pre-initiator human errors: Temporal similarity Spatial similarity Similarity in the type of action Same people, or group of people

Different levels of dependence are given below, based on [ Ref. 1 ], Table 20-21 , for a factor model (second order dependency):

Level of dependence Negligeable Low Moderate High Complete Dependent HEP (for 2nd error, given first error) Median EF 0.05 3 0.15 3 0.5 2 1 -

-5-

Human Factors and Training

Olivier Nusbaumer Kernkraftwerk Leibstadt AG

3. References

[1] U.S. Nuclear Regulatory Commission, NUREG/CR-1278, Handbook of Human Reliability Analysis with Emphasis on Nuclear Power Plant Applications, A.D. Swain, H.E. Guttmann, Sandia National Laboratory, August 1983. Norbert Semmer, Alex Regenass. Der menschliche Faktor in der Arbeitssicherheit. Mechanismen, Ver-htung und Korrektur von menschlichen Fehlhandlungen. In Gudela Grote, Cuno Knzler, Theorie und Praxis der Sicherheitskultur, Hochschulverlag AG an der ETH Zrich, 1996.

[2]

-6-

Você também pode gostar

- Semi-Markov Models: Control of Restorable Systems with Latent FailuresNo EverandSemi-Markov Models: Control of Restorable Systems with Latent FailuresAinda não há avaliações

- Evaluation Human Error in Control Room: EngigrarlanigiroDocumento5 páginasEvaluation Human Error in Control Room: EngigrarlanigiroJesús SarriaAinda não há avaliações

- Chemical Process Safety: Kathmandu UniversityDocumento28 páginasChemical Process Safety: Kathmandu UniversityRaushan KumarAinda não há avaliações

- THERPDocumento6 páginasTHERPedumm001Ainda não há avaliações

- Human Error Chap 8 (James Reason)Documento44 páginasHuman Error Chap 8 (James Reason)Nasir DanialAinda não há avaliações

- Human Error Assessment and Reduction TechniqueDocumento4 páginasHuman Error Assessment and Reduction TechniqueJUNIOR OLIVOAinda não há avaliações

- OI - Briefing Note - Human Reliability AnalysisDocumento4 páginasOI - Briefing Note - Human Reliability AnalysisPeddy NesaAinda não há avaliações

- Two Step Approach For Software Process Control: HLSRGMDocumento7 páginasTwo Step Approach For Software Process Control: HLSRGMInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- LOPA and Human ReliabilityDocumento26 páginasLOPA and Human ReliabilityAyoun Ul Haque100% (1)

- Human Error Identification in Human Reliability Assessment - Part 1 - Overview of Approaches PDFDocumento20 páginasHuman Error Identification in Human Reliability Assessment - Part 1 - Overview of Approaches PDFalkmindAinda não há avaliações

- LOPA and Human Factors 2Documento26 páginasLOPA and Human Factors 2sandhyakasturiAinda não há avaliações

- A Comparative Study of Software Reliability Models Using SPC On Ungrouped DataDocumento6 páginasA Comparative Study of Software Reliability Models Using SPC On Ungrouped Dataeditor_ijarcsseAinda não há avaliações

- 14 Quantifying Human Reliability in Risk AssessmentsDocumento3 páginas14 Quantifying Human Reliability in Risk AssessmentsTirumal raoAinda não há avaliações

- NASA Hazard AnalysisDocumento27 páginasNASA Hazard AnalysishvananthAinda não há avaliações

- Addressing Human Factors During PHAsDocumento19 páginasAddressing Human Factors During PHAsAnil Deonarine100% (1)

- Human Reliability AssessmentDocumento39 páginasHuman Reliability AssessmentAqiel Siraj - El - Sayyid AdamAinda não há avaliações

- Modul 4 Human ErrorDocumento16 páginasModul 4 Human ErrorLuthfan SetiawanAinda não há avaliações

- Ocra 1Documento24 páginasOcra 1Maryko Awang HerdianAinda não há avaliações

- Maintenance Error Oriented Reliability Determination Model.: Uche Remy, Ph.D. and Chidozie C. Nwobi-OkoyeDocumento8 páginasMaintenance Error Oriented Reliability Determination Model.: Uche Remy, Ph.D. and Chidozie C. Nwobi-OkoyeHassana MhfAinda não há avaliações

- FourthDocumento11 páginasFourthShms GaneemAinda não há avaliações

- Paper Analysis of Human Factors For Process Safety Application of Lopa HF To A Fired FurnaceDocumento24 páginasPaper Analysis of Human Factors For Process Safety Application of Lopa HF To A Fired FurnaceAbdul AwanAinda não há avaliações

- Risk Assessment SheetDocumento25 páginasRisk Assessment Sheetcheveresan123100% (1)

- Failure Modes and Effects Analysis (FMEA) ToolDocumento2 páginasFailure Modes and Effects Analysis (FMEA) ToolVERANO ZASCKIALYNAinda não há avaliações

- Efficient PHA of Non-Continuous Operating ModesDocumento25 páginasEfficient PHA of Non-Continuous Operating ModesShakirAinda não há avaliações

- Failure Modes and Effects AnalysisDocumento6 páginasFailure Modes and Effects Analysiskp pkAinda não há avaliações

- The Application of ATHEANA: A Technique For Human Error AnalysisDocumento5 páginasThe Application of ATHEANA: A Technique For Human Error AnalysisAlfi SyanantikaAinda não há avaliações

- Failure Mode and Effect Analysis (FMEA)Documento7 páginasFailure Mode and Effect Analysis (FMEA)Anonymous 21xH6NcvcAinda não há avaliações

- Human Reliability Data, Human Error and Accident Models-Illustration Through The Three Mile Island Accident AnalysisDocumento15 páginasHuman Reliability Data, Human Error and Accident Models-Illustration Through The Three Mile Island Accident AnalysisMitchel HerreraAinda não há avaliações

- RBI For PSVDocumento10 páginasRBI For PSVWelkin SkyAinda não há avaliações

- Feature MapDocumento9 páginasFeature Map이성군Ainda não há avaliações

- Risk Anaylsis by Hybrid Hazop and Fmea TechniqueDocumento12 páginasRisk Anaylsis by Hybrid Hazop and Fmea TechniqueGiuseppe GoriAinda não há avaliações

- Failure Mode Effects AnalysisDocumento3 páginasFailure Mode Effects Analysis'Rittchii Guerreroo KuunAinda não há avaliações

- Selection of Hazard Evaluation Techniques PDFDocumento16 páginasSelection of Hazard Evaluation Techniques PDFdediodedAinda não há avaliações

- N-1-1 Contingency Analysis Using Powerworld SimulatorDocumento15 páginasN-1-1 Contingency Analysis Using Powerworld Simulatorchandana901Ainda não há avaliações

- Analysis of Accidents Through The Approach of Human Error and Job Safety Analysis (JSA)Documento8 páginasAnalysis of Accidents Through The Approach of Human Error and Job Safety Analysis (JSA)dian puspitaAinda não há avaliações

- Reliability of Safety Systems and Probabilistic Risk AssessmentDocumento6 páginasReliability of Safety Systems and Probabilistic Risk Assessment89simbuAinda não há avaliações

- 10 Steps To Conduct A PFMEADocumento8 páginas10 Steps To Conduct A PFMEASudhagarAinda não há avaliações

- Module 2 Ergonomics at Work PlaceDocumento5 páginasModule 2 Ergonomics at Work PlaceDanish ShaikhAinda não há avaliações

- Spectrum-Based Health Monitoring For Self-Adaptive SystemsDocumento10 páginasSpectrum-Based Health Monitoring For Self-Adaptive Systemsfalcon_vamAinda não há avaliações

- Utilizing Criteria For Assessing Multiple-Task Manual Materials Handling JobsDocumento12 páginasUtilizing Criteria For Assessing Multiple-Task Manual Materials Handling JobsdessynurvitariniAinda não há avaliações

- Rio Pipeline Conference Presentation v5Documento20 páginasRio Pipeline Conference Presentation v5Sara ZaedAinda não há avaliações

- Failure Analysis of FMEA: March 2009Documento9 páginasFailure Analysis of FMEA: March 2009swapnil pandeAinda não há avaliações

- FMEADocumento25 páginasFMEAfajar septiani siradzAinda não há avaliações

- Quality Engineering and Management System Accounting EssayDocumento12 páginasQuality Engineering and Management System Accounting EssayvasudhaaaaaAinda não há avaliações

- Standard Operating Procedure: A Process Failure Mode Effects Analysis (PFMEA)Documento2 páginasStandard Operating Procedure: A Process Failure Mode Effects Analysis (PFMEA)Nikhil Singla0% (1)

- IfDocumento11 páginasIfifrahabubakar275Ainda não há avaliações

- Layers of Protection Analysis For Human Factors (LOPA-HF)Documento11 páginasLayers of Protection Analysis For Human Factors (LOPA-HF)felisianusAinda não há avaliações

- T12A Papierz Arkadiusz TORASDocumento6 páginasT12A Papierz Arkadiusz TORASArek PapierzAinda não há avaliações

- 005 How To Do A Process FMEA For Medical Devices After ISO-14971 Risk Analysis WTDocumento6 páginas005 How To Do A Process FMEA For Medical Devices After ISO-14971 Risk Analysis WTKira HoffmanAinda não há avaliações

- Layer of Protection Analysis Effectivetool in PHA PDFDocumento13 páginasLayer of Protection Analysis Effectivetool in PHA PDFkenoly123Ainda não há avaliações

- Risk Tree GTDocumento11 páginasRisk Tree GTkp pkAinda não há avaliações

- Expert Systems For Monitoring and Control: Daniel L. DvorakDocumento24 páginasExpert Systems For Monitoring and Control: Daniel L. DvorakMohamed A. ShishtawyAinda não há avaliações

- Risk Assesment For StudentsDocumento20 páginasRisk Assesment For StudentsjjjjjAinda não há avaliações

- Semi Quantitative ExampleDocumento7 páginasSemi Quantitative ExampleEra SutrajayaAinda não há avaliações

- BTH 780 Reliability Engineering: Topic: Repairable Systems, Non-Parametric Analysis, Reliability GrowthDocumento66 páginasBTH 780 Reliability Engineering: Topic: Repairable Systems, Non-Parametric Analysis, Reliability GrowthNeuky ElsAinda não há avaliações

- Parti - The Context of Doe'S Accident Investigation ProgramDocumento10 páginasParti - The Context of Doe'S Accident Investigation ProgramEyoma EtimAinda não há avaliações

- Process Safety Management: A Legal and Technical Overview: Session No. 526Documento15 páginasProcess Safety Management: A Legal and Technical Overview: Session No. 526Waqas Ahmad KhanAinda não há avaliações

- Improve Process Safety With Near-Miss Analysis: On The HorizonDocumento8 páginasImprove Process Safety With Near-Miss Analysis: On The HorizonUsama NiaziAinda não há avaliações

- 1990 - Read - Baron - Environmentally Induced Positive Affect: Its Impact On Self Efficacy, Task Performance, Negotiation, and Conflict1Documento17 páginas1990 - Read - Baron - Environmentally Induced Positive Affect: Its Impact On Self Efficacy, Task Performance, Negotiation, and Conflict1Roxy Shira AdiAinda não há avaliações

- College ReadinessDocumento26 páginasCollege ReadinessMyDocumate100% (1)

- Qualitative Quantitative: DefinationDocumento3 páginasQualitative Quantitative: DefinationMargo ShaezAinda não há avaliações

- Feminist, Historical and Reader-ResponseDocumento2 páginasFeminist, Historical and Reader-ResponseMia TaalAinda não há avaliações

- Blenker 2014Documento20 páginasBlenker 2014Kwadwo Owusu MainooAinda não há avaliações

- Artificial Intelligence by DiproDocumento15 páginasArtificial Intelligence by DiproUchchhwas Saha 181-15-10842Ainda não há avaliações

- Independent Essay TemplateDocumento5 páginasIndependent Essay Templatepreciousgem7Ainda não há avaliações

- Introduction To NLP 2021Documento13 páginasIntroduction To NLP 2021Vũ ĐinhAinda não há avaliações

- Curriculum Vitae: Personal InformationDocumento4 páginasCurriculum Vitae: Personal InformationKaaya GodfreyAinda não há avaliações

- Action PlanDocumento2 páginasAction PlanPhebelyn BaloranAinda não há avaliações

- War Vs BusinessDocumento6 páginasWar Vs BusinesschuinAinda não há avaliações

- CBLM For PlanDocumento280 páginasCBLM For PlanownlinkscribdAinda não há avaliações

- AminaDocumento9 páginasAminaapi-300023906Ainda não há avaliações

- Thesis Research Proposal Template: Thesis Option: Project OptionDocumento3 páginasThesis Research Proposal Template: Thesis Option: Project Optionnashra janAinda não há avaliações

- Lesson 2.3 Language Features of An Argumentative TextDocumento19 páginasLesson 2.3 Language Features of An Argumentative Textandy100% (4)

- English 8-Q3-M16Documento19 páginasEnglish 8-Q3-M16Leah Erica VillaranteAinda não há avaliações

- Cover LetterDocumento2 páginasCover LetterQazi Zarif Ul IslamAinda não há avaliações

- Manual: Research Project Secondary Teacher EducationDocumento56 páginasManual: Research Project Secondary Teacher EducationAyesha akramAinda não há avaliações

- Symbolic Convergence TheoryDocumento4 páginasSymbolic Convergence TheoryLauren WestAinda não há avaliações

- LDM2 Study NotebookDocumento72 páginasLDM2 Study NotebookThelma Ruiz SacsacAinda não há avaliações

- Sentence StemsDocumento2 páginasSentence Stemss3pkoAinda não há avaliações

- Round and Flat Characters LPDocumento4 páginasRound and Flat Characters LPJames Andrew PaddayumanAinda não há avaliações

- GMAT Pill E-BookDocumento121 páginasGMAT Pill E-BookNeeleshk21Ainda não há avaliações

- IIFT - Entrepreneurship-Course - Outline - Rev 2Documento8 páginasIIFT - Entrepreneurship-Course - Outline - Rev 2Deepak PanditAinda não há avaliações

- PL1101E Full SummaryDocumento44 páginasPL1101E Full SummaryLe Hoang VanAinda não há avaliações

- Teacher Resume Dwight Thompson 06Documento1 páginaTeacher Resume Dwight Thompson 06api-460800427Ainda não há avaliações

- Docslide - Us Fp601-CyberpreneurshipDocumento4 páginasDocslide - Us Fp601-CyberpreneurshipKadem AmirudinAinda não há avaliações

- Research Management - Leadership & Management SkillsDocumento13 páginasResearch Management - Leadership & Management Skillspuiying80Ainda não há avaliações

- Black Rustic Dried Flower Wedding Thank You Letter A4 DocumentDocumento7 páginasBlack Rustic Dried Flower Wedding Thank You Letter A4 Documentshamma salemAinda não há avaliações

- MGT502 OnlineQuiz5 - 750MCQs - Solved PDFDocumento176 páginasMGT502 OnlineQuiz5 - 750MCQs - Solved PDFZuha RaniAinda não há avaliações